Modifications and errors excepted!

Version: 2020-29-09

Table of contents

Table of contents ................................................................................................................... 2

1Introduction ....................................................................................................................... 4

2About this operating manual .............................................................................................. 5

3Technical data ................................................................................................................... 6

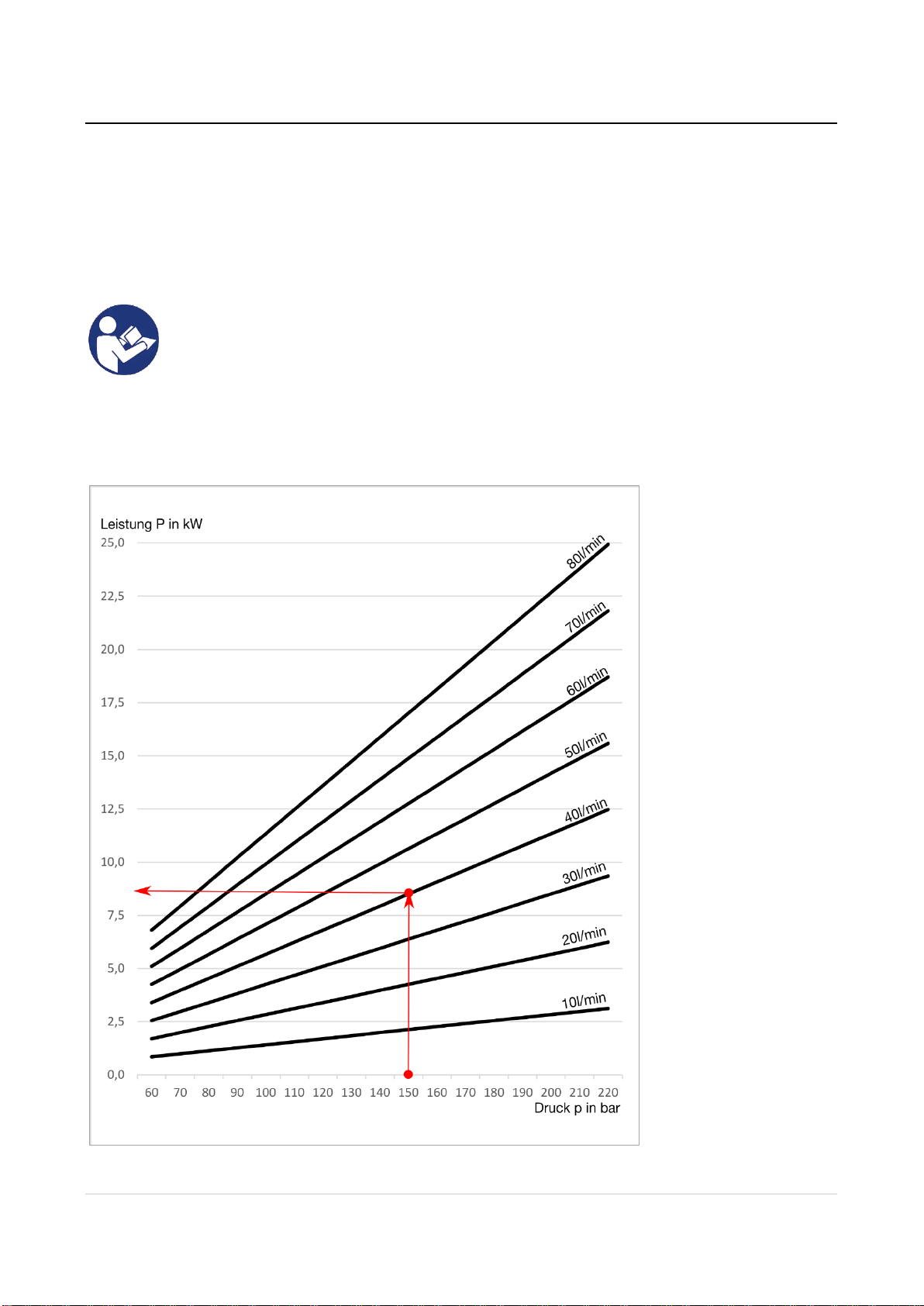

Power diagram, hydraulic ......................................................................................... 73.1

4General safety notices ....................................................................................................... 8

Presentation of the general safety notices ................................................................ 84.1

Intended use ............................................................................................................ 84.2

Instructions for the owner ......................................................................................... 94.3

4.3.1 Qualifications of personnel ............................................................................ 9

4.3.2 Accident prevention ...................................................................................... 9

4.3.3 Instruction ..................................................................................................... 9

Warning signs .......................................................................................................... 94.4

4.4.1 General warning signs .................................................................................. 9

4.4.2 Machine-specific notice ............................................................................... 10

Safety devices ........................................................................................................ 114.5

4.5.1 Protective device on the machine ............................................................... 12

4.5.2 Safety notices on the machine .................................................................... 17

5Equipmentvariants ........................................................................................................... 20

Basic implements with rigid or hydraulic driving frame ............................................ 205.1

Optionally required accessories.............................................................................. 20

5.2

5.2.1 Attachments ................................................................................................ 20

5.2.2 Mower inserts ............................................................................................. 20

5.2.3 Drive kits ..................................................................................................... 21

Required accessories ............................................................................................. 225.3

Optional accessories .............................................................................................. 225.4

6Operation of the mower ................................................................................................... 24

Application area ..................................................................................................... 246.1

Function ................................................................................................................. 246.2

Instructions for mowing .......................................................................................... 246.3

6.3.1 Clean the work terrain before mowing ......................................................... 24

6.3.2 Mowing irregular areas................................................................................ 25

6.3.3 Mowing large areas ..................................................................................... 25

6.3.4 Mowing small areas .................................................................................... 25

7Installation ....................................................................................................................... 26

Operation of the mower .......................................................................................... 297.5

Secure the mower for road travel to the work site ................................................... 307.6

Adjusting the mower incline .................................................................................... 317.7