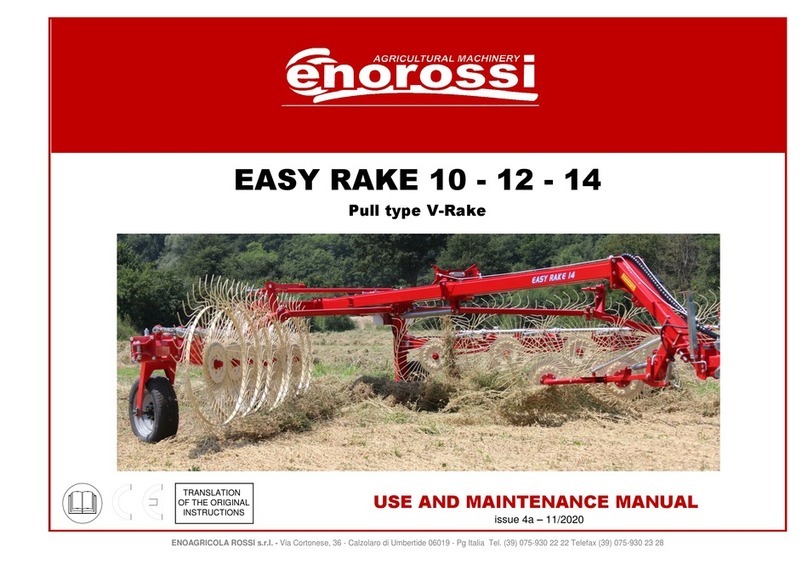

EC CONFORMITY DECLARATION

(All.IIA Machinery Directive 2006/42/EC)

The Manufacturer ENOAGRICOLA ROSSI s.r.l.

located in via Cortonese s.n. - 06018

Calzolaro di Umbertide (PG) - Italia

declares under sole responsibility that the machine

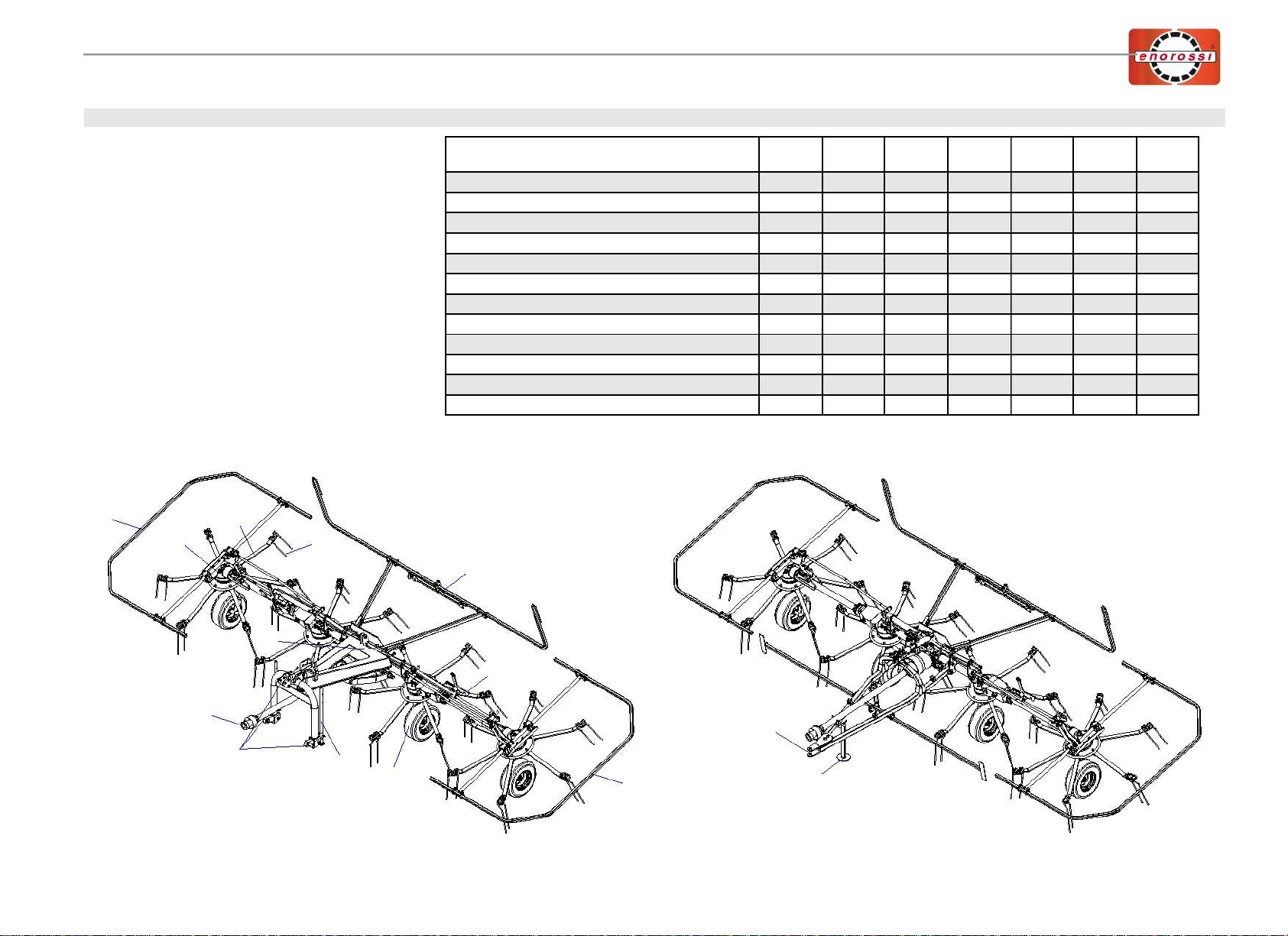

HAY TEDDER

………………………………………………………………………………………….

Denomination (generic and commercial)

Machine Directive and Harmonized standards

The hay tedder was designed according to the Machinery Directive 2006/42CE rules and

meets the following harmonized standards:

EN 349: Machinery safety – Minimum distances to avoid damage to body parts (1993) + A1

(2008)

EN 982: Machinery safety – Systems and components safety requirements for hydraulic and

pneumatic transmissions - Hydraulics (1997) + A1 (2008)

EN ISO 4254-1: Agricultural machines - self-propelled, mounted, semi-mounted

and pulled type agricultural machines - Common safety requirements (2008)

G..

2011

EN ISO 4254-10: Agricultural machines - self-propelled, mounted, semi-mounted and pulled

…………………………..

……………………………………………

…………….

type agricultural machines - Safety - Part 10: Hay rake and Hay tedder (2010)

Series/Modell

Serialnumber Construc. year

The functions of which are described in this manual

complies with the essential requirements of Health Protection and

Safety in Machinery Directive 2006/42/EC, and (for the drawn type) to

Directive 94/20/EC concerning the mechanical coupling devices of motor

vehicles and their trailers and their attachment to those vehicles.

For the compliance verification of the directives set out above, the following

EN Harmonized Standards were consulted:

EN 349 (1993) + A1 (2008) - EN 982 (1997) + A1 (2008)

EN ISO 4254-1 (2008) - EN ISO 4254-10 (2010) - EN 11684 (1995)

EN 12100-1 (2003) + A1 (2009) - EN 12100-2 (2003) + A1 (2009)

EN ISO 12965 (2003) + A1 (2004) + A2 (2009)

EN ISO 13857 (2008) - EN 14121-1 (2007)

And authorizes Mr. Giovannini Massimo

Via Cortonese s.n. - 06018 Calzolaro di Umbertide (PG) - Italia

to compile the technical file on its behalf

GIOVANNINI ADELMO

EN ISO 11684: Tractors, forestry and agricultural machinery, gardening motor machines -

Safety graphic symbols and hazards indication pictograms - General Principles (1995)

EN 12100-1: Machinery safety – Basic concepts, general design principles - Part 1:

terminology, basic methodology (2003) + A1 (2009)

EN 12100-2: Machinery safety – Basic concepts, general design principles - Part 2:

Technical principles and specifications (2003) + A1 (2009)

EN 12965: Tractors and agricultural machinery and forestry. Power Take Off (PTO)

shafts and guards. Safety (2003) + A1 (2004) + A1 (2009)

EN 13857: Machinery safety - Safety distances to keep dangerous areas out of reach (2008)

EN 14121-1: Machinery safety – Risk assessment principles (2007)

Calzolaro di Umbertide, ……..

….……………………….

Legal representative

ENOAGRICOLA ROSSI s.r.l.

06018 Calzolaro di Umbertide Perugia Italia

Tel. (39) 075-930 22 22 - Telefax (39) 075-930 23 28

e-mail: enorossi@enorossi.it - info@enorossi.it

web: http://www.enorossi.it - http://www.enoagricolarossi.com

All rights reserved. Reproduction of any part of this manual, in any form without the express

written permission of ENOROSSI, is prohibited. The contents of this manual can be modified

only by the manufacturer and without notice to the Client.

.