i

Table of Contents

L-Series PTM - User Guide - Version 1 Issue 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . 1

Conditions. . . . . . . . . . . . . . . . . . . . . . . 1

Safety Considerations . . . . . . . . . . . . . 1

Certification. . . . . . . . . . . . . . . . . . . . . . 2

About this Manual. . . . . . . . . . . . . . . . . 2

Technical Support. . . . . . . . . . . . . . . . . 2

Safety Requirements . . . . . . . . . . . . 3

Handling the Equipment . . . . . . . . . . . . 3

General Considerations . . . . . . . . . . . . 3

Overview. . . . . . . . . . . . . . . . . . . . . . 5

In the Box . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Equipment . . . . . . . . . . . . . . 5

PTM Description . . . . . . . . . . . . . . . . . . 5

External Components . . . . . . . . . . . . 6

Labeling . . . . . . . . . . . . . . . . . . . . . . 8

Operating Requirements. . . . . . . . . . 8

System Overview . . . . . . . . . . . . . . . . . 9

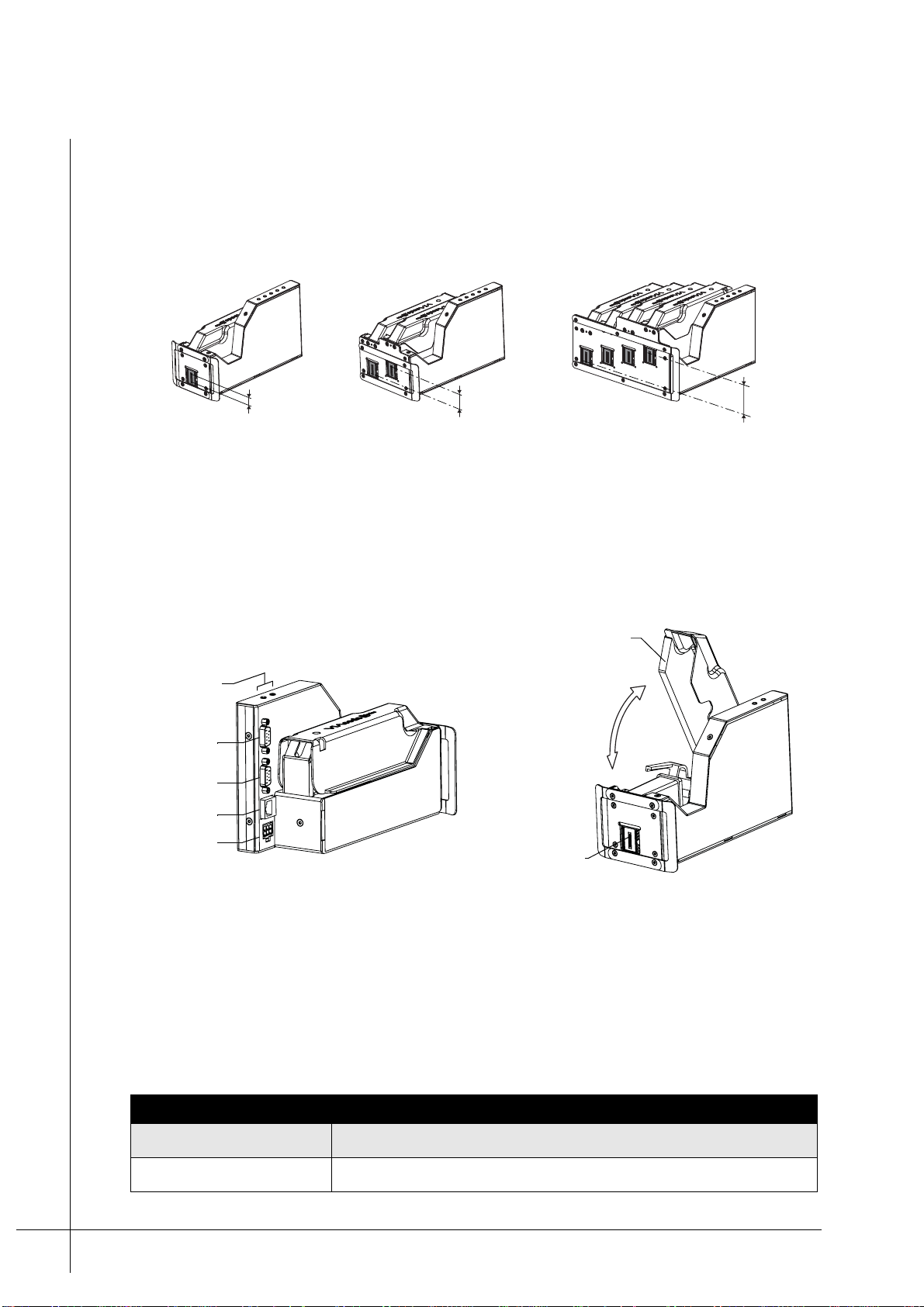

Dimensions. . . . . . . . . . . . . . . . . . . . . . 10

Mounting Holes . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . 15

Mounting a PTM . . . . . . . . . . . . . . . . . . 15

Vertical or Horizontal Mounting. . . . . 15

Print Target Guide. . . . . . . . . . . . . . . 16

Installing a Photocell. . . . . . . . . . . . . . . 17

Installing an Encoder . . . . . . . . . . . . . . 17

Connecting to a PCM . . . . . . . . . . . . . . 17

Installing Ink-Cartridges . . . . . . . . . . . . 18

Nozzle Alignment . . . . . . . . . . . . . . . . . 19

Initial Installation . . . . . . . . . . . . . . . . 19

Nozzle Alignment Settings . . . . . . . . 20

Maintenance and Handling . . . . . . . 23

PTM Cleaning. . . . . . . . . . . . . . . . . . . . 23

Replacing an Ink-Cartridge. . . . . . . . . . 24

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 24

More than Three Days . . . . . . . . . . . 24

Purging the Nozzles . . . . . . . . . . . . . . . .25

Appendix . . . . . . . . . . . . . . . . . . . . . .27

Technical Specifications . . . . . . . . . . . . .27

Documentation History . . . . . . . . . . . . . .28

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .29