Table of Contents

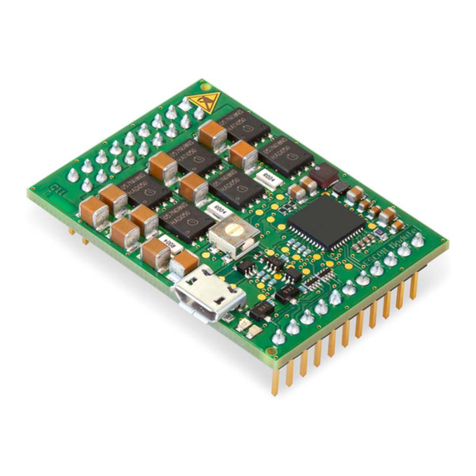

ESCON Module 50/4 EC-S Hardware Reference

A-2 CCMC | 2021-08 | rel9026

1 ABOUT 5

1.1 About this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 About the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 About the Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 SPECIFICATIONS 9

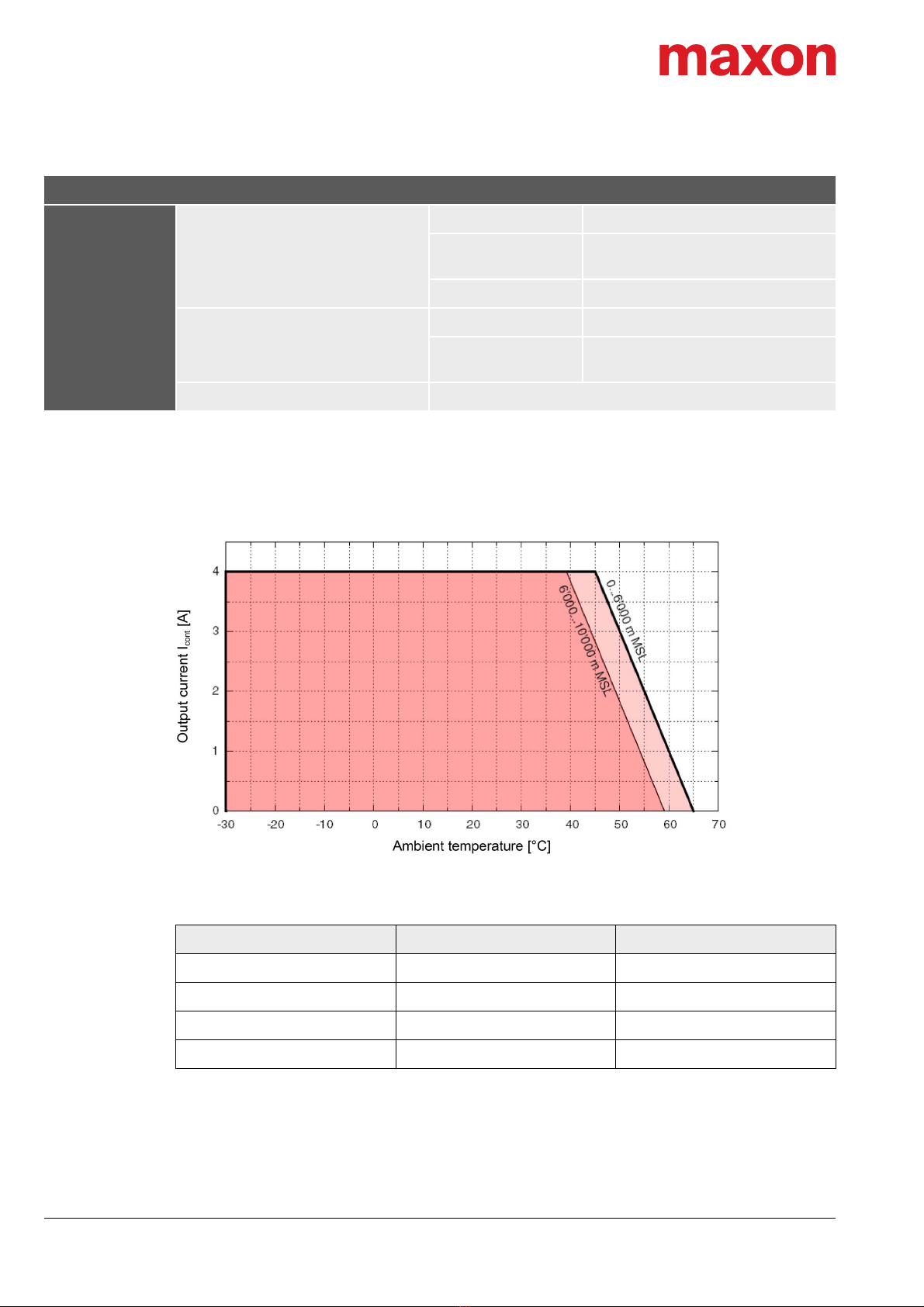

2.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 SETUP 13

3.1 Generally applicable Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Configuration of Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 WIRING 25

5 MOTHERBOARD DESIGN GUIDE 27

5.1 Requirements for Components of Third-party Suppliers. . . . . . . . . . . . . . . . . . . 27

5.2 Design Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 THT Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

TABLE OF CONTENTS

READ THIS FIRST

These instructions are intended for qualified technical personnel. Prior commencing with any activities …

• you must carefully read and understand this manual and

• you must follow the instructions given therein.

The ESCON Module 50/4 EC-S is considered as partly completed machinery according to EU Directive 2006/42/EC, Article 2,

Clause (g) and is intended to be incorporated into or assembled with other machinery or other partly completed

machinery or equipment.

Therefore, you must not put the device into service, …

• unless you have made completely sure that the other machinery fully complies with the EU directive’s requirements!

• unless the other machinery fulfills all relevant health and safety aspects!

• unless all respective interfaces have been established and fulfill the herein stated requirements!