About

About the Device

EPOS4 50/5 Hardware Reference

1-8 CCMC | 2022-04 | rel10445

1.2 About the Device

Capabilities of the

device, included

features, and sup-

ported motors.

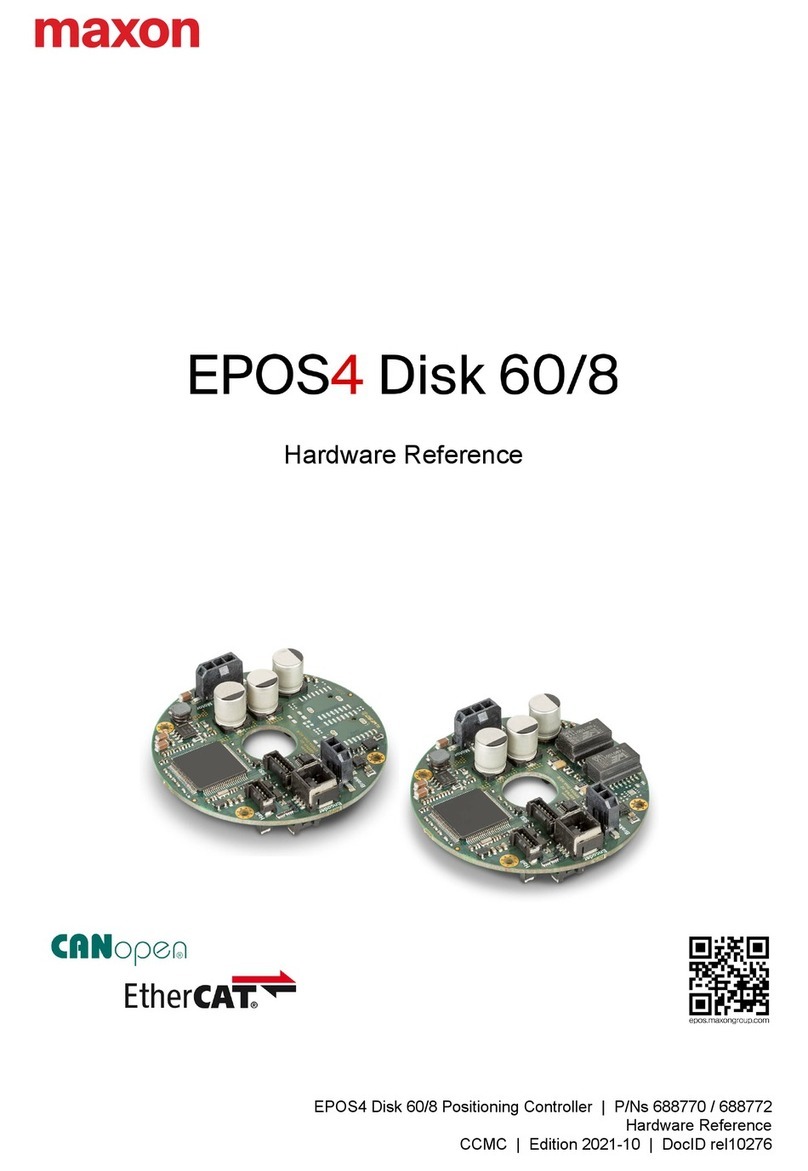

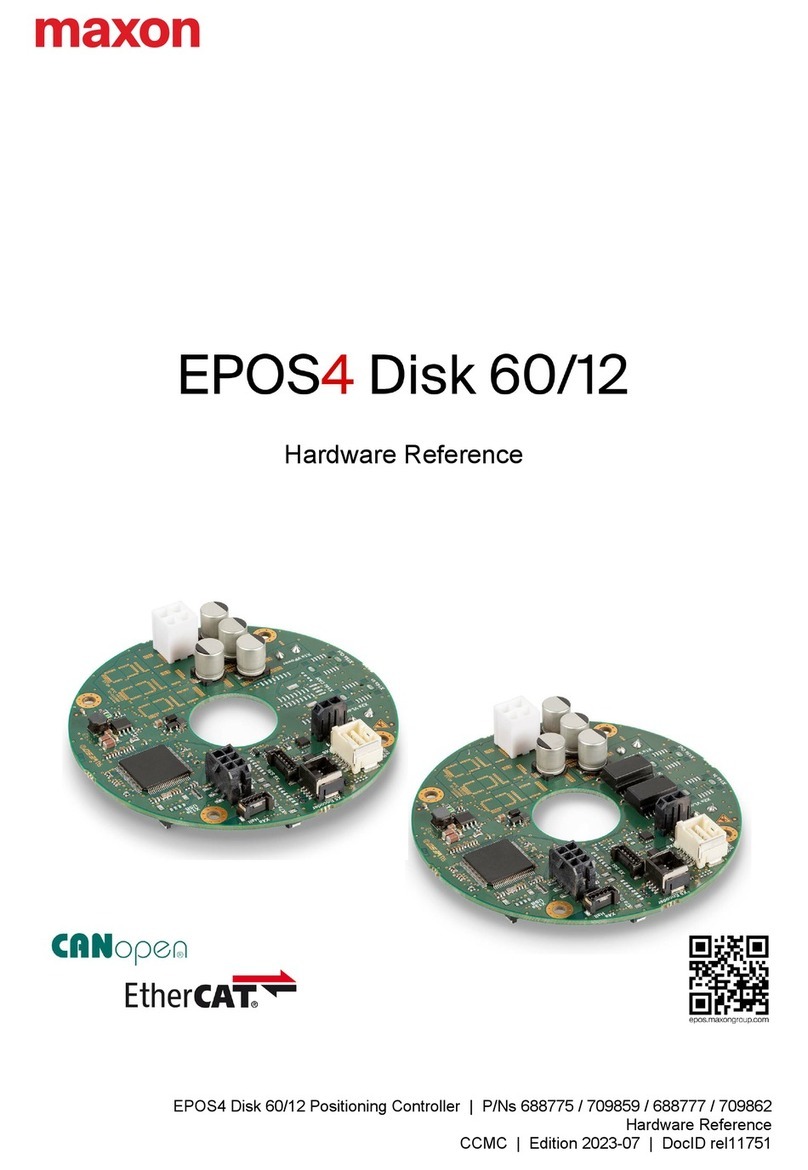

maxon’s EPOS4 50/5 is a small-sized, full digital, smart positioning control unit. Its high power density

allows flexible use for brushed DC and brushless EC (BLDC) motors up to approximately 250 Watts with

various feedback options, such as Hall sensors, incremental encoders as well as absolute sensors in a mul-

titude of drive applications.

The device is specially designed to be commanded and controlled as a slave node in a CANopen network.

In addition, the unit can be operated via any USB or RS232 communication port of a Windows or Linux

workstation. Moreover, the integrated extension interface allows pooling with optionally available communi-

cation interfaces, such as EtherCAT or other additional functionalities.

Latest technology, such as field-oriented control (FOC), acceleration/velocity feed forward, or dual loop, in

combination with highest control cycle rates allow sophisticated, ease-of-use motion control.

Find the latest edition of the present document as well as additional documentation and software for EPOS4

positioning controllers also on the Internet: http://epos.maxongroup.com

In addition, you may wish to browse the EPOS video library. It features video tutorials that provide easy to

follow instructions on how to get started with «EPOS Studio» and shows you tips and tricks on how to setup

communication interfaces, and so on. Explore on Vimeo: https://vimeo.com/album/4646388

1.3 About the Safety Precautions

Keep in mind:

Safety first!

Always!

• Make sure that you have read and understood the note “READ THIS FIRST” on page A-2!

• Do not engage with any work unless you possess the stated skills (chapter “1.1.2 Target Audi-

ence” on page 1-5)!

• Refer to chapter “1.1.4 Symbols & Signs” on page 1-6 to understand the subsequently used indi-

cators!

• You must observe any regulation applicable in the country and/or at the site of implementation with

regard to health and safety/accident prevention and/or environmental protection!

Requirements

• Make sure that all associated devices and components are installed according to local regulations.

• Be aware that, by principle, an electronic apparatus cannot be considered fail-safe. Therefore, you must

make sure that any machine/apparatus has been fitted with independent monitoring and safety equip-

ment. If the machine/apparatus should break down, if it is operated incorrectly, if the control unit breaks

down or if the cables break or get disconnected, etc., the complete drive system must return – and be

kept – in a safe operating mode.

• Be aware that you are not entitled to perform any repair on components supplied by maxon.

Electrostatic sensitive device (ESD)

• Wear working cloth and use equipment in compliance with ESD protective measures.

• Handle device with extra care.

DANGER

High voltage and/or electrical shock

Touching live wires causes death or serious injuries!

• Consider any power cable as connected to live power, unless having proven the opposite!

• Make sure that neither end of cable is connected to live power!

• Make sure that power source cannot be engaged while work is in process!

• Obey lock-out/tag-out procedures!

• Make sure to securely lock any power engaging equipment against unintentional engagement and tag

it with your name!