10

2 General safety instructions

1. Due diligence of the operating company

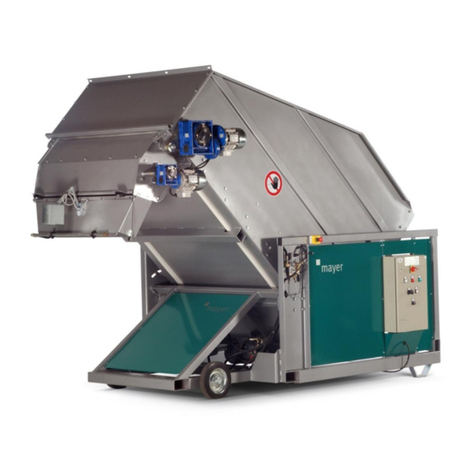

The MAYER TM 2400DR potting machine was

designed and built taking a danger analysis into

consideration and after careful selection of the

harmonised standards to be complied with as well as

other specifications. It therefore meets the state of

the art and guarantees a maximum degree of safety.

However, only if all the measures required for such

are taken can this safety be achieved in actual

operational practice. Planning these measures and

checking their implementation is subject to the

operating organisation's duty to take due care.

The operating organisation must in particular guarantee

that:

•… the machine is only used in accordance

with its intended use (cf. the Product

description section).

•… the machine is only operated when in

flawless working order and, especially,

that the working order of the safety

equipment is regularly checked.

•… the Operating Instructions are always

available in legible condition and complete

at the location where the machine is used.

•… only sufficiently qualified and authorised

personnel operate, service and repair the

machine.

•… these personnel are regularly instructed

about all relevant matters concerning

industrial safety and environmental

protection and that they know the

Operating Instructions and especially the

safety instructions they contain.

•… none of the safety and warning signs

attached to the machine are removed and

that all remain legible.

•Users must obligate themselves only to

ever operate the machine when it is

flawless condition.

•No unauthorised conversions or

alterations are allowed that influence the

machine's safety.

•Only when it has stopped, must any work

ever be carried out on the machine.