0

Installation and Operational Instructions for

ROBA®-brake-checker plus AC Type 029.700.2 (B.0297002.EN)

your reliable partner

26/06/2019 HH/GF

Page 8 of 10

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

www.mayr.com, E-Mail: info@mayr.com

88

Intended Use

ROBA®-brake-checker products have been developed,

manufactured and tested as electronic equipment in

compliance with the DIN EN 50178 standard and in

accordance with the EU Low Voltage Directive. During

installation, operation and maintenance of the product, the

requirements for the standard must be observed. ROBA®-

brake-checker products are for use in machines, systems

and devices and must only be used in the situations for

which they are ordered and confirmed. The products are

designed for installation into electrical control cabinets and

terminal boxes. Using them for any other purpose is not

allowed.

Basically:

Apply supply voltage 24 VDC (control terminal) before

switching input voltage VAC (power terminal). Otherwise an

error can occur.

Coil Capacity

If the switching frequency is higher than

1 cycle per minute or if the overexcitation

time tOis longer than double the separation

time t2, please observe the following:

P ≤ PN

The coil capacity P must not be larger than

PN or the nominal current IRMS which flows

through the ROBA®-brake-checker must not

be exceeded, as otherwise the coil and the

ROBA®-brake-checker can fail due to ther-

mal overload.

At high input voltage and low brake perfor-

mance, the initial bridge rectification of 50

ms can lead to thermic overload.

Calculations:

P [W] RMS coil capacity dependent on switching fre-

quency, overexcitation, reduction in capacity

and duty cycle

P=

POx tO+ PH x tH

T

PN[W] Coil nominal capacity (catalogue values, Type

tag)

PO[W] Coil capacity on overexcitation

PO= (

UO)² x PN

UN

PH [W] Coil capacity at reduced capacity

PH= (

UH)² x PN

UN

tO[s] Overexcitation time

tH[s] Time of operation with reduction in capacity

toff [s] Time without voltage

ton [s] Time with voltage

T [s] Total time (tO+ tH+ toff)

UO [V] Overexcitation voltage (bridge voltage)

UH[V] Holding voltage (half-wave voltage)

UN[V] Coil nominal voltage

IRMS [A] RMS current dependent on switching frequen-

cy, overexcitation time and duty cycle

IRMS =

P x PN

UN ²

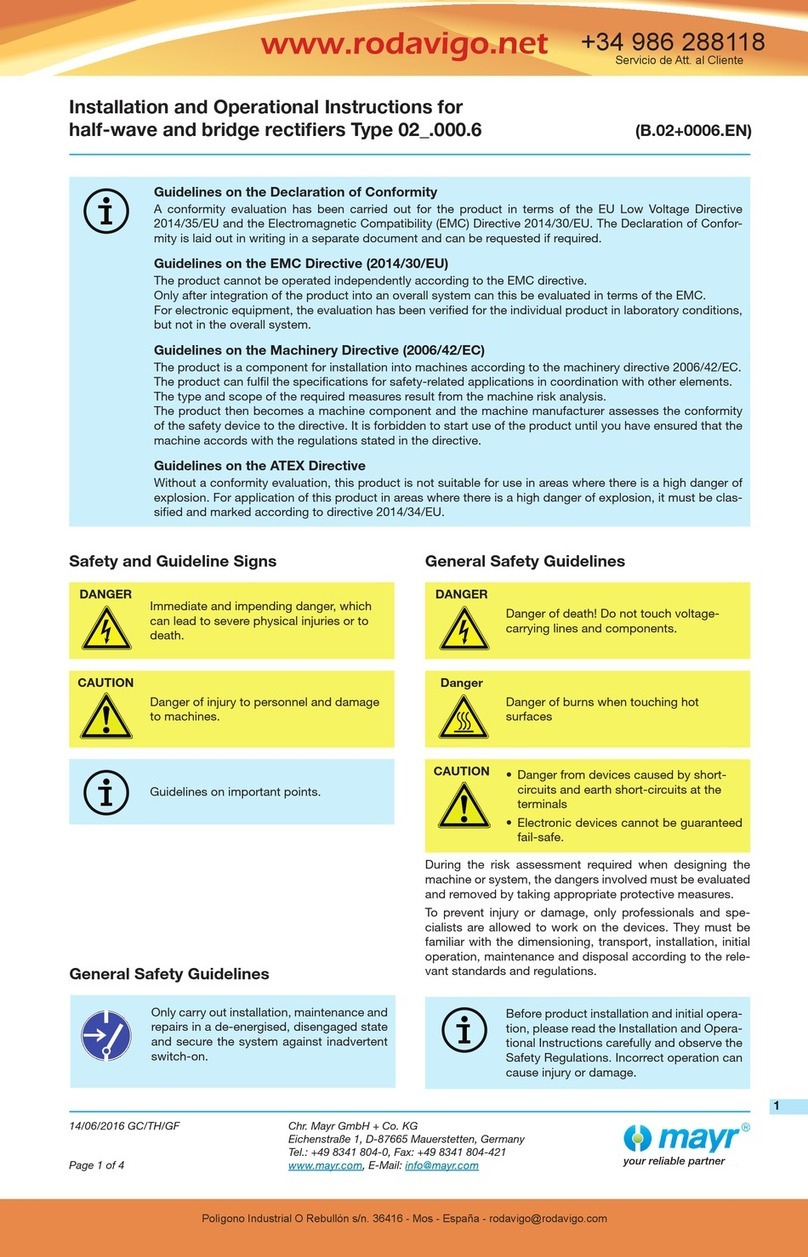

Time Diagram:

T

ton toff

tO tH

U

UO

UN

UH

t

Protection circuit

When using DC-side switching, the coil

must be protected by a suitable protection

circuit according to VDE 0580, which is inte-

grated in mayr® monitoring modules. Never-

theless, the high switch-off voltage produc-

es switching sparks, which lead to contact

consumption.

Therefore, only use the main contacts of a

contactor suitable for inductive loads with

a minimum contact opening of 3 mm for

switching the DC-side contact SDC. Series

connection of main contacts reduces wear.

88