Page 8/16 Operating instructions SG-RST 204 231019 v2.00-RiA

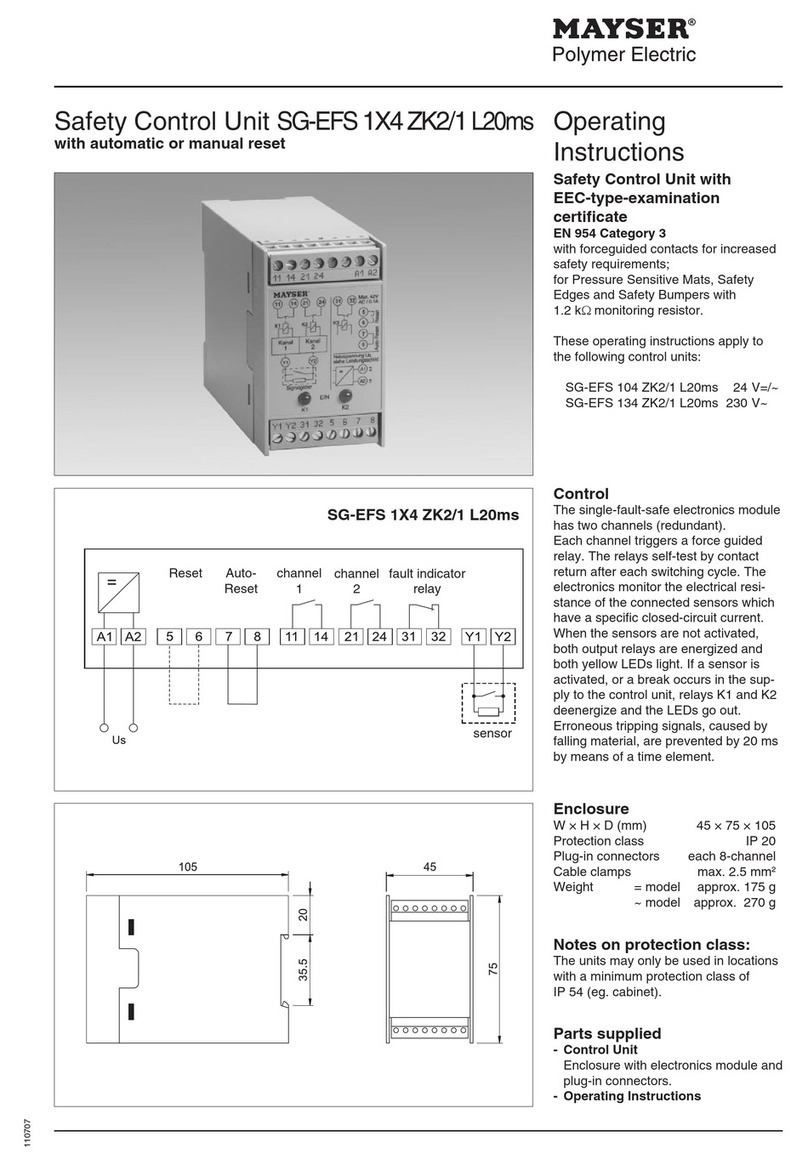

Operation

The single-fault-safe electronics module has dual channels (redundant). Two mon-

itoring circuits each control two force-guided relays and check them constantly to

ensure correct functioning. The electronic system monitors the electrical resistance of

the sensor with a defined zero signal current.

The control unit is operated with DC 24 V. If the supply voltage is connected, the

green LED “Power“ is on.

In sensors that are not actuated, the relays from monitoring circuit 1 (K1, K2) and

monitoring circuit 2 (K3, K4) are energized. The green LEDs “Sensor 1” and “Sensor 2”

light up.

Monitoring circuit 1

If sensor 1 is actuated, relays K1 and K2 de-energize. The green LED “Sensor 1” goes

out and the switching channels 1.1 and 1.2 are opened. In the case of a cable break

at sensor 1, relays K1 and K2 de-energize. The green LED “Sensor 1” goes out, the red

LED “Fault 1” lights up, and the switching channels 1.1 and 1.2 are opened.

Monitoring circuit 2

If sensor 2 is actuated, relays K3 and K4 de-energize. The green LED “Sensor 2” goes

out and the switching channels 2.1 and 2.2 are opened. In the case of a cable break

at sensor 2, relays K3 and K4 de-energize. The green LED “Sensor 2” goes out, the red

LED “Fault 2” lights up, and the switching channels 2.1 and 2.2 are opened.

Automatic reset

The control unit operates without a reset function.

If the sensor 1 is released after actuation, relays K1 and K2 energized again with a

delay of tw.

If the sensor 2 is released after actuation, relays K3 and K4 energized again with a

delay of tw.

If a new sensor 1 is connected after a cable break, relays K1 and K2 re-energize with a

delay of tw.

If a new sensor 2 is connected after a cable break, relays K3 and K4 re-energize with a

delay of tw.

Delay of tw: see reactivation time twin chapter Technical data.

Operation