Page 2/12 Operating instructions SG-RSV 205 280513 v2.2cd

Copyright

The reproduction, distribution and utilisation of this document as well as the communication of its contents with-

out express authorisation is prohibited. Oenders will be held liable for the payment of damages. All rights reserved

in the event of the grant of a patent, utility model or design.

© Mayser Ulm 2013

Table of contents

About these operating instructions.......................................................................................................................... 3

Intended use.................................................................................................................................................................. 4

Safety instructions ....................................................................................................................................................... 4

Parts supplied................................................................................................................................................................ 5

Transport and storage ................................................................................................................................................. 5

Packaging and transport ......................................................................................................................................................5

Storage.......................................................................................................................................................................................5

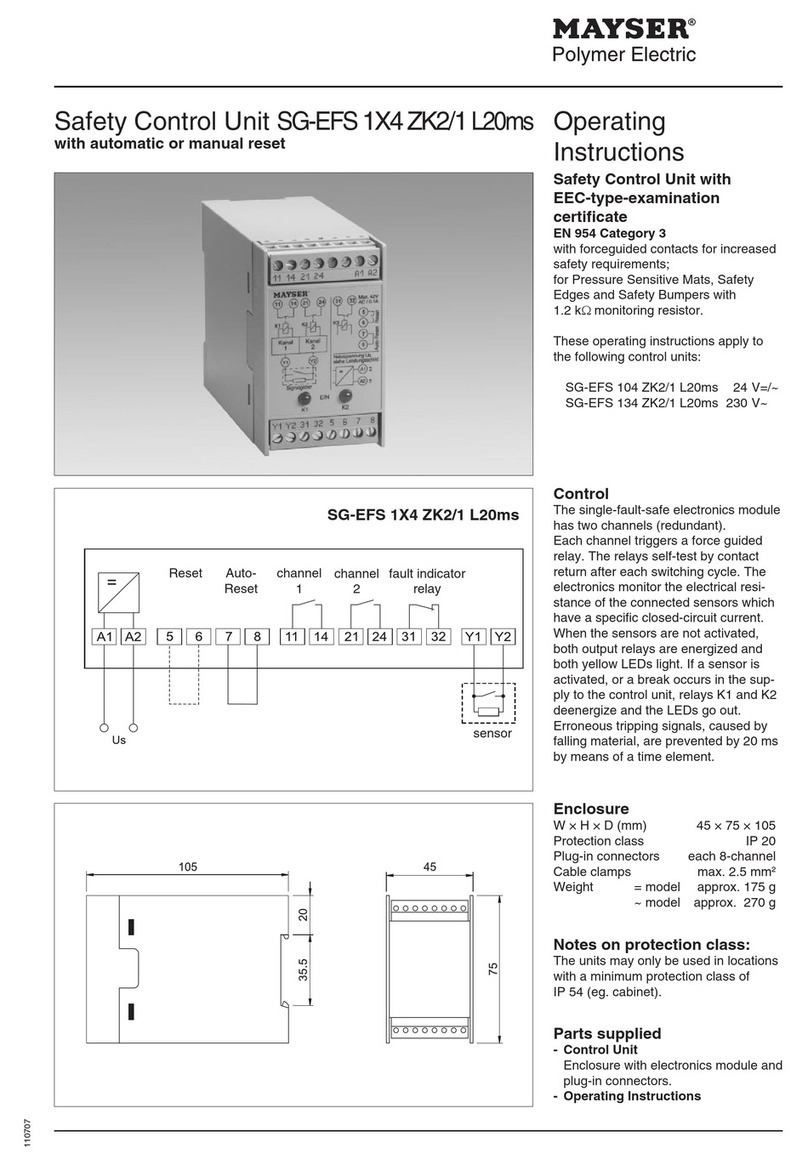

Product overview ......................................................................................................................................................... 6

Connections..............................................................................................................................................................................6

Function, installation and commissioning............................................................................................................... 6

Function.....................................................................................................................................................................................6

Flowchart.......................................................................................................................................................................6

Installation................................................................................................................................................................................7

Commissioning........................................................................................................................................................................8

Testing the function...................................................................................................................................................8

Recommissioning....................................................................................................................................................................9

Automatic reset...........................................................................................................................................................9

Connection example..............................................................................................................................................................9

Maintenance and cleaning ....................................................................................................................................... 10

Maintenance ......................................................................................................................................................................... 10

Cleaning.................................................................................................................................................................................. 10

Troubleshooting and remedies................................................................................................................................ 10

Replacement parts .............................................................................................................................................................. 11

Disposal ........................................................................................................................................................................ 11

Conformity................................................................................................................................................................... 11

Technical data.............................................................................................................................................................. 12