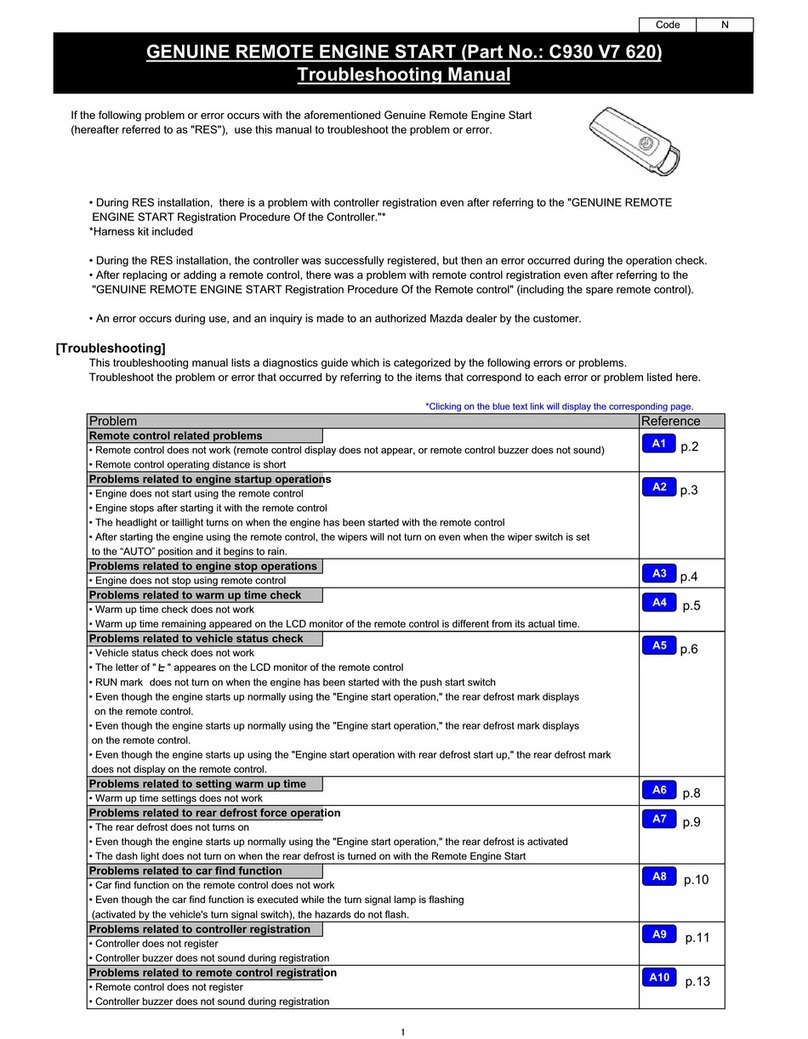

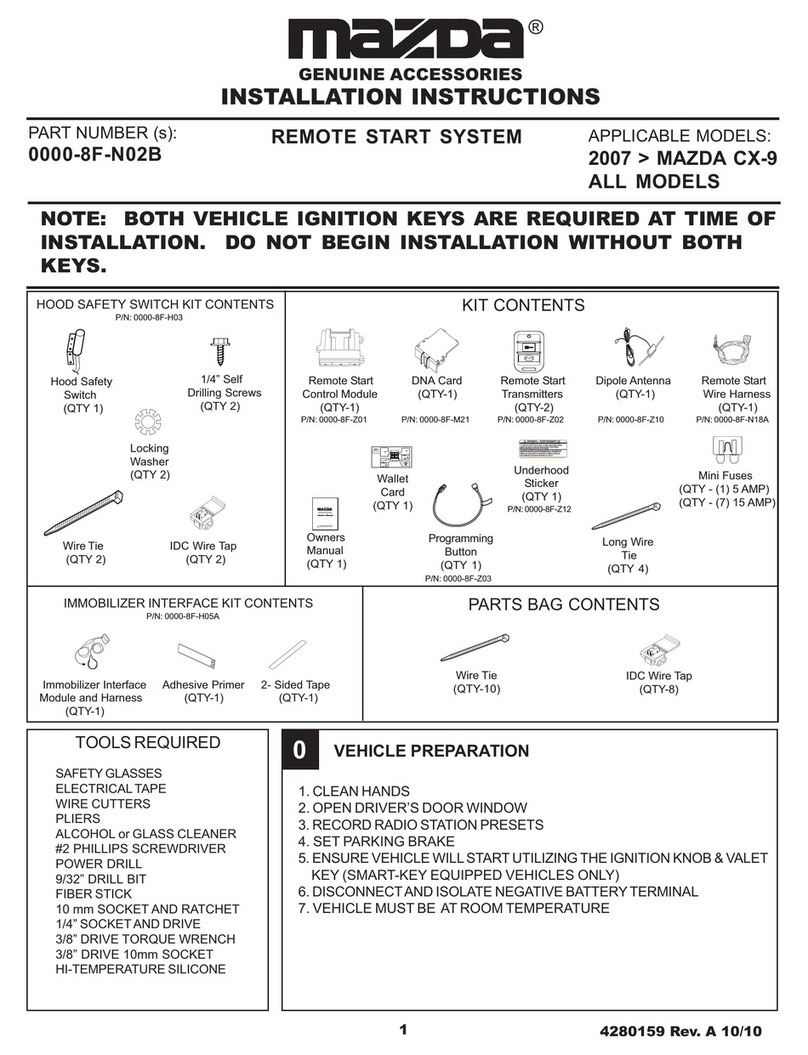

34280246 Rev. B 11/10

VEHICLE PREPARATION

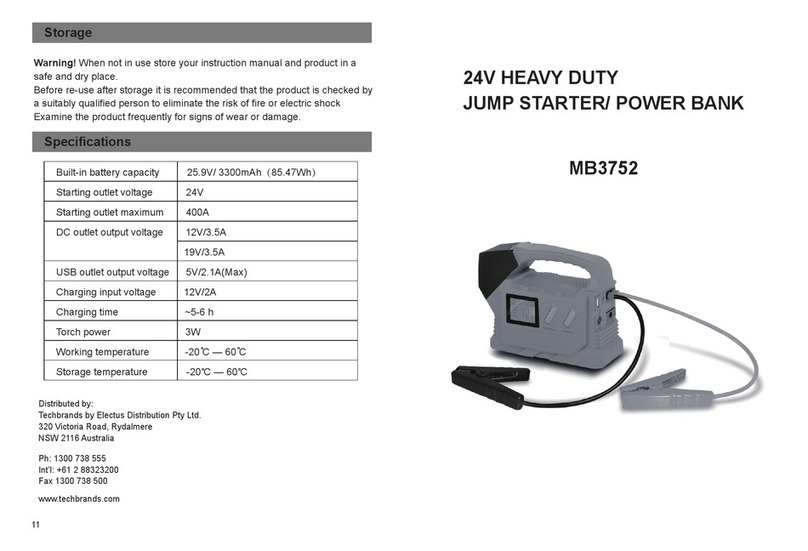

1. Disconnect and Remove Battery

a. Disconnect and isolate the negative and positive battery

terminals. (FIGURE A)

b. Remove battery hold-down bracket assembly by loosen-

ing both 10 mm nuts and pivoting lower retainers toward

vehicle dashwall. (FIGURE A)

c. Carefully remove the battery from vehicle.

2. Remove the following components:

a. Using a fiber stick, remove the driver’s side scuff plate.

Panel is held by 3 clips. (FIGURE B)

b. Remove the driver’s side kick panel by removing the plas-

tic nut. (FIGURE C) Partially peel back the rubber

weatherstrip away from the kick panel. Insert a fiber stick

between the body and kick panel to disengage the re-

taining clip. Gently pull the kick panel toward the rear of

the vehicle to remove.

c. Remove the black, lower dash panel by using a fiber stick

to pull the plastic center button of the plastic fastener out

to disengage. Use a fiber stick to disengage the two clips

located at the front of the panel and remove. (FIGURE D)

d. Remove the ignition knob by depressing both buttons on

either side of knob and pulling away from ignition switch.

(Smart-Key equipped vehicles only)

e. Remove the three (3) phillips head screws from the lower

steering column cover. (FIGURE E)

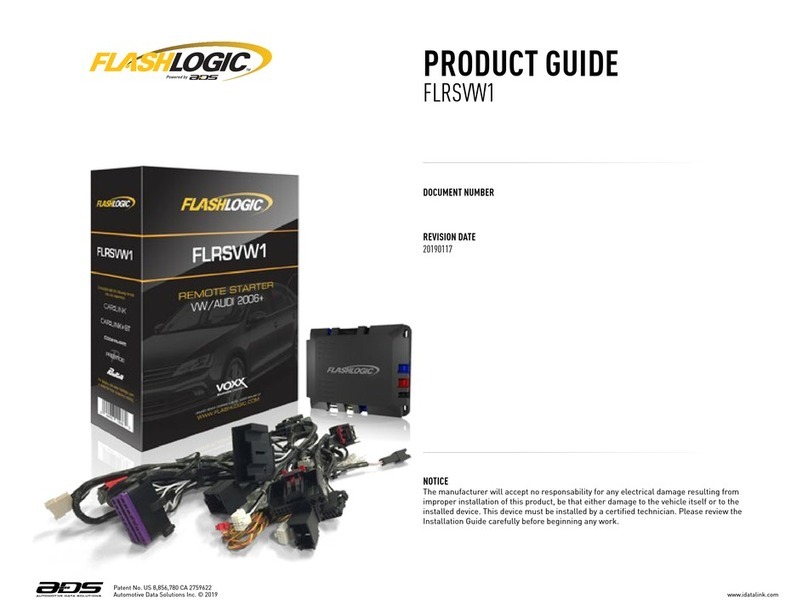

f. Insert a fiber stick between the combination switch and

the lower cover. Gently rotate the fiber stick until top and

bottom covers separate. (FIGURE E)

g. Gently unclip the ignition key light (Retractable Key

equipped vehicles only) and remove the lower cover.

1

10 mm

Socket

FIGURE A

FIGURE D

FIGURE B

Plastic Nut

Fig. 1-4

Plastic Nut

FIGURE C

FIGURE E