内容

1 机器识别...........................................................................................................................................page

1.1 参数辨别 ........................................................................................................................................................................ 1.01

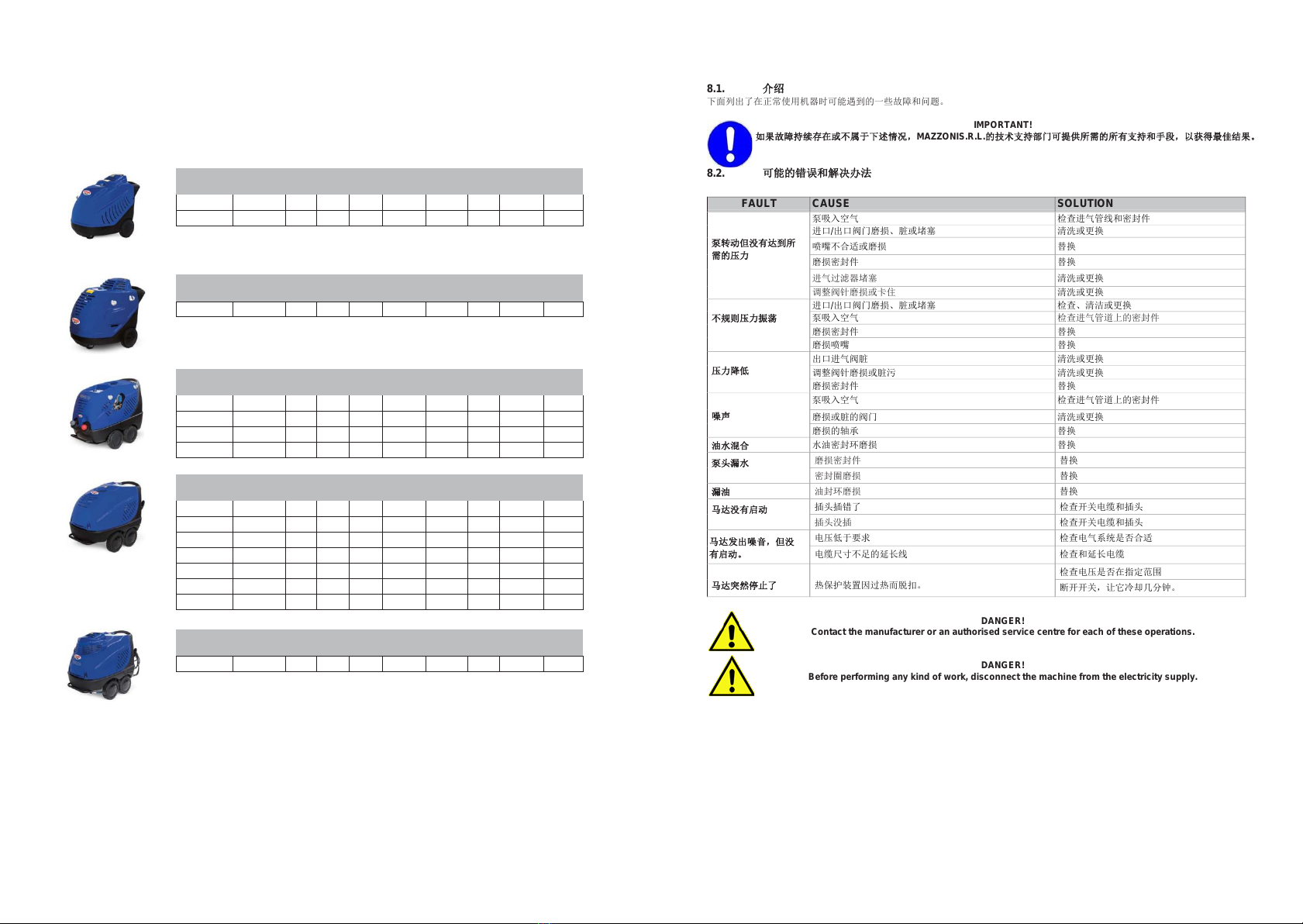

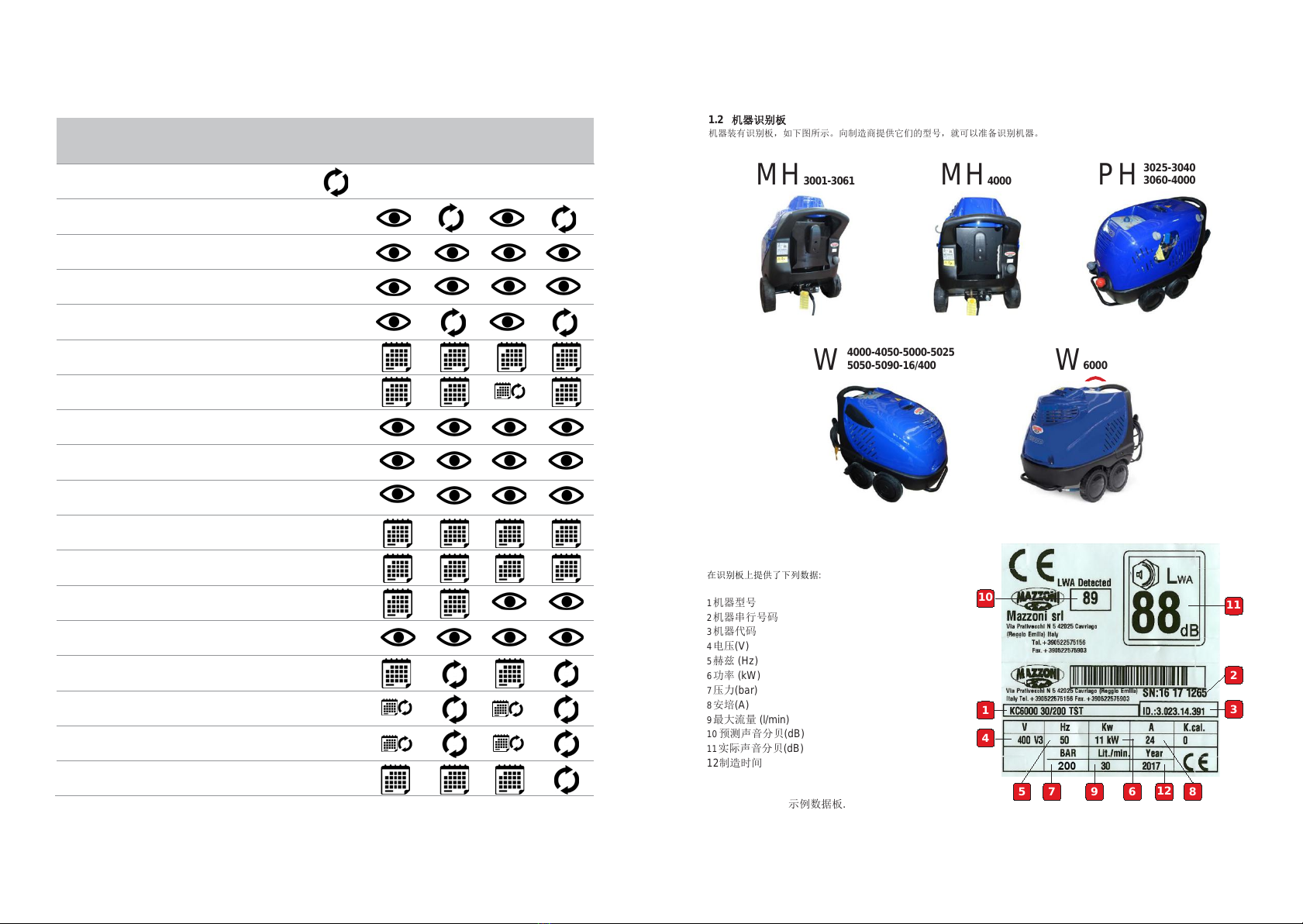

1.2 机器识别 ........................................................................................................................................................................ 1.02

1.3 MH3001 CE 符合声明.................................................................................................................................................... 1.03

1.4 MH3061 CE 符合声明.................................................................................................................................................... 1.03

1.5 MH3061 CE 符合声明.................................................................................................................................................... 1.04

1.6 MH4000 CE 符合声明.................................................................................................................................................... 1.04

1.7 PH3025 CE 符合声明 .................................................................................................................................................... 1.05

1.8 PH3040 CE 符合声明 .................................................................................................................................................... 1.05

1.9 PH3060 CE 符合声明 .................................................................................................................................................... 1.06

1.10 PH4000 CE 符合声明 .................................................................................................................................................... 1.06

1.11 W4000 CE 符合声明...................................................................................................................................................... 1.07

1.12 W4050 CE 符合声明...................................................................................................................................................... 1.07

1.13 W5000 CE 符合声明...................................................................................................................................................... 1.08

1.14 W5025 CE 符合声明...................................................................................................................................................... 1.08

1.15 W5050 CE 符合声明...................................................................................................................................................... 1.09

1.16 W5090 CE 符合声明...................................................................................................................................................... 1.09

1.17 W16/400 CE 符合声明................................................................................................................................................... 1.10

1.18 W6000 CE 符合声明...................................................................................................................................................... 1.10

1.19 保证,担保......................................................................................................................................................................1.11

1.20 观众 ................................................................................................................................................................................1.11

2 指令手册描述

2.1 介绍 ............................................................................................................................................................................... 2.01

2.2 人工识别数据 ................................................................................................................................................................. 2.01

2.3 手册的供应和保存.......................................................................................................................................................... 2.01

2.4 补充资料 ........................................................................................................................................................................ 2.01

2.5 语言 ............................................................................................................................................................................... 2.01

2.6 用户提示 ........................................................................................................................................................................ 2.01

2.7 使用术语 ........................................................................................................................................................................ 2.01

3 一般安全指示

3.1 事前资料 ........................................................................................................................................................................3.01

- 参考标准和立法...........................................................................................................................................................3.01

3.2 一般安全指示 .................................................................................................................................................................3.01

3.3 安全技术 .............................................................................................................................................................................................3.02

3.4 手册中的安全符号 ..........................................................................................................................................................3.02

3.5 机器上的安全警告 ..........................................................................................................................................................3.03

3.6 经营者资格.....................................................................................................................................................................3.05

3.7 操作者的保障 .................................................................................................................................................................3.05

3.8 机器上的安全装置 ..........................................................................................................................................................3.06

摆动...............................................................................................................................................................................3.06

赫兹...............................................................................................................................................................................3.06

电磁适应性 ....................................................................................................................................................................3.06

3.9 残留风险 ........................................................................................................................................................................3.07

3.10 -预期用途 .......................................................................................................................................................................3.07

-合理可预见的滥用 .........................................................................................................................................................3.07

-不正确的使用 ................................................................................................................................................................3.07

4 机器描述

4.1 技术规格 ........................................................................................................................................................................ 4.01

4.2 主要组成 ........................................................................................................................................................................ 4.03

4.3 电气面板及规管小组 ...................................................................................................................................................... 4.04

4.4 安全设备 ........................................................................................................................................................................ 4.05

4.5 标准附件 ........................................................................................................................................................................ 4.06

4.6 任选设备 ........................................................................................................................................................................ 4.06

5 运输和安装

5.1 客户责任 ........................................................................................................................................................................ 5.01

5.2 环境条件 ........................................................................................................................................................................ 5.01

DANGER!

In order to eliminate any risk, repair operations and the installation of spare parts must only be performed by

an authorised service centre.

WARNING!

Use only accessories and spare parts authorised by the manufacturer.

Original spare parts and accessories guarantee safe machine operation without malfunctions.

10.1 TECHNICALSUPPORT

All support requests must be sent to the Customer Technical Support Service:

Specifying:

1. The machine’s characteristics (obtainable from the identificationplate)

2. The defect(s)encountered

3. The name, telephone number, email address (or fax number) of the person requesting the work and who will become the

contact person for futurecommunications.

Or else by filling out the following form

10.2 SPAREPARTS

All requests for spare parts must be sent to the Customer Technical Support Service:

Specifying:

1. The machine’s characteristics (obtainable from the identification plate, per section1.2)

2. Spare partcode

3. Quantity required

4. Shipping method

Please also indicate:

• Whether you are placing an order or requestingprices

• The required date ofdelivery

• The delivery address and invoice address (wheredifferent)

• Any shippinginstructions

• The name, telephone number, email address (or fax number) of the person making the request and who will become the

contact person for future communications Or complete the spare parts requestform.