Contents

1. Rules and general warnings ................................................................................ 4

1.1 Introduction....................................................................................................... 4

1.2 Terms of the warranty....................................................................................... 5

1.3 Service.............................................................................................................. 5

2. General description .............................................................................................. 6

3. System installation............................................................................................... 7

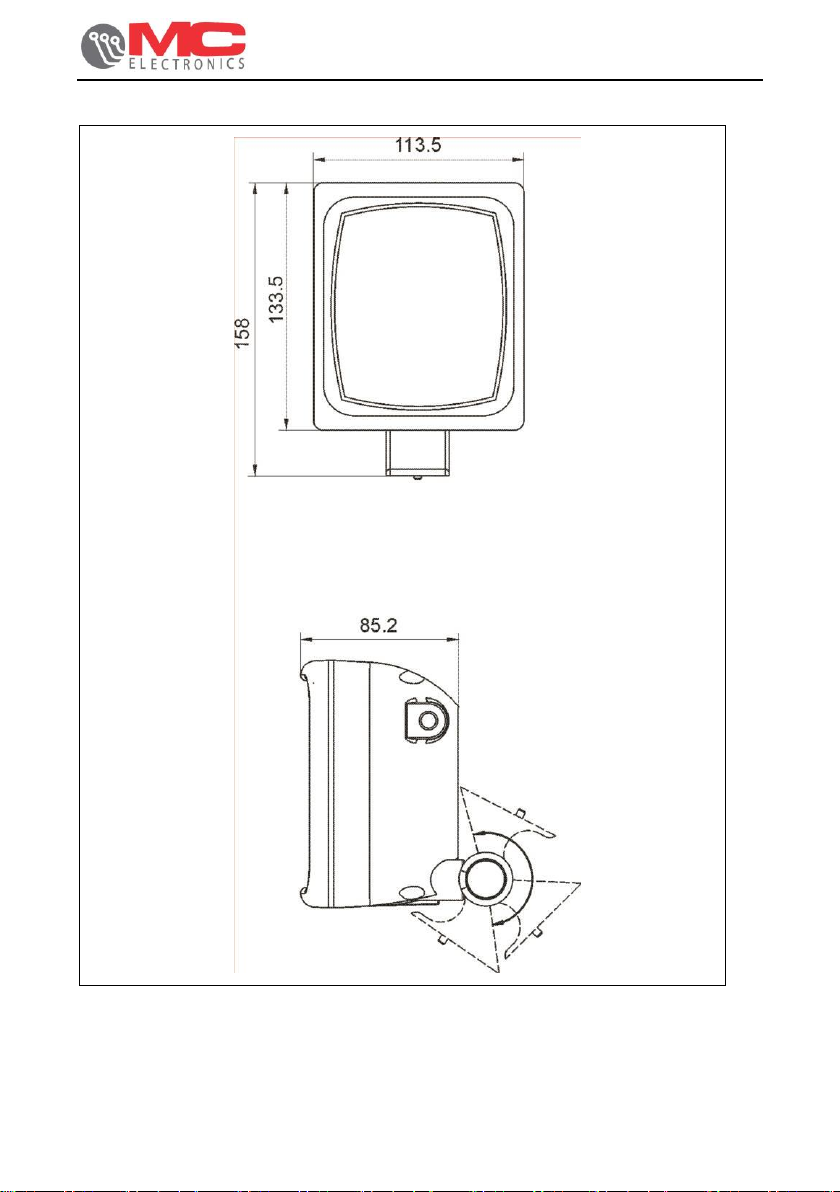

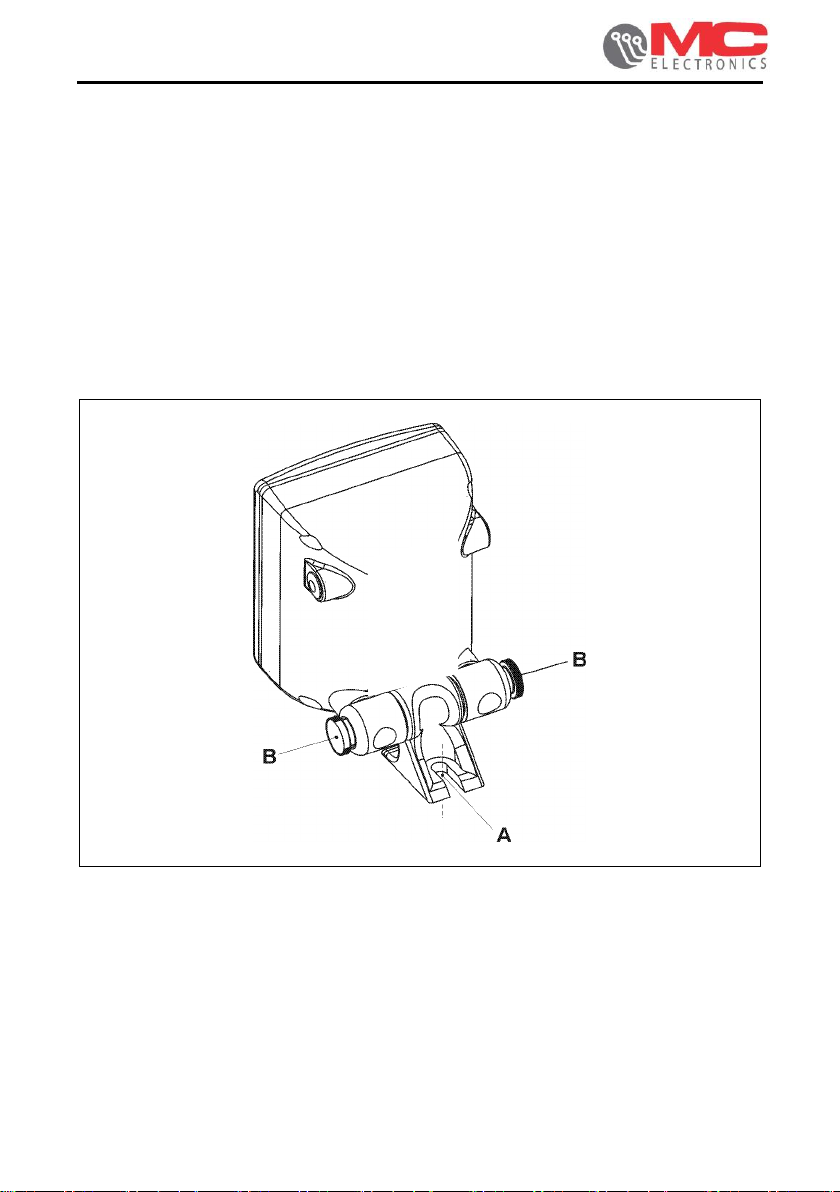

3.1 Mounting the Monitor ........................................................................................ 8

3.2 Sensor installation............................................................................................. 9

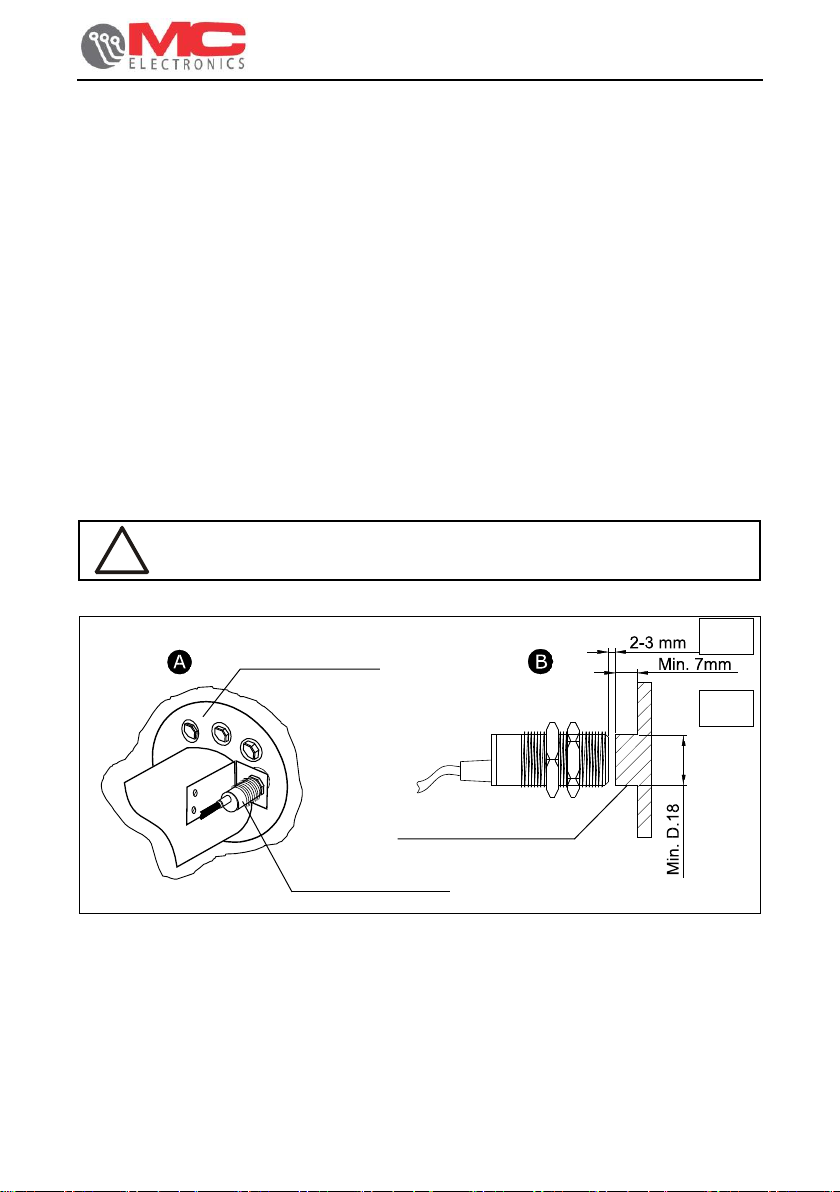

3.2.1 Speed sensor installation........................................................................... 9

3.2.1.1 Automatic calibration of the “C” parameter ......................................... 10

3.2.2 Installing the mechanical counting sensor (if present) ............................. 11

3.2.3 Installing the reflection seed sensor (if present)....................................... 12

3.2.3.1 Adjusting the sensitivity of the seed sensor ........................................ 13

3.3 Front view ....................................................................................................... 14

3.3.1 Keyboard.................................................................................................. 15

3.3.2 LCD Display............................................................................................. 16

4. Accessories......................................................................................................... 16

4.1 Standard accessories...................................................................................... 16

5. Setting the work parameters.............................................................................. 17

5.1 Setting the working width................................................................................ 17

5.2 Setting the calibration of the feed-rate ............................................................ 17

5.3 Setting the number of divisions of the total width............................................ 18

5.4 Setting the hectare count mode ...................................................................... 18

5.5 Programming the date/clock (if present) ......................................................... 19

5.6 Check the speed sensor operating ................................................................. 20

5.7 Check that the mechanical counting sensor functions .................................... 20

5.8 Check that the seed sensor functions (if present)........................................... 20

6. Operation............................................................................................................. 21

7. Maintenance........................................................................................................ 23

7.1 Routine maintenance...................................................................................... 23

7.1.1 How to protect the main connector .......................................................... 23

7.2 Extraordinary maintenance............................................................................. 23

8. Troubleshooting.................................................................................................. 24

9. Technical data..................................................................................................... 25

9.1 MCK 3000 Area Control Technical data.......................................................... 25

9.2 Accessory technical data ................................................................................ 25

9.2.1 MC speed inductive sensor –code 481................................................... 25