HDI 2100 User manual

HDI 2100 Pump Stroke Counter

USER'S MANUAL

Revision D

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

2

TABLE OF CONTENTS

•Section 1 – Introduction……………………………………………………………….4

1.A General Information

1.B Unpacking and Inspection

1.C Cautionary Information

1.D Personnel Qualifications

•Section 2 – HDI 2100 Pump Stroke Counter System Overview………………..5

2.A Control Head

2.B Power Pack

2.C Pump Stroke Sensors

o2.C.1 Microswitch Sensor

o2.C.2 Proximity Sensor

2.D Certification

•Section 3 – Installation………………………………………………………………..8

3.A Control Head

3.B Cable Assembly

o3.B.1 Microswitch Sensor

o3.B.2 Proximity Sensor

3.C Sensor Assembly

o3.C.1 Microswitch Sensor

o3.C.2 Proximity Sensor

•Section 4 – Maintenance…………………………………………………………….10

4.A Power Pack

4.B Processor Boards

4.C Sensors

4.D Increasing Existing PSC Pump Capacity

•Section 5 – Troubleshooting………………………………………………………..11

5.A Battery Voltage

5.B Simulate Signals

o5.B.1 Microswitch Sensor

o5.B.2 Proximity Sensor

5.C Debounce / Main PCB

•Section 6 – Options…………………………………………………………………..12

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

3

•Section 7 – Technical Overivew……………………………………………………14

7.A General Layout Overview

7.B Sensor Illustrations

7.C Exploded BOM

7.D Common Operational Spare Parts

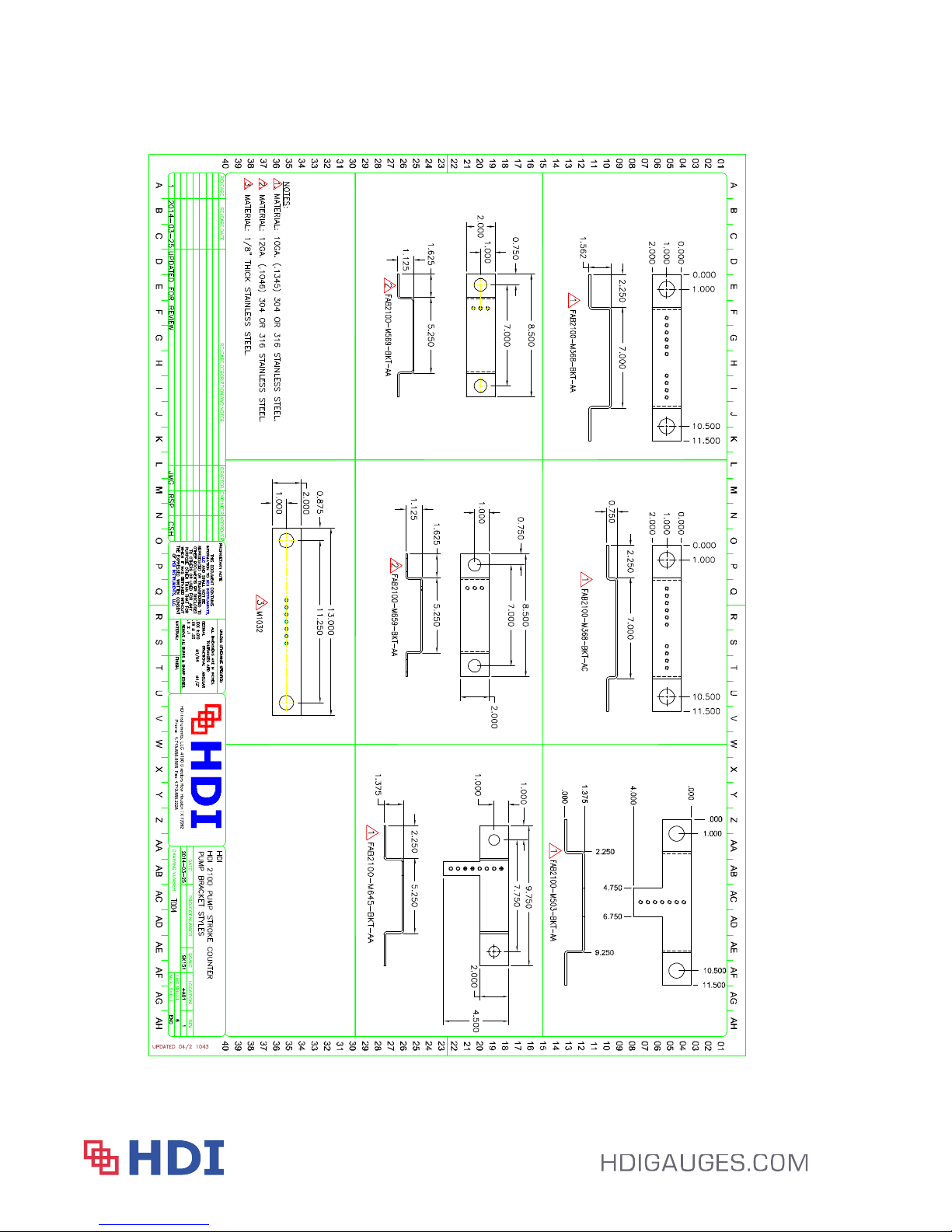

7.E Proximity Sensor Mounting Brackets

7.F Proximity Sensor Sample Installation

•Section 8 – Warranty…………………………………………………………………21

•Appendix……………………………………………………………………………….22

HDI 2100 Specification Sheet

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

4

Section 1 – Introduction

1.A General Information

This manual describes the installation, operation, and maintenance of the HDI 2100 Pump

Stroke Counter (PSC) System. This manual provides the user with all the necessary information

to properly operate the Pump Stroke Counter and perform troubleshooting and repair.

The HDI 2100 PSC, like all of HDI’s core products, have three (3) key elements: the Control

Head, a Sensor Assembly specified by the end client, and the Cable Assembly connecting the

Control Head to the Sensor Assembly. These items will be discussed at greater detail in Section

2.

1.B Unpacking and Inspection

Upon receipt of the equipment, it is critical to confirm all the necessary items are accounted as

some items can settle to the bottom of the box or be thrown out/misplaced if previously inspected

by a freight forwarder or third party (Customs) during transit. If any items are missing, contact

the freight forwarder or third party. If there are still missing items, please contact HDI.

1.C Cautionary Information

Power

This system is typically configured with an internal power pack and dry contact sensors that will

be damaged if tested or connected to a 24VDC system without proper modifications from HDI.

Exposed Electronics

Caution: Do not leave the equipment out and unconnected (open cables or display) as this may

expose the connector leads to moisture and outside elements damaging the electronics.

Returns

Proper protection of the equipment should be a top priority when returning the equipment back to

HDI or an authorized agent for repair. Additionally, the shipper must ensure all equipment

clears all Customs duties and inspection as different agencies may hold equipment without

notifying HDI.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

5

1.D Personnel Qualifications

Caution: Anyone testing the equipment should have basic Electronic Technician understanding

and knowledge of electronic circuitry and use of voltage meters. Read the entire manual prior to

opening the display, testing or making any modifications as work performed by personnel without

the proper qualifications may null the warranty.

Section 2 – HDI 2100 Pump Stroke Counter System Overview

The HDI 2100 System is comprised of a Control Head with a Power Pack, a Cable Assembly,

and one or multiple Sensors (Microswitch or Proximity).

2.A Control Head

The Control Head has two (2) LCD windows that display combined total strokes overall, an

individual total count per pump, and strokes per minute (SPM) on each pump.

The upper LCD window displays total strokes for all active pumps as well as total strokes for

each individual pump.

There is a maximum digit display limitation of 65,535 for the total stroke count window. This will

require periodic reset.

The lower LCD window displays each individual pump stroke rate and can toggle between each

active pump. The HDI 2100 is able to monitor up to 4 active pumps.

The Control Head does not have any applicable output options.

UPPER

DISPLAY Displays the Total Accumulative Stroke count under normal conditions and total count for

each individual active pump.

LOWER

DISPLAY

Displays the RATE of the currently selected active pump (in SPM).

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

6

To Power On: To Power Off:

1. Press Power/Clear Button 1. Press the Select Button once

once. and within four seconds -

2. Press the Power/Clear Button.

There are seven buttons and two LCD displays on the front panel of the gauge.

1. Power / Clear Button (A) – multifunction button to power on or off the gauge. Also

clears the displayed total strokes and/or individual pump stroke count seen on the top

screen.

2. Battery Indicator (B) – battery symbol is displayed when the power voltage drops below

3.x VDC so the user is able to secure a spare / replacement. The symbol appears when

the battery has roughly 30-45 remaining days of use.

3. Pump Monitored (C) – displays the active pump being monitored. This format is also

used in the upper window if an individual pump is being displayed to show an individual

pump’s stroke total.

4. Display (D) – toggles the top screen between Total System Strokes and Individual Pump

Strokes. If the unit only has 3 active pumps, the user will see Zero (0) when toggling the

upper display to Pump 4.

5. Select (E) – toggles in between pump functions.

6. Pumps (#s) – Used to toggle lower screen between different pumps.

“1” – represents Pump 1 “2” – represents Pump 2

“3” – represents Pump 3 “4” – represents Pump 4

A

B

C

D

E

#

#

#

#

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

7

2.B Power Pack

The unit has an internal Power Pack with a 3.6 VDC source.

2.C Pump Stroke Sensors

The signal generated by the sensors is a simple contact closure. As the pump cycles across the

magnet or the contact switch, the contact closure is sensed by the Control Head allowing both

total strokes and strokes per minute to be displayed. The HDI 2100 Pump Stroke Counters are

capable of detecting and monitoring a minimum stroke per minute (SPM) rate of 11 SPM and a

maximum of 300 SPM.

There are two different sensor configurations show below. Further detail is found in Section 7.

2.C.1 Microswitch Sensor

The Microswitch is a standard limit switch

with a contact lever box, wand, and a 5” C

Clamp. The contact lever box comes with a

½” NPT gland entry.

2.C.2 Proximity Sensor

The Proximity Sensor is comprised of a

magnet assembly, an all thread pick up sensor

stem, and a mounting bracket.

2.D Certification

The HDI 2100 Pump Stroke Counter is certified by CSA as Intrinsically Safe for Class I Div 1

Groups A – D and ATEX Certification is available upon request.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

8

Section 3 – Installation

3.A Control Head

The Control Head can be mounted from either the front or back of a control panel console. The

Control Head comes with four (4) ¼-20 Bolts and Lock Nuts used for mounting.

If the LCD is mounted from the front of the panel, the user will remove the Lock Nuts, drop the

Control Head into the panel/bracket, and secure it by threading the Lock Nuts back onto the ¼-

20 Bolts.

If the LCD is mounted from the back of the panel, the user will remove the ¼-20 Bolts from the

Control Head. Then, place the Control Head in line with the holes on the panel or bracket and

place the ¼-20 Bolts back through the console to the Control Head. The Lock Nuts will not be

needed as the Control Head has threaded holes.

Caution: Take care to not over tighten the Bolts as cracking the Front Lens is possible.

3.B Cable Assembly

The Cable Assembly, by default, is arranged differently depending on the type of Sensor

ordered. Cable lengths are ordered in increments of five (5) feet.

3.B.1 Microswitch Cable

The Cable Assembly is configured into a “Y” configuration with each pump leg being the

shorter sections of the “Y” with the main stem of the “Y” representing the main cable from

the Control Head to the “Y” split. By default, the pump legs are identical lengths;

however, based on final wiring, adjustments can be made locally to shorten each pump

leg to the proper length. The Microswitch pump legs are combined into a permanent 3M

epoxy splice kit at the “Y” split combining the legs together before being routed to the

Control Head.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

9

The Microswitch assemblies are pre-connected to the “Y” cable assembly and may

require the cable to be disconnected from the contact lever box ½” NPT gland so the

cable assembly can be routed into the cable trays.

3.B.2 Proximity Cable

The Cable Assembly is routed through a local J-Box in the Pump Room. There will be

one cable from the Control Head to the J-Box, and from the J-Box to the Sensor, there will

be a cable for each pump being monitored, these cables are referred to as the pump legs.

3.C Sensor Assembly

3.C.1 Microswitch

The switch assembly has the contact lever box, wand, and C clamp. The C Clamp

mounts to the adapter plate for easy installation.

3.C.2 Proximity

In order to install the proximity sensor onto the pump shaft properly, the user will need to

know the specific pump model and manufacturer being monitored so that HDI can review

its list of existing fabricated brackets. See current available bracket list provided by HDI

in Section 7.E of this manual.

Note: The proximity sensors require careful measurements to ensure proper installation.

The Sensors can double stroke on the out and return stroke. The all

thread pick up sensor stem is assembled with a 2’ pigtail and a connector. The mating

cable assembly has an open lead for local junction box termination. Please review the

appendix for an example step-by-step guideline on how to properly install the proximity

sensors based on the Wirth 2200 Series pumps.

The all thread stem and magnet should be adjusted so the components are no more than

1.25” apart. Typical installation would leave a ½” – ¾” gap when properly installed.

Prior to closing up the inspection plate, review the details to ensure no potential damage

will be caused by having the all thread stem and magnet positioned too close together.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

10

Special attention should be observed when replacing a proximity sensor assembly to

ensure the sensor is properly adjusted to pick up the pulses as the pump strokes.

Section 4 – Maintenance

The HDI 2100 Pump Stroke Counter System will require the following periodical maintenance.

4.A Power Pack

The System is powered by an internal 3.6VDC power pack that is warranted for 12 months from

the date of shipment. On average, the power pack will last 18 months based on 24 / 7 operation;

however, if the user is able to turn off the unit when not in use, the battery life can be greatly

extended.

4.B Processor Boards

The LCD has two (2) internal processor boards: the HDI 012 and the HDI 02 debounce

processor board, both of which can be replaced in the field if either component has failed. In the

event there is an issue with a specific pump’s SPM rate, the user may be able to simulate signals

to help isolate which PCB has failed. Section 5 provides some basic troubleshooting tips.

Additionally, please contact HDI Technical Support for additional suggestions.

4.C Sensors

Depending on the pump configuration, either sensor type can be replaced as a full assembly kit

or partial components based on what components have been damaged or have been found

faulty. See related Section 7 BOM illustrations.

4.D Increasing Existing PSC Pump Capacity

To increase the number of pumps on an existing PSC, a pump sensor kit will need to be

purchased. The kit includes a spare sensor (Proximity or Microswitch) with specified cable. The

bulkhead connector on the back of the Control Head and the mating connector for the cable

assembly must be replaced; the replacement connectors are shipped with the pump sensor kit.

In addition, if the pump legs are joined together with a 3M-splice kit, the user will have to cut the

legs, remove the splice and replace it with a J-Box. The J-Box is also included in the pump

sensor kit.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

11

Section 5 – Troubleshooting

5.A Battery Voltage

The System effectiveness and accuracy is impacted when voltage of the power pack drops

below xxx VDC. Once the voltage drops below xxx. VDC, the battery indicator symbol will

accent on the display providing the user a warning / notification to source a replacement. This

will provide the user with a 30-45 day advance notice to obtain a replacement. See Section 2.A

for the battery symbol location.

5.B Simulate Signals

In the event a faulty sensor assembly or main PCB board assembly is failing, the user is able to

simulate signals to isolate the failed component. Be sure to clear out both Total Strokes and all

individual Pump Strokes prior to testing to verify results.

5.B.1 Microswitch

Using a flat head screwdriver to twist the rod to simulate a stroke, the installation

can be tested to see if the pump’s contact point is properly striking the Microswitch

sensor. If simulating the stroke displays properly on the Control Head, the pump’s

contact point is not making contact with the rod. Adjust rod/sensor location to allow the

rod to be properly struck during each pump stroke.

Opening the contact level box on the Microswitch Sensor is another way to test the

Microswitch Sensor. By tapping the White and Black wire leads, found inside the contact

level box, the user can simulate a stroke. If the Control Head registers a stroke, the

Microswitch Sensor will need to be replaced.

5.B.2 Proximity

Troubleshooting the Proximity Sensor will require the user to open up the local J-Box in

the pump room. At the local J-Box, the user can tap the Black and White wire leads to

simulate a stroke back to the Control Head. If a stroke is seen on the Control Head, the

Proximity Sensor will need to be replaced.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

12

5.C Main PCB / Debounce:

The user can also conduct a similar test to the Sensor tests above; directly on the PCB or

Debounce Board found within the Control Head. Using the pin details listed below, the user can

simulate strokes. The test will allow the user to determine whether a new PCB or Debounce

Board is needed. If the system being tested has an available spare connection on the PCB, the

user can move the signal over to test on the input another pump. For example, if the System is

a 3 pump unit and pump 2 isn’t displaying correctly, move the white wire to pump 4 to test.

Each System’s pump configuration is different. Please review the table below which identifies

each System’s wiring configuration for testing. Test either board by tapping the faulty pump’s

wires with the common. For example, to test Pump 2 on a 2 Pump System, tap the pins B and

C.

1 Pump

1 Pump 2 Pump

2 Pump 3 Pump

3 Pump 4 Pump 4 Pump

Pin A Black P1 A - B Black P1 A - C

Black P1 A – D Black P1 A – E

Pin B White White P2 B - C

White P2 B – D White P2 B – E

Pin C Green Red P3 C – D Red P3 C – E

Pin D Green Common P4 D – E

Pin E Green

Section 6 – Options

Backlight and External Power

The System can be modified to add backlighting and the unit can be powered by an external 12

or 24VDC power source provided basic precautions and barriers are used. Please note, these

two options can be carried out in the field after the fact but are costly to do so as the internal

components would be replaced.

Output

HDI offers dual proximity sensors in one all thread stem allowing the signals to be split to the

Control Head and an HMI or secondary remote display.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

13

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

14

Section 7 – Technical Overview

7.A General Layout Overview

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

15

7.B Sensor Illustrations

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

16

7.C Exploded BOM

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

17

7.D Common Operational Spare Parts

Item

HDI Part # Description

1 HDIBATTE260DOTAA MICRO P POWER PACK, INCLUDE MSDS CLASS IX

UN 3090

2 FAB2100M485PNLAA PSC PIEZO PANEL 4BTN

3 FAB2100M041GSKAA PSC GASKET W/ 16 HOLES INNER GASKET

BETWEEN CASE AND PIEZO

4 KIT21000103HRW PSC HARDWARE KIT: DESI PACK, COROSION

INHIBITOR, HUMIDITY INDICATOR, AND SCREWS

5 HDI012D-PUMP-PCB-KT HDI 012 PSC PROCESSOR BOARD ASSY W/

DEBOUNCE BOARD

6 HDI012DPSC0COMPL HDI 012 PSC PROCESSOR BOARD ASSY

7 HDI-002STUFBRDAA HDI 002 PSC DEBOUNCE BOARD ASSY

8 HDI2100MICROKITAA MICROSWITCH SENSOR PUMP REPLACEMENT

KIT W/ CLAMPS AND MOUNTING HARDWARE

9 ELESWTH0101CNTPS CONTACT SWITCH – PUMP STROKES

10 ELESWTH0102LVRCN CONTACT SWITCH LEVER (WAND)

11 HDI2100PROXKITAD PROXIMITY SENSOR KIT W/ 2’ PIGTAIL CABLE W/

CONNECTOR FOR CLIENT TO INSTALL ON

EXISTING CABLE AND PICK UP MAGNET ASSY

(REPLACEMENT KIT ONLY)

12 FAB7103M513MGTAA PSC PROXIMITY MAGNET ASSY

13 HDI2100PROXKIT50 PROXIMITY SENSOR KIT W/ PICK UP MAGNET W/

2’ PIGTAIL AND 50’ OPEN LEAD CABLE FOR JBOX

TERMINATION (REPLACEMENT KIT NO JBOX - )

14 ELECONN01133PNTR CONNECTOR 3 PIN TERMINATOR

15 ELECONN01564PNTR CONNECTOR 4 PIN TERMINATOR

16 ELECONN01055PNTR CONNECTOR 5 PIN TERMINATOR

17 21141000000000AA 1 PSC CONTROL HEAD (LCD)

18 21142000000000AA 2 PSC CONTROL HEAD (LCD)

19 21143000000000AA 3 PSC CONTROL HEAD (LCD)

20 21144000000000AA 4 PSC CONTROL HEAD (LCD)

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

18

7.E Proximity Mounting Brackets

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

19

7.F Proximity Sample Installation Details

SUBJECT: Modify Inspection Plate

DATE: May 4, 20

This memo is to cover the basic step by step instructions on modifying the Wirth 2200

Series Mud Pumps to install the HDI Proximity Sensors for proper installation whether

interfacing directly with the HDI 2 00 Pump Stroke Counter or our HDI V9000 Virtual

Control System.

Per the supplied drawing from the Aker manufacturing plant in Germany, marked Appendix

A, you will need a two (2) man team to complete the basic work. Please review both

Appendix A and B so you can become familiar to the additional reference documents.

You will need to have the following supplies with you to avoid any unexpected delays:

. Plastic (approx. 2mm thick) to cover the inspection plate while the inspection is

removed and modifications are being completed to prevent debris from entering

the Mud Pump. See attached picture showing the inspection plate removed.

2. Tape – to secure the plastic to the mud pump

3. Torque Wrench suitable to the specified tolerances for the mud pump

4. Socket / Wrench Set to remove the inspection plate bolts approx. ¾”, see Aker

team or manual for actual sizes.

5. HDI Sensor kits – specific bracket for pump model and manufacturer (2200 is the

M368)

6. Tape Measure

7. Drill / Tap for ¾- 0

Step

First is to loosen all the bolts on the inspection plate after ensuring you have the

correct materials.

Step 2

Remove the inspection plate and put to the side for measuring for modification using

Appendix A. Give to the appropriate personnel to make the necessary modifications

ensuring that you noted top and bottom references.

Step 3

Depending on the location of the piston when the pump was stopped you may be

able to install the M368 bracket without any additional work. Remove the (2) bolts in order

to install the bracket as shown in Appendix B. Install Magnet as noted in the hole placement

on Appendix B and secure the bracket to the piston. Using the manufacturing

specifications, please follow their procedure to Torque the bolts and suggest that they

oversee this process.

Pump Stroke Counter

User’s Manual – 2100, Rev D | Aug 2014

20

Note: If the piston can not be accessed, you may have to remove the secondary cover to

manually move the piston forward so you can complete the bracket installation.

Step 4

Prior to installing the HDI Proximity All thread stem (stainless threaded rod) into the

inspection plate, you will need to measure the internal clearance from the magnet to the

outer edge of the pump frame. You will then proceed to thread the stem into the inspection

plate and ensure that you have a maximum ¾” gap between the magnet and all thread.

This measurement needs to be verified to ensure they do not collide inside once the pump is

re-assembled. Once you are certain the measurements are correct, install the washers and

nuts on the stem so the pump vibration does not cause the stem to become loose and create

potential damage.

Step 5

Install the Inspection plate back on to the pump and route the cable lead that is

attached to the stem to the appropriate designated jbox location for termination. The

configuration provided for this project is a Dual pick up sensor with a set on Black / White,

the secondary signals on Red / Green.

Step 6

Repeat above steps until all the pumps are completed.

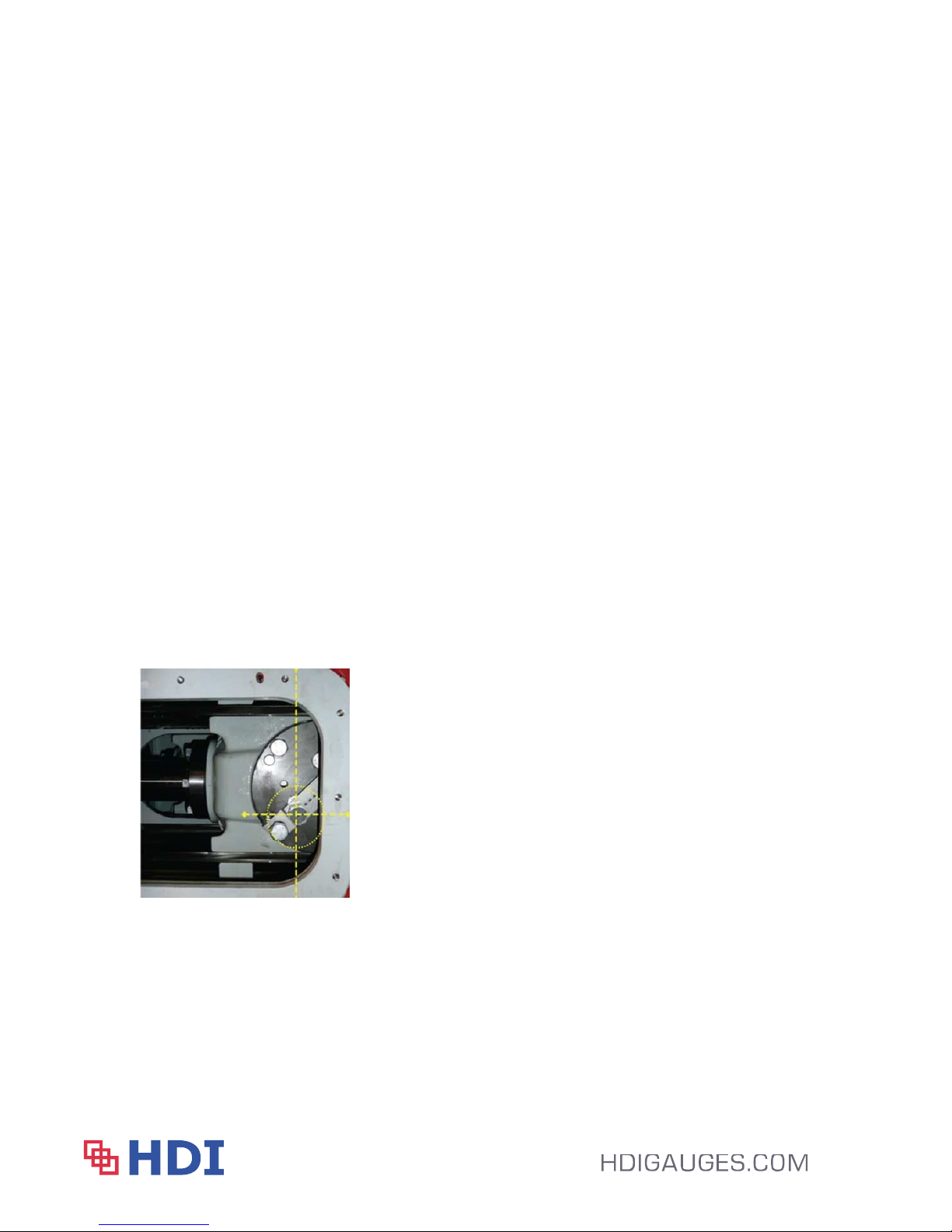

Sample Wirth 2200 Installation of Proximity Sensor w/ bracket

Table of contents