Commercial in confidence 36-261

C1 S-VDR service manual Issue 1

Table of Contents

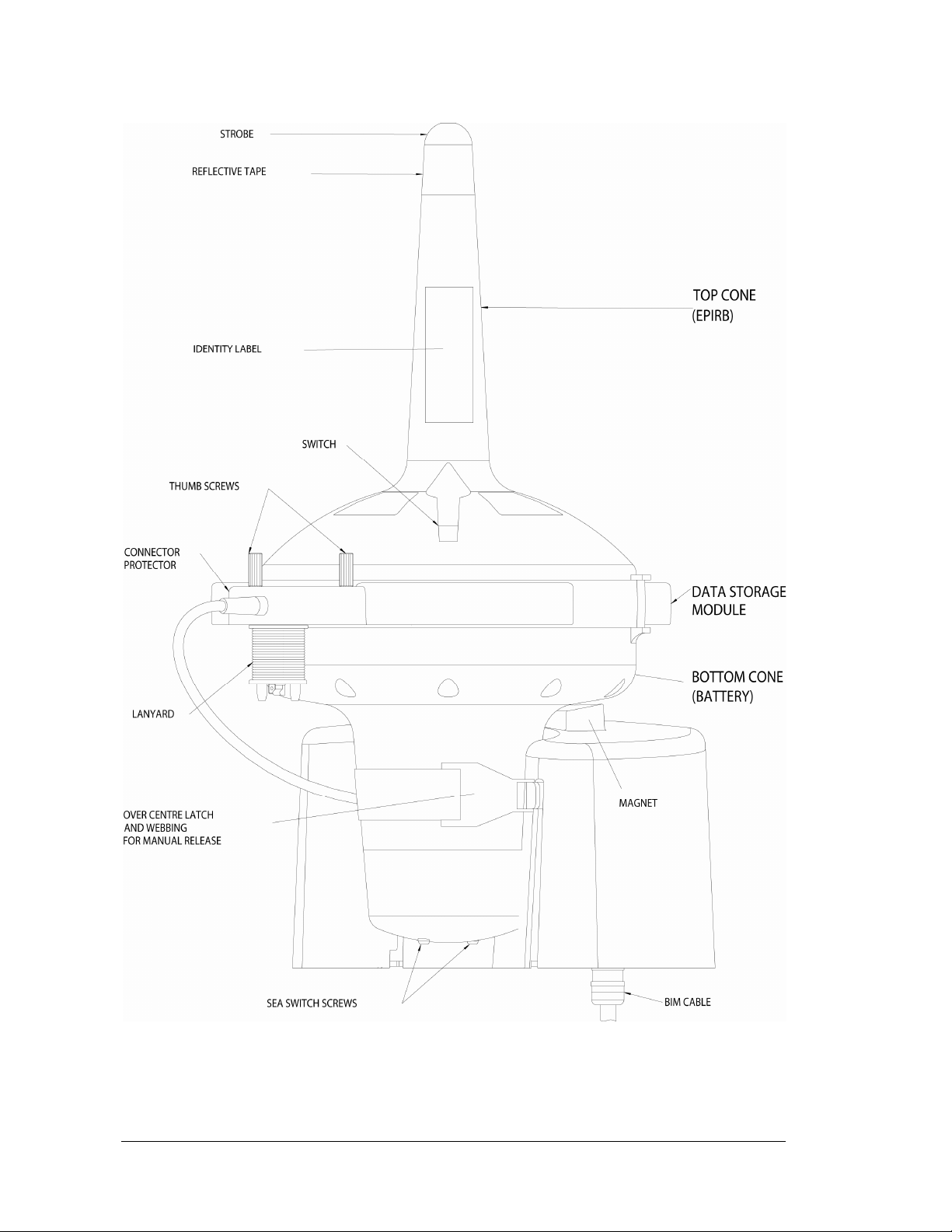

1. Introduction ..........................................................................................................1

1.1 Scope..............................................................................................................1

1.2 Applicability .....................................................................................................1

1.3 Servicin equipment .......................................................................................3

1.4 Safety notices .................................................................................................4

1.5 False alarms ...................................................................................................6

1.6 Deactivatin the EPIRB ..................................................................................6

2. Assessment ..........................................................................................................7

2.1 Maintenance tasks..........................................................................................7

2.2 Routine testin ................................................................................................7

2.3 Assessment ....................................................................................................8

3. Maintenance rocedures ..................................................................................11

3.1 Inspection......................................................................................................11

3.2 Functional tests.............................................................................................12

3.3 Messa e read ...............................................................................................13

3.4 Internal inspection.........................................................................................14

3.5 Disassembly..................................................................................................15

3.6 Reassembly ..................................................................................................20

3.7 Leak testin ...................................................................................................28

3.8 Battery replacement......................................................................................29

3.9 Disposal of batteries .....................................................................................29

3.10 HRU Replacement Kit...................................................................................30

3.11 Pro rammin ................................................................................................34

3.12 Data Recovery ..............................................................................................34

4. Fault finding........................................................................................................36

4.1 Confirmin PCB faults ..................................................................................36

5. Repair procedures .............................................................................................37

6. Spares .................................................................................................................38

7. Appendix 1: Specification .................................................................................40

DRU section.............................................................................................................40

EPIRB section..........................................................................................................40

Appendix 2 : IMO recommendations.......................................................................41

This document is McMurdo Limited copyri ht (©) and contains proprietary owned intellectual property ri hts and

confidential data. All ri hts are strictly reserved. The information must not be used except for the a reed purpose.

Unauthorised use, reproduction or issue to any third party is not permitted without the prior written authority of

McMurdo Limited. This document is to be returned to McMurdo Limited when the a reed purpose is fulfilled.