The function is not only error correcting, it also gives

the operator a tool to see the limitations of the nature,

as well as it can give the answer to a range problem.

Wrong sound velocity input gives error in absolute

accuracy, but influences very little in relative position

changes and stability.

At some stage, the ray-bending will cause the ray to

deflect upwards (see figure). In such conditions the

interrogation pulse from the transducer will never reach

the seabed transponder, and thereby no positioning can

take place.

An alternative tool for handling the ray-bending effect,

is to use depth sensing transponders, or entering opera-

tor set transponder depth into the HiPAP / HPR system.

Then the system will use this depth instead of calculat-

ing it.

Signal-to-Noise ratio

The next important factor is the Signal-to-Noise ratio

at the receiving transducer onboard the vessel. This is

often the most noisy place, as it is close to propellers

and thrusters. There are two ways of getting the highest

possible Signal-to-Noise ratio:

1. Suppress the noise as much as possible

2. Increase the transponder source level

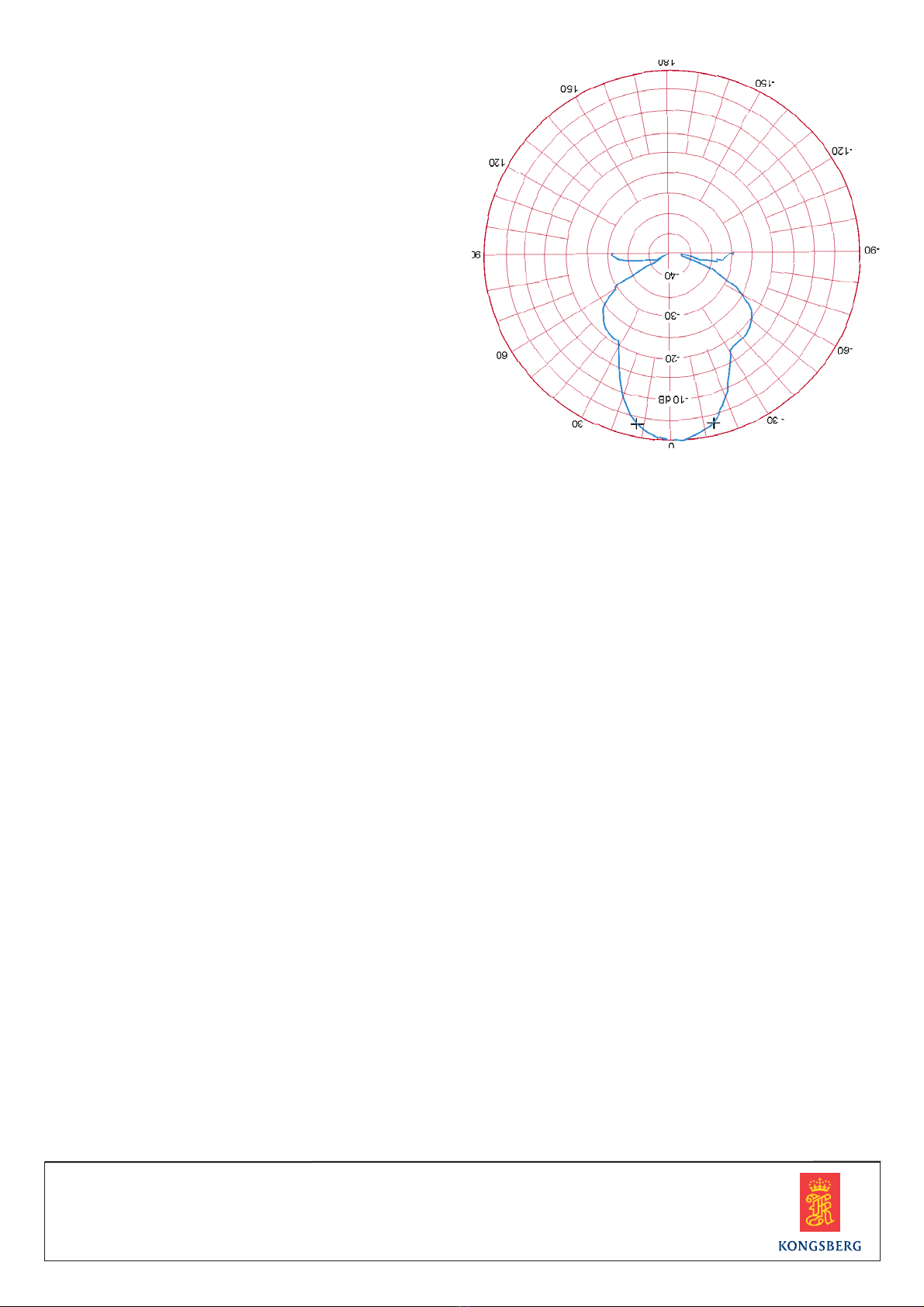

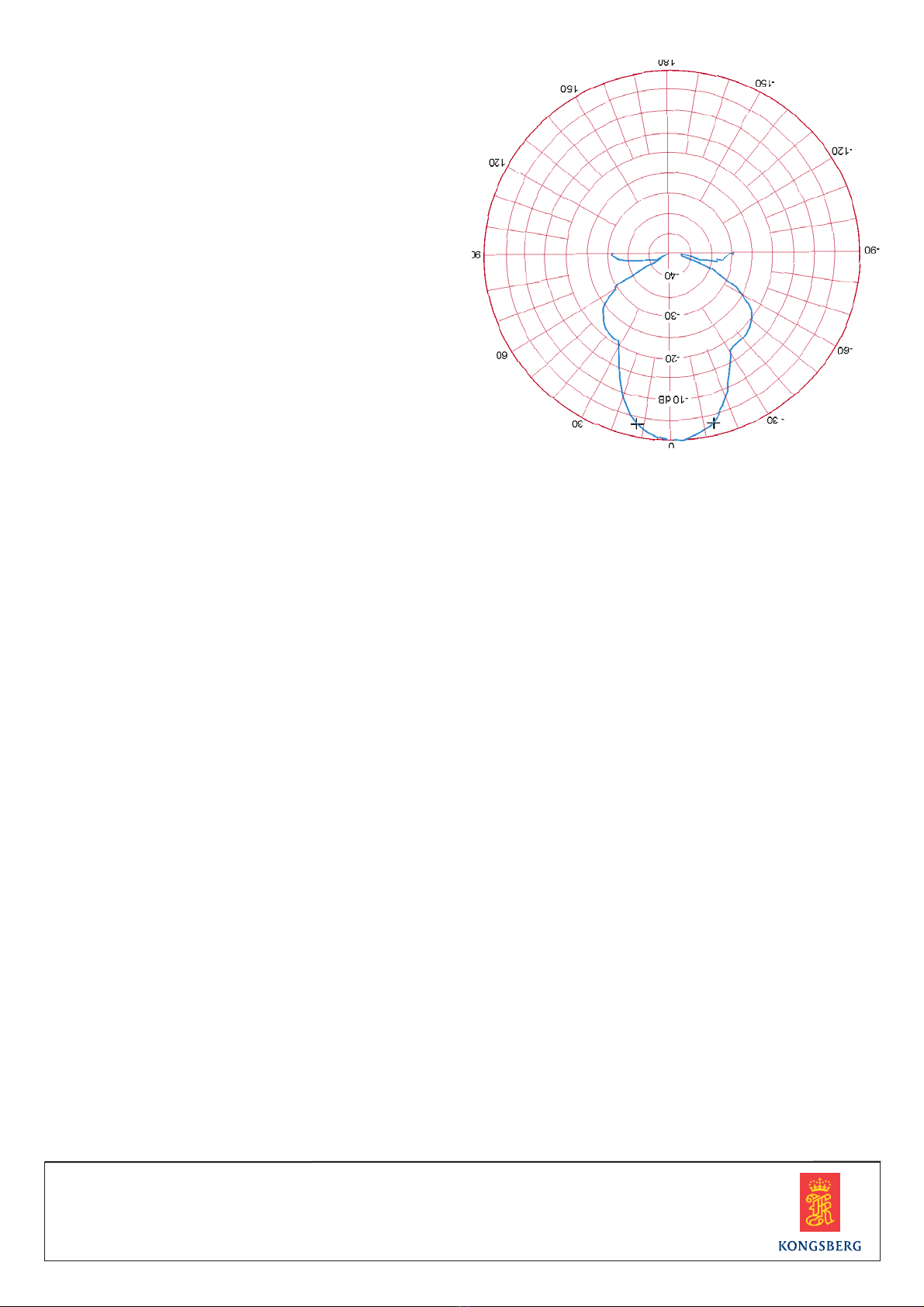

Kongsberg Maritime extensively uses beam forming

transducers to obtain maximum sensitivity towards the

seabed transponder. This gives less sensitivity towards

the noise sources (thrusters and propellers) and sup-

presses the influence from noise. A sensitivity diagram

of a 30 degree transducer beam is shown in the figure

to the right. As you can see, the horizontal sensitivity

(towards the thrusters) is some 30 decibel (dB) lower

than maximum sensitivity vertically!

• The HiPAP system can steer a narrow beam of only

10 degrees to any direction.

• The HPR 400 series of systems has different trans-

ducers - all with directive beams.

Transponder source level

Kongsberg Maritime manufactures many different

types of transponders. It is always important to select

the right transponder for the specific application.

Transponders vary in size, battery lifetime, transmitter

source level and beam pattern. If success is difficult in

for example a noisy environment, you should always

see to that you have a transponder with high source

level to obtain the best Signal-to-Noise ratio. These

transponders are often large due to narrow beamwith

which concentrates the energy in the right direction.

A high power transponder typically has a source level

of 205 dB. A transponder rated for less than 1000 meter

typically has 190 dB. A high power transponder has

approximately 32 times higher source level.

To handle possible noise problems on a plough / tow

fish we suggest to use a responder instead of a trans-

ponder. The responder is triggered and controlled from

the onboard HiPAP / HPR system through an umbili-

cal.

Aerated water

The hull units are designed to allow the transducer to

work some 3,5 meters below the hull. The main reason

to have the transducer at this depth is to get the trans-

ducer down below the “natural” aerated waters sur-

rounding the hull.

The transducer location in the hull is also important.

Kongsberg Maritime will assist to recommend this

location, based on a General Arrangement drawing

showing the entire hull with all propellers and thrust-

ers.

If a Dynamic Positioning (DP) system controls the

engines, it is important that any azimuth thrusters have

“abandoned zones”, to avoid water flushing towards

the transducer(s).

Strandpromenaden 50

P. O . B o x 1 1 1

N-3191 Horten,

Norway

KongsbergMaritimeAS

Telephone: +47 33 02 38 00

Telefax: +47 33 04 47 53

www.kongsberg.com