30926

TABLE

OF

CONTENTS

SECTION

PAGE

1.

GENERAL

DESCRIPTION

В

о

Control

Panel

。

Center

(Storage)

Compartment

-

Control

Head

Assembly

Door

Switch

上

ユー

スー

で

ーー

ドド

<

ドド

이

이이 우우

Reversible

Door

1

上

1

上

ーー

トー

トー

トド

ドド

ドド

ーー

Shelf

Filter

(Models

5520

&

5530

Only)

..............

Adjustable

Shelves

(Models

5520

&

5525

Only)

Optional

Recorder

....1....%..........1%2...,.....

Temperature

Conversion

Chart

....

oe

Heatad

AirFIOW:

ee

see

ele

e

lale

ŞA

es

ola

e

elele

siye

emele

поме

еее

ее

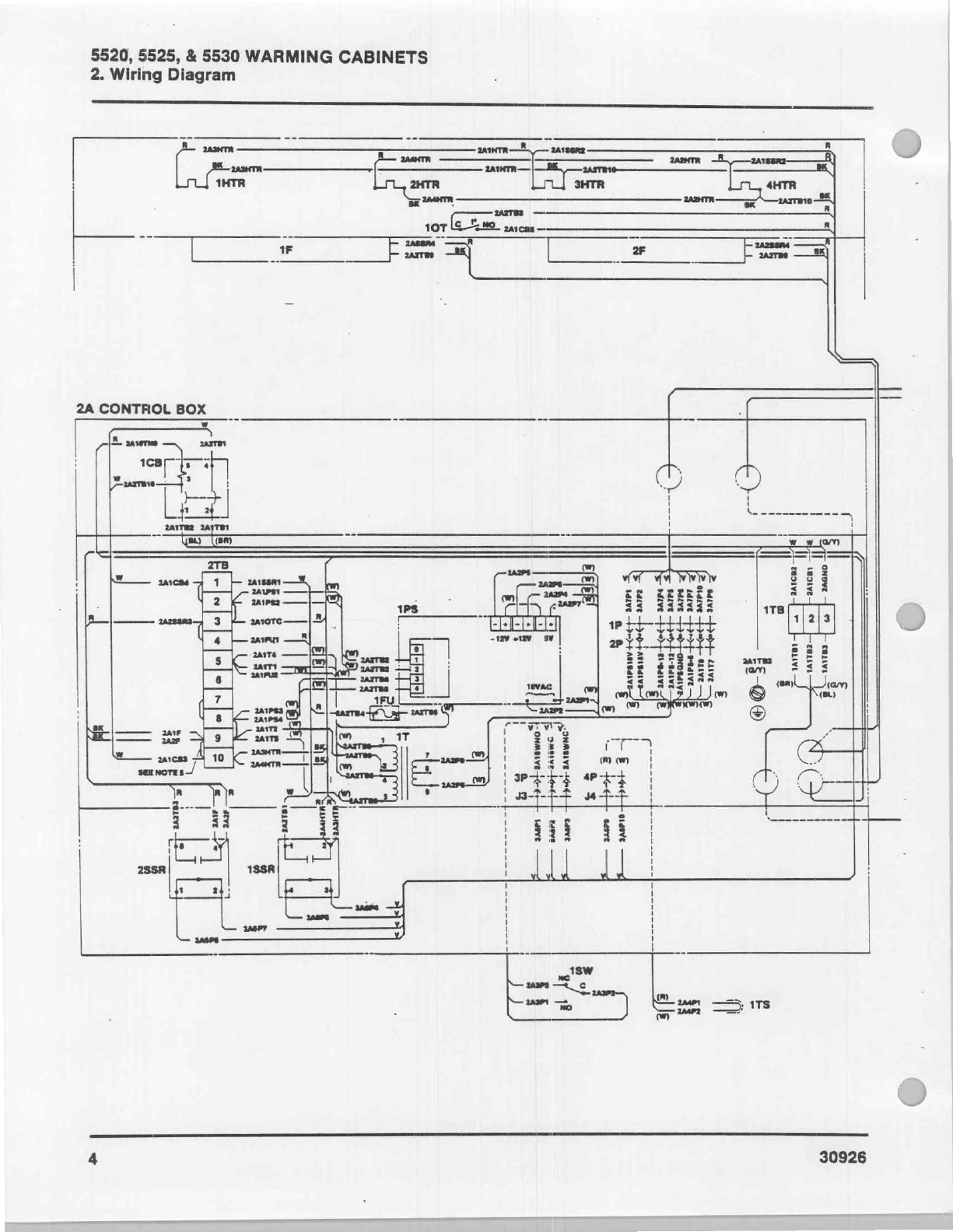

2.

WIRING

DIAGRAM

Warming

Cabinet

Wiring

Diagram

.......................................

4

3.

TROUBLE

ANALYSIS

ПОЛ

МОЕ

О

ео

αρ

ο

ος

оное

в

rea

6

Circuit

Breaker

Trips

7

Unit

Will

Not

Heat

Up

8

Jumper

Connections

on

J3

of

Printed

Circuit

Board

...............

9

UnitiNot'AtProper

Temperature

e

cen

ca

haa

er

aida

aos

eje

10

+5V

Power

Supply

Problem

.....................

11

+11.6V

or

-11.6V

Power

Supply

Problem

12

18

VAC

Power

Supply

Problem

13

24

VAC

Power

Supply

Problem

14

Yellow

Warning

Lit

............

15

We

16

Heater/Fan

Operational

Checks

17

4.

ADJUSTMENTS

&

CALIBRATION

Safety

During

Adjustments

&

Calibration

....................,............

18

Power

Supply

Voltage

Calibration

18

Temperature

Control

Calibration

19

DGOrAGiustMment

“tino

iene

nie

enni

eee

20

Recorder

Calibration

pronao

eae

sure

sie

eds

21

5.

REPAIR

Safety.

DuringRepaif

cdr

e

ian

бое

о

ие

ани

09

23

Access

to

Control

Head

Components

...........

23

Access

to

Control

Box

Components

............

23

Circuit

Breaker

Replacement

23

Fuse

Replacement

............

23

Transformer

Replacement

.....

24

Low

Voltage

Power

Supply

Replacement

........

24

EaniReplacemant:

MMM...

uen

24

Heater

Replacement

..........

24

Thermostat

Replacement

24

Door

Switch

Replacement

26

Recorder

Replacement

(Optional

Equipment)

zes

26

Printed

Circuit

Board

Replacement

...............

se

26

Relay

Meplacemente

...................:0.x».5

302

mee

22

Door

Gasket

Replacement

.......................

ss

22

Reversing'DoonSwWing.

Lu.

ο

siete

nec

eme

Mala

Kase

é

27