43M™ Bair Hugger™ Warming Unit Model 775 – Service Manual

Explanation of Signal WordConsequences

!

WARNING:

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

!

CAUTION:

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE:

Indicates a situation which, if not avoided, could result in property

damage only.

!

CONTRAINDICATION: To reduce the risk of thermalinjury:

• Do not apply heat to lower extremities during aortic

cross-clamping. Thermal injury may occur if heat is applied to

ischemiclimbs.

!

WARNING: To reduce the risk of thermalinjury:

• The Bair Hugger Model 775warming unit has been designed to

operate safely ONLY with 3M disposable warming products. Use

with other products may cause thermal injury. To the full extent

permitted by law, the manufacturer and/or importer declines all

responsibility for thermal injury resulting from the warming unit

being used in conjunction with non-3M products.

• Do not treat patients with the warming unit hose alone.

Always attach the hose to a 3M warming blanket/gown

before providing warmingtherapy.

• Do not allow the patient to lie on the warming unithose.

• Do not allow the warming unit hose to directly contact the

patient’s skin during warmingtherapy.

• Do not leave neonates, infants, children and other vulnerable

patient populations unattended during warmingtherapy.

• Do not leave patients with poor perfusion unmonitored during

prolonged warmingtherapy.

• Do not place the non-perforated side of the warming blanket/

gown on the patient. Always place the perforated side (with the

small holes) directly on top of the patient in contact with the

patient’sskin.

• Do not connect a torn or damaged blanket/gown to the

warmingunit.

• For over-body warming blankets and gowns; do not place

patient securement device (i.e. safety strap or tape) over the

warmingblanket/gown.

• For underbody or side channel warming blankets; if a securement

device (i.e. safety strap, tape) is used, en-sure the warming

channels are notoccluded.

• Do not place the warming blanket/gown directly over a dispersive

electrodepad.

• Do not continue warming therapy if the red Over-temp indicator

light illuminates and the alarm sounds. Unplug the warming unit

and contact a qualified servicetechnician.

• Do not continue 241blood/fluid warming therapy if the red

Over-temp indicator light illuminates and the alarm sounds.

Immediately stop fluid flow, and discard the blood/fluid

warming set. Unplug the warming unit, and contact a qualified

servicetechnician.

• For the BairHugger flex warming gown; ensure that the blood

pressure cuff, ECG, IV or other lines or cords are not between the

upper sleeve insert and the gown prior to deploying the upper

sleeve warming insert(s), as this could result in tearing of the

insert duringdeployment.

• Do not perform the over-temperature detection system test while

the warming unit is being used for warmingtherapy.

!

WARNING: To reduce the risk of patient injury or death due to

altered drugdelivery:

• Do not use a warming blanket/gown over transdermal

medication patches.

!

WARNING: To reduce the risk of injury due to interference

with ventilation:

• Do not allow the warming blanket/gown or head drape to

cover the patient’s head or airway when the patient is not

mechanicallyventilated.

!

WARNING: To reduce the risk of injury due to patientfalls:

• Do not use a warming blanket/gown to transfer or move

thepatient.

!

WARNING: To reduce the risks associated with hazardous voltage

andfire:

• Keep power cord visible and accessible at all times. The plug on

the power cord serves as the disconnectdevice.

• Only connect to outlets marked “Hospital only,” “Hospital Grade,”

or a reliable groundedoutlet.

• Use only the power cord specified for this product and certified

for the country ofuse.

• Do not allow the power cord to get wet.

• Do not use the warming unit when it appears the unit, power cord

or any component is damaged. Replace the warming unit. Contact

3M TechnicalSupport.

• Do not disassemble the warming unit unless you are a qualified

service technician. There are electrically live parts within the

warming unit when it is connected to a power source.

• Connect each warming unit being tested to a separate

powersource.

!

CAUTION: To reduce the risk of cross‑contamination:

• Except for specific Bair Hugger warming blanket models, 3M

blankets/gowns are not sterile. Each warming blanket/gown is

intended for single patient use ONLY. Placing a sheet between

the warming blanket/gown and the patient does not prevent

contamination of the product.

• Clean the warming unit and the outside of the warming unit hose

after each patient use. See “Cleaning Instructions” on page 11.

• Follow applicable regulations when disposing of this warming unit

or any of its electricalcomponents.

• Do not attempt to clean the air filter as it may be contaminated

from use. Discard the filter in a manner consistent with

institutional protocol.

• Do not operate the BairHugger warming unit with the hose

detached from the 3M warming blanket/gown. The Bair Hugger

warming unit is intended to be used with the hose properly

attached to its corresponding warming blanket/gown and

in accordance with good practices for operating room

steriletechnique.

!

CAUTION: To reduce the risk of patient or caregiverinjury:

• If mounted on an IV pole, the distance from the bottom of the

warming unit to the floor must be less than 44” (112 cm) and

the IV pole wheelbase diameter must be at least 28” (71cm) to

preventtipping.

5

GB / 34-8718-8817-7

!

CAUTION: To reduce the risk of fire:

• 3M warming blankets and gowns are classified as Class I Normal

Flammability as defined by the Consumer Product Safety

Commissions flammable fabric regulation, 16CFR 1610. Follow

standard safety protocols when using high intensity heat sources.

!

CAUTION: To reduce the risks of thermal injury, hyperthermia

or hypothermia:

• 3M recommends continuously monitoring core temperature. In

the absence of continuous monitoring, monitor the temperature

of patients who are incapable of reacting, communicating and/or

who cannot sense temperature a minimum of every 15minutes or

according to institutional protocol.

• Monitor cutaneous responses of patients who are incapable

of reacting, communicating and/or who cannot sense

temperature a minimum of every 15minutes or according to

institutional protocol.

• Adjust air temperature or discontinue warming therapy when

the therapeutic goal is reached, if elevated temperatures are

recorded or if there is an adverse cutaneous response in the

warmed area.

• Do not place the warming unit on a soft uneven surface, such

as a bed, or a visibly wet surface as the air in-take may become

blocked and cause the warming unit to overheat, compromising

the warming unit’sperformance.

• Perform all temperature testing of the warming unit with a 3M

Model 22110 temperature testunit.

!

CAUTION: To reduce the risk associated with electromagnetic

interference (EMI) due to portable and mobile radio frequency (RF)

communicationsequipment:

• The 3M BairHugger temperature management system has

been tested to be resistant to both EMI and electro-static

discharge(ESD).

• Install and put into service the 3M Bair Hugger temperature

management system according to the electromagnetic

compatibility (EMC) information provided in the Guidance and

Manufacturer’sDeclaration.

• Should interference occur, move away from the portable or

mobile RF communicationsequipment.

Notices

1. The Bair Hugger warming unit meets medical electronic interference

requirements. If radio frequency interference with other equipment

should occur, connect the warming unit to a different power source.

2. To avoid warming unitdamage:

• Use proper Electrostatic Discharge (ESD) procedures when

performing maintenance.

• Do not modify this equipment without authorization from

the manufacturer.

• Do not immerse the warming unit, warming unit parts

or accessories in any liquid or subject them to any

sterilizationprocess.

• Do not use cleaning solutions with greater than 80% alcohol or

solvents, including acetone and thinner, to clean the warming unit

or hose. Solvents may damage the labels and other plasticparts.

Proper Use andMaintenance

3M assumes no responsibility for the reliability, performance, or safety of

the warming unit if the following eventsoccur:

• Modifications or repairs are performed by unqualified personnel.

• The warming unit is used in a manner other than that described in

the Operator’s or ServiceManuals.

• The warming unit is installed in an environment that does not

meet the appropriate electrical and groundingrequirements.

• The warming unit not maintained in accordance with the

procedures described in the ServiceManual.

Read Before ServicingEquipment

All repair, calibration, and servicing of the warming unit require the skill

of a qualified, medical equipment service technician who is familiar

with good practice for medical device repair. If service does not require

the manufacturer’s attention, the Model 775 Service Manual provides

the technical information needed to service the warming unit. Perform

all repairs and maintenance in accordance with the instructions in the

Service Manual. For additional service information, please contact 3M

technicalsupport.

SafetyInspection

Perform a safety inspection after making repairs to the warming unit and

before returning the warming unit to service. A safety inspection should

include calibrating the operating temperature settings and testing the

over-temperature detection function as described in this service manual as

well as testing for leakage current and continuity check on safetyground.

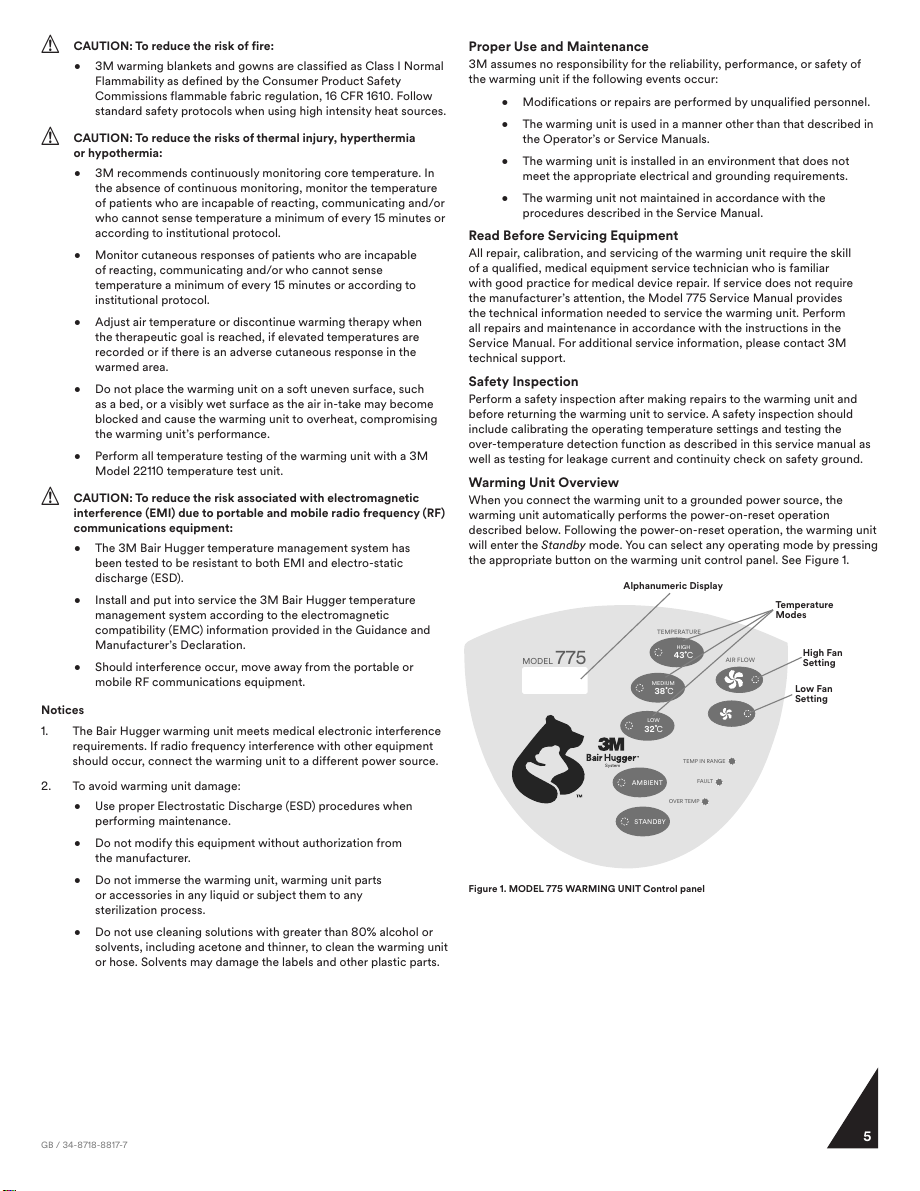

Warming Unit Overview

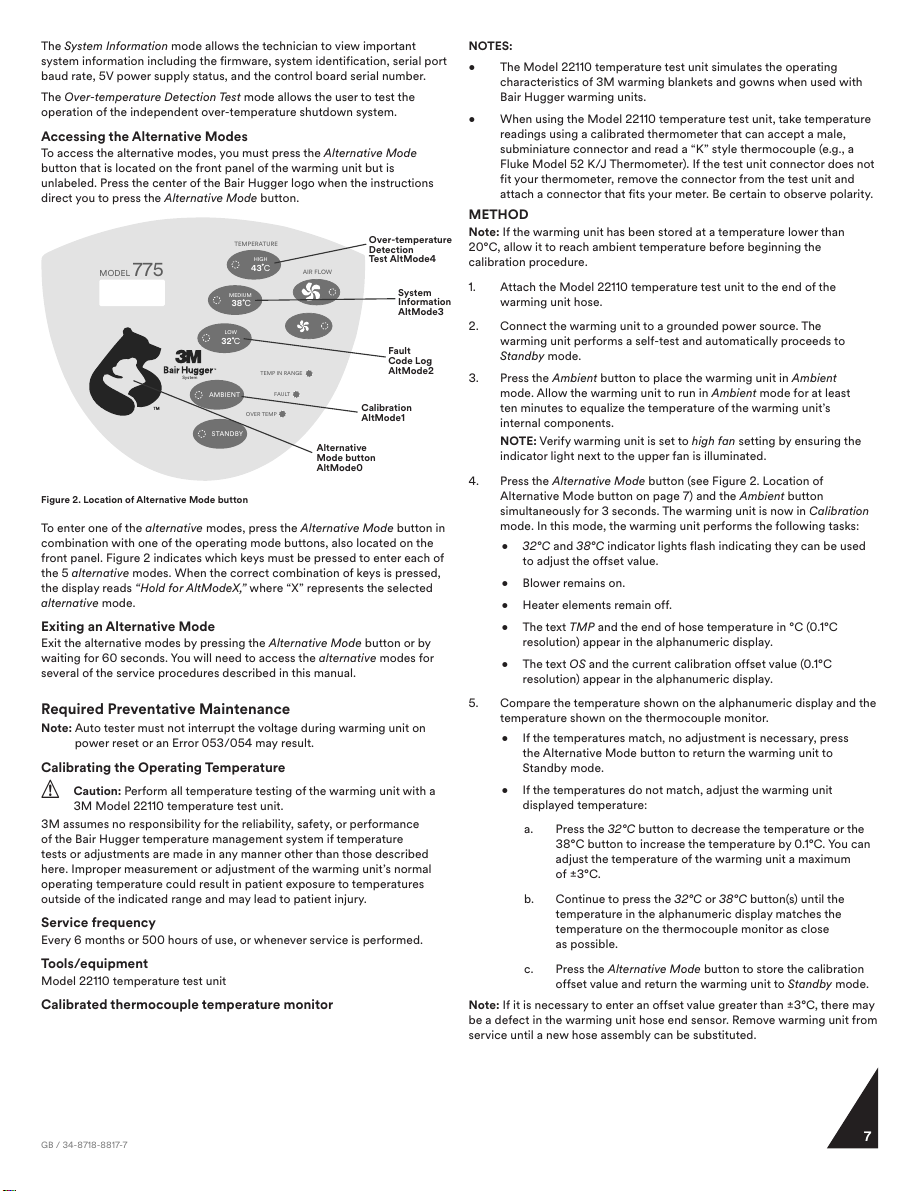

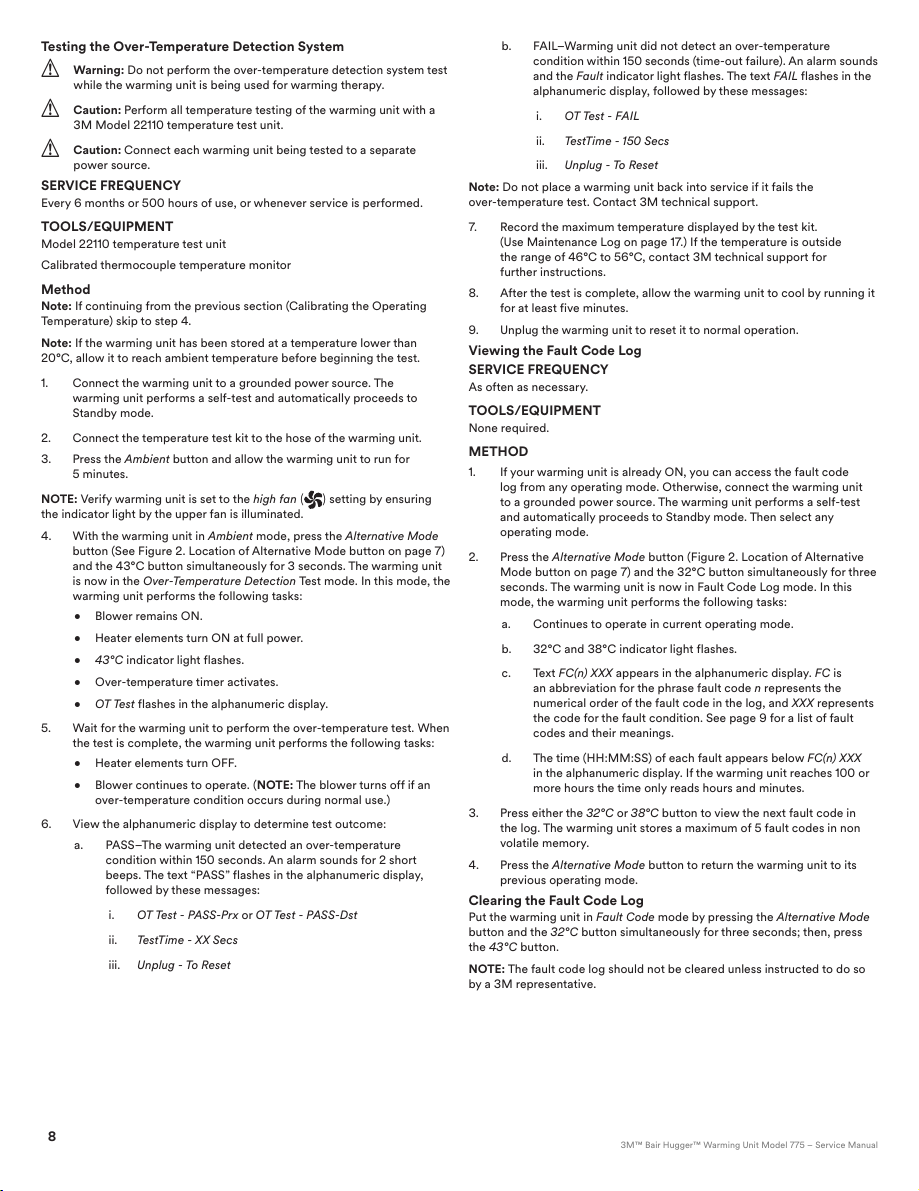

When you connect the warming unit to a grounded power source, the

warming unit automatically performs the power-on-reset operation

described below. Following the power-on-reset operation, the warming unit

will enter the Standby mode. You can select any operating mode by pressing

the appropriate button on the warming unit control panel. See Figure 1.

TEMP IN RANGE

FAULT

OVER TEMP

STANDBY

AMBIENT

MODEL 775 43 C

MEDIUM

HIGH

TEMPERATURE

AIR FLOW

38 C

LOW

32 C

System

High Fan

Setting

Alphanumeric Display

Temperature

Modes

Low Fan

Setting

Figure 1. MODEL 775 WARMING UNIT Control panel