Meanwell DBU-3200 Series User manual

DBU-3200

Instruction Manual

DBU-3200 Instruction Manual

Index

................................................................................

.................................................................................

.........................................

.......................................................................................

.......................................................................................

.......................................................................................

...............................................................

.....................................................

....................................................

.........................................................................................

........................................

...............................................................................

................................................................................

................................................................

...........................................................

...................................................................................

.........................................................................

.............................................

........................................................

......................................................

.............................................................

1

1

1

2

2

3

3

4

5

28

28

29

29

29

28

5

28

6

28

2

2

Jul. 2022 Version 3

0.Product Description

1.Notes on Operation

2.Mechanical Design and Installation Procedure

3.Derating Curve

4.Pin Assignment

5.LED Indication

6.Explanation of Operation Logic

8.PMBus and CANBus Communication Interface

9.Function Description

10.Wiring for Battery

11.Suggested Battery Capacity

12.Series and Parallel Connection

13.Troubleshotting

3.1 Charging Current vs Temperature

3.2 Charging Current vs Input Voltage

9.1 Input Voltage Range

8.1 PMbus Addressing and CAN ID setting

9.2 Power Factor Correction(PFC)

8.2 PMBus Communication Interface

9.3 Temperature Compensation

7.Charge Curve

1

0.Product Description

1.Notes on Operation

DBU-3200 is MEAN WELL's new generation intelligent battery charger with high power density.

Different battery brands and types (lead acid batteries, such as flooded, Gel, AGM, and so on, or

lithium-ion batteries, such as lithium iron, lithium manganese, and so on) may require different

charging curves and protection mechanisms for batteries, DBU-3200 is able to be accommodated

through the communication interface; parameters, such as charge voltage, charge current and taper

current, can be adjusted and the protection mechanisms for batteries can also be cancelled.

◎ The charger must be installed in a dry and well ventilated area. It should not be exposed to rain

or snow.

◎ The cables between charger and battery should be kept as short as possible to prevent excessive

voltage drop. Too much voltage drop will lead to longer charging period.

◎ Please make sure charging voltage and current meet battery specification.

◎ While charging batteries in series, do not mix old and new batteries in the same connection.

◎ When connecting or disconnecting wires, please ensure the charger is OFF.

◎ Under normal operating conditions, a 5 years warranty is offered for DBU-3200. If failure results

from improper operation, the warranty will not apply to the defective units.

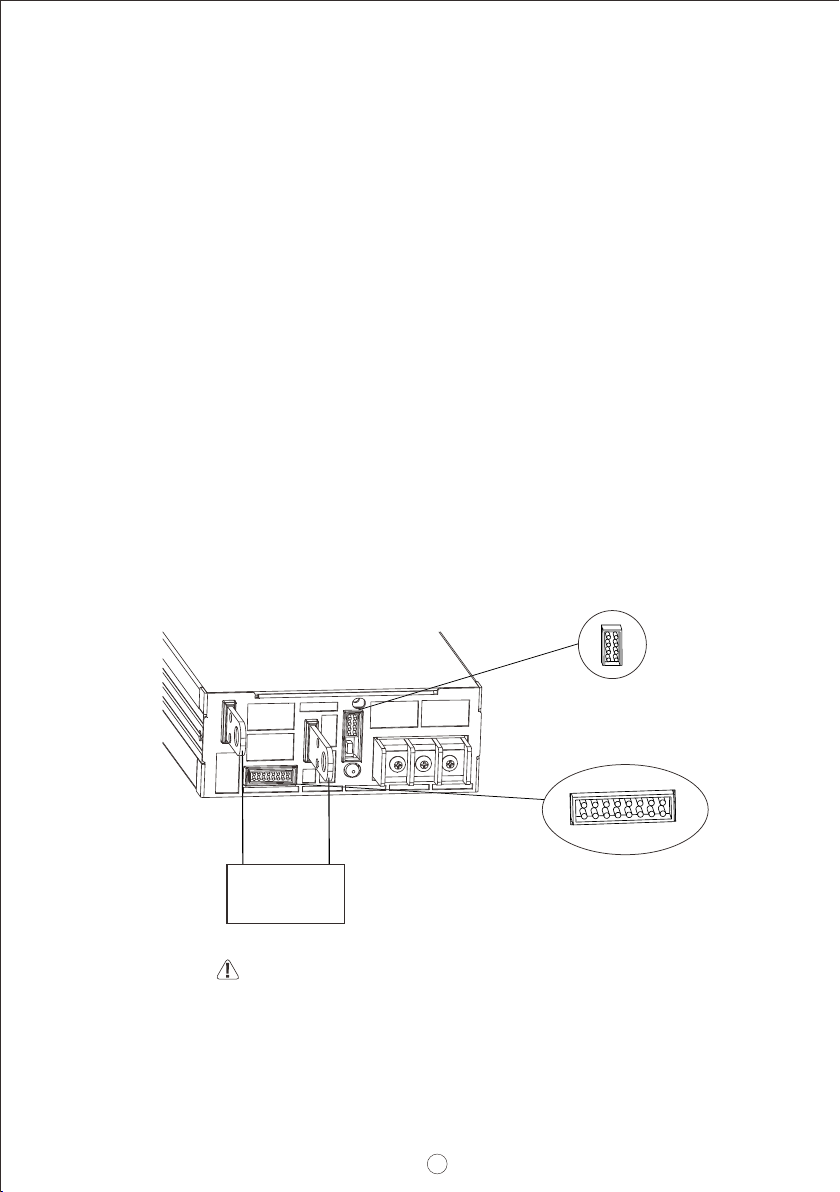

2.Mechanical Design and Installation Procedure

Warning: Before connecting a battery, please make sure

the polarity is correct to avoid damaging the charger

Figure2.1 Front panel

+

-

Batteries

CN500

CN1

8

115

2

16

2

7

1

15

16

RTH+

RTH-

Temperature sensor(NTC, 5KOhm) comes along with the charger can be connected to the unit to allow temperature

compensation of the charging voltage.

Installation Procedure:

Please make sure the charger is OFF before connecting the battery to the output terminal. Choose a

cable with suitable wire gauge according to the charging current to connect between the charger and

the battery. Battery polarity must be connected correctly:Terminal(+) to Battery(+); Terminal(-) to

Battery(-), and take notice that the positive and negative ends are not shorted.

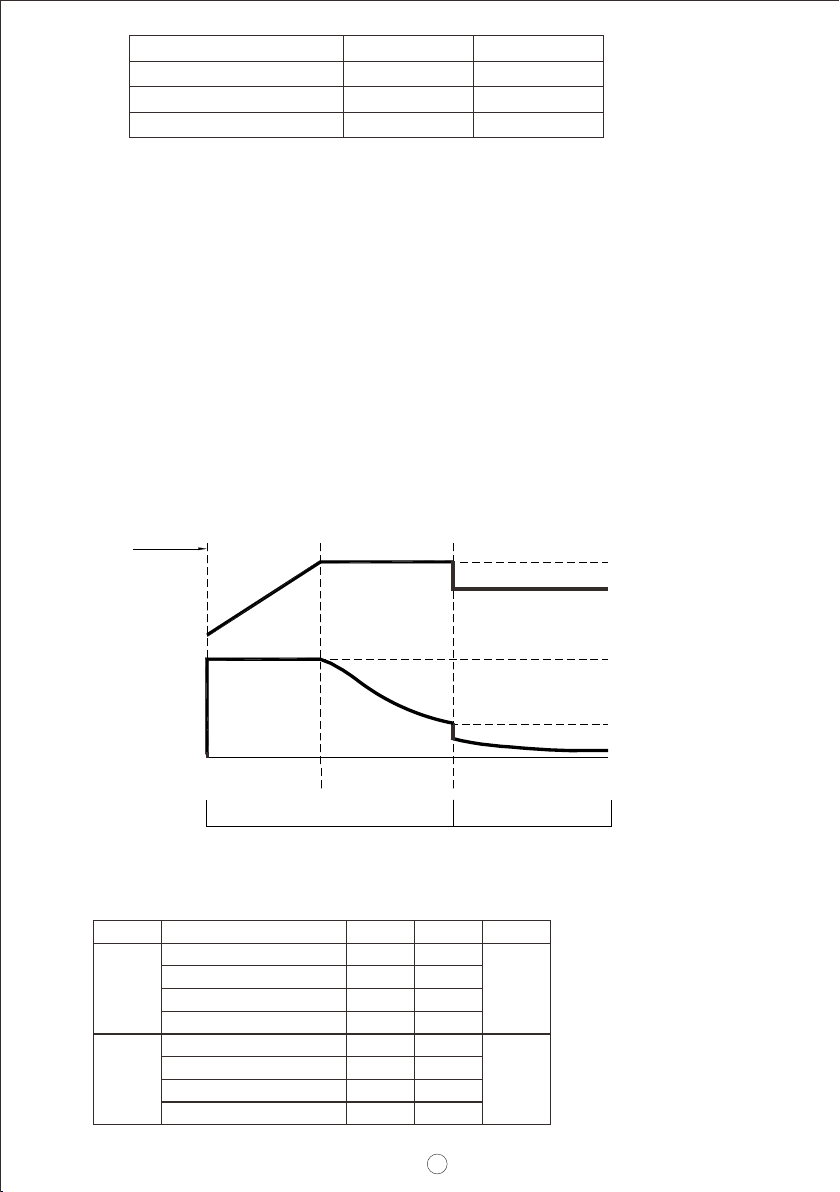

3.Derating Curve

4.Pin Assignment

3.1 Charging current vs Temperature

3.2 Charging current vs Input Voltage

AMBIENT TEMPERATURE (℃)

LOAD (%)

LOAD (%)

INPUT VOLTAGE (VAC) 60Hz

CN1

230VAC

Input only

-30 -25 0-10 15 30 50 60 70

20

40

60

50

80

100

(HORIZONTAL) 90 100 115 180 264

80

90

100

70

60

50

40

30

1

2

15

16

2

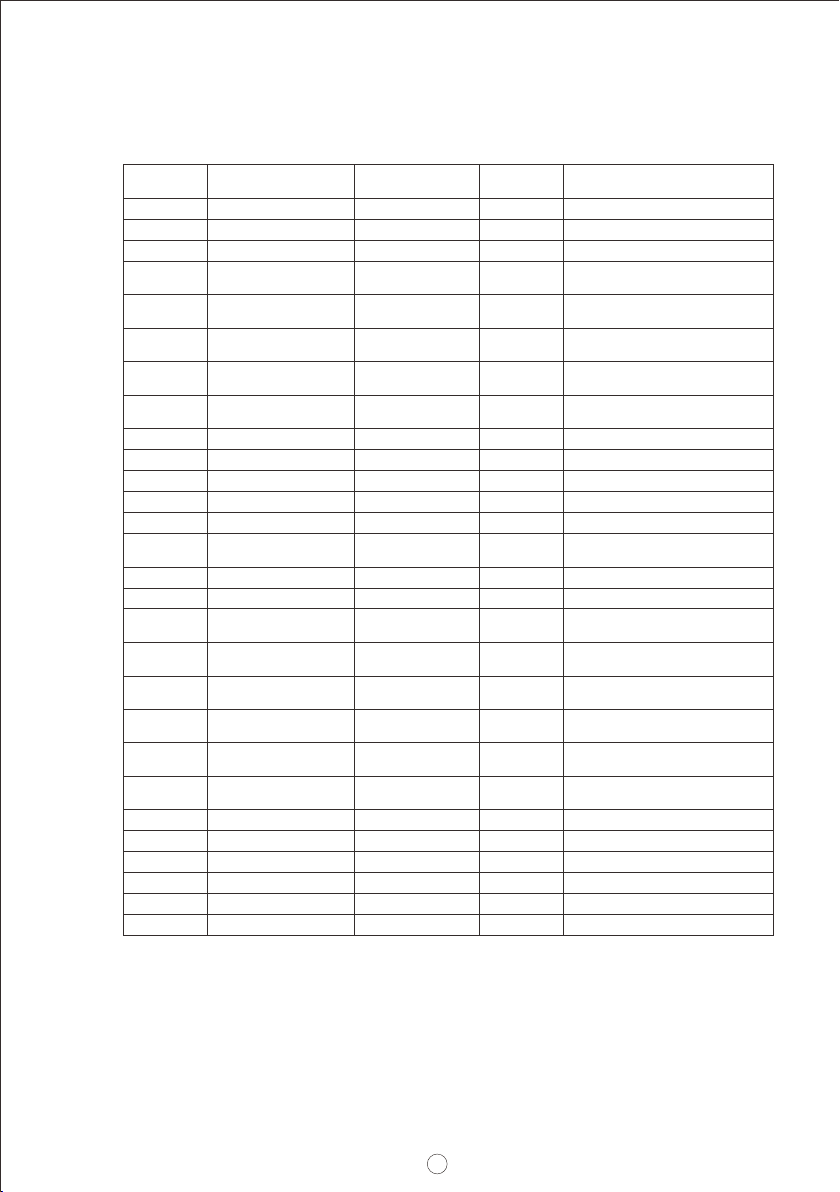

Pin No. Function Description

4

2

7,8,9

10

5

6

3

1

12

11

Remote

ON-OFF

GND-AUX

DC-OK

T-ALARM

+5V-AUX

+12V-AUX

PV

PC

A0,A1,A2

D0

Auxiliary voltage output GND.

The signal return is isolated from the output terminals (+V & -V).

Auxiliary voltage output, 4.5~5.5V, referenced to GND-AUX (pin2).

Auxiliary voltage output, 10.6~13.2V, referenced to GND-AUX (pin2).

The maximum load current is 0.3A. This output has the built-in "Oring diodes" and is not controlled by “Remote ON-OFF

The maximum load current is 0.8A. This output has the built-in "Oring diodes" and is not controlled by “Remote ON-OFF”.

Connection for output voltage programming. (Note.1)

High (3.5 ~ 5.5V) : When the internal temperature exceeds the limit of temperature alarm, or when Fan fails.

Low (-0.5 ~ 0.5V) : When the internal temperature is normal, and when Fan works normally.

The maximum sourcing current is 10mA and only for output(Note.2)

Connection for output current programming. (Note.1)

Low (-0.5 ~ 0.5V) : When Vout ≧16V/32V ±1V. The maximum sourcing current is 10mA and only for output. (Note.2)

DC OK is associated with battery low protection.

High (3.5 ~ 5.5V) : When the Vout ≦16V/32V ±1V.

PMBus interface address lines. (Note.1)

DIP-switch interface lines for charging curve selection. (Note.1)

The unit can turn the output ON/OFF by electrical signal or dry contact between Remote ON/OFF and +5V-AUX. (Note.2)

Short (4.5 ~ 5.5V) : Power ON ; Open (-0.5 ~ 0.5V) : Power OFF ; The maximum input voltage is 5.5V.

Note1: Non-isolated signal, referenced to the [-V(signal)].

Note2: Isolated signal, referenced to GND-AUX.

13

14

+V (Signal)

-V (Signal)

Positive output voltage signal.

Negative output voltage signal.

It cannot be connected directly to the load.

It is for certain function reference; it cannot be connected directly to the load.

3

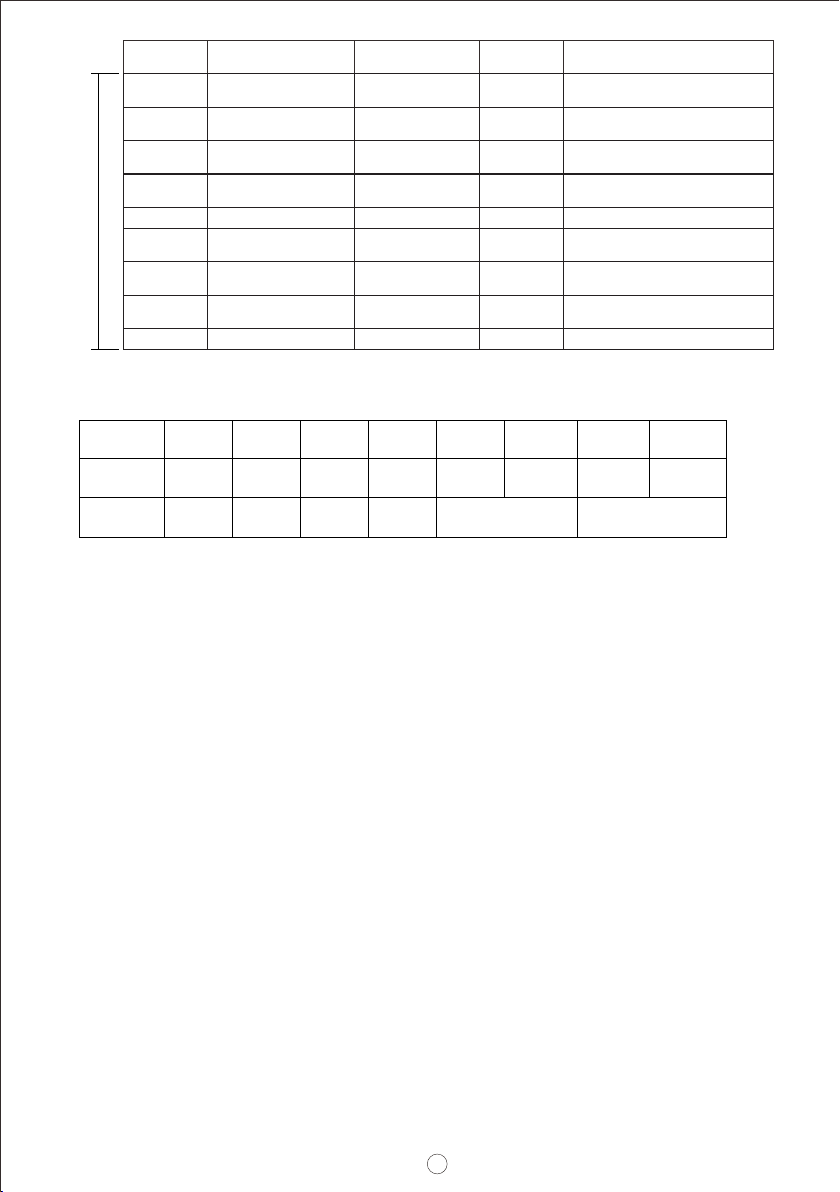

CN500 21

87

6.Explanation of Operation Logic : (3 stage charge)

5.LED Indicators

SW1

Pin No.

1,2

Function

Terminal

resistance

Description

SW1 is the selector of terminal resistor that is designed for DA/DB signals and parallel control function.

At the beginning stage of operation, the charger provides the largest current to charge the batteries,

the LED indicator will lighten in orange. After a period of time (probably a couple of hours, based on

the capacity of the batteries), charging current will decrease gradually. When the output current

reduces to 10% of its maximum value, the charger will go into “float” mode, the LED indicator will

turn to green. The relationship between charging current and charging voltage for each operation

stage is shown in the curves below:

Charge Current

Constant Current

(CURVE_CC)

stage 1 stage 2 stage 3

Constant Voltage

(CURVE_CV) (CURVE_FV)

Float

Start

Charge Voltage

100% CC

10% CC

boost

float

V

V

Orange Green

Color of LED

Pin No.

1,2

7

8

5,6

3,4

Function

DA

NC

NC

SDA

SCL

CANH

CANL

DB

-V (Signal)

Description

Differential digital signal for parallel control.

Differential digital signal for parallel control.

For standard model: None.

For standard model: None.

For PMBus model: Serial Data used in the PMBus interface. (Note)

For PMBus model: Serial Clock used in the PMBus interface. (Note)

For CANBus model: Data line used in CANBus interface. (Note)

For CANBus model: Data line used in CANBus interface. (Note)

Negative output voltage signal.

It is for local sense; and certain function reference; it cannot be connected directly to the load.

LED

Green

Orange

Red

Float (stage 3)

Charging (stage 1 or stage 2)

Description

Abnormal status (OTP, OLP, Fan Fail, Charging timeout)

Note: Isolated signal, referenced to GND-AUX.

◎ Embedded 3 stage charging curve

4

7.Charge Cureve

The factory setting is “default”, which can be programmed via PMBus.

◎ Default 3 stage charging curve

Charge Current

Start

Charge Voltage

Color of LED

Constant Current

(CURVE_CC)

stage 1 stage 2 stage 3

Constant Voltage

(CURVE_CV) (CURVE_FV)

Float

100% CC

10% CC

boost

float

V

V

Orange Green

Explanation for 3 stage charge curve

(0) Initial stage (battery analysis):Check battery voltage level to see whether there is a battery

connected.

(1) Stage 1 (constant current):A constant current is provided so that the battery can be quickly

charged to 2.4V per cell.

(2) Stage 2 (constant voltage):A constant voltage of 2.4V per cell is provided until the charging

current gradually reduces to 10%.

(3) Stage 3 (float):The output voltage switches to the float voltage, making it 2.3V per cell to keep the

battery fully charged.

Note: By factory default, PIN10 and PIN14 on CN1 are connected.

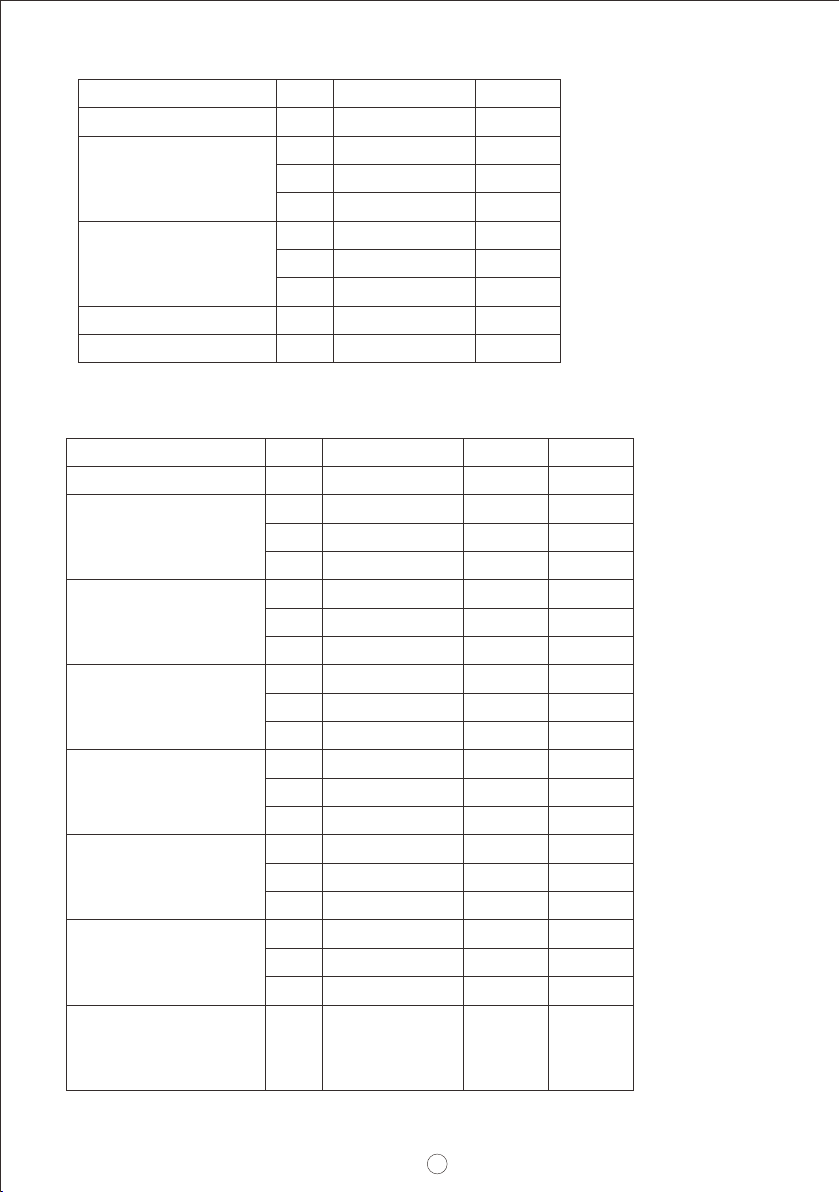

MODEL

24V

48V

Vboost

28.8

57.6

28

56

28.4

56.8

29

58

Vfloat

27.6

55.2

27.2

54.4

26.8

53.6

27

54

Description

Default, programmable

Default, programmable

#1 Pre-defined, gel batter

#1 Pre-defined, gel batter

#2 Pre-defined, flooded battery

#2 Pre-defined, flooded battery

#3 Pre-defined, AGM battery

#3 Pre-defined, AGM battery

CC(default)

110A

55A

STATUS

BOOST CHARGE VOLTAGE

FLOAT CHARGE VOLTAGE

28.8V

27.6V

DBU-3200-24

57.6V

55.2V

DBU-3200-48

Figure Charge Curve 6.1

CONSTANT CURRENT 110A 55A

5

8.Communication Protocol

8.1 PMbus Addressing and CAN ID setting

◎Each DBU-3200 unit should have their unique and own device address or ID to communicate over the bus.

*PMbus 7-bit addressing definition :

*CAN message ID definition :

1

MSB

0 0 0 A2 A1 A0

LSB

Users can use three different methods to control outputs of DBU-3200. The control priority between

the methods is as follows: Communication (PMBus or CAN bus) > PV/PC > SVR. These three control

methods can be used interchangeably. When using communication control, it is essential to

communicate with the device within 4 seconds. Otherwise, the program will reset the control priority

and set the communication parameters back to the factory default values(NOTE 1). However, the

following condition will bypass this control logic: setting DBU-3200 to charger mode. In charger

mode, PV/PC and SVR controls will become inactive and charging-related settings can only be

changed via communication.

NOTE: 1.When D0 is set at “1” and communication function is used, some of the parameters will

return to the factory default values if any of the conditions happens, AC recycling and

communication timeout. Take DBU-3200-24 as an example, command OPERATION

becomes ON, Vo and Io change to 24V and 110A.

2.In charger mode, Remote ON/OFF or OPERATION ON/OFF can be used to activate new

curve procedures and import parameters and settings for a new curve profile. Additionally,

it can also release protections caused by CURVE_CC_TIMEOUT, CURVE_CV_TIMEOUT,

or CURVE_TP_TIMEOUT due to timeouts.

Message ID

0xC00XX

0xC01XX

0xC01FF

Description

DBU-3200 to Controller Message ID

Controller to DBU-3200 Message ID

Controller broadcasts to DBU-3200

XX means the CAN ID of DBU-3200

A0-A2 allows users to designate an address or ID for the DBU-3200 unit; these three bits are

defined through PIN7 (A0), PIN8 (A1) and PIN9 (A2) on CN1. There are up to 8 different

addresses are available to be assigned. When connecting one of these pins, for example, PIN8

with PIN14 (-V(Signal)), the corresponding bit, A1, is set to logic “0”; when it is kept opened, for

example, PIN7, the corresponding bit, A0, is set to logic “1”. Please refer to Table 8-1(left) for

detailed setup.

◎Charge mode can be activated by settings over D0 (PIN10) on CN1. When D0 is logic “0”,

connecting PIN10 to PIN14(-V(Signal)), DBU-3200 follows a built-in charging curve to

charge the batteries; when D0 is logic “1”, PIN10 kept opened, operation of the unit is

completely defined by the control over PMBus, PV/PC or SVR. Please refer to Table 8-

1(right).

Module

No. A0

0

1

2

3

4

5

6

7

A1 A2

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

Device address/ID

Table 8-1

D0 Function describe

0 Charging curve

1 PMBus or PV/PC or SVR control

Charging Curve

When it is opted for charging curve, D0 set to 0, charging curve function is enabled with additional

PMBus or CAN bus commands. There are 4 built-in charging curves, “default” curve, one pre-

defined curve for “gel battery”, one pre-defined curve for “flooded battery” and one pre-defined

curve for “AGM battery”. Each curve can be selected by Command CURVE_CONFIG (PM: B4h;

CAN: 0x00B4). In addition, users are able to customize their own charge curves, which will be

stored to “default” after modification. Constant voltage level can be set by Command CURVE_CV

(PM:B1h; CAN: 0x00B1); Float voltage level can be set by Command CURVE_FV (PM:B2h; CAN:

0x00B2) ;Charge current level of stage1 can be set by Command CURVE_CC(PM:B0h; CAN:

0x00B0);Taper current level from stage2 to stage3 can be set by Command CURVE_TC(PM:B3h;

CAN: 0x00B3)). Please refer to the command list of PMBus or CAN bus for detailed information on

commands and parameters.

NOTE:

1. The updated charging parameters is saved into EEPROM. The updated charging curve takes

effect after DBU-3200 is restarted, remoted on/off or operation on/off.

2. When charging curve is enabled, the following commands will be invalid while other commands

are still effective: Command VOUT_TRIM(22h)/ (regarding Output VOUT_SET(0x0020)

voltage programming function) and Command IOUT_OC_FAULT_LIMIT(46h)/

IOUT_SET(0x0030) (regarding Output current programming function).

8.2 PMBus Communication Interface

◎DBU-3200 is compliant with PMBus Rev.1.1, the maximum communication speed is 100KHz and

the maximum number of assignable addresses is up to 8 units on a bus.

◎PMBus communication interface is able to provide the current operating status and information as

follows:

1. Output voltage, current and internal temperature.

2.Alarm and status.

3.Manufacturer's and model data.

4. Read/write of charge curve settings.

6

7

47h

79h

7Ah

7Bh

7Ch

7Dh

1

2

1

1

1

1

Define protection and response when an

output overcurrent fault occurred

Summary status reporting

Output voltage status reporting

Output current status reporting

AC inpit voltage statusreporting

Temperature status reporting

IOUT_OC_FAULT_RESPONSE

STATUS_WORD

STATUS_VOUT

STATUS_IOUT

STATUS_INPUT

STATUS_TEMPERATURE

R Byte

R Word

R Byte

R Byte

R Byte

R Byte

22h 2 Output voltage trimmed value

(format: Linear 16, N= -9)

VOUT_TRIM R/W Word

46h 2Output overcurrent setting value

(format: Linear 11, N= -2)

IOUT_OC_FAULT_LIMIT R/W Word

7Eh 1 Communication, logic,

Memory status reporting

STATUS_CML R Byte

Command

Code

01h

02h

19h

20h

21h

# of data

Bytes

1

1

1

1

2

Description

Remote ON/OFF control

ON/OFF function configuration

Capabilities of a PMBus device

Define data format for output voltage

(format: Linear 16, N= -9)

Output voltage setting value

(format: Linear 16, N= -9)

Command

Name

OPERATION

ON_OFF_CONFIG

CAPABILITY

VOUT_MODE

VOUT_COMMAND

Transaction

Type

R/W Byte

Read Byte

Read Byte

R Byte

R Word

Table 8-2

◎PMBus commands: The command list of the DBU-3200 is shown in Table 8-2. It is compliant

with the standard protocol of PMBus Rev. 1.1. For more detailed information, please refer to

PMBus official website (http://pmbus.org/specs.html)

90h

91h

98h

2

2

1

Fan speed 1 reading value

(format: Linear 11, N= 5)

Fan speed 2 reading value

(format: Linear 11, N= 5)

The compliant revision of the PMBus

(default: 11h for Rev. 1.1)

READ_FAN_SPEED_1

READ_FAN_SPEED_2

PMBUS_REVISION

R Word

R Word

R Byte

99h

9Ah

9Bh

9Ch

9Dh

9Eh

12

12

6

3

6

12

Manufacturer's name

Manufacturer's model name

Firmware revision

Manufacturer's factory location

Manufacture date. (format: YYMMDD)

Product serial number

MFR_ID

MFR_MODEL

MFR_REVISION

MFR_LOCATION

MFR_DATE

MFR_SERIAL

Block Read

Block Read

Block Read

Block R/W

Block R/W

Block R/W

81h

80h

88h

8Bh

8Ch

1

1

2

2

2

Fan1 and 2 status reporting

Manufacture specific status reporting

AC input voltage reading value

(format: Linear 11, N=-1)

Output voltage reading value

(format: Linear 16, N= -9)

Output current reading value

(format: Linear 11, N= -2)

STATUS_FANS_1_2

STATUS_MFR_SPECIFIC

READ_VIN

READ_VOUT

READ_IOUT

R Byte

R Byte

R Word

R Word

R Word

◎ Definition of Command B4h CURVE_CONFIG:

Note:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

High byte - - - - - FVTOE CVTOE CCTOE

Low byte - STGS - - TCS CUVS

Low byte

Bit 1-0 CUVS :Charge Curve selecting

00=Customized Charge Curve (default)

01=Gel Battery

10=Flooded Battery

11=AGM Battery

Bit 3-2 TCS:Temperature Compensation setting

Bit 6 STGS:2/3 stage charge setting

High byte

00= disable

0= 3 (default, Curve_VBST and CURVE_V FLOAT) stage charge

Bit 0 CCTOE:Constant Current Stage timeout indication enable

Bit 1 CVTOE:Constant Voltage Stage timeout indication enable

Bit 2 FTTOE:Float Stage timeout indication enable

01= -3 mV/℃/cell (default)

1= 2 (only CURVE_VBST) stage charge

0= (default)disabled

0= (default)disabled

0= (default)disabled

1= enabled

1= enabled

1= enabled

10= -4 mV/℃/cell

11= -5 mV/℃/cell

Command

Code

# of data

Bytes Description

Command

Name

Transaction

Type

B8h 2Charger's status reportingCHG_STATUS READ Word

B4h

B5h

B6h

B7h

B3h

2

2

2

2

Configuration setting of charging curve

CC stage timeout setting value of charging curve

(format: Linear, N= 0)

CV stage timeout setting value of charging curve

(format: Linear, N= 0)

Floating timeout setting value of charging curve

(format: Linear, N= 0)

CURVE_CONFIG

CURVE_CC_TIMEOUT

CURVE_CV_TIMEOUT

CURVE_FLOAT_TIMEOUT

R/W Word

R/W Word

R/W Word

R/W Word

B0h

B1h

B2h

Valid when charging according to charge curve (D0=0)

2

Taper current setting value of charging curve

(format: Linear, N= -2)

CURVE_TC R/W Word

2

2

2

Constant current setting value of charging curve

(format: Linear, N= -2)

Constant voltage setting value of charging curve

(format: Linear, N= -9)

Constant voltage setting value of charging curve

(format: Linear, N= -9)

CURVE_CC

CURVE_CV

CURVE_FV

R/W Word

R/W Word

R/W Word

8

Bit 2 CVM:Constant Voltage Mode Status

0=the charger NOT in constant voltage mode

1=the charger in constant voltage mode

Bit 3 FVM:Float Mode Status

0=the charger NOT in float mode

1=the charger in float mode

High byte

Bit 0 EEPER: EEPROM Charge Parameter Error

Bit 2 NTCER: Temperature Compensation Status

Bit 3 BTNC: Battery Detection

Bit 5 CCTOF:Time-out Flag of Constant Current Mode

Bit 6 CVTOF:Time-out Flag of Constant Voltage Mode

Bit 7 FTTOF:Time-out Flag of Float Mode

0=data of charge parameter correct

0=NO short-circuit in the circuitry of temperature compensation

0=battery detected

0=time-outNO in constant current mode

0=time-outNO in constant voltage mode

0= NO time-out in float mode

1=data of charge parameter error

1=the circuitry of temperature compensation has short-circuited

1=NO battery detected

1=constant current mode timed out

1=constant voltage mode timed out

1=float mode timed out

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2

High byte FVTOF CVTOF CCTOF - NTCERBTNC

CVMFVM

Low byte - - - -

Low byte

Bit 0 FULLM:Fully Charged

0=NOT fully charged

1=fully charged

Bit 1 CCM:Constant Current Mode Status

0=the charger NOT in constant current mode

1=the charger in constant current mode

◎ Definition of Command B8h CHG_STATUS:

Bit1 Bit0

-

CCM

EEPER

FULLM

9

Note:

EEPER:When EEPROM Charge Parameter Error occurs, the charger stops charging the battery and

the LED indicator turns red. The charger needs to re-power on to re-start charging the

battery.

NTCER:When Temperature Compensation Short occurs, the charger output will shut down and the

LED indicator will turn red. The charger will automatically restart after the Temperature

Compensation Short condition is removed.

BTNC:When there is no battery detected, the charger stops charging the battery and the LED

indicator turns red. The charger needs to re-power on to re-start charging the battery.

CCTOF:When timeout arises in the Constant Current stage, the charger stops charging the battery

and the LED indicator turns red. The charger needs to re-power on to re-start charging the

battery.

CVTOF:When timeout arises in the Constant Voltage stage, the charger stops charging the battery

and the LED indicator turns red. The charger needs to re-power on to re-start charging the

battery.

FVTOF:When timeout arises in the Float stage, the charger stops charging the battery and the LED

indicator turns green. This charging flow is finished; the charger needs to re-power on to

start charging a different battery.

10

PMBus command

OPERATION

CURVE_CV

(Note. 3)

CURVE_FV

(Note. 3)

IOUT_OC_FAULT_LIMIT

CURVE_CC

CURVE_TC

CURVE_CC_TIMEOUT

CURVE_CV_TIMEOUT

CURVE_FLOAT_TIMEOUT

VOUT_COMMAND

(Note. 2)

VOUT_TRIM

(Note. 2)

Adjustable range

00h(OFF) / 80h(ON)

9 ~ 15V

9 ~ VBST

20 ~ 100A

5 ~ 30A

18 ~ 30V

18 ~ VBST

11 ~ 55A

2.75 ~ 16.5A

60 ~ 64800 Minute

36 ~ 60V

36 ~ VBST

5.5 ~ 27.5A

1.5 ~ 8.3A

-3 ~ 3V

-6 ~ 6V

-12 ~ 12V

Tolerance Default

N/A

N/A

N/A

N/A

80h(ON)

±0.18V

±0.18V

±2.5A

±2.5A

±0.36V

±0.36V

±1.34A

±1.34A

±5 Minute

±0.48V

±0.48V

±0.67A

±0.67A

14.4V

13.8V

100A

10A

28.8V

27.6V

55A

5.5A

600 Minute

57.6V

55.2V

27.5A

2.8A

±0.18V

±0.36V

±0.48V

0V

0V

0V

Model

ALL

12V 12V 12V

12V

12V

12V

12V

12V

24V 24V 24V

24V

24V

24V

24V

24V

ALL

48V 48V 48V

48V

48V

48V

48V

48V

◎ Control parameter

Table 8-4

READ_FAN_SPEED_1

READ_FAN_SPEED_2

READ_VOUT

READ_IOUT

(Note. 1)

0 ~ 26500RPM

0 ~ 26500RPM

0 ~ 150A

0 ~ 30V

0 ~ 80A

0 ~ 60V

0 ~ 40A

±2000RPM

±2000RPM

±2.5A

±0.36V

±1.34A

±0.48V

±0.67A

ALL

ALL

12V

24V

24V

48V

48V

PMBus Data Range and Tolerance

◎ Display parameters

PMBus command

READ_VIN

Range

80 ~ 264V

0 ~ 15V

Tolerance

±10V

±0.18V

Model

ALL

12V

Table 8-3

11

Minimum readable currentModel

24V 2.7A±1A

48V 1.3A±1A

1.READ_IOUT will display ZERO amp when output current is less than values in the table below:

Note:

Adjustable voltage rangeModel

24V 18 ~ 30V

48V 36 ~ 60V

2.

When using PMBus to adjust output voltage, VOUT_COMMAND only can be used to display the

rated voltage of the unit and cannot be . It is VOUT_TRIM that swritten ets up the amount of

trimmed voltage. Taking DBU-3200-24 as an example, to get a 18V output, please set value of

VOUT_TRIM to -6V Adjustable voltage range for each model is shown as below:.

3.The value of CURVE_FV should be set less or equal to CURVE_CV,If CURVE_FV is greater

than CURVE_CV, it will be saved as CURVE_FV = CURVE_CV in EEPROM.

Notes on PMBus

1.Insert a at least 50msec delay between commands

2. Examples for Format Conversion :

(1) LINEAR16 format:VOUT_COMMAND、VOUT_TRIM、READ_VOUT、CURVE_CV、CURVE_FV.

N

Actual voltage = communication reading V × 2 . There are two definitions in the VOUT_MODE

command that refer to N requirements.

VOUT_MODE

Data Byte For

Linear Mode

0 0 01 1 12 2 23 3 34 4 45 5 56 6 67 7 7

Mode

=000b

VOUT_COMMAND Data Bvtes

For Linear Mode

MantissaExponent

VN

Data Byte High Data Byte Low

12

Linear Format Data Bytes

The Mode bits are set to 000b.

The Voltage, in volts, is calculated from the equation:

N

2

Voltage V=

Where:

Voltage is the parameter of interest in volts;

V is a 16 bit unsigned binary integer; and

N is a 5 bit two's complement binary integer.

N

EX: Vo_real (actual output voltage) = V x 2 , V is from READ_VOUT. N If VOUT_MODE = 0x17,

-9

meaning N is -9. READ_VOUT is 0x3000 12288, then Vo_real =12288 × 2 =24.0V.

(2)LINEAR11 format:IOUT_OC_FAULT_LIMIT、READ_VIN、READ_IIN、READ_IOUT、

READ_TEMPERATURE_1、READ_FAN_SPEED_1、READ_FAN_SPEED_2、CURVE_CC

、CURVE_TC、CURVE_CC_TIMEOUT 、CURVE_CV_TIMEOUT 、

CURVE_FV_TIMEOUT。

N

Actual value X = communication read value Y x 2 . Among them, the definition of the description

column for each aircraft type is referred to

N

EX: Io_real (actual output current) = Y× 2 , Y is from READ_IOUT. N If READ_IOUT is 0xF188h, meaning N is -2 and

-2

Y is 0x0188. Y is 0x0188 → 392, then Io_real = 392 × 2 = 98.0A.

76543 21076543210

N Y

Data Byte High Data Byte Low

MSB

MSB

Linear Data Format Data Bytes Y, N and the "real world" value is:

The relation between

X = Y 2 N

Where, as described above:

X is the "real world" value;

Y is an 11 bit, two's complement integer; and

N is a 5 bit, two's complement integer.

Devices that use the Linear format must accept and be able to process any value of N.

13

Communication Example - Practical Operation of Charger Mode

The following steps will describe how to set the DBU-3200-48 to charger mode and adjust its curve for a

2-stage charging process, with a constant current (CC) of 30A and a constant voltage (CV) of 56V.

1.Set the address of the charger to “0” and set it to charge mode.

2.Connect the SDA, SCL and GND pins of the master to the corresponding SDA (PIN7) and SCL

(PIN8) of CN500 and GND-AUX (PIN2) of CN1 on the charger.

◎Set speed: 100KHz

DBU-3200

SDA(CN500)

7

8

2

SDA

SCL(CN500)SCL

GND-AUX(CN1)GND

Controllor

3.Communication function can be accessed immediately after is connected to AC. Frist set DBU-3200

the charger to 2-stage charging mode.

4.Set the constant current (CC) point to 30A.

Command code: 0xB4(CURVE_CONFIG)

Data: 44(Lo) + 00(Hi). Please refer to definition of CURVE_CONFIG for detailed information.

Command code: 0xB0(CHURVE_ICHG)

Data: 30A → 0x78(Lo) + 0xF0(Hi)

NOTE: CURVE_ICHG is LINEAR11 format

Address(7 bit)

Address(7 bit)

0x40

0x40

Operation

Operation

Write

Write

Command Code

Command Code

0xB4

0xB0

Data

Data

0x44, 0x00

0x78, 0xF0

DBU-3200

A0(CN1)

A1(CN1)

A2(CN1)

D0(CN1)

-V-signal(CN1)

7

8

9

10

14

14

6.Before connecting to the batteries, it is recommended to review all of the settings and parameters

using the appropriate commands. In the event that they do not meet your requirements, you may

rewrite them as needed. EX: Read CHURVE_VBST to check whether CV level or Vboost was set to a

proper level.

7.Finally, short circuit Remote ON-OFF (PIN4) and +5-AUX (PIN3) pins of the CN1 connector on the

charger to remote on it to charge the batteries.

Read CURVE_VBST

The unit returns data below

-9

Data: 0x00(Lo) + 0x70(Hi) → 0x7000 → 28672 × 2 = 56V。

5. Set the constant voltage (CV) point to 56V.

Command code: 0xB1(CHURVE_VBST)

Data: 56V → 0x00(Lo) + 0x70(Hi)

NOTE: CHURVE_VBST is LINEAR16 forma

Address(7 bit)

Address(7 bit)

Address(7 bit)

0x40

0x40

0x40

Operation

Operation

Write

Read

Command Code

Command Code

0xB1

0xB1

Data

Data

0x00, 0x70

0x00, 0x70

Remote ON-OFF

CN1 +5V-AUX

DBU-3200

3

4

15

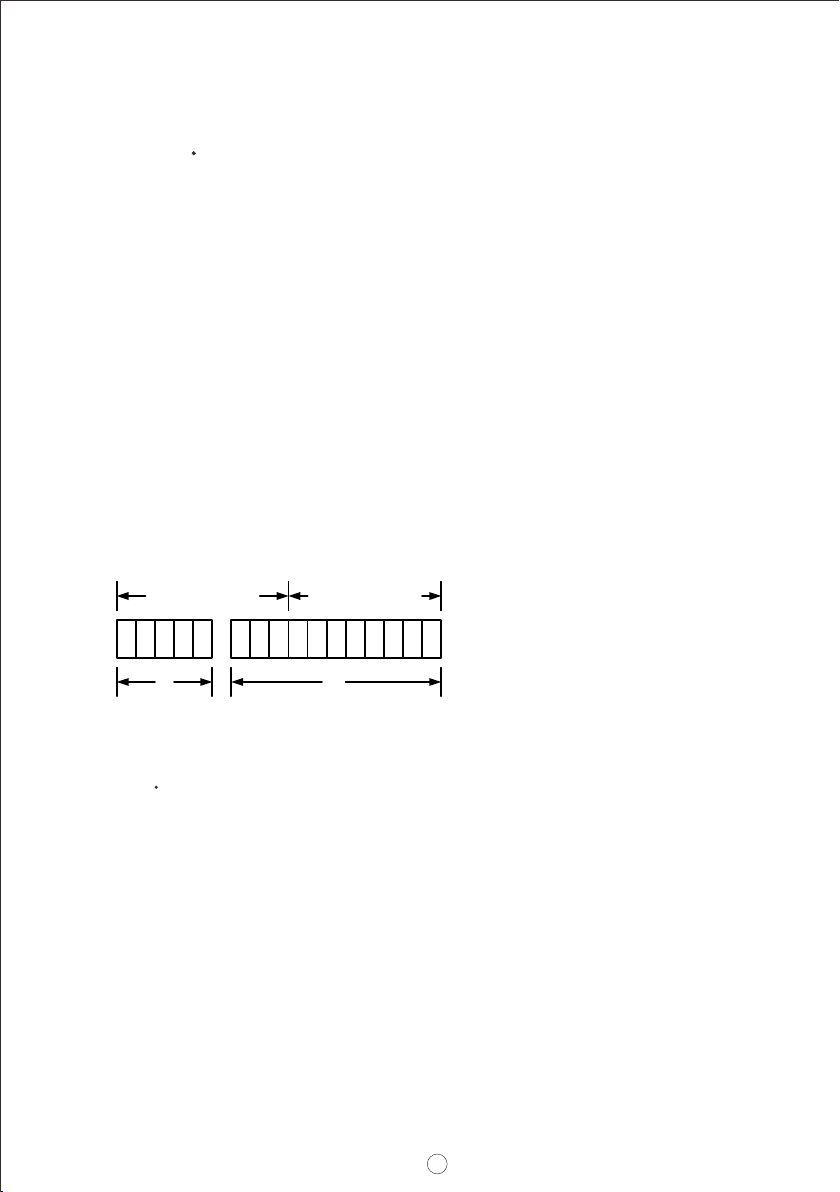

This protocol follows CAN ISO-11898 with Baud rate of 250Kbps.

◎Data Frame

◎Communication Timing

This protocol uses Extended CAN 29-bit identifier frame format or CAN 2.0B.

Min. request period (Controller to DBU-3200): 50mSec。

Max. response time (DBU-3200 to Controller): 12.5mSec。

Min. packet margin time (Controller to DBU-3200): 12.5mSec。

PSU CAN-RX

(form Controller)

PSU CAN-TX

Request period

(Controller to PSU/CHG)

Response time

(PSU/CHG to Controller)

RX data

TX data

RX data

Packet Margin time

(Controller to PSU/CHG)

8.3 CANBus Communication Interface

◎Physical layer specification

◎Data Field Format

Controller to DBU-3200

Write :

COMD. low byte

COMD. low byte

COMD. high byte

COMD. high byte

Data low byte Data high byte

Data filed bytes

Data filed bytes

Read:

0

0

1

1

2 3

16

8.3.1 CANBus Command list

Command

Code

0x0000

0x0020

0x0030

0x0050

0x0060

0x0061

0x0062

0x0070

0x0071

0x0080

0x0081

0x0082

0x0083

0x0040

# of data

Bytes

1

2

2

2

2

2

2

2

2

6

6

6

6

2

Description

ON/OFF control

ON: 01h

OFF: 00h

Output voltage set

(format: value, F=0.1)

Output current set

(format: value, F=0.1)

Input voltage read value

(format: value, F=1)

Output voltage read value

(format: value, F=0.1)

Output current read value

(format: value, F=0.1)

Internal ambient temperature

(format: value, F=0.1)

Fan speed 1 reading value

(Format: value, F=1, unit: RPM)

Fan speed 2 reading value

(Format: value, F=1, unit: RPM)

Manufacture's name

Manufacture's name

Manufacture model name

Manufacture model name

Abnormal status

Command

Name

OPERATION

VOUT_SET

IOUT_SET

READ_VIN

READ_VOUT

READ_IOUT

READ_

TEMPERATURE_1

READ_FAN_SPEED_1

READ_FAN_SPEED_2

MFR_ID_B0B5

MFR_ID_B6B11

MFR_MODEL_B0B5

MFR_MODEL_B6B11

FAULT_STATUS

Transaction

Type

R/W

R/W

R/W

R

R

R

R

R

R

R

R

R

R

R

0x0085

0x0086

3

6

Manufacture place

Manufacture date

MFR_LOCATION_B0B2

MFR_DATE_B0B5

R

R

0x0084 6Firmware version

MFR_REVISION_B0B5 R

COMD. low byte COMD. high byte Data low 1 ..... Data high 6

Data filed bytes

Response:

DBU- 0032 to Controller

NOTE: DBU-3200 will not send data back when writing parameters, such as VOUT_SET

0 1 2 7

17

0x00B5

0x00B6

0x00B7

0x00B8

2

2

2

2

CC charge timeout setting of charging curve

(format: value, F=1)

(format: value, F=1)

(format: value, F=1)

CV charge timeout setting of charging curve

FV charge timeout setting of charging curve

Charging status reporting

CURVE_CC_TIMEOUT

CURVE_CV_TIMEOUT

CURVE_FV_TIMEOUT

CHG_STATUS

R/W

R/W

R/W

R

Table 8-8

Command

Code

# of data

Bytes Description

Command

Name

Transaction

Type

0x00B0

0x00B1

0x00B2

0x00B3

0x00B4

2

2

2

2

2

Constant current setting of charge curve

(format: value, F=0.1)

Constant voltage setting of charge curve

(format: value, F=0.1)

Floating voltage setting of charge curve

(format: value, F=0.1)

Taper current setting of charge curve

(format: value, F=0.1)

Configuration setting of charge curve

CURVE_CC

CURVE_CV

CURVE_FV

CURVE_TC

CURVE_CONFIG

R/W

R/W

R/W

R/W

R/W

Valid when charging according to charge curve(D0=ON)

Bit 0 FAN_FAIL:Fan locked flag

0 =Working normally

1=Fan locked

Bit 1 OTP:Over temperature protection

0 =Internal temperature normal

1=Internal temperature abnormal

Bit 2 OVP:DC over voltage protection

0=DC voltage normal

1=DC over voltage protected

Bit 3 OLP:DC over current protection

0 =DC current normal

1=DC over current protected

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2

Low byte OVPOLPSHORTAC_FAILOP_OFFHI_TEMP

◎Definition of Command FAULT_STATUS(0x0040):

8.3.2 Definition and contents of CANBus Command list

Bit1

OTP

FAN_FAIL

Bit0

0x0088 6Manufacture serial number

MFR_SERIAL_B6B11 R

0x0087 6Manufacture serial number

MFR_SERIAL_B0B5 R

18

Other manuals for DBU-3200 Series

1

Table of contents

Other Meanwell Batteries Charger manuals

Meanwell

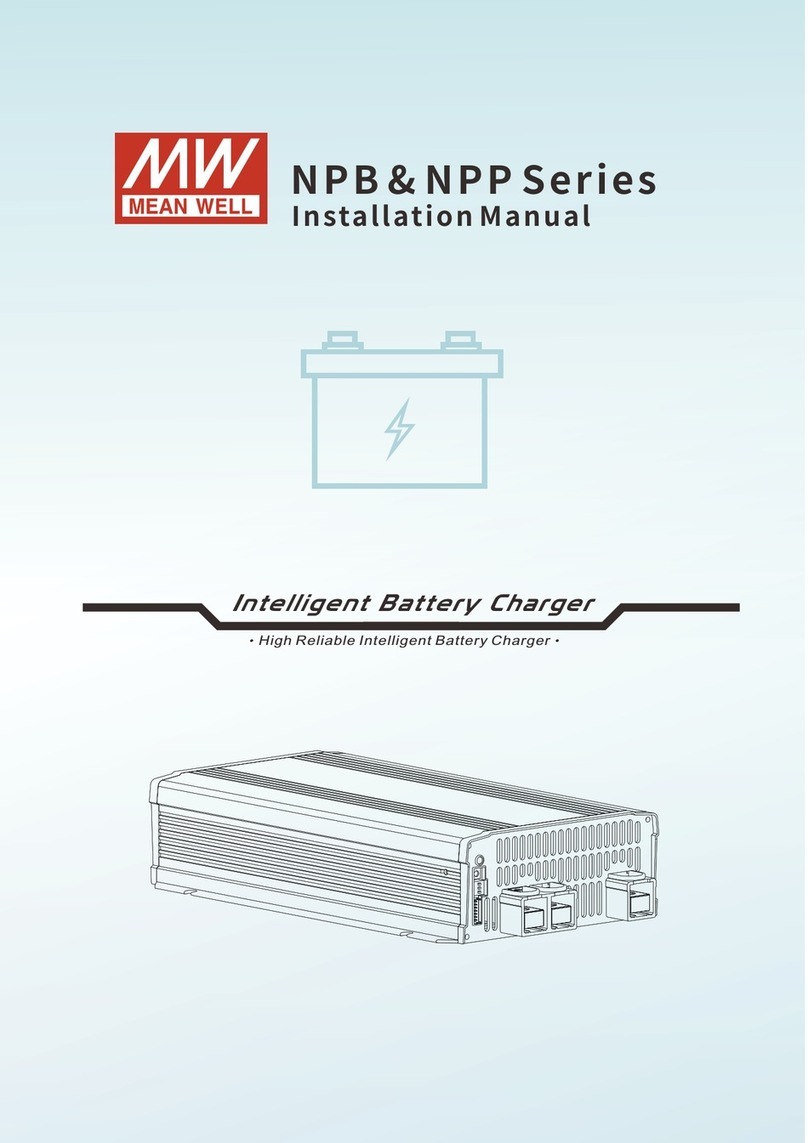

Meanwell NPB-450 NFC Series User manual

Meanwell

Meanwell RPB-1600 Series User manual

Meanwell

Meanwell PB-1000 User manual

Meanwell

Meanwell PB-230 User manual

Meanwell

Meanwell PB-1000-12 User manual

Meanwell

Meanwell NPB Series User manual

Meanwell

Meanwell ENC Series User manual

Meanwell

Meanwell GC160 User manual

Meanwell

Meanwell PA-120 User manual

Meanwell

Meanwell DBU-3200 Series User manual