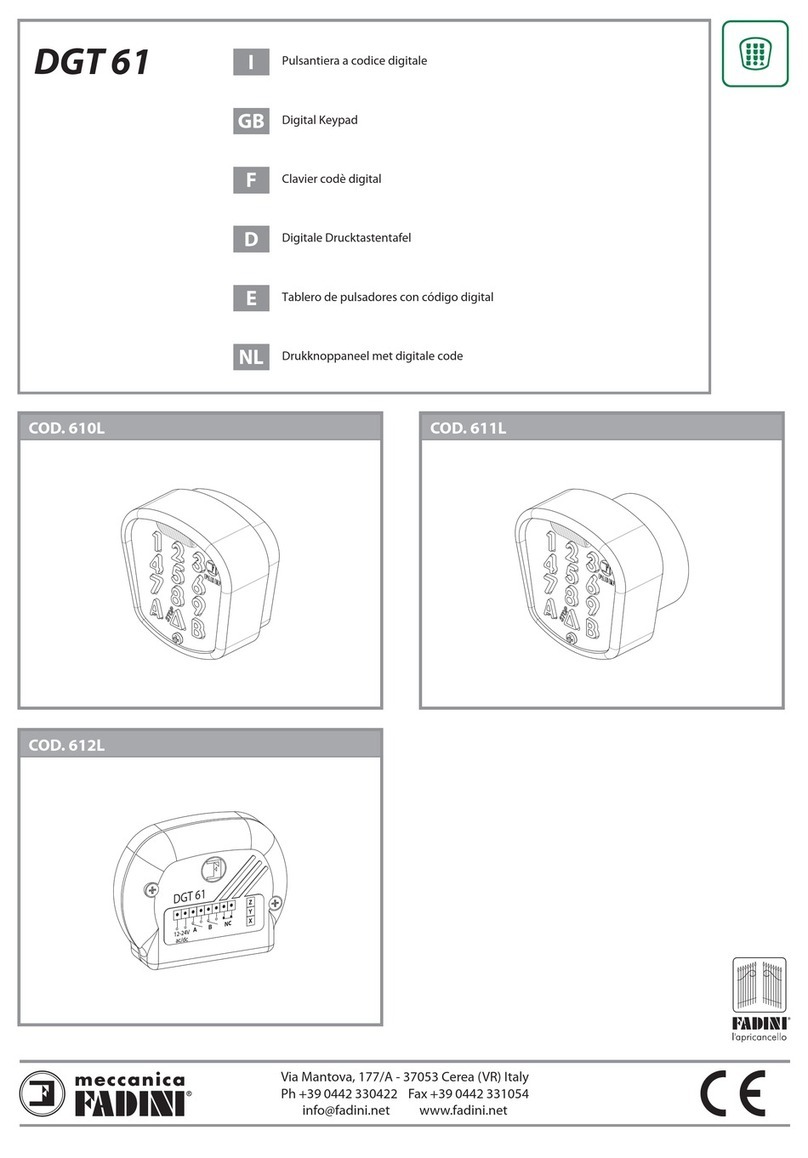

Meccanica Fadini DGT 61 User manual

Via Mantova, 177/A - 37053 Cerea (VR) Italy

Ph +39 0442 330422 Fax +39 0442 331054

[email protected] www.fadini.net

I

DGT 61

GB

F

D

Pulsantiera a codice digitale

Digital Keypad

Clavier codè digital

Digitale Drucktastentafel

E

NL

Tablero de pulsadores con código digital

Drukknoppaneel met digitale code

DGT 61

12-24V

ac/dc

NC

COD. 610L COD. 611L

COD. 612L

DIGITAL KEYPAD

DGT 61

GB

8

GENERAL WARNINGS FOR PEOPLE SAFETY

INTRODUCTION

This operator is designed for a specic scope of applications as

indicated in this manual, including safety, control and signaling

accessories as minimum required with FADINI equipment. □

Any applications not explicitly included in this manual may

cause operation problems or damages to properties and

people. □Meccanica Fadini snc is not liable for damages

caused by the incorrect use of the equipment, or for

applications not included in this manual or for malfunctioning

resulting from the use of materials or accessories not

recommended by the manufacturer. □The manufacturer

reserves the right to make changes to its products without

prior notice. □All that is not explicitly indicated in this manual

is to be considered not allowed.

BEFORE INSTALLATION

Before commencing operator installation assess the suitability

of the access, its general condition and the structure. □Make

sure that there is no risk of impact, crushing, shearing,

conveying, cutting, entangling and lifting situations, which

may prejudice people safety. □Do not install near any source of

heat and avoid contacts with ammable substances. □Keep all

the accessories able to turn on the operator (transmitters,

proximity readers, key-switches, etc) out of the reach of the

children. □Transit through the access only with stationary

operator. □Do not allow children and/or people to stand in the

proximity of a working operator. □To ensure safety in the

whole movement area of a gate it is advisable to install

photocells, sensitive edges, magnetic loops and detectors. □

Use yellow-black strips or proper signals to identify dangerous

spots. □Before cleaning and maintenance operations,

disconnect the appliance from the mains by switching o the

master switch. □If removing the actuator, do not cut the

electric wires, but disconnect them from the terminal box by

loosening the screws inside the junction box.

INSTALLATION

All installation operations must be performed by a qualied

technician, in observance of the Machinery Directive

2006/42/CE and safety regulations EN 12453 - EN 12445. □

Verify the presence of a thermal-magnetic circuit breaker

0,03 A - 230 V - 50 Hz upstream the installation. □Use

appropriate objects to test the correct functionality of the

safety accessories, such as photocells, sensitive edges, etc. □

Carry out a risk analysis by means of appropriate instruments

measuring the crushing and impact force of the main opening

and closing edge in compliance with EN 12445. □Identify the

appropriate solution necessary to eliminate and reduce such

risks. □In case where the gate to automate is equipped with a

pedestrian entrance, it is appropriate to prepare the system in

such a way to prohibit the operation of the engine when the

pedestrian entrance is used. □Apply safety nameplates with CE

marking on the gate warning about the presence of an

automated installation. □The installer must inform and instruct

the end user about the proper use of the system by releasing

him a technical dossier, including: layout and components of

the installation, risk analysis, verication of safety accessories,

verication of impact forces and reporting of residual risks.

INFORMATION FOR END-USERS

The end-user is required to read carefully and to receive

information concerning only the operation of the installation

so that he becomes himself responsible for the correct use of it.

□The end-user shall establish a written maintenance contract

with the installer/maintenance technician (on -call). □Any

maintenance operation must be done by qualied technicians.

□Keep these instructions carefully.

WARNINGS FOR THE CORRECT OPERATION OF THE

INSTALLATION

For optimum performance of system over time according to

safety regulations, it is necessary to perform proper

maintenance and monitoring of the entire installation: the

automation, the electronic equipment and the cables

connected to these.

□The entire installation must be carried out by qualied

technical personnel, lling in the Maintenance Manual

indicated in the Safety Regulation Book (to be requested or

downloaded from the site

www.fadini.net/supporto/downloads).

□Operator: maintenance inspection at least every 6 months,

while for the electronic equipment and safety systems an

inspection at least once every month is required. □The

manufacturer, Meccanica Fadini snc, is not responsible for

non-observance of good installation practice and incorrect

maintenance of the installation.

DISPOSAL OF MATERIALS

Dispose properly of the packaging materials such as

cardboard, nylon, polystyrene etc. through specializing

companies (after verication of the regulations in force at the

place of installation in the eld of waste disposal). Disposal of

electrical and electronic materials: to remove and dispose

through specializing companies, as per Directive 2012/19/UE.

Disposal of substances hazardous for the environment is

prohibited.

UE DECLARATION OF CONFORMITY (DoC)

Manufacturer: Meccanica Fadini snc

Address: Via Mantova, 177/A - 37053 Cerea - VR - Italy

declare that the DoC is issued under our sole responsibility and

belongs to the following product:

Digital Keypad DGT 61

is in conformity with the relevant Union harmonisation legislation:

- Electromagnetic Compatibility Directive 2014/30/UE

- Low Voltage Directive 2014/35/UE

Cerea, 19/04/2017 Meccanica Fadini s.n.c.

Responsible Manager

GB

NOTE: screws and expanding bolts not supplied by us.

9

DGT 61

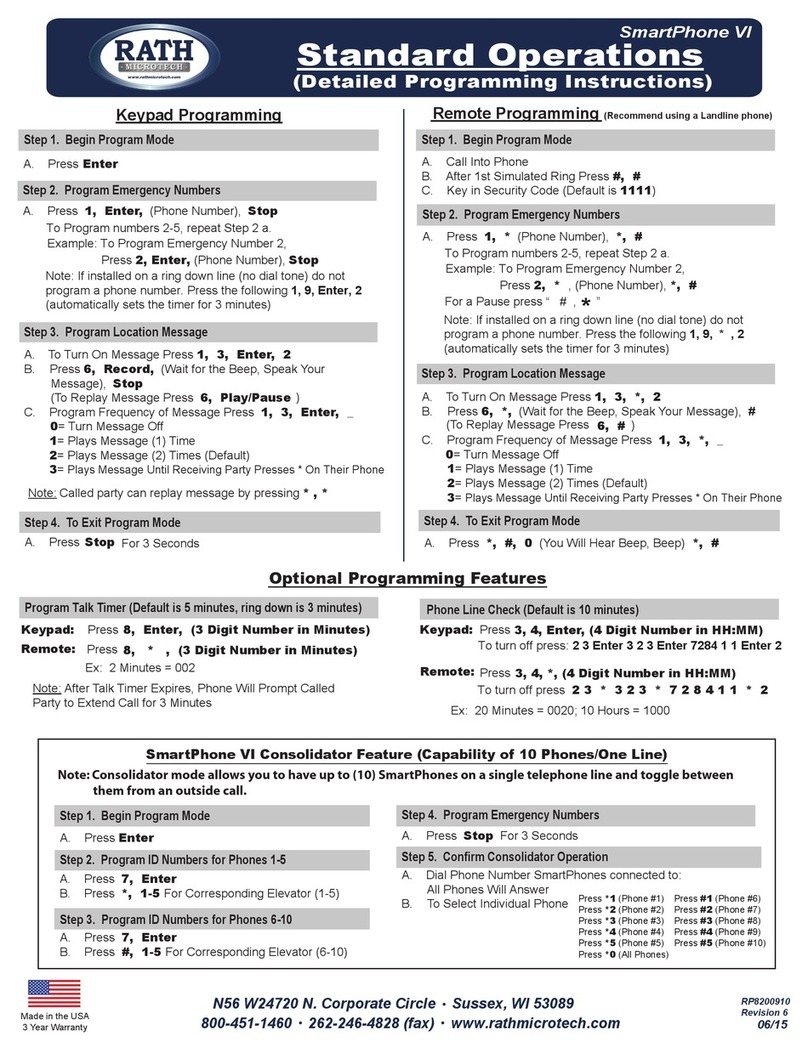

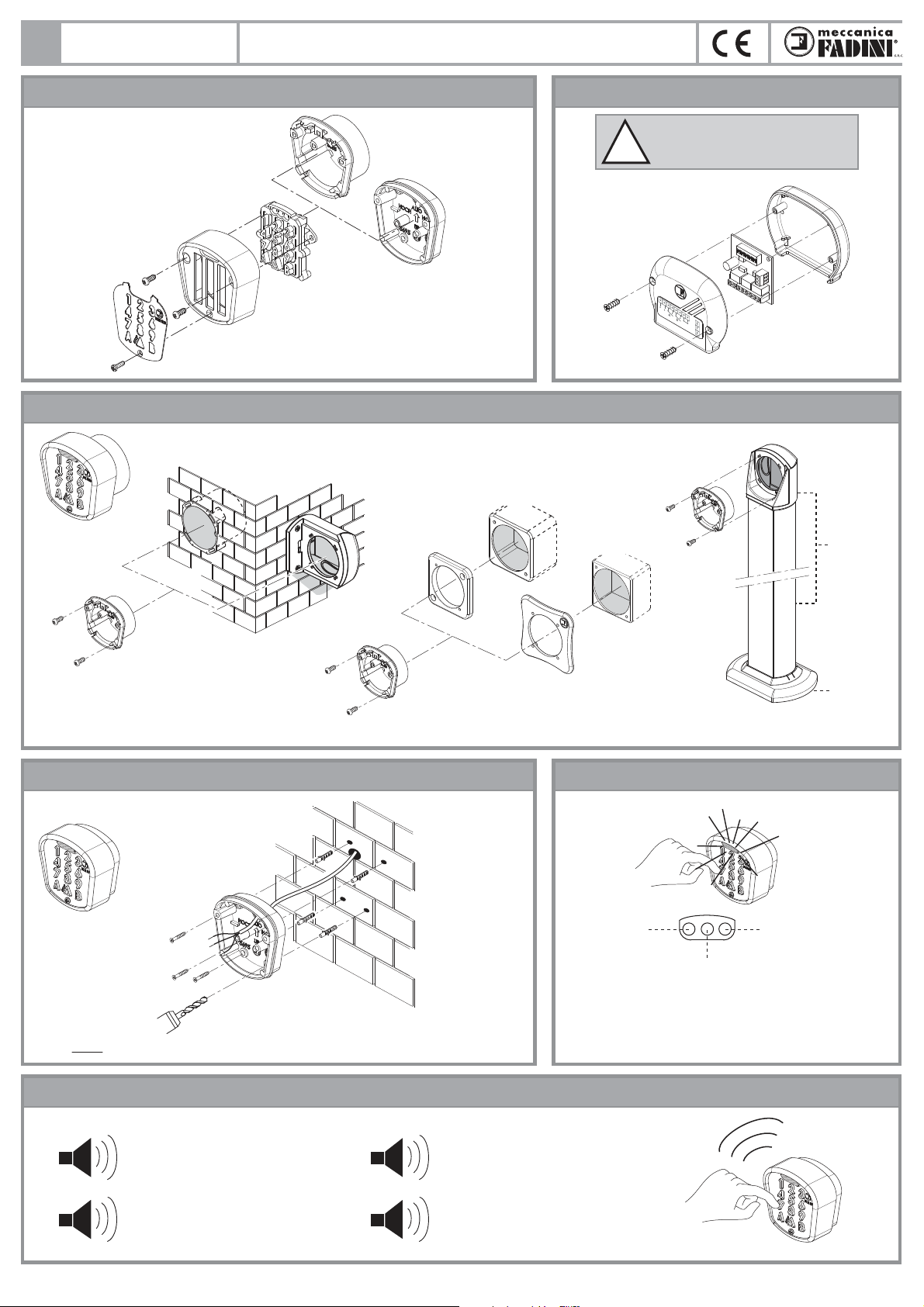

BRINGING THE KEYPAD APART BRINGING THE MAIN PCB APART

Treated aluminium

front unit

GREEN LED:

access code OK

BLUE LED:

• Fixed light: - unit on voltage

- night illumination of the keypad

• Flashing light: professionaly advanced timed

functions in progress

RED LED: wrong

access code

or STOP button

activated

Stainless steel

front cover

Treated aluminium

back casing

surface mount

Plastic back casing

recess mount

Keypad

DGT 61

12-24V

ac/dc

NC

code 612L

LED LIGHTSSURFACE APPLICATION OF THE KEYPAD TO A WALL

SOUND DEVICE

ACCESSORIES TO FIT THE KEYPAD, RECESS APPLICATION

code 552L

code 560L

code 553L

Sech 15 code 557L

code 554L

Prit 19

code 611L

code 558L

code 610L

1

Long Beep: a long beep conrms the

correct access code sequence

n°1 short beep: is emitted whenever

a key button is pressed

n°3 short beeps: the access code

sequence is wrong

n°5 short beeps: memory clearing

carried out correctly

3

5

Pic. 2

Pic. 3

Pic. 1

Pic. 5

Pic. 6

Pic. 4

ATTENTION: This unit is

recommended to be installed in a

safe and sheltered place.

!

DIGITAL KEYPAD

GB

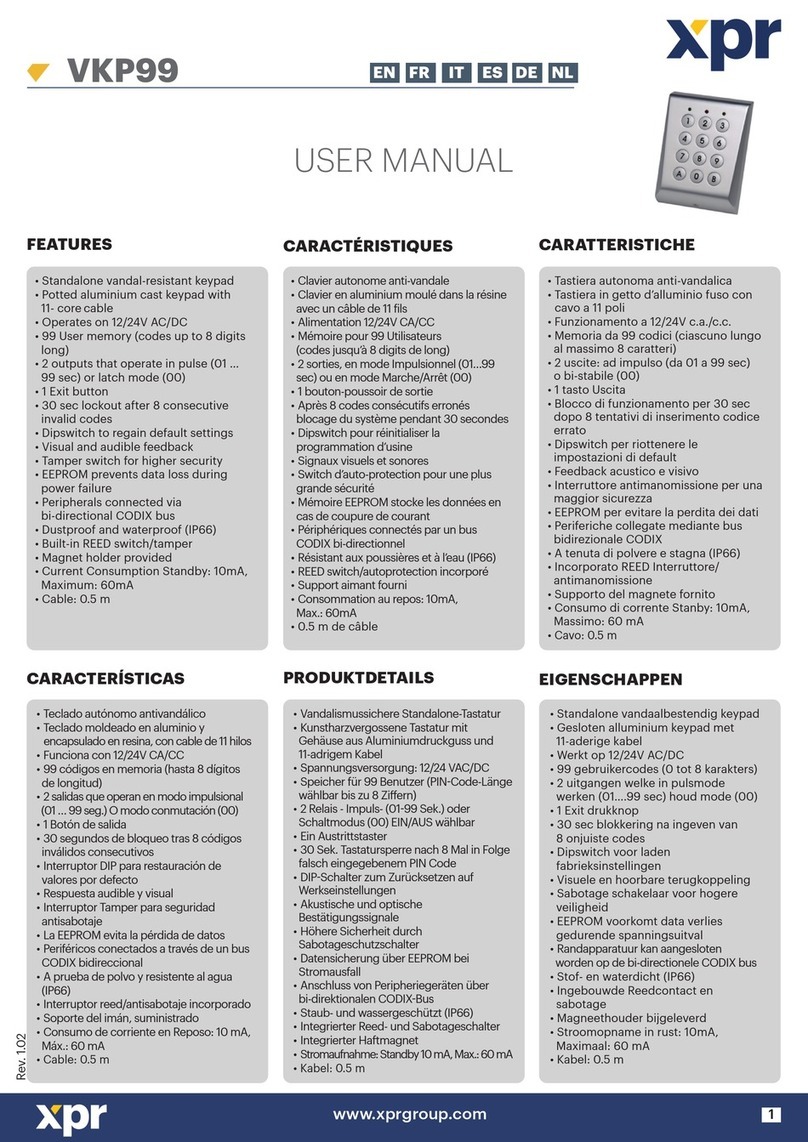

DGT 61 is a custom-encoded control accessory designed to open and close any automatic access system. It can be also used to control other external applications.

DGT 61 consists of a Keypad (in an anti-corrosion treated aluminium casing, in two options either to be partially recessed or surface mounted) cable

connected (x 4 wires) to the Main PCB; this one is to be installed near the Elpro electronic control box for the electrical connections. The keypad incorporates

the button keys, illuminated in blue from the back: nine digits, two outputs A and B and one output for the emergency stop button. The main PCB is tted with a

terminal block where power supply is to be connected (in parallel also to the keypads), with the N.O. contacts of the A and B output relays and with one pure

N.C. terminal output of a third relay, providing connections for an emergency stop. A second block of terminals X and Y (and a third one Z for long distance or

disturbed signals) receive the encoded signal from the keypads. Programming is simple and immediate by Dip-switches on the main PCB. Each channel can

take up to 4 dierent numerical codes; any one code, through the same channel either A or B, operates the same function. Other professionally advanced

functions can be achieved by the two relays (bistable outputs, timed bistable outputs, output delay, etc.), and can be enabled by the Dip-switches on the main

PCB. Other external control applications are also made possible (eg. illumination, alarm systems and watering) besides automatic door/gate systems, etc.

In these cases, it is recommended that a relay be always tted between the PCB and the other possible applications.

10

GENERAL DESCRIPTION

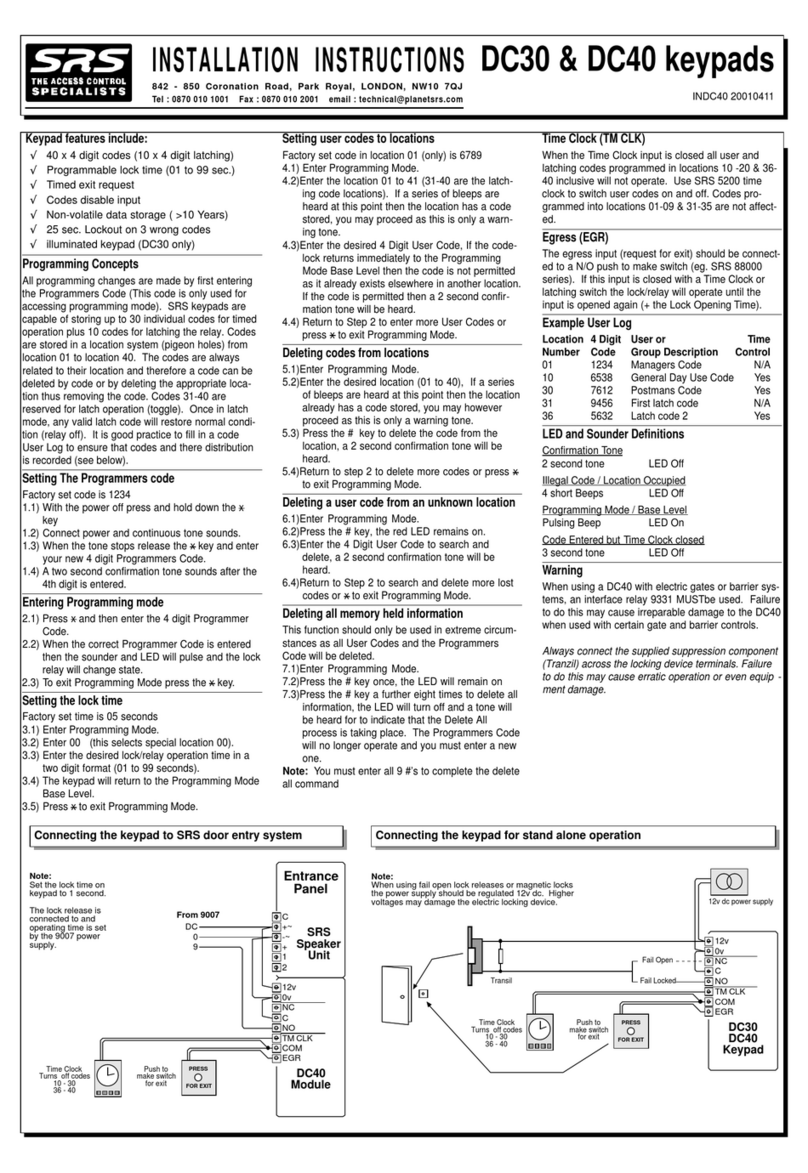

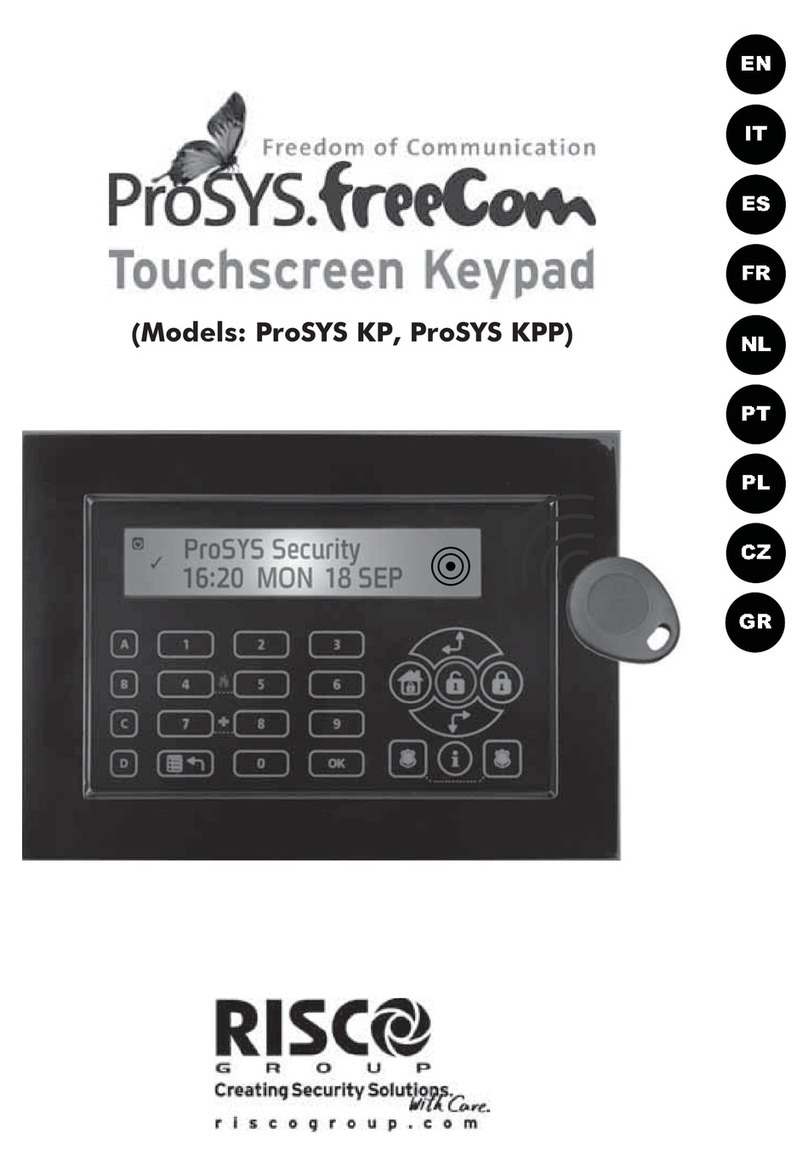

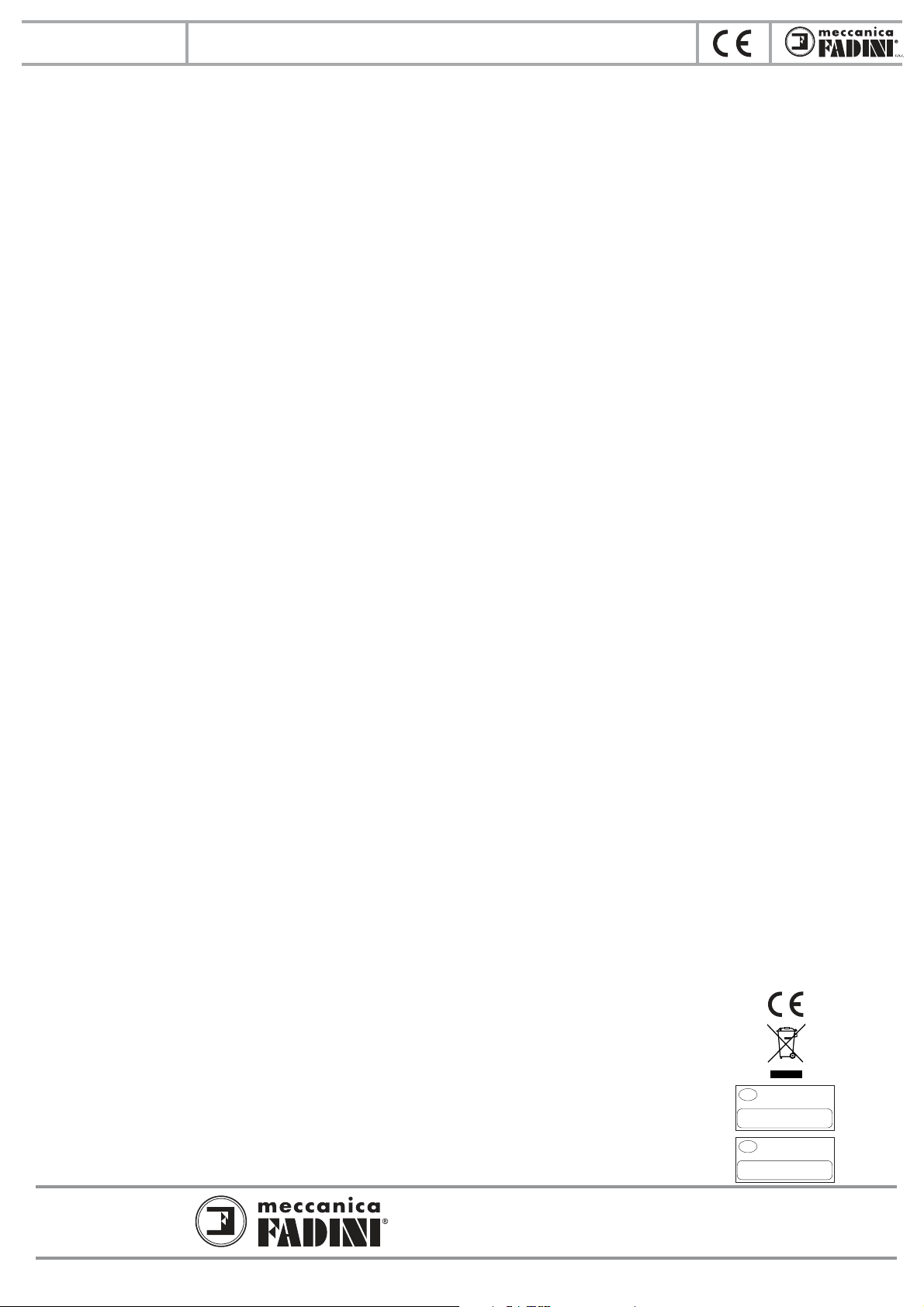

DIAGRAM OF A POSSIBLE INSTALLATION WITH TWO KEYPADS AND ONE PCB

Pic. 7

Pic. 8

Red led 1:

It ashes during

programming phase

Main PCB

1 or more

keypads DGT 61

(*) the connection to the

Z terminal is required in

case of weak or

disturbed signal

12-24V

ac/dc

12-24V

ac/dc

24V

ac/dc

12-24V

ac/dc

12-24V ac/dc STOP

max 0,5mm² up to 100m

Red led 2:

It ashes slowly when X Y are

properly connected to the keypad

Jumper for 12Vdc power supply:

when jumper is tted, 12Vdc

power supply is possible

X Y Z

ABS

CNO NOC NC

C

ON

OFF 1 2 3 4 5 6 7 8 9 10 (*)

1**

ON

ON

3**

ON

4**

ON

2**

ON

ON

ON

ON

1**

2**

3**

4**

relay NO relay NO relay NC

= Pure contact for STOP function only: direct to

the relay in case of an emergency

**once encoding/programming phases are completed, all Dip-switches are to be set to OFF

Automated

access B or

other applications

Automated

access A or

other applications

1st CODE

to relay A

2nd CODE

to relay A

3rd CODE

to relay A

4th CODE

to relay A

Keypad DGT 61 Controll box series

Elpro - access A

Controll box

Elpro 6 - access B

Keypad DGT 61

1st CODE

to relay B

2nd CODE

to relay B

3rd CODE

to relay B

4th CODE

to relay B

X Y Z

1 2 3 4 5 6 7 8 9 10

A B

C NO NOC NCC

X Y Z

3 4 6

X Y Z

3 4

3

33

X Y Z

S

ON

OFF

(*) (*)

(*)

DGT 61

12-24V

ac/dc

NC

open

open

stop

common

open

stop

24Vac/dc

common

open/stop/close

main PCB

relay NO relay NO relay NC

(*) The connection

to Z terminal is

required in case of

weak or disturbed

signal

max 0,5mm²

up to 100m

0,5mm² up to 100m

DGT 61 DIGITAL KEYPAD

GB

STORING ONE OR MORE ACCESS CODES ONTO THE RELAY OUTPUT A

11

!PLEASE NOTE: this operation erases completely all the access codes and any additional functions stored with the relay involved in this process.

DGT 61

1) Carry out the electrical connections to the MAIN PCB (Pic.8).

2) Set only one of the switches DIP 1 or DIP 2 or DIP 3 or DIP 4 to ON (It is

through the rst four DIp-switches that dierent ACCESS CODES can be

stored). The red led 1 on the main PCB ashes.

3) Press the ACCESS CODE (from 1 to 6 digits) - press A.

The green led goes on followed by a long conrming beep.

4) Set all DIP-switches to OFF. The red led 1 on the PCB goes o.

NOTE: The relay A can take up to 4 dierent access codes max. Each code is

to be stored individually by setting any one of the rst 4 DIP-switches to ON.

OFF

1) 3) 4)

1

1

ON 2)

Diagram

relay A

ACCESS

CODE

main PCB

ALL DIP-SW.

TO OFF

main PCB

STORING ONE OR MORE ACCESS CODES ONTO THE RELAY OUTPUT B

1) Carry out the electrical connections to the MAIN PCB (Pic.8).

2) Set only one of the switches DIP 1 or DIP 2 or DIP 3 or DIP 4 to ON (It is

through the rst four DIp-switches that dierent ACCESS CODES can be

stored). The red led 1 on the main PCB ashes.

3) Press the ACCESS CODE (from 1 to 6 digits) - press B.

The green led goes on followed by a long conrming beep.

4) Set all DIP-switches to OFF. The red led 1 on the PCB goes o.

NOTE: The relay B can take up to 4 dierent access codes max. Each code is

to be stored individually by setting any one of the rst 4 DIP-switches to ON.

HOW TO OPERATE WITH DGT 61 KEYPAD

Once satised that the main PCB is properly connected to the Elpro control

box, and the selected ACCESS CODES stored with the required output, to operate

with the keypad just press the keys corresponding to the ACCESS CODE,

followed by the key corresponding to the required OUTPUT (Aor B).

The green led goes on followed a long conrming beeping.

If the access code sequence is

incorrect: the unit gives out 3

beeping souds and the red led

illuminates for 2 seconds. Dial

correctly or reprogram the unit. n°3 short beeps

3

Red led

for 2 seconds

Diagram

OFF

1) 3) 4)

1

1

ON 2)

relay B

ACCESS

CODE

main PCB

ALL DIP-SW.

TO OFF

main PCB

1)

or

ACCESS

CODE

A or B output

Diagram

2)

LONG

BEEPING

green led

for 1 second

ENABLING THE STOP BUTTON KEY

Carry out the electrical connections to the keypad, main PCB and the Elpro

control box (or to a control relay). Pic. 8.

The DGT 61 keypad incorporates also a pure NC contact to get the STOP function.

The contacts of the C - NC terminals on the main PCB are opened on

pulsing the STOP button in the keypad, and no code is required to be entered.

red led

for 2 seconds

main PCB

STOP

pure contact

press

STOP

Diagram

NCC

S

MEMORY CLEARING

1) Set the Dip-sw. 10 to ON. The red led 1

ashes.

2) Press the key 9 9 9 (three times).

3) Press button A or Bto erase the encoding

and the functions from output A or B

4) Set all the DIP-switches to OFF.

5 short beeps conrm the operation

while the green led keeps ashing as

long as beeping can be heard.

5

OFF

4)

10

main PCB

ALL DIP-SW.

TO OFF

or

n°5 Beeps green led

Diagram

main PCB keypad A or B output

1) 2) 3)

ON

10

DIGITAL KEYPAD

GB

12

OFF

1) 3) 4)

5

5

ON 2)

Diagram

A or B output

time in minutes

(max 1439 = 24h)

main PCB

ALL DIP-SW.

TO OFF

main PCB

or

ADDITIONAL FUNCTIONS: can be achieved by the A and B outputs through one or more access codes

OUTPUT DELAY

Connect the main PCB to the control box (Pic. 8) or to the external control relay, then store an access code with required outputs.

Dierent functions can be achieved by one or both of the outputs, but dierent access codes to one relay carry out the same function.

NOTE WELL: functions are reset in case of a power failure, even if instantaneous.

Programming:

1) Set DIP-sw. 5 to ON. The red led 1 on the PCB ashes.

2) Press the number of minutes corresponding to the activation delay as

required (max.1439 minutes).

3) Press output Aor Bthrough which the required function is activated.

4) Set all the DIP-switches to OFF.

Conrmation of the operation: long beep and green led alight for 2 s

Using the function:

Press the access code followed by Aor Bas programmed. The green led goes on

for 1 s followed by an activation beep. The blue led starts ashing and indicates

that the function has been activated.

In order to RESET (the function is cancelled) press the following sequence:

Aor B- access code - A or B

The green led goes on for 1 s followed by a conrmation beep, while the

blue led stays illuminated.

Time

pulse

output

pulse

output

pulse

output

pulse

output

The pulse is delayed (for a number

of minutes) after pressing the access

code.

OFF

1) 3) 4)

6

6

ON 2)

Diagram

A or B output

time in minutes

(max 1439 = 24h)

main PCB

ALL DIP-SW.

TO OFF

main PCB

or

TIMED WITH 2 PULSES

Programming:

1) Set DIP-sw. 6 to ON. The red led 1 on the PCB ashes.

2) Press the number of minutes for the time required after the rst pulse

(max. 1439 minutes).

3) Press either Aor Boutput by which the function is to be activated.

4) Set all the DIP-switches to OFF.

Conrmation of the operation: long beep and green led alight for 2 s

Using the function:

Press the access code followed by Aor Bas programmed. The green led goes on

for 1 s followed by an activation beep. The blue led starts ashing and indicates

that the function has been activated.

In order to RESET (the function is cancelled) press the following sequence:

Aor B- access code - A or B

The green led goes on for 1 s followed by a conrmation beep, while the

blue led stays illuminated.

A pulse is given after the access code

has been pressed and another one is

given after a set time (minutes).

Time

TIMED DELAY

Programming:

1) Set DIP-sw. 8 to ON. The red led 1 ashes.

2) Press the number of minutes for the delay with time 1 (max 1439 minutes).

3) Press either Aor Boutput by which the required function is to be activated.

4) Press the numer of minutes for time 2 (max. 1439 minutes).

5) Press ether Aor Bas set in step 3).

6) Set all the DIP-switches to OFF.

Conrmation of the operation: long beep and green led alight for 2 s

Using the function:

Press the access code followed by Aor Bas programmed.

The green led goes on for 1 s followed by an activation beep.

The blue led starts ashing and indicates that the function has been activated.

In order to RESET (the function is cancelled) press the following sequence:

Aor B- access code - A or B

The green led goes on for 1 s followed by a conrmation beep, while the

blue led stays illuminated.

Each pulse by the access code

delays (for a number of minutes)

the energizing of the timed relay.

OFF

1) 3) 4)

7

7

ON 2)

Diagram

A or B output

press key 7 main PCB

ALL DIP-SW.

TO OFF

main PCB

or

BISTABLE

Programming:

1) Set DIP-sw. 7 to ON. The red led 1 on the PCB ashes.

2) Press only the button key No. 7.

3) Press either Aor Boutput by which the required function is to be actived.

4) Set all the DIP-switches to OFF

Conrmation of the operation: long beep and green led alight for 2 s

Using the function:

Press the access code followed by Aor Bas programmed.

The green led goes on for 1 s followed by an activation beeping.

Each pulse by the access code energizes or

de-energizes the output relay.

ALL DIP-SW.

TO OFF

Diagram

main PCB keypad

time 1 in

minutes

(max 1439)

time 2 in

minutes

(max 1439)

A or B output keypad

or or

1)

ON

8

2) 3)

OFF

8

4) 5)

6)

Time 1 Time 2

DGT 61 DIGITAL KEYPAD

13

GB

Pic. 9

A or B output

A or B outputA or B output

pulse

output

OFF

1) 3) 4)

9

9

ON 2)

Diagram

time in minutes

(max 1439 = 24h)

main PCB

ALL DIP-SW.

TO OFF

main PCB

or

ADDITIONAL FUNCTIONS: can be achieved by the A and B outputs through one or more access codes

TIMED BISTABLE

Programming:

1) Set DIP-sw. 9 to ON. The red led 1 on the PCB ashes.

2) Press the number of minutes corresponding to the activation time as

required (max. 1439 minutes).

3) Press output A or B as required for the function to be activated.

4) Set all the DIP-switches to OFF.

Conrmation of the operation: long beep and green led alight for 2 s

Using the function:

Press the access code followed by Aor Bas programmed.

The green led goes on for 1 s followed by an activation beep.

The blue led starts ashing and indicates that the function has been activated.

In order to RESET (the function is cancelled) press the following sequence:

Aor B- access code - A or B

The green led goes on for 1 s followed by a conrmation beep, while the

blue led stays illuminated.

Time

The relay is energized and remain

energized for the time as set (in minutes).

REMOVING THE ADDITIONAL FUNCTIONS

1) Set DIP-sw. 5 to ON. The red led 1 on the PCB ashes.

2) Press A (or B) - access code - press A (or B).

3) Set all the DIP-switches to OFF.

Conrmation of the operation: long beep and green led alight for 2 s

Steps to cancel the additional functions from the single relay and set the

DGT 61 unit back to normal functioning.

OVERALL DIMENSIONS

TECHNICAL DATA

DGT 61

LONG BEEP gree led

for 2 seconds

ALL DIP-SW.

TO OFF

Diagram

main PCB main PCBACCESS

CODE

or

1)

ON

5

2)

or

OFF

5

3)

DGT 61

12-24V

ac/dc ABNC

91

73

27

40

29 25

54

Ø56

Recess mount keypad

Keypad Surface mount

keypad

Main

PCB

Power supply 2x0,5 mm² 12-24 Vac/dc

Connections to the keypad 4 x 0,5 mm²

Keypad absorption 15 mA

Stand-by relay absorption 4 mA

Energized relay absorption 27 mA

Working temperature -20 °C + 80 °C

N.O. channels 2

N.C. channels 1

Communication distance max 100 m

Output contacts 1 A - 125 V - 60 VA

Keypad protection standards IP 54

PCB protection standards IP 53

DIGITAL KEYPAD

72 mm

74

DGT 61

2018/04

Via Mantova, 177/A - 37053 Cerea (VR) Italy

Ph +39 0442 330422 Fax +39 0442 331054

info@fadini.net www.fadini.net

IDirettiva 2012/19/UE

Smaltimento dei materiali

elettrici ed elettronici

VIETATO GETTARE NEI RIFIUTI

MATERIALI NOCIVI PER L'AMBIENTE

GB Directive 2012/19/UE

Disposal of electric and

electronic material

DO NOT DISPOSE OF AS NORMAL WASTE.

HARMFUL FOR THE ENVIRONMENT

Other manuals for DGT 61

1

This manual suits for next models

3

Table of contents

Other Meccanica Fadini Keypad manuals