This information is designed to help suitably qualified

personnel install and operate Mechan Safety Switch

equipment. Before using this product, read this guide thoroughly along with

any relevant European and/or National standards e.g. Machinery Directive

89/392/EEC and it’s amendments, Provision and Use of Work Equipment

Regulations.

Further information can be obtained from Mechan Controls PLC

***** KEEP THIS GUIDE FOR FUTURE REFERENCE *****

CAUTION

DESCRIPTION

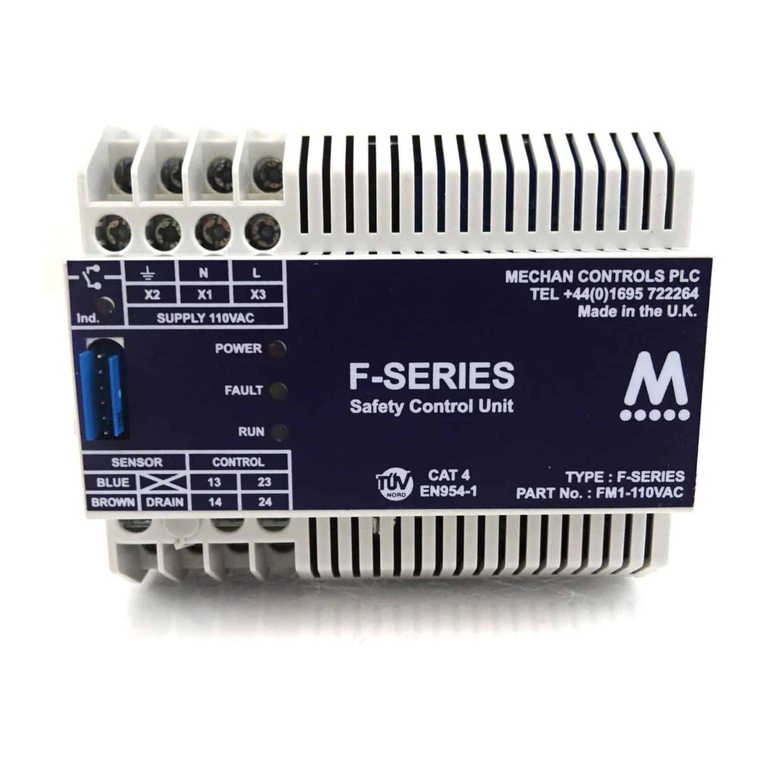

The ISIS safety system is a tamper resistant non-contact

safety switch system, suitable for use in most types of

machine guarding applications where guard locking is not

required. The system comprises of a control unit and 1 or

more safety switches and actuators. The ISIS non-contact

safety switches are easy to install, tolerant to misalignment

and suitable for use in harsh or wet environments.

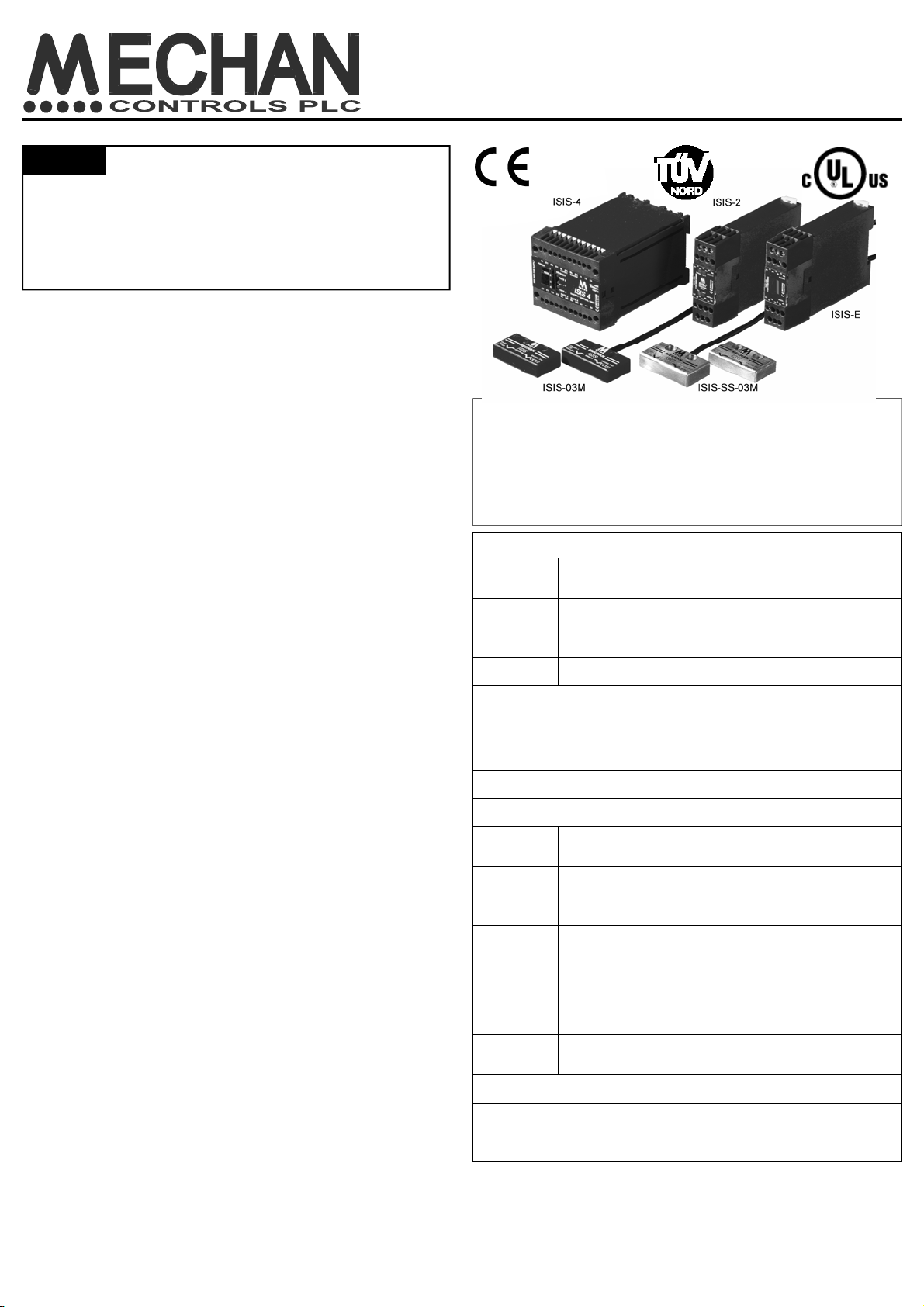

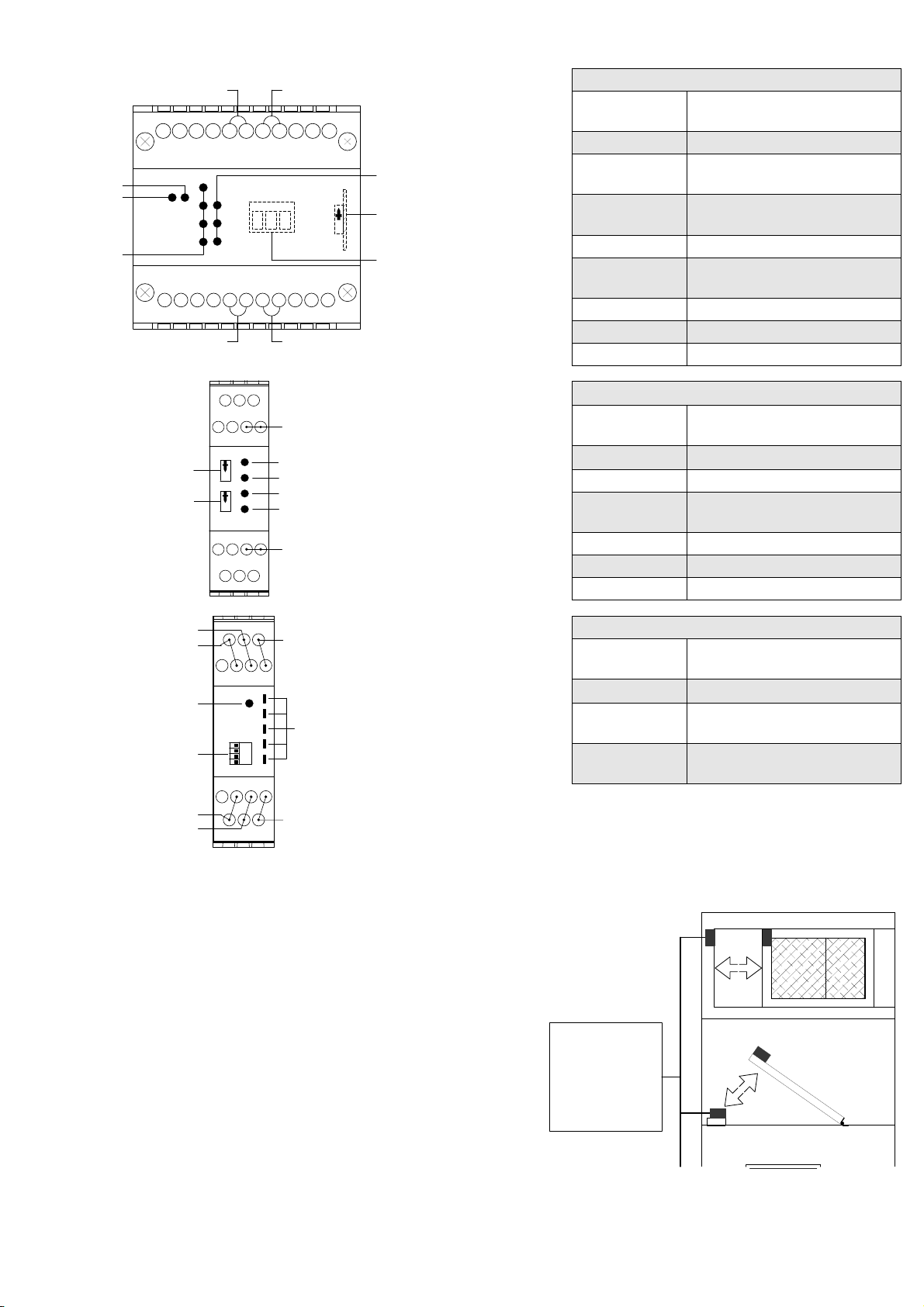

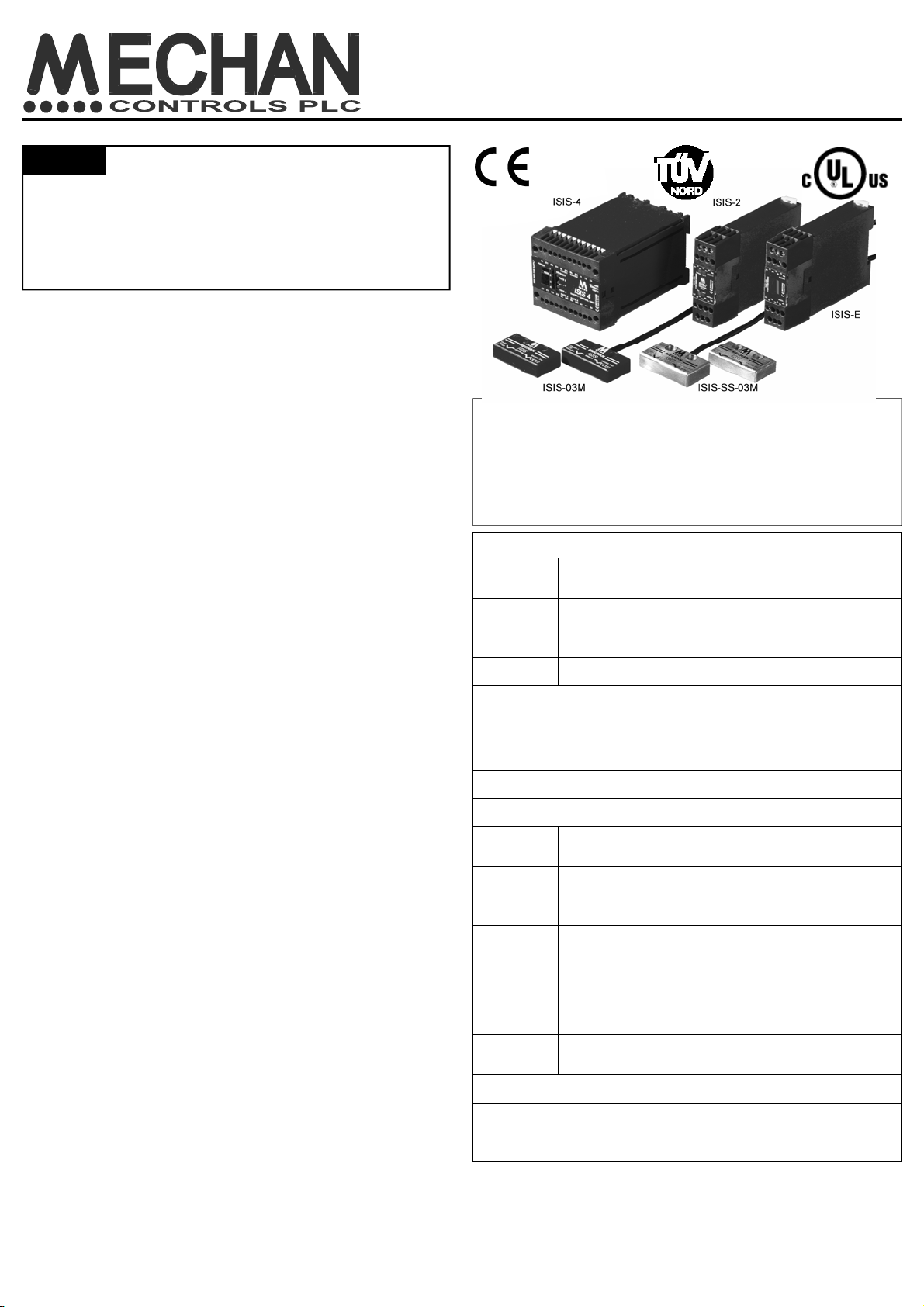

ISIS-4 - Control Unit

The ISIS-4 is a combined Safety Switch and E-Stop control

unit. Along with the ability to monitor up to four ISIS safety

switches it can also monitor the normally closed contacts of

emergency stop buttons or mechanical safety switches in

dual channel control circuits.

The ISIS-4 has 2 normally open safety contact outputs and 1

normally closed auxiliary output, an external re-set/proving

circuit and LED indication for ‘Power’, ‘Run’ and the status of

each activated gate switch.

ISIS-2 - Control Unit

The ISIS-2 control unit is a 24V ac/dc system that can

monitor up to 2 ISIS safety switches.

The ISIS-2 has 2 normally open safety contact outputs and 1

normally closed auxiliary output, an external re-set/proving

circuit and LED indication for ‘Power’, ‘Run’ and the status of

each activated gate switch.

ISIS-E - Extender Module

The ISIS-E Extender module is a 24V ac/dc unit that can be

added to either the ISIS-4 or ISIS-2 to monitor an additional

5 ISIS safety switches. Connection to the main control unit is

by a simple 2-wire bus connection. The status of each guard

switch is shown by the YELLOW LED’s. Additional ISIS-E

extender modules can be added to monitor larger systems.

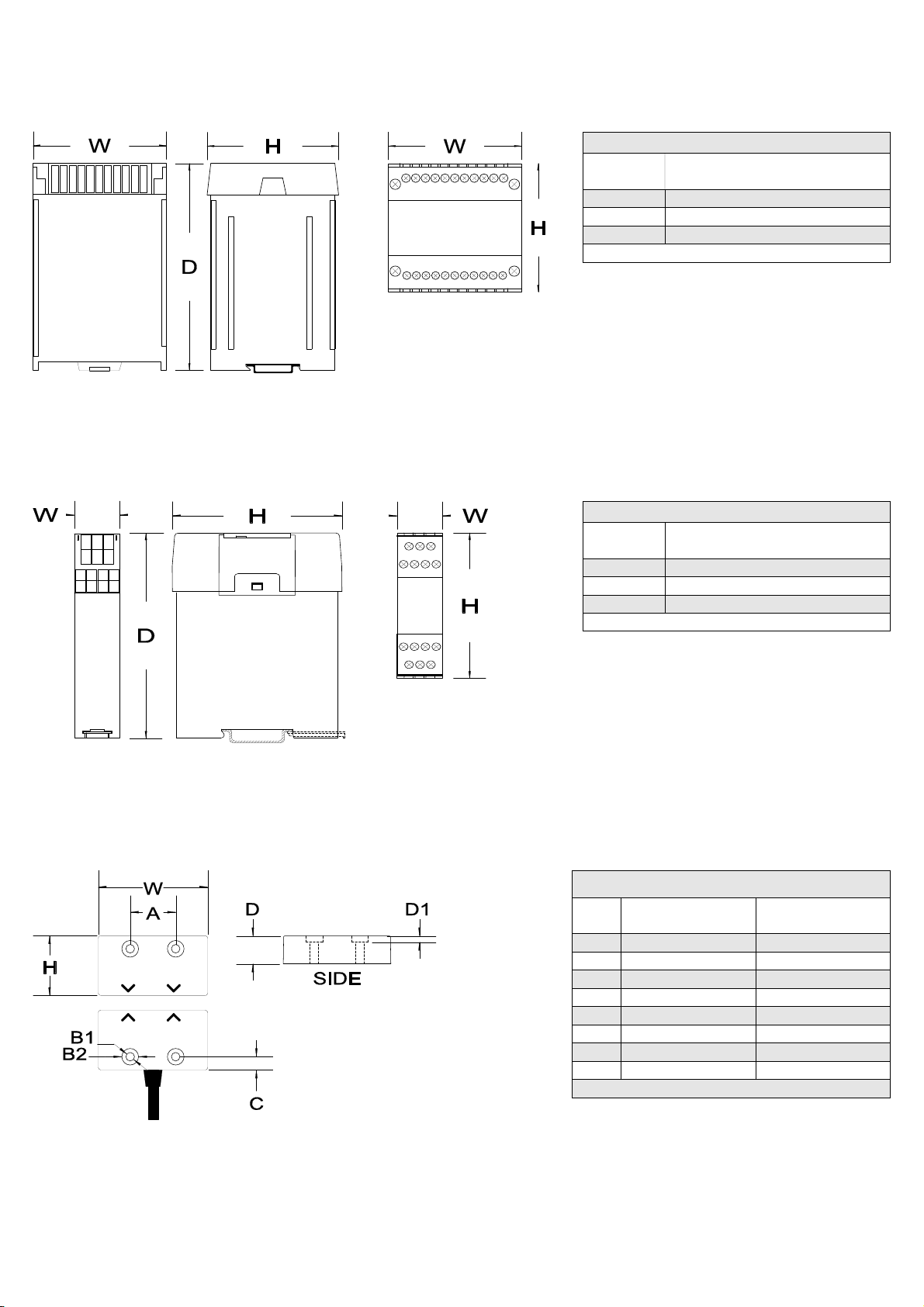

ISIS-03M / ISIS-SS-03M - Safety Switches

The ISIS safety switches are non-contact, tamper resistant

safety switches. Resin encapsulated into an ABS or

Stainless Steel case providing environmental protection to

IP67, the switches can withstand most conditions including:

water, dust and high pressure hose cleaning.

The 2-wire connection to each safety switch is

monitored by the control unit, detecting both open and

short circuit faults immediately and returning the control

unit to the off state even if the gate is not operated.

APPLICATIONS

Interlocked guards where door locking is not required.

Food and Beverage packing/filling systems; Diary,

Pharmaceutical, Paper Industry, Can Forming and Filling,

(Aluminum, Steel, Plastic), Semiconductor Manufacture/

Assembly. Concrete Block Manufacture.

ISIS SAFETY SYSTEM

Installation guide

APPROVALS

CE Complies with the relevant sections of the CE

marking directive.

UL Tested by the Underwriters Laboratories, USA,

to comply with the relevant USA and Canadian

requirements. UL 508 Industrial Control

TUV CAT 3 SIL 3 PLe

EUROPEAN DIRECTIVES

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/EC

EUROPEAN STANDARDS

EN ISO

13849-1 Safety of Machinery - Safety related parts of

control systems

EN ISO

62061 Safety of Machinery - Functional safety of safety

related electrical, and electronic and

programmable electronic control systems

EN 60204 Safety of Machinery - Electrical equipment of

machines.

EN 1088 Interlocking devices associated with guards.

EN

60947-5-3 Safety of Machinery - Specification for low

voltage switchgear and control gear.

CERTIFICATE OF CONFORMITY

A certificate of conformity can be supplied covering Mechan

non-contact safety switch equipment.

Call our technical help-line on +44 (0)1695 722264

EN 60947-

5-1 Low voltage switchgear and control gear.

UK Office

5 Caulside Drive, Antrim, BT41 2DU

United Kingdom

TEL: +44 (0) 28 9448 1800

www.pneutrol.com/industrialspares

European Office

Unit 6, Saint Anthony’s Business Park, Ballymount Road, D22 VW95

Ireland

TEL: +353 (0) 1 4373653

www.pneutrol.com/industrialspares

__________________________________________________________________________________________

Pneutrol International Limited