Model 5500WD Barrel Mounting and 3-Point Hitch Instructions

3-Point Hitch & Barrel Mounting

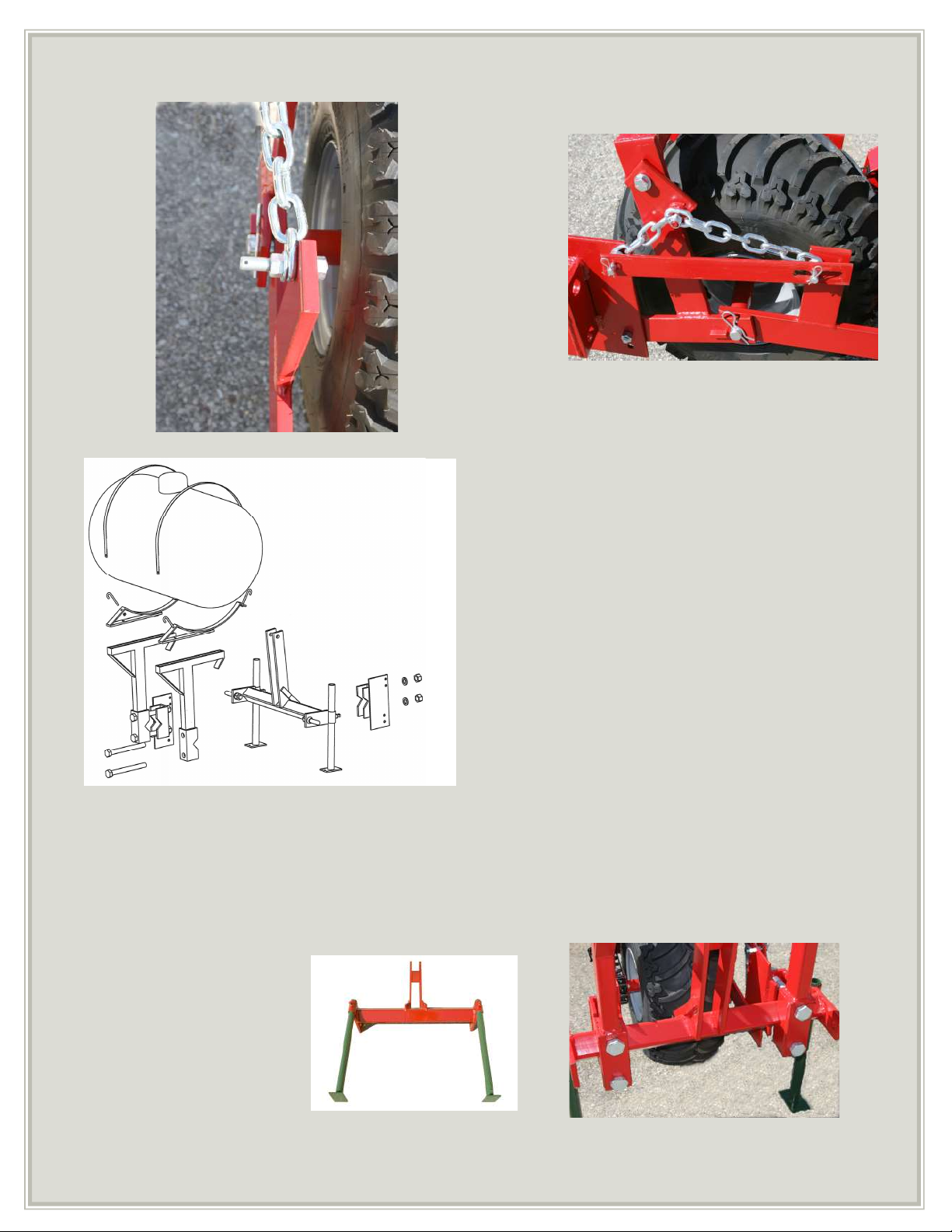

1. On the 3-Point hitch, connect the Category I hitch pins through the holes on the outside of the hitch.

Put the pins in through the outside and secure with the lock washer and hex nut included with the pin.

2. Slide the green pipe stands up through the pipes on the hitch, then tighten by turning the set screw.

Note: The following steps

will be easier with two

people

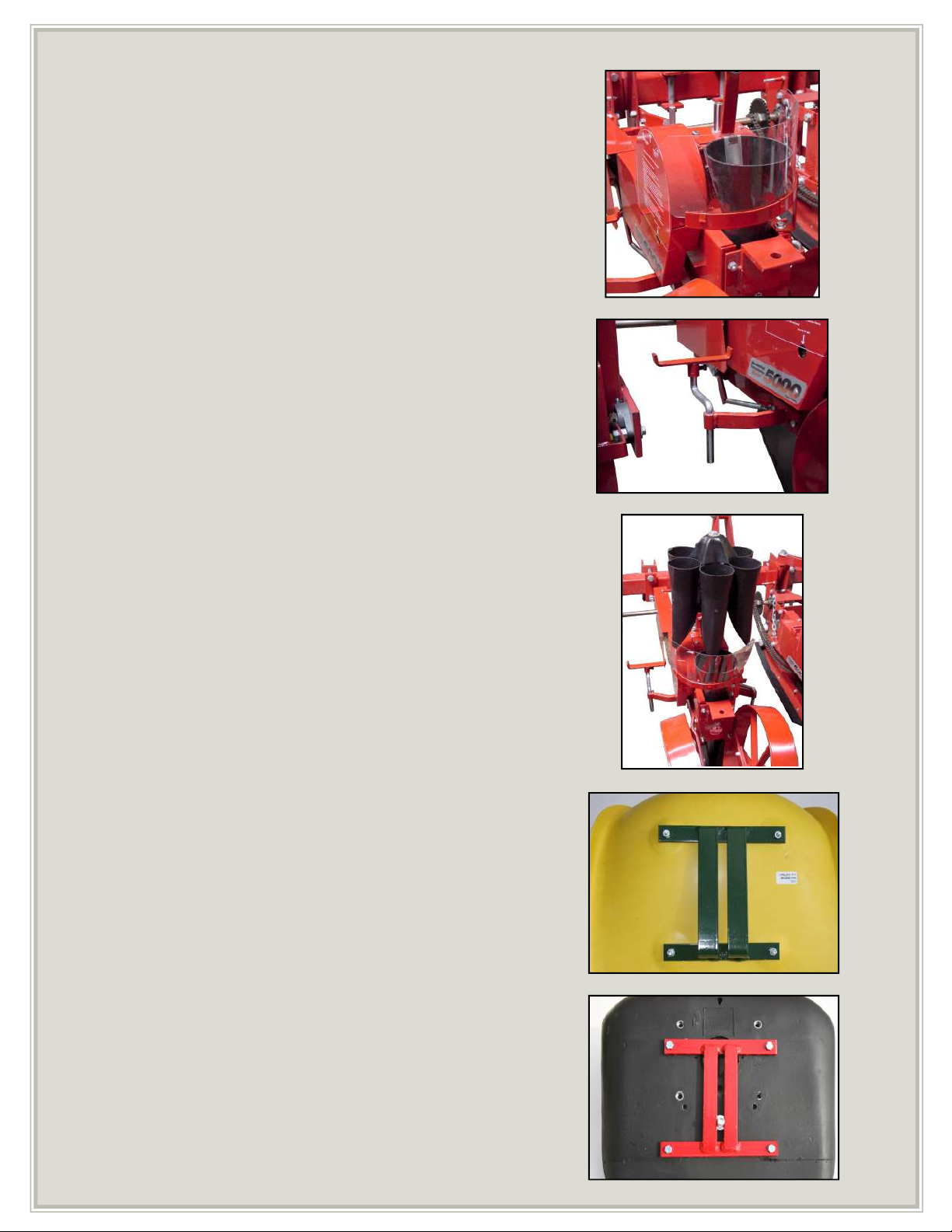

3. Center the 3-Point hitch toolbar with the clamps on your transplanter. Next, line up one of the barrel mounting

brackets with the direct drive clamps. Secure using two 1 x 8-1/2” bolts and hex nuts. Do the same with the

other barrel mounting bracket.

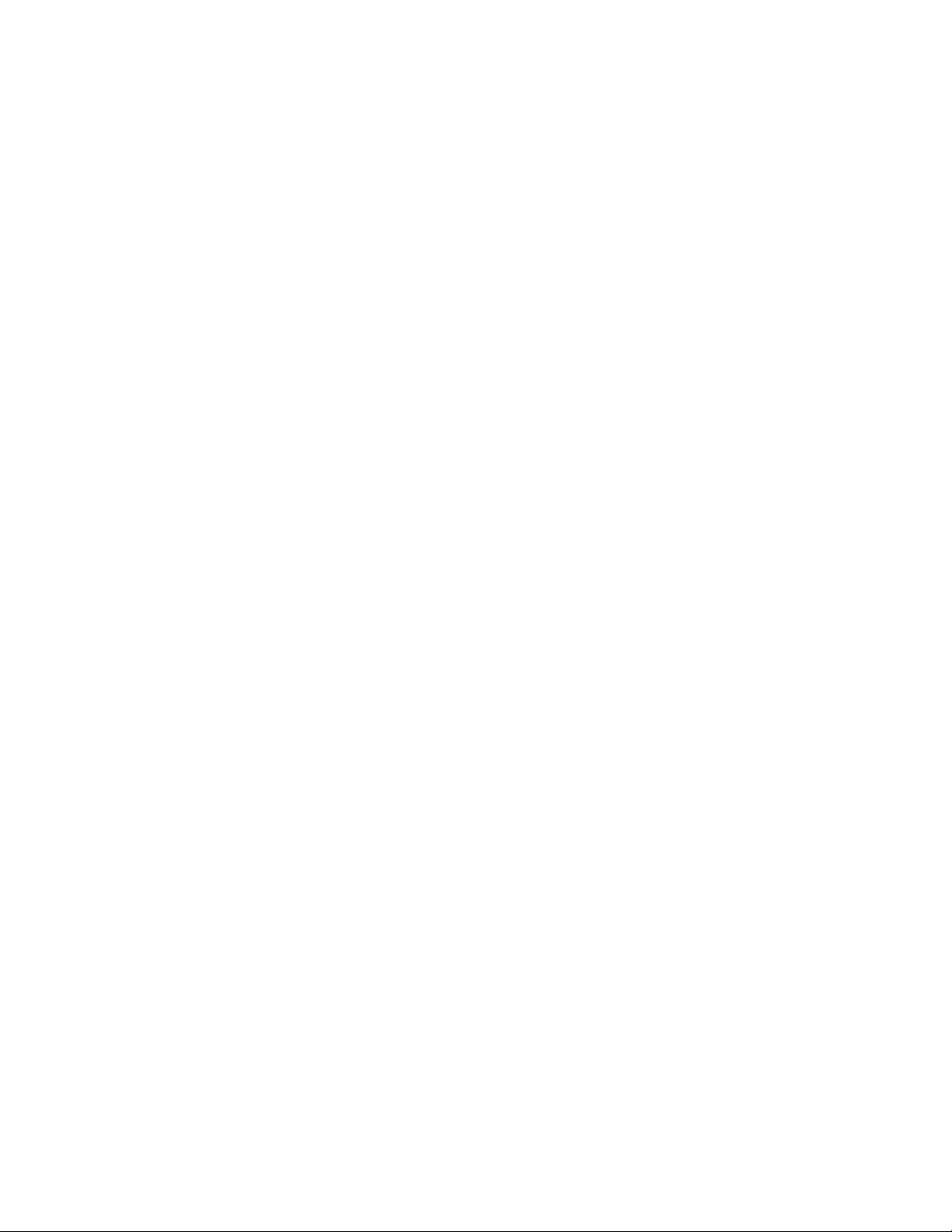

To mount this safety bar, you must remove the 7/16

x 1-1/4” bolt from on side of the direct drive wheel.

1. Locate the special 2-1/2” stud in your bag

of bolts and nuts.

2. Turn a 7/16” hex nut all the way onto the stud.

3. Put the 7/16” washer on the stud next to the nut.

4. Place the lift chain up against the washer.

5. Slide the stud through the hole on the Direct

Drive frame and secure with a 7/16” hex nut.

6. Assemble another stud the same way and fasten

it to the top hole of the front Direct Drive clamp.

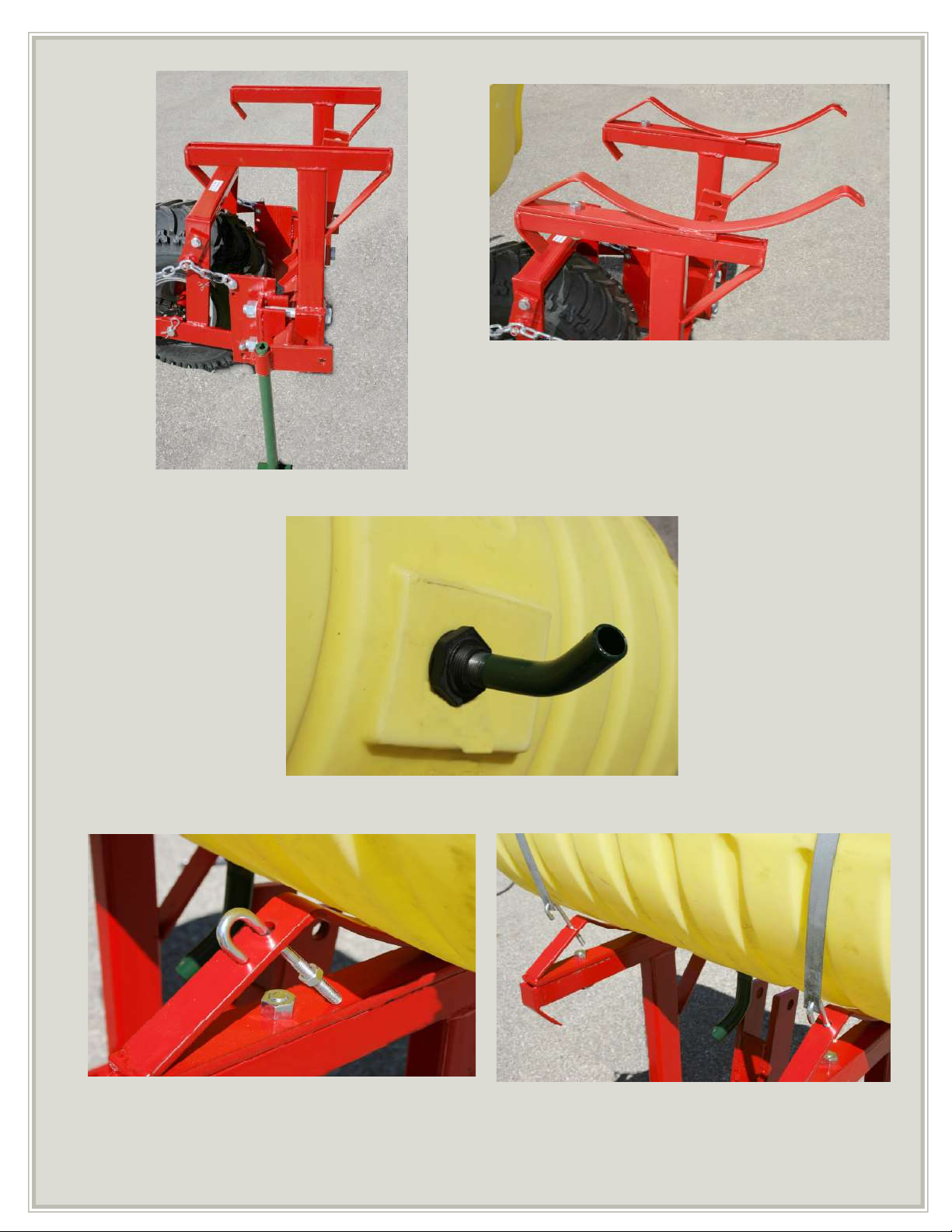

7. Attach the red seat safety bar to the stud on your

drive wheel. The end with the hole must go on the

clamp. The slotted end must go on the frame.

After the safety bar is attached, place small clip

pins through the small holes.

5