Turn on the power to the Vortex by means of the rocker switch

at the rear of the base unit, the power LED (2) will illuminate.

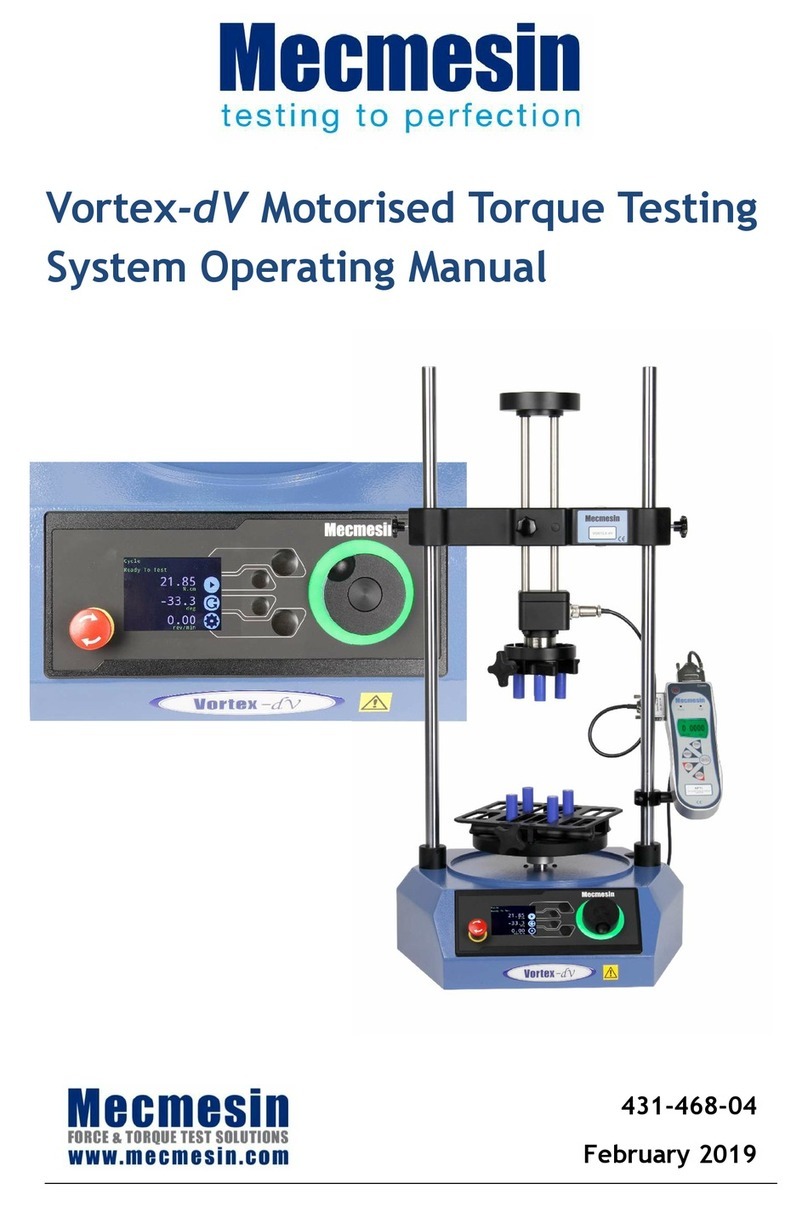

The control panel of the Vortex has a rotary speed controller

(5) for both clockwise and anticlockwise rotation. Turning this

controller clockwise will increase speed, and turning it

anticlockwise will decrease it. Some test Standards place

particular requirements upon speed accuracy/reproducibility,

which may exceed the normal performance of the Vortex.

Under such circumstances calibration of each individual test

stand may be appropriate.

To rotate the lower mounting table, or whichever base fixture

is attached to the drive shaft adaptor (see (D), below), press

the green [Enable] button (7), then,

while still holding down

this button

, select either ‘Torque Applied’ or ‘Torque Released’

with the direction control switch (6) and

hold in this position

.

The base fixture will continue to rotate until one of the following

occurs:

a) The [Enable] button is released

b) The direction control switch is released

c) The power is disconnected

d) A pre-set alarm point is reached (see ‘Measuring &

Displaying Torque’, below)

The ‘two-handed operation’ of the Vortex is designed as a

safety feature to ensure that the operator’s hands are kept clear

of the rotating fixture.

Pressing the red [Emergency Stop] button (1) will, at any

time, cut power to the motor and stop the lower fixture rotating.

Power to the motor can be reconnected by twisting the button

either clockwise or anticlockwise.

It is advisable to check and

become familiar with the operation of the Emergency Stop

once the system is connected to the appropriate mains supply.

The LCD display on the control panel will allow either actual

speed (in revolutions per minute, i.e. rpm) or degrees of

rotation to be displayed. Pressing the [SEL] button (3) will

toggle between these two options. Angle and speed values

OPERATING

INSTRUCTIONS

Powering on

Speed Setting

Rotating the Lower Fixture

Note: that when ‘Torque

Applied’ is selected the base

fixture will be driven

anticlockwise, i.e. the upper

fixture will be twisted in a

clockwise direction relative to the

lower fixture.

Emergency Stop

Speed & Rotation Display

page 3