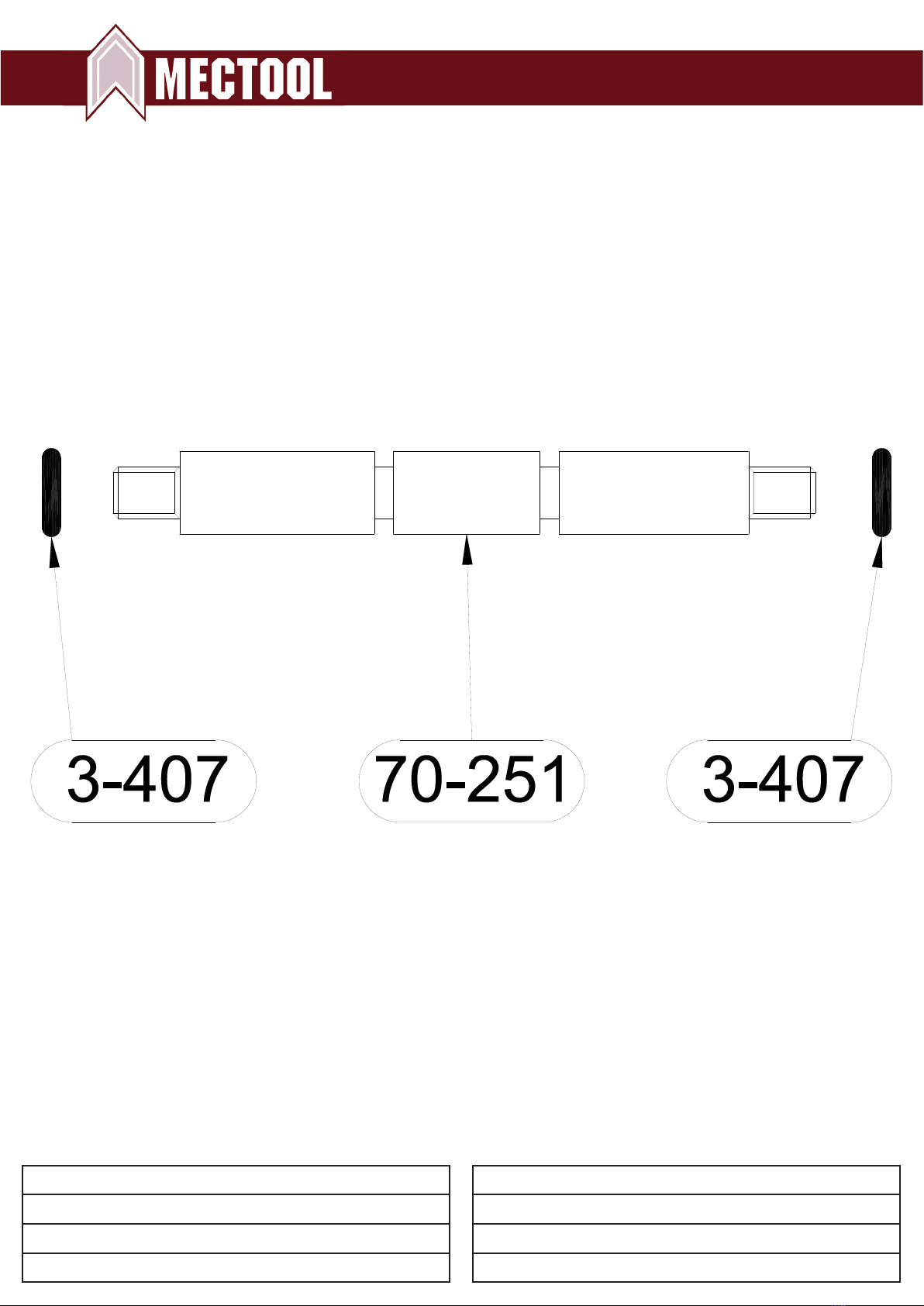

Model Quantity Metric Inch

TP3 4 M8 5/16

TP10 4 M8 5/16

TP40 2 M10 3/8

TP70 6 M8 5/16

TP140 6 M8 5/16

1. Rigidly mount the Transporter to a solid surface using

these recommended bolt sizes:

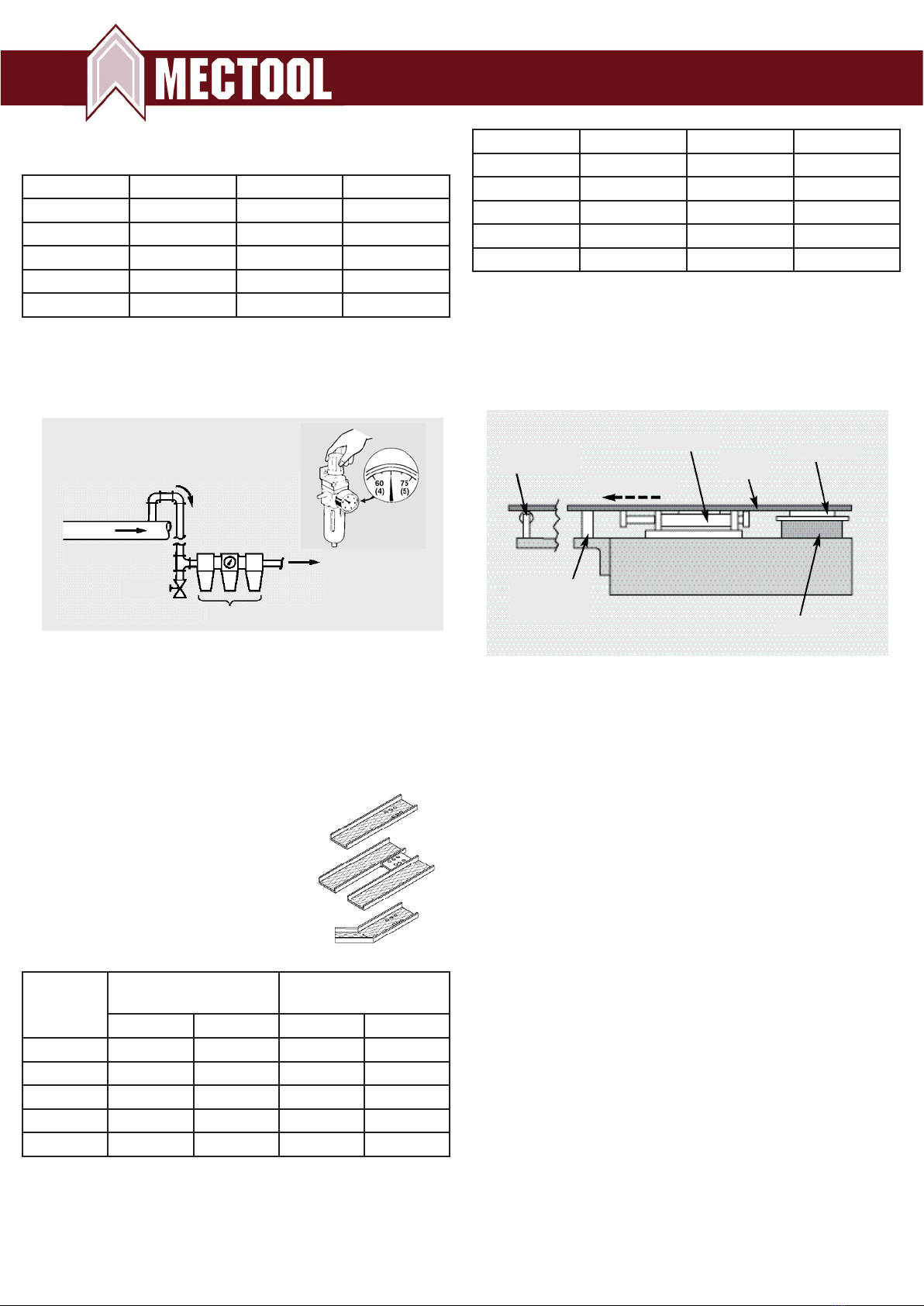

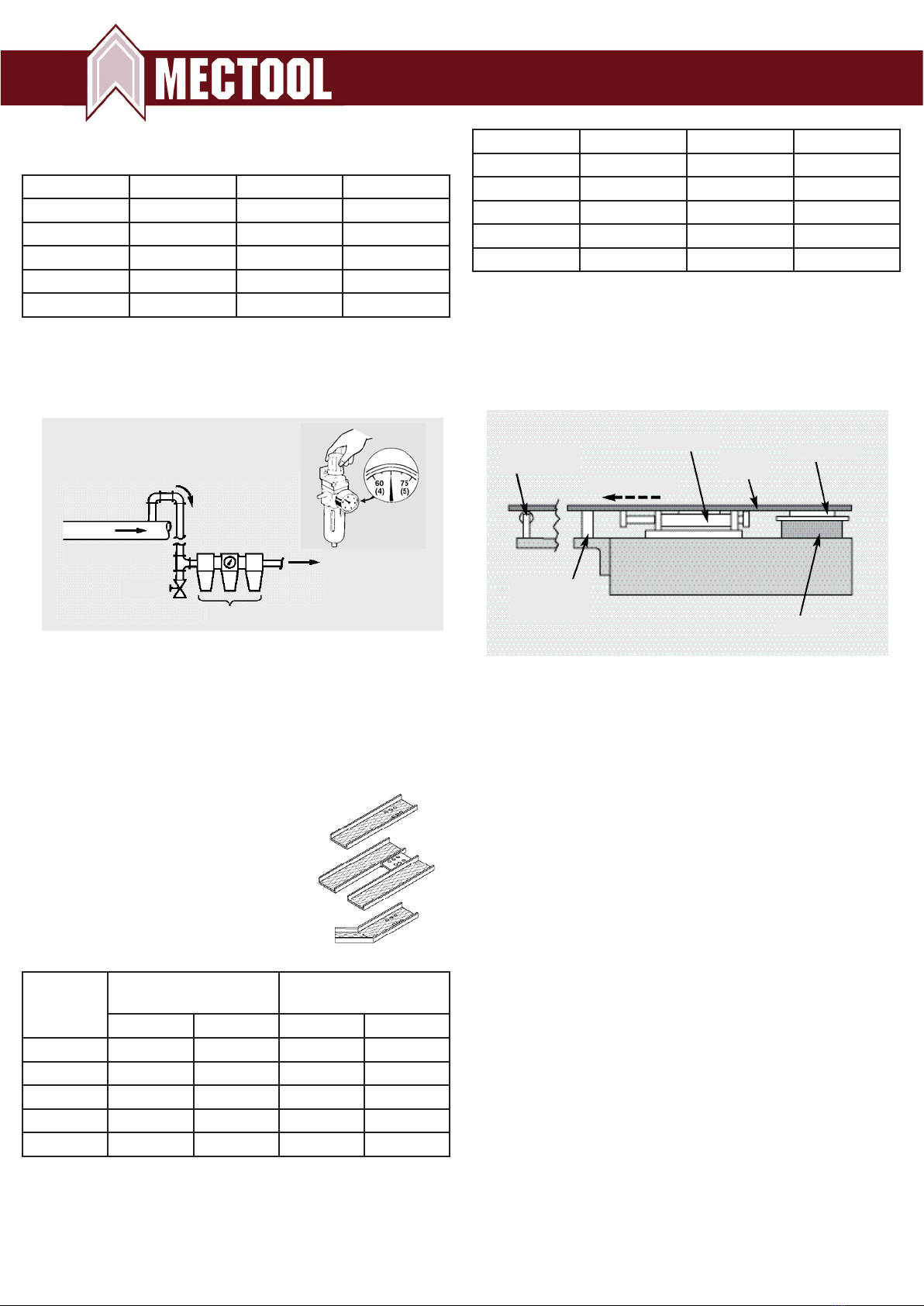

Recommended Air Line

Connection to Eliminate Moisture

and Particles from Main Line

3. Fill the lubricator with a good grade of hydraulic oil such

as Shell Tellus 32 or equivalent. Set the lubricator for

one (1) drop per minute.

4. Connect the air line with exible poly-ow tubing into the

threaded inlet. On model TP3 use 1/4” tubing for 1/8” NPT.

Models TP10, TP40, TP70 and TP140 use

3/8” tubing for 1/4” NPT.

5. A custom ”U” prole tray or chute

must be designed to handle each

specic application or tool. Any

material can be used but we

recommend aluminum or any light

gauge material to reduce tray weight.

Maximum tray weight should not

exceed the following table data:

2. Air line requires use of an oil mist-type combination

lter/regulator/lubricator, and pressure gauge. Set pressure

to 4-5 bar (60-75 psi). Do not exceed 5.5 bar (80 psi) as

excess pressure will damage the Transporter.

Main Air Line

Drain

To Transporter

Filter/Regulator/Lubricator

Model Max. weight

tray only

Max. weight

of parts

Kg Lbs. Kg Lbs.

TP3 1,5 3,3 3 6,6

TP10 3 6,6 10 20

TP40 15 33 40 80

TP70 50 110 70 140

TP140 100 200 140 300

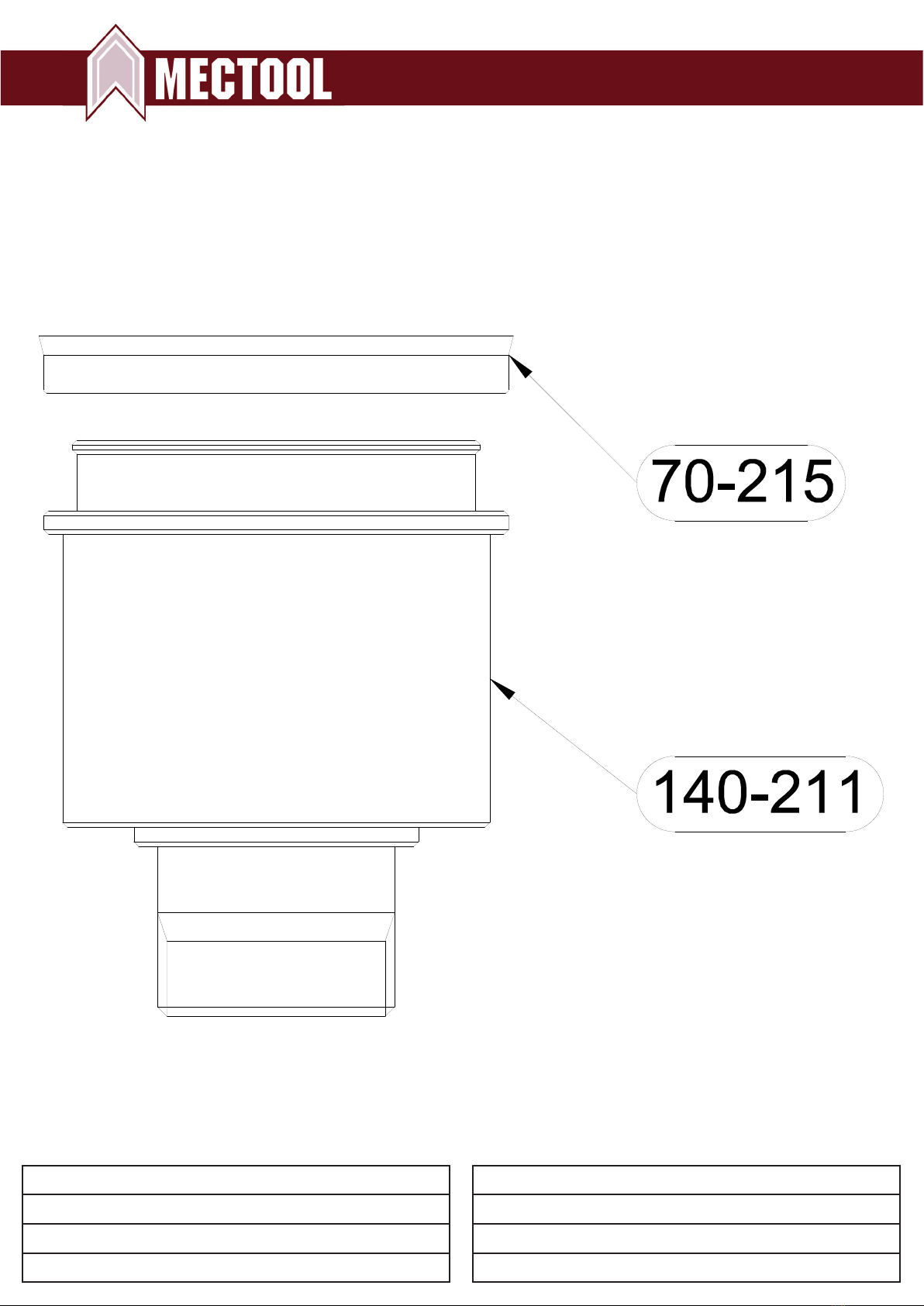

6. Fasten the tray or chute to the Transporter with metric

screws at all holes. Be sure to use spacers or washers

between the Transporter and the tray to reduce contact friction

between the moving tray and the Transporter body.

Refer to the following table:

Model Quantity Screw size Depth

TP3 6 M6 8 mm

TP10 6 M6 8 mm

TP40 6 M8 9 mm

TP70 6 M8 8 mm

TP140 6 M8 8 mm

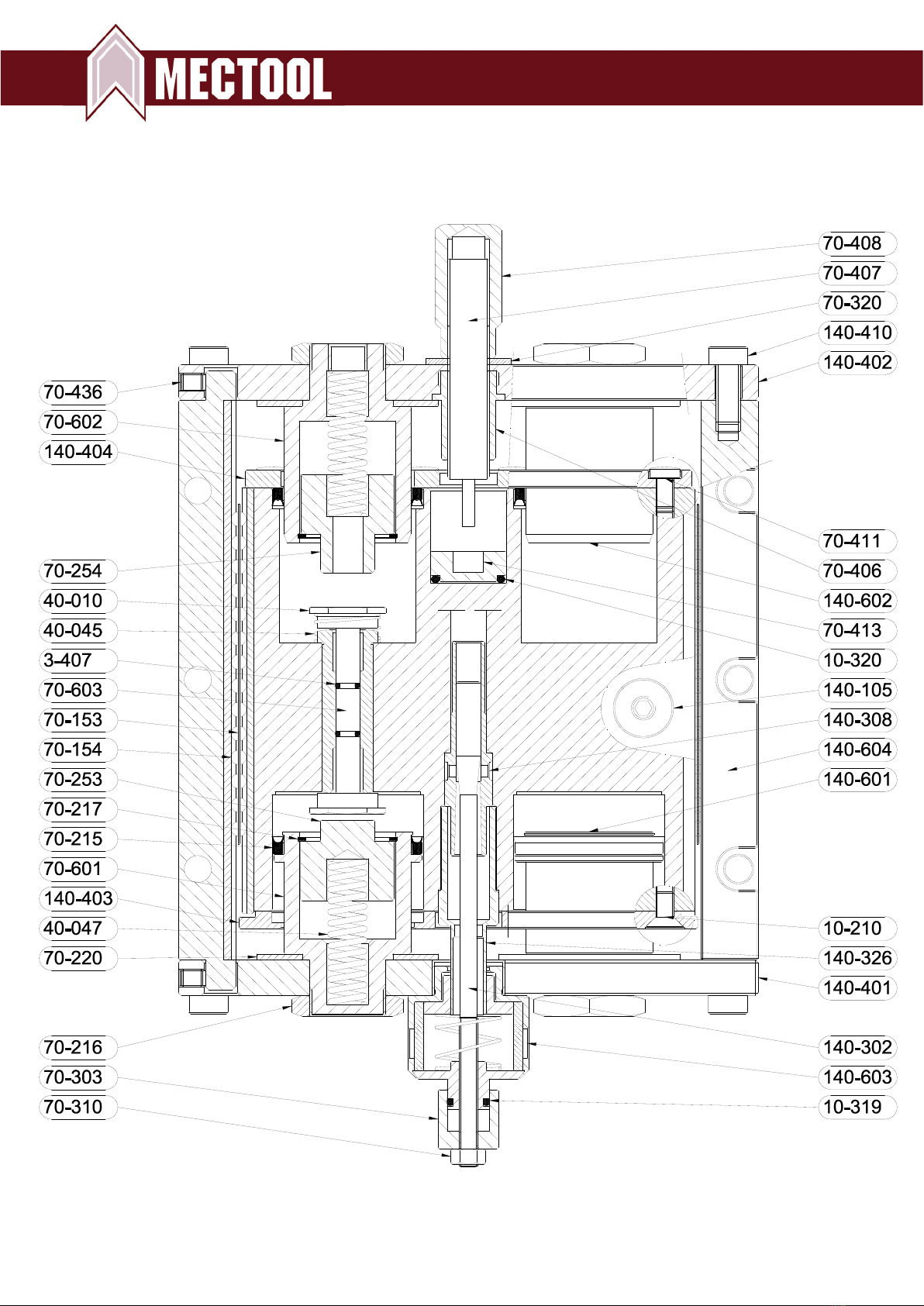

7. The conveyor tray or chute must be supported at both ends

to minimize vibration and deection. A block of Delrin GP-500

or Nylon, low friction material can be used for the tray to slide.

Ball bearing

roller

TransporterChute

or tray

Roller slide

Spacer

Press bolster

Solid slide -

Low Friction

Material

Feed Direction

8. The speed adjustment is preset at the factory with the

correct frequency for a lightweight tray or chute. The speed

can be adjusted by turning the screw or knob clockwise to

decrease the movement on the models TP3, TP10 and TP40.

The TP70 and TP140 are adjusted by turning the screw or

knob counter-clockwise to decrease the movement.

Maximum speed is not required to move parts or scrap

eciently.

9. If the TP40 speed frequency is inadequate, release the

air regulator rod 40-029 and gently push forward to increase

speed or backwards to decrease.

10. The TP10 may require a slight adjustment to maintain

proper speed frequency after a period of operation.

If speed adjustment screw 10-405 does not slow the unit

suciently, it may be necessary to slightly snug the two

screws at the air regulator valve 10-603. This reduces the air

being released from the valve and decreases speed.

Snugging the screws too tightly will cause bending of the air

regulator rod and poor performance.

11. Spray the same Tellus oil used in lubrication on the

pistons every week.

12. If there is a build-up of sticky oil on the conveyor tray or if

the scrap parts are very oily, they may stick to the surface and

reduce movement. To reduce friction, try dimpling the surface

of the conveyor chute with a ballpeen hammer or use a

dierent material like expanded metal or proled, roll-formed

material.

Installation