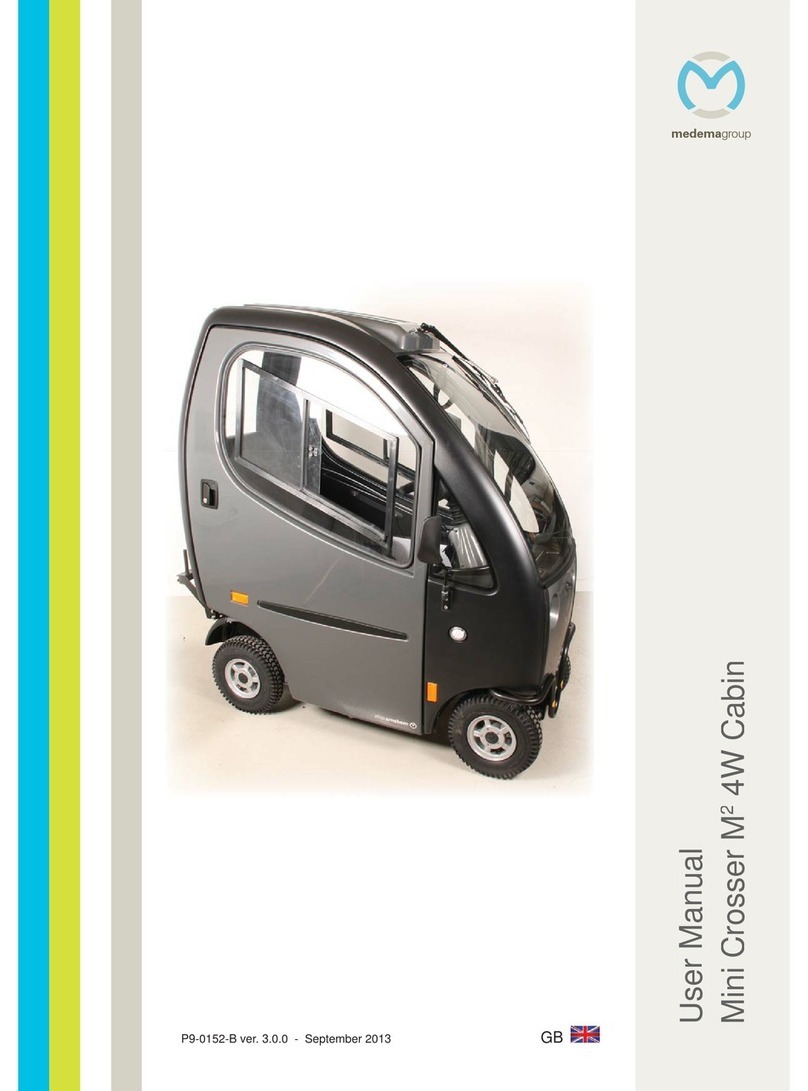

Medema Mini Crosser M2 User manual

Service Manual

Mini Crosser M2

P9-0157-S ver. 2.1.0 - December 2018 GB

medemagroup

Service manual P9-0157-S 2 of 70 Version 2.0.9 - 2018

Medema A/S

Service manual P9-0157-S 3 of 70 Version 2.0.9 - 2018

Medema A/S

Contents

Contents................................................................................. 3

Introduction............................................................................ 5

Symbols.................................................................................. 6

Warning! ................................................................................. 6

Alarm ...................................................................................... 6

Contagion!.............................................................................. 6

Safe servicing ........................................................................ 7

Tool list ................................................................................... 8

Storage ................................................................................... 9

Cleaning ................................................................................. 9

Declaration of conformity..................................................... 10

Maintenance........................................................................... 11

User menu.............................................................................. 12

Service summary for Mini Crosser M Model....................... 15

Control panel ......................................................................... 21

Programming the technician menu ..................................... 22

Display charge curve ............................................................ 29

Troubleshooting .................................................................... 32

The vehicle’s driving characteristics................................... 35

Batteries ................................................................................. 35

Battery disposal..................................................................... 36

Charging................................................................................. 36

Standby power....................................................................... 37

Fitting an accelerator switch................................................ 39

Fitting corner speed reduction, 3W ..................................... 41

Fitting corner speed reduction, 4W ..................................... 42

Fitting a foot pedal ................................................................ 43

Fitting a twist grip accelerator, right & left.......................... 45

Electrical seat turning from right to left .............................. 47

Elevated footrest ................................................................... 48

Anti-theft alarm, tilt alarm and temperature sensor. .......... 48

Fitting accessories on the C-rail.......................................... 50

Wear of magnetic brake........................................................ 53

Replacing bulb in headlight.................................................. 54

Fitting a side-view mirror...................................................... 54

Wheel radius data m2............................................................ 55

Radius = 160 mm ................................................................... 55

Radius = 175 mm ................................................................... 55

Radius = 160 mm ................................................................... 55

Radius = 170 mm ................................................................... 55

Securing to vehicle oor with belts..................................... 56

Transporting by plane ........................................................... 59

Towing .................................................................................... 59

Front wheel alignment, 4W................................................... 60

Service manual P9-0157-S 4 of 70 Version 2.0.9 - 2018

Medema A/S

Programming ......................................................................... 61

Technical data........................................................................ 61

Fejlkoder................................................................................. 66

Service manual P9-0157-S 5 of 70 Version 2.0.9 - 2018

Medema A/S

Introduction

This manual contains servicing instructions for the Mini Crosser

M2Model mobility scooter.

The Service Manual is a supplement to our Spare Parts

Catalogue and User Manual.

The Mini Crosser M2is designed for safe travel for at least

10 years, up to a max. of 5,000 hours, provided it is serviced

and safety-checked every year, corresponding to 500 hours of

operation. The service must be carried out either by Medema

A/S or an authorised workshop.

IMPORTANT! For safety reasons it is of the utmost importance

that the servicing and safety check intervals are complied with,

as this minimises the risk of brake failure and short-circuits in

the wiring, which could generate heat and cause a re.

If help is required with troubleshooting, Medema Production is

always happy to provide telephone assistance. If the problem

seems to be an electrical fault that prevents the scooter from

working, please tell us the error code. This can be found on the

battery indicator on the control panel. Read more about this in

the section on Troubleshooting.

Please also have the scooter’s serial number handy when

contacting Medema A/S.

If you have any questions that are not answered directly by this

manual, you are always welcome to contact us at:

Medema A/S

Tel: +45 7010 2054

Email: info@minicrosser.com

Internet: www.minicrosser.dk

NB: Errors and omissions excepted. Specications subject to

change.

Medema A/S also reserves the right to update the service

manual in line with any modications or improvements to the

product.

Service manual P9-0157-S 6 of 70 Version 2.0.9 - 2018

Medema A/S

Symbols

Used in the manual to indicate sections describing situations

where extra care is required owing to the risk of personal injury.

Used to indicate sections on electromagnetic compatibility (EMC).

Warning!

For safety reasons the vehicle must not be lent to persons who

are not completely familiar with it. The vehicle is designed for

one person only.

The Mini Crosser M Model has been designed for users

weighing max. 175 kg. Can be supplied in a HD version as

standard for a max person weight of 250 kg.

Alarm

Temperature sensor, alarm system and tilt alarm are built into

the same box that can be acquired as an option for the Mini

Crosser M2.

Note!

The alarm is always turned off on delivery. See the chapter

about ”Programming the User Menu” to turn on the alarm.

Contagion!

Note!

The tires can sometimes rub off on oor coverings, particularly

linoleum. Medema Production assumes no responsibility in

case of contagion.

To prevent this, we recommend that you protect delicate oors

with some sort of driving surface.

Service manual P9-0157-S 7 of 70 Version 2.0.9 - 2018

Medema A/S

Safe servicing

To avoid injuries to both the service engineer and the subsequent

user of the scooter, it is important to get to know the product

before servicing it.

Be particularly aware of the following:

The Mini Crosser MUST be turned off at the main switch. If

electrical components are being serviced, the positive terminal on

the battery MUST also be disconnected.

If the voltage needs to be measured in the course of

troubleshooting, take great care not to short-circuit anything.

Take great care not to short-circuit the battery terminals.

Be careful not to lift heavy parts such as the seat, battery and

motor gear incorrectly or drop them.

Make sure to raise one rear wheel off the ground so that the

scooter cannot drive off accidentally.

Use professionally maintained tools.

Where lock nuts are used, NEW ones MUST be tted when the

scooter is reassembled.

Take care to t new cable strips in the same way as the old ones.

Make sure that no cables can be trapped by moving parts or stick

out in such a way as to catch on things.

End every service by making sure that the product is roadworthy:

- Check that all the connectors are plugged in correctly.

- Check that all the mechanical parts are properly secured.

Turn the scooter on and check

- that the magnetic brake clicks when the accelerator is activated.

- When the accelerator is released, it must not be possible to push

the scooter.

Service manual P9-0157-S 8 of 70 Version 2.0.9 - 2018

Medema A/S

Tool list

The following tools are needed to service the scooter:

Circlip pliers

Allen keys

Box spanners, 7-17 mm

Open-ended spanners, 7-17 mm

Phillips and torx screwdrivers, 10/15/20/25 slot

Needle-nose pliers

Side-cutting pliers

Plastic hammer

Set of punches

Retractable knife

Steel brush

Water pump pliers

Wire strippers

Crimping tool

Pliers for Molex 5556/5558 crimps

Riveting pliers

Small cable ties

Multimeter

Battery tester

Tyre pressure gauge

Tyre pump with Schrader valve

Acid-free oil and grease

Loctite 406 / 603

Cable ties

PC

PC Programming package for S180

Service manual P9-0157-S 9 of 70 Version 2.0.9 - 2018

Medema A/S

Storage

The Mini Crosser is designed for use in all types of weather.

The scooter should, however, be stored and charged under

cover at temperatures in excess of 0°C. The charger must also

be kept dry.

If the scooter is not going to be used for a long time, it is

advisable to protect the tyres by chocking the scooter up. It is

also a good idea to cover the scooter to protect it from dirt, dust

and sunlight.

Cleaning

The Mini Crosser should be cleaned with a damp cloth. A little

washing-up liquid can be used if necessary. The plastic covers

can be polished with an ordinary glass cleaner or car wax.

Note!

Using a high-pressure cleaner or hose may damage the Mini

Crosser’s electronics.

While drying, the Mini Crosser must be placed on a at surface.

It must be kept indoors; preferably in a heated room. The

temperature must not exceed 50°.

Service manual P9-0157-S 10 of 70 Version 2.0.9 - 2018

Medema A/S

Declaration of conformity

Medema A/S hereby declares that:

Machine: Mini Crosser

Use: (Prescribed use in

User Manual)

Model No: M2

Complies with the Medical Device Directive 93/42/EEC

The product is made in accordance with the harmonized

standard EN 12184 - Electrically powered wheelchairs, scooters

and their chargers.

The product is risk analysed in accordance with the harmonized

standard DS/EN ISO 14971:2007-04-10 2. edition - Medical

devices - Application of risk management to medical devices.

Mini Crosser scooters can, for a fee, be taken to the nearest

dealer for disposal in accordance with current environmental

regulations.

Manufacturer: Medema A/S

Address: Enggårdvej 7, DK-7400 Herning

Tel./Fax +45 7010 2054 +45 9716 8582

Date: 02.01.2014 Signature: _____________________

Service manual P9-0157-S 11 of 70 Version 2.0.9 - 2018

Medema A/S

Maintenance

Daily:

Test the lights and indicators before using the scooter in the dark

or poor visibility.

Every three months:

Test the brakes. With the disengagement lever up, it must not

be possible to push the Mini Crosser.

Test the brake disengagement function.

With the brake disengagement lever down, the scooter must

not be able to go when the accelerator is activated. The battery

indicator should ash error 9.

When the disengagement lever is up and the scooter has been

switched off and on, the scooter should be able to go again. It

must not be possible to push it.

Test the accelerator.

With the scooter turned off, activate the accelerator while turning

the scooter on. The scooter must not be able to go. The battery

indicator should show running lights from the center and out.

With the scooter turned on, press the accelerator forward a touch.

When it is released, the scooter should stop completely and the

brake should click. It must not be possible to push the scooter.

Perform the same test again, but pressing the accelerator back.

Lubricate the lever arm on the front brake hub with acid-free oil.

Check the tyre pressure and tread.

Annual

Safety checks

The Mini Crosser M2is designed for safe travel for at least 10 years,

up to a max. of 5,000 hours, provided it is serviced and safety-checked

every year, corresponding to 500 hours of operation. The service must be

carried out either by Medema A/S or an authorised workshop.

IMPORTANT! For safety reasons it is of the utmost importance that the

servicing and safety check intervals are complied with, as this minimises

the risk of brake failure and short-circuits in the wiring, which could

generate heat and cause a re.

Service manual P9-0157-S 12 of 70 Version 2.0.9 - 2018

Medema A/S

User menu

Term Description

Menu / information Press the button and a menu at the top of the display

switches between ”Date”, ”Time”, ”Complete km”,

”Complete running time”, ”Battery Voltage” Service

”and” inclination ”.”Slope” is optional, and appears

only if it is engaged.

Button Menu / information are also used to modify the

user parameters.

Access these parameters by holding the menu button

for approx. 3 sec.

Key switch To start the vehicle:

Turn the key to position (1). The rst half second after

the Mini Crosser is on, the control is making a safety

check of the electrical system. If the accelerator is

affected during this time, the Mini Crosser will not be

able to run, before the key again has been turned at 0

and back to 1 again.

Speed selector The turtle indicates lowest speed range. 0-6 km / h.

The hare indicates the highest speed range. Up to 15

km / h. Increase/decrease with + / - button.

The icons turtle/hare can be turned on/off from the

User menu.

Battery indicator The left side of the display shows battery level indicator.

Indicates that after approx. ½ seconds, the battery

state of charge. Provides a more accurate indication

after approx. 1 minute drive. When both red, yellow and

green box lights are the batteries fully charged. Can be

divided into 10 or 3 boxes. When the view is down the

bottom of the yellow batteries should be recharged as

soon as possible. If there is only light in the red boxes

or ashing the batteries must be charged immediately.

Trip meter TRIP button resets the trip meter. Can be used while

driving.

Hand brake Works on the left rear wheel and should only be used

as extra brake / emergency brake and parking brake.

It can be blocked in the locked position. Also available

as a foot brake.

Service manual P9-0157-S 13 of 70 Version 2.0.9 - 2018

Medema A/S

Term Description

Accelerator

Forw. / Backw.

Front arm activates slowly and the Mini Crosser will

start running forward. The more press, the faster it will

run. When the lever is released, the arm ips itself

back

to the starting position and Mini Crosser stops.

Upon activation of the posterior arm, the Mini Crosser

run backward. The Magnetic brake on the rear wheels

will strike at standstill, corresponding to the parking

brake on a car. With speed regulation, speed can also

be regulated downhill. The engine will then act as a

brake.

Light switch Turns on the front and rear lights. The key switch must

however be turned to position 1 (drive).

Hazard warning lights Turns on all lamps at once. Also works when the key

is removed, or turned to 0 (stop position).

Indicator lights switch Arrow left: lamp left side. Arrow Right: lamp right side.

Activate the same button again to turn off ashing

lights.

Horn Electric horn which can be programmed in volume in

the User Menu. Activated by pressing the horn button.

Charging socket Turn off the Mini Crosser (key in position 0) during

charging. Note that it is not possible to run while the

batteries recharge. See also the section ”Batteries

and Charging.”

Service manual P9-0157-S 14 of 70 Version 2.0.9 - 2018

Medema A/S

Term Description

Extras

Anti-theft alarm (Extra) With this parameter set to ON, the anti-theft

alarm is turned on every time you turn off the Mini

Crosser. An activated alarm is turned off by turning the

key to 1 (drive).

If you have no opportunity to get to the Mini Crosser

with the key, the alarm will stop after approx. 20

seconds. Shake the scooter again, the alarm will be

activated again.

Tilt Tilt-symbols.

Tilt Alarm sideways By exceeding the preset value, the symbol ashes and

the horn hoots, if the parameter is enabled.

Tilt Alarm forw./backw. By exceeding the preset value, the symbol illuminate

and the horn hoots, if the parameter is enabled.

Overheating step 1 Step 1: The symbol ashes and the speed is reduced to

half power. Wait for 3-5 min and start again.

Overheating step 2 Step 2: The symbol will illuminate and Mini Crosser

stops. Wait 3-5 minutes and start again.

Service manual P9-0157-S 15 of 70 Version 2.0.9 - 2018

Medema A/S

Service summary for Mini Crosser M Model

Area Component Check and remedy

Suspension and

wheels

Rear suspension Check whether the rear of the

scooter is drooping. The rear wheel

must not rub on the mudguard with

a load on the seat. Replace the

shock absorbers/springs behind

the batteries. See the Spare Parts

Catalogue.

Check the shock absorbers for oil

leaks.

Check that the swivel axle/transaxle

is securely mounted. Retighten or t

bolts/nuts.

Check that no cables

can be trapped by

moving parts.

Fit cable ties.

Check the wheels Check the fastenings and the

condition of the rims.

Check the tyre

pressure and tread.

Recommended tyre pressure: 2.8 bar

(50 psi)

The minimum tread depth for good

grip is approx. 1 mm.

See the Spare Parts Catalogue for

disassembly. NB! The rear and front

wheels on the 4W MUST always be

removed using the ve bolts. NEVER

undo the actual ange using the bold

in the centre. See the Spare Parts

Catalogue. NB! ALWAYS let the air

out of the inner tube before taking a

wheel apart!

Check that the

handbrake is working.

Lubricate the lever arm on the brake

hub with acid-free oil. Adjust the

cable length using the adjusting

nipple. If parts are defective: See the

Spare Parts Catalogue.

3W: Front fork.

Suspension and

straightness.

Check that the front fork can bounce.

Is it crooked?

Is there an oil leak?

If there is a defect that needs to be

repaired, replace the entire front fork

and Sealing ring Ø42 - Ø20 - 10. See

the Spare Parts Catalogue.

3W: Front wheel. Check the ball bearings for play and

wear.

4W: Front suspension.

Check that the front wheels do not hit

the underside of the front mudguards.

Check that the rubber dampers are

secure. They should just touch the

axle beam. See the Spare Parts

Catalogue.

Check that the T-suspension block is

working and does not droop.

Service manual P9-0157-S 16 of 70 Version 2.0.9 - 2018

Medema A/S

Area Component Check and remedy

Suspension and

wheels (contd)

Front wheel

suspension.

Check that the guide rods and balls

are in good condition and properly

tightened.

Check the ball bearings in the front

wheels and guide spindles for play/

wear.

Front wheel tracking. See the sketch

for correct tracking if uneven tyre

wear shows that adjustment is

necessary.

Steering/Control

panel

Lights, indicators,

hazard warning and

horn

Check functioning and the condition

of the switches.

If an indicator is not working: Check

the connectors and the fuse in the

control panel.

Or change the bulb.

Seals Check that the rubber switch covers

are intact and in good condition.

Check that all the holes have plugs.

Fit new ones if necessary.

Check that the sign on the control

panel is straight.

Accelerator and

handlebars

Check that the accelerator

is mounted securely on the

potentiometer shaft.

Function test: Turn the scooter on

while the accelerator is activated. The

scooter must not be able to go. The

battery indicator should show.running

lights from the center and out.

With the scooter turned on, press the

accelerator forward a touch. When it

is released, the scooter should stop

completely and the brake should click.

It must not be possible to push the

scooter. Perform the same test again,

but pressing the accelerator back.

Max. speed

potentiometer

(Battery indicator)

Check that all the lamps come on

when the batteries are fully charged.

If there is no indication at all, check

the batteries. If they are okay, the

card or the S-180 will have to be

replaced.

Motor / gear /

brake

(Transaxle)

Wear Check: That the motor runs smoothly

and evenly. If not, the carbon brushes

in the motor usually need to be

replaced. The minimum length of the

brushes is 10 mm. See the Spare

Parts Catalogue for replacement.

Motor / gear /

brake

(Transaxle)

(contd)

Check: The rear wheel bearings in

the gear for wear. Lift the rear of the

scooter. Get hold of one wheel at

a time. Lift it up and down to see if

there is any play in the bearings in

the transaxle. If there is, the whole

unit should be replaced.

Service manual P9-0157-S 17 of 70 Version 2.0.9 - 2018

Medema A/S

Area Component Check and remedy

Power consumption Power consumption on a level road

with a tyre pressure of 2.8 bar and

75-100 kg on the seat:

10 km/h = 12 - 15 A

15 km/h = 17 - 20 A

Measure on one of the battery cables

using a clip-on ammeter.

Power consumption when the scooter is

turned off and the key turned to 0 = 50 mA

Brakes and

disengagement

Check function

When the disengagement lever is up:

It must not be possible to push the

scooter.

It must be possible to drive normally

when the scooter is turned on.

When the disengagement lever is

down:

It must be possible to push the

scooter.

The scooter must not be able to

go. Error 9 should appear when the

accelerator is activated.

The brake must be able to hold the

scooter on a 15° (26%) slope with 75

- 100 kg on the seat.

If not, it must be adjusted or

replaced, depending on how much

wear there is.

Braking distance 10 km/h - 2.0 m

15 km/h - 3.5 m

Please note that the braking distance

must not be longer than specied

in order to comply with ofcial

requirements.

Steering column Play/wear Check the following:

- Universal joint

- Pins in steering shaft/front fork

- That the aluminium bottom section

of the steering column is rmly

secured to the steering shaft. (*)

Wear/rust on the bearings in the

steering column. Top support bearing.

The bearings in the head tube are

protected by seal rings. If the front

fork is a bit stiff, the seal rings can be

lubricated with a little grease.

Service manual P9-0157-S 18 of 70 Version 2.0.9 - 2018

Medema A/S

Area Component Check and remedy

Steering column

(contd)

(*) On models with an 8 mm bolt

going into the steering shaft from

the aluminium bottom section of

the steering column. The bolt can

work loose if the steering column

is twisted/knocked hard. This can

be remedied by drilling a hole for a

split pin between the steering shaft

and the aluminium section. Contact

Medema A/S.

Cables Check that the cables cannot

become trapped or be subjected

to strain when the handlebars are

turned or the steering column is

folded down.

Gas spring Check:

That the gas spring locks the steering

column securely.

Check that there is no play in the

release lever and the bolts/bushes

securing the gas spring.

Key switch / charging

socket

Check that the key switch does not

wobble.

Clean with a damp cloth or

compressed air if dirty. If the contacts

are corroded, clean them with

contact spray or replace the charging

sockets.

Chassis / seat /

covers

Footplate Check the plastic rivets securing the

mat. Fit new ones if necessary.

Seat post Check that it is properly secured and

in good condition.

Chassis / seat /

covers (contd)

Seat Check that:

The release lever locks the seat

properly.

The seat is rmly secured on the seat

frame/plate.

The seat tube is in good condition. If

necessary, lubricate the tube with a

little acid-free grease.

The armrests are in good condition.

Covers Check that the plastic covers are in

good conditions. Parts with sharp or

projecting edges should be replaced.

The same applies to covers with an

operational function, e.g. the splash

guard and battery cover. (water in the

controller)

Cleaning: See the section on

Cleaning.

Other mechanical

components

Check that the other components

work properly.

Service manual P9-0157-S 19 of 70 Version 2.0.9 - 2018

Medema A/S

Area Component Check and remedy

Electrical

components

Control card Check that it is dry and in a good

condition.

Check that all the connectors are

rmly in place.

Cables/plugs Check that the cables are rmly in

place and not sticking out in such a

way as to catch on something or get

trapped.

Check that the plugs are rmly in

place.

Battery straps Check that they are properly secured.

Batteries/charger

(see also the

section on

Batteries)

Batteries Check that there are no cracks in the

batteries, that batteries look good

and that the battery connections are

rmly in place.

Battery capacity

Check this with a battery tester.

Mount new batteries if needed. Apply

a little acid-free vaseline to the battery

terminals before connecting them.

Battery charger Check that the indicator lamp on

the battery charger changes to

CHARGING when the scooter is

connected.

If necessary, measure the charging

voltage during charging. It should be

approx. 28.8 V.

Leave the scooter to charge

overnight. Disconnect the charger

and measure the battery voltage

after about 15 minutes. It should be

approx. 27.6 V for fresh batteries.

Check that the scooter cannot

go while the battery charger is

connected.

Brakes Magnetic brake Check the distance between the

brake plate and the magnet using

a feeler gauge blade. The distance

should be between 0.15 mm and

0.30 mm. If the distance is larger,

the friction disc will be worn and the

magnet brake must be replaced. See

page 53.

See the carbon specication overleaf.

10 mm

Service manual P9-0157-S 20 of 70 Version 2.0.9 - 2018

Medema A/S

Check if the carbon is okay or needs replacing.

Whether it is a Schmid or Mini Crosser transaxle, the carbon

must be replaced when it has been worn down to 10mm.

Full length

Other manuals for Mini Crosser M2

1

Table of contents

Other Medema Scooter manuals

Medema

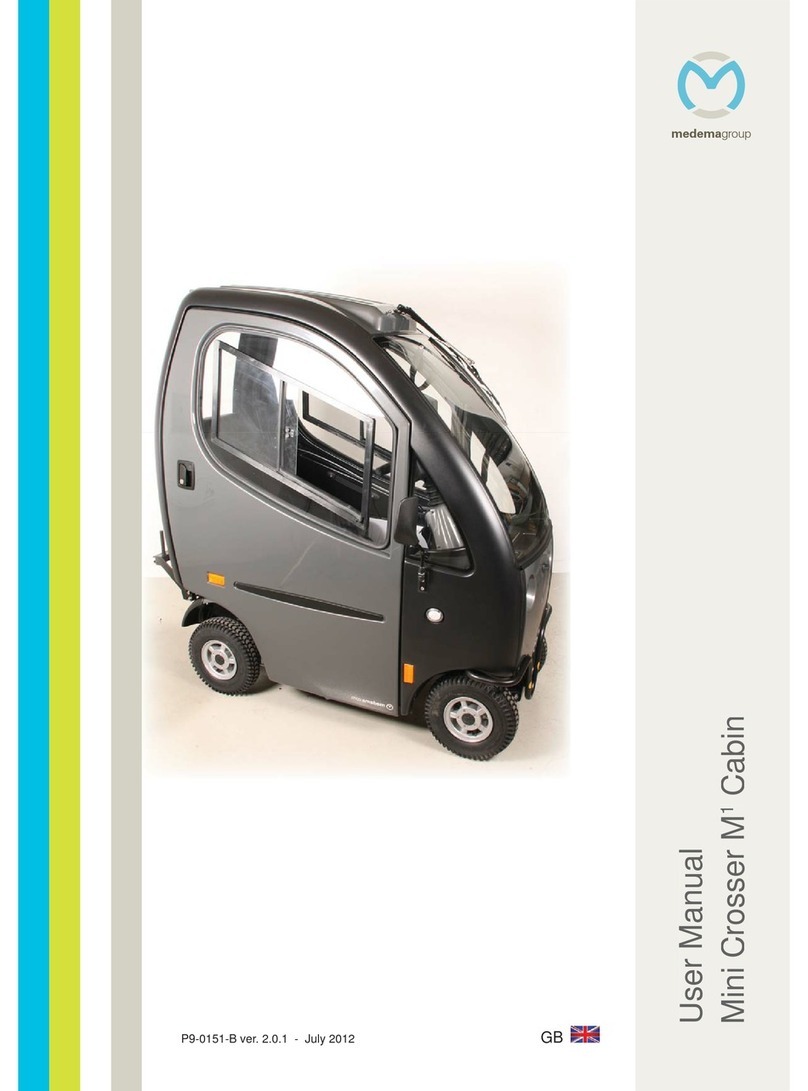

Medema Mini Crosses M2 4W Cabin User manual

Medema

Medema Mini Crosser M1 User manual

Medema

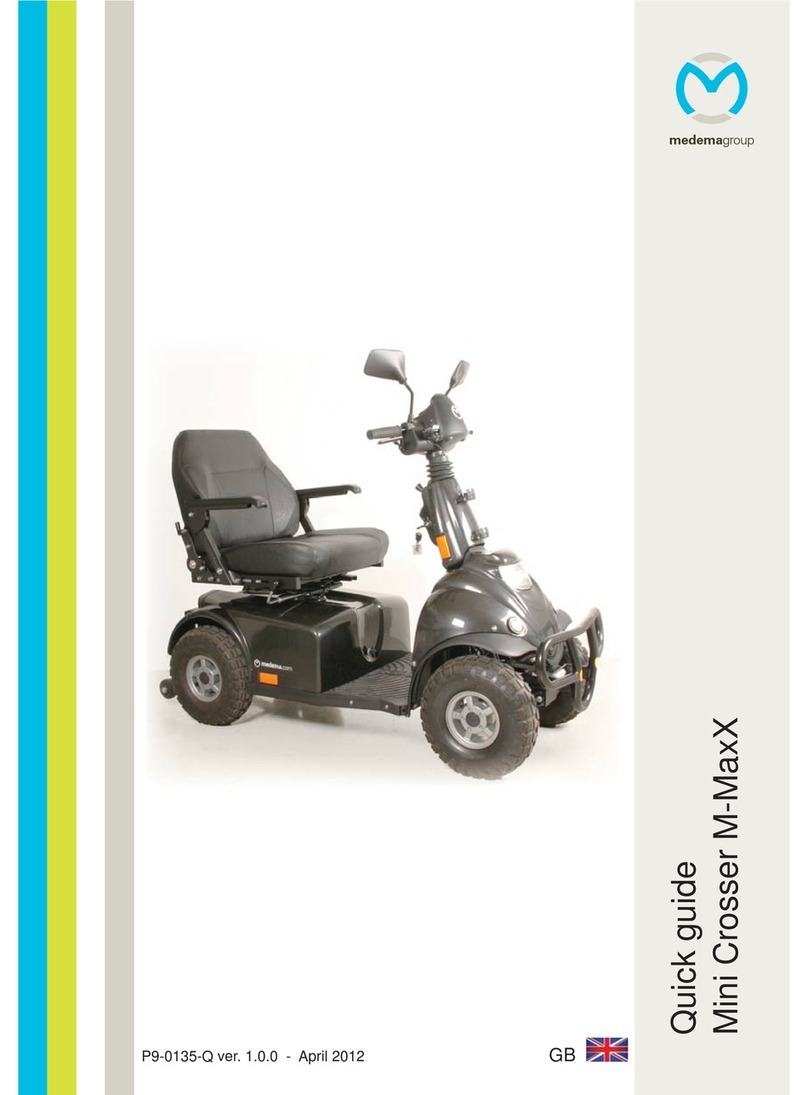

Medema Mini Crosser M-MaxX User manual

Medema

Medema MC 1122 Quantum User manual

Medema

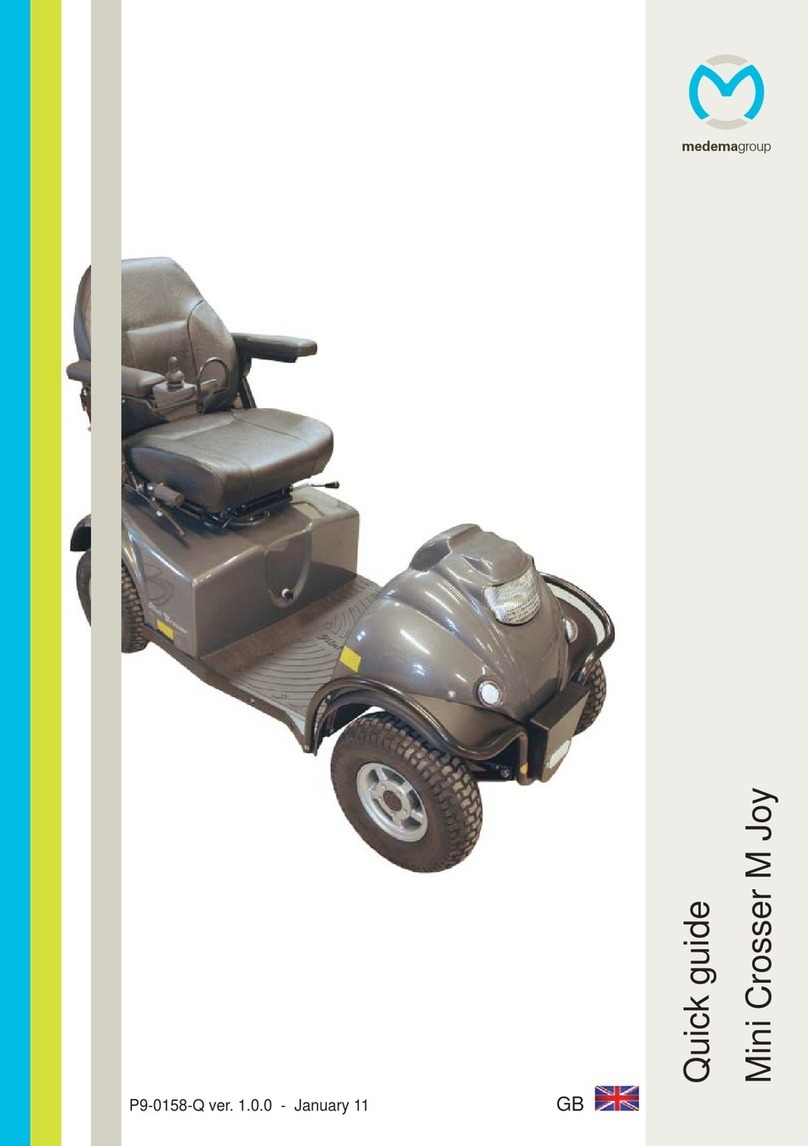

Medema M1 joy User manual

Medema

Medema Mini Crosser X1 User manual

Medema

Medema Mini Crosser M1 Cabin User manual

Medema

Medema Mobility Scooter User manual

Medema

Medema M Joy User manual

Medema

Medema Mini Crosser M1 User manual