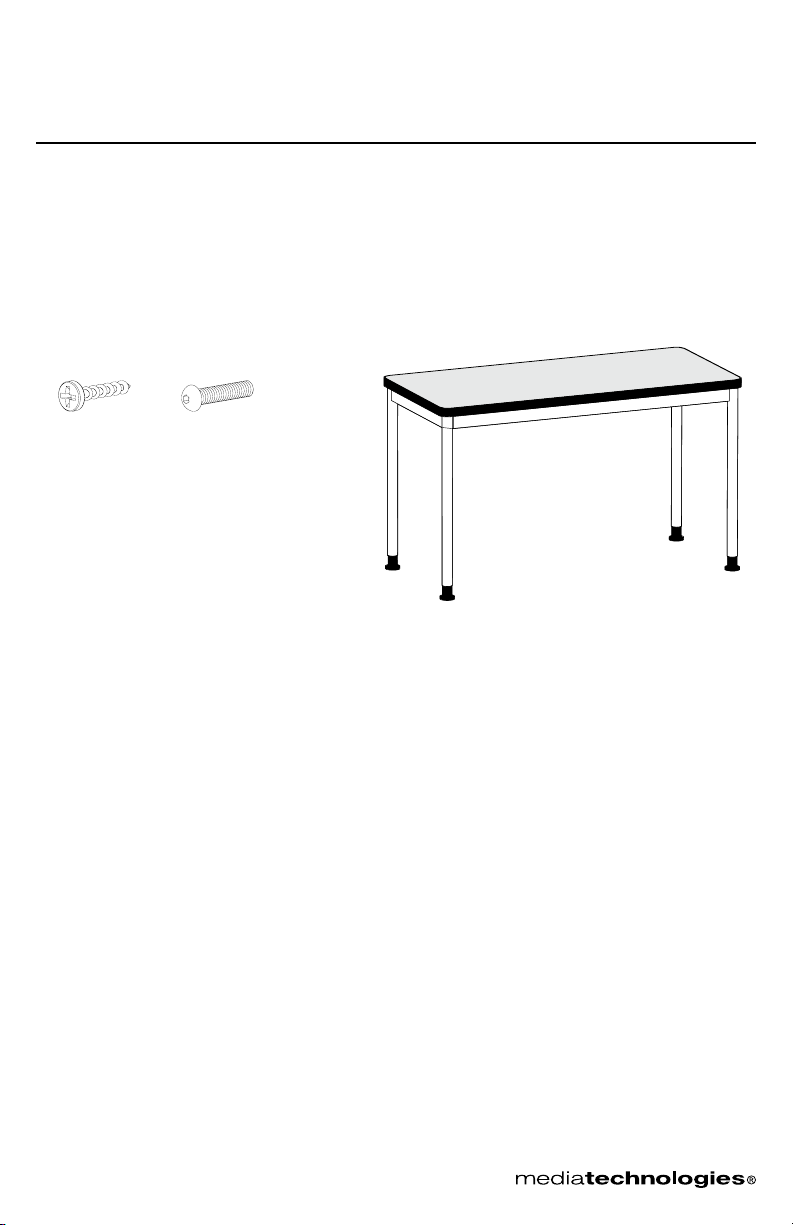

Media Technologies Cirrus Guide

This manual suits for next models

17

Table of contents

Other Media Technologies Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Forte

Forte MARIDA MDNR814 Assembling Instruction

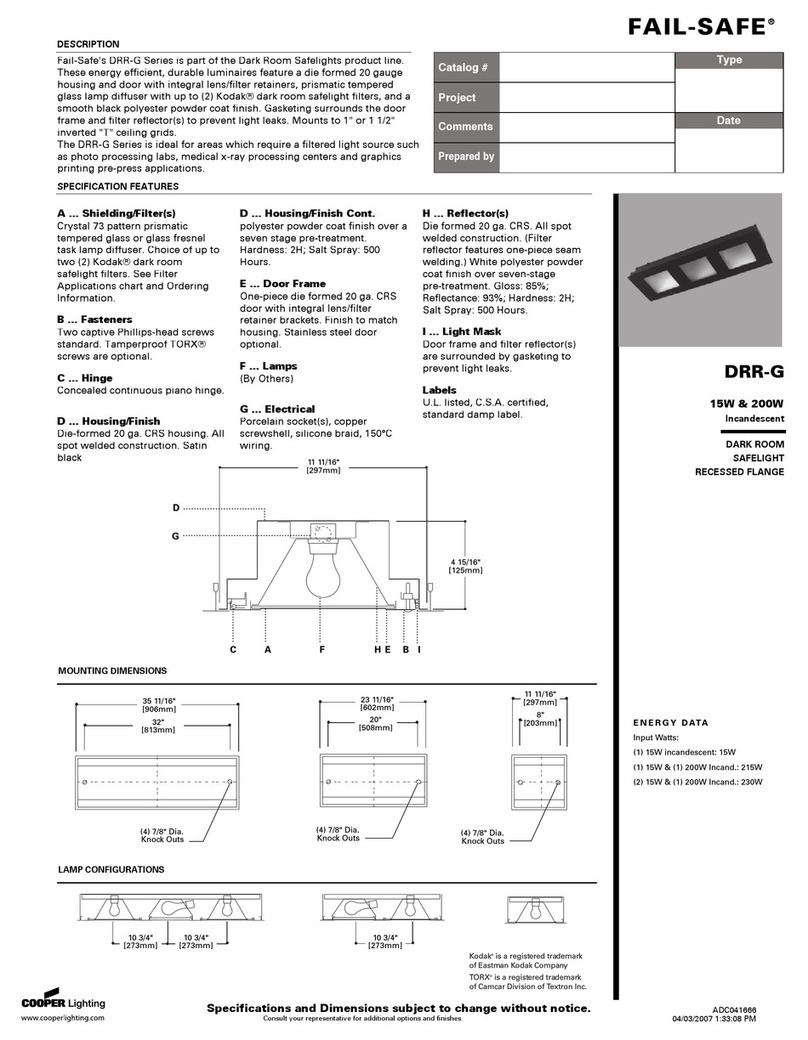

Cooper Lighting

Cooper Lighting FAIL-SAFE DRR-G specification

HoMedics

HoMedics MIRRA EUPHORIA WFL-540 user manual

Ameriwood HOME

Ameriwood HOME 5664412COM manual

aspenhome

aspenhome I91-366A Assembly instructions

Better Homes and Gardens

Better Homes and Gardens Ellis Shutter manual

Rauch

Rauch M0003 Assembly instructions

Furniture of America

Furniture of America FOA7917C Assembly instructions

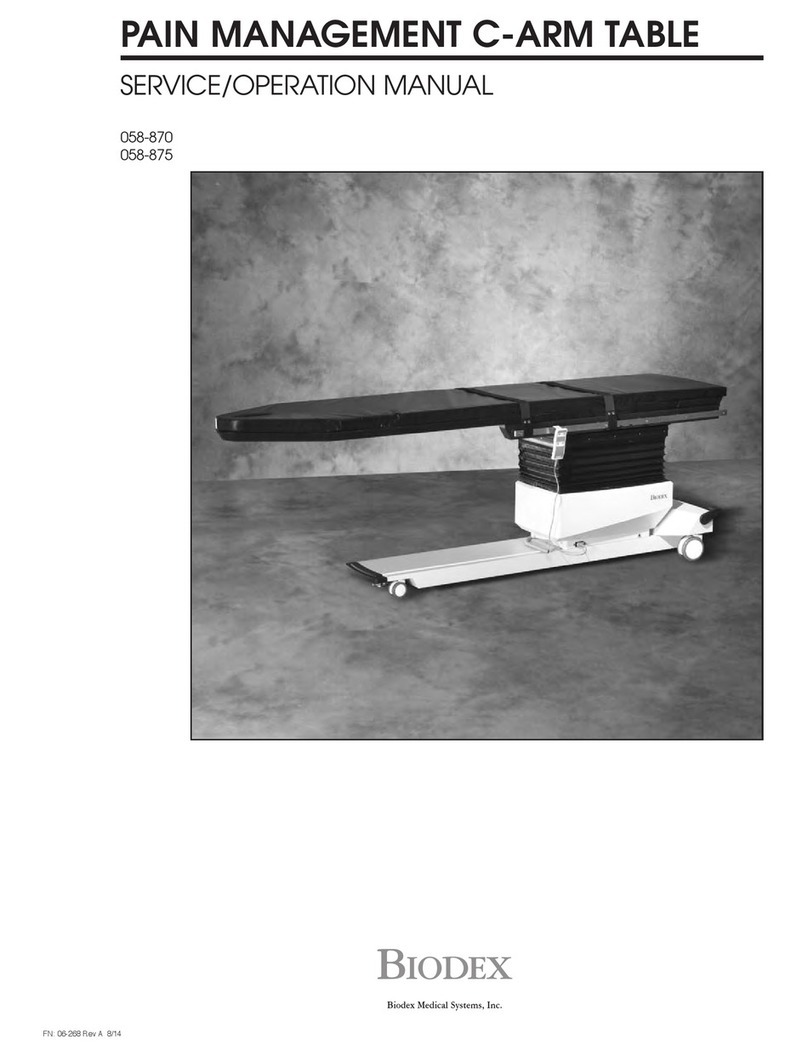

biodex

biodex 058-870 Service & operation manual

Sintesi

Sintesi SAPIENS Assembly instructions

Whale

Whale Bayside CUS7PD-3-BL manual

Furniture of America

Furniture of America CM5011-PCR Assembly instructions

DOM FAMILY

DOM FAMILY TWIN BED Assembly instructions

Next

Next BRONX T90936 Assembly instructions

Paragon

Paragon MAKER INVENT Assembly instructions

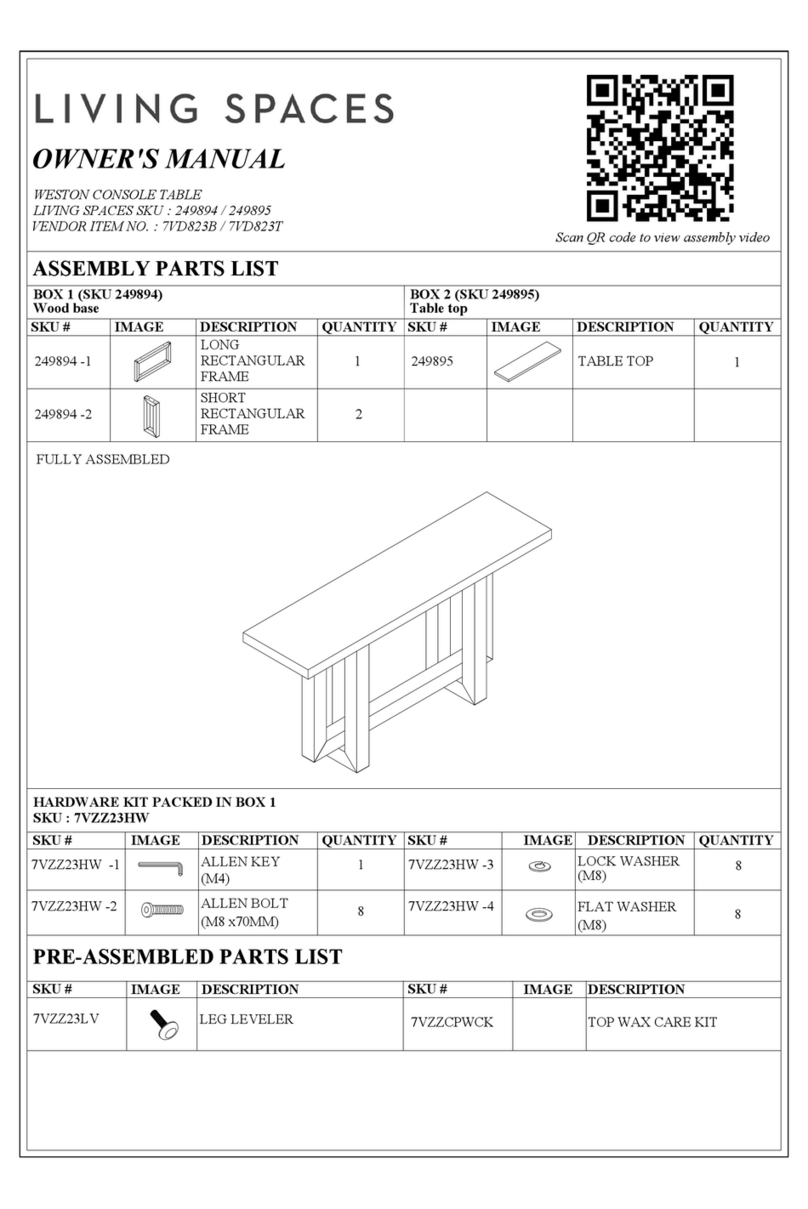

Living Spaces

Living Spaces WESTON 249894 owner's manual

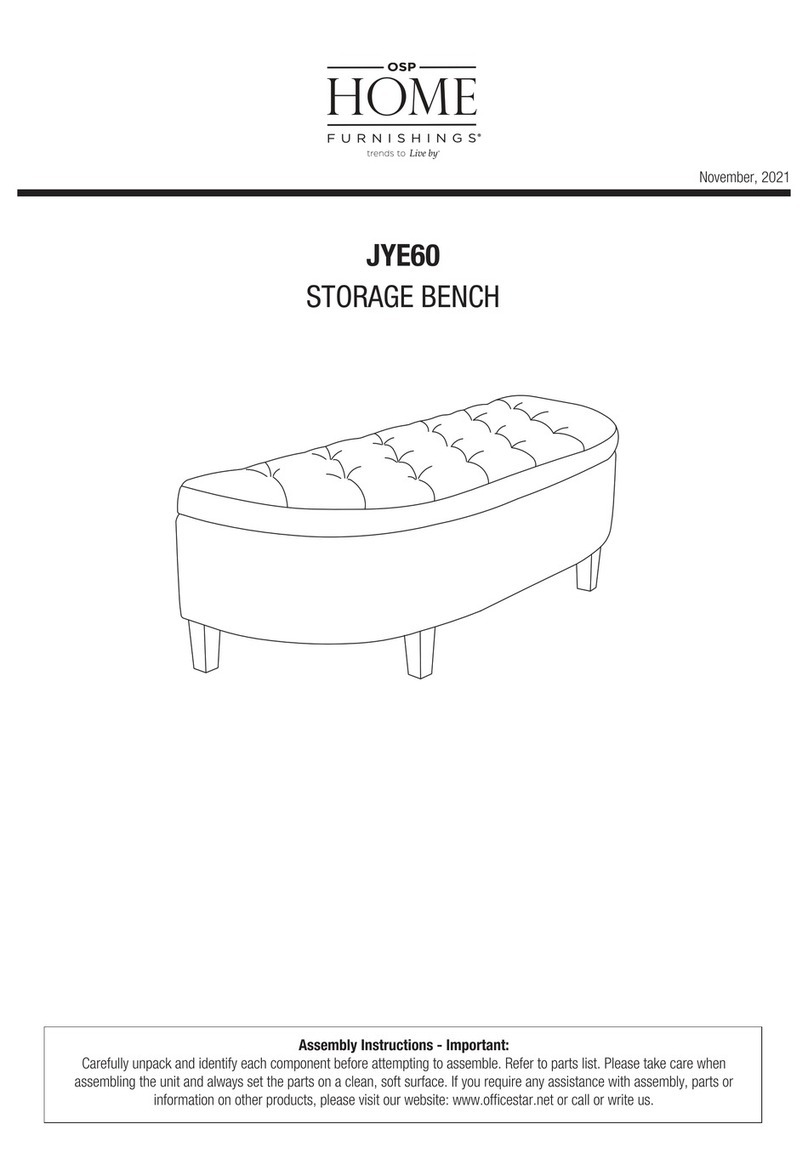

OSP Home Furnishings

OSP Home Furnishings JYE60 Assembly instructions

BOGFRAN

BOGFRAN DELUXE DX2 Assembly instructions