epredia STP120 Manual

1

2

387718 Issue 16

3

Company Information

© Copyright 2022. Epredia. All rights reserved.

Epredia makes every attempt to ensure that the information contained in this supporting

document is correct and clearly stated, but does not accept responsibility for any errors or

omissions. The development of Epredia products and services is an ongoing process.

Please ensure that any published information you use as a reference is up to date and

relates to the condition of the product. If necessary, check with your local Epredia

representative.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated

or converted to any electronic or other form without prior written consent of Epredia. All

information contained in this manual is proprietary and confidential, and the exclusive

property of Epredia and is protected by copyright.

Contact Addresses

Manufacturer:

Shandon Diagnostics Limited, a subsidiary of Epredia

Tudor Road, Manor Park, Runcorn

Cheshire, WA7 1TA, UK

Tel: +44 (0) 1928 534000

Fax: +44 (0) 1928 534001

Web: www.epredia.com

USA Distributor:

Richard-Allan Scientific LLC, a subsidiary of Epredia

4481 Campus Drive

Kalamazoo, MI 49008, USA

Tel: 1-800-522-7270

Fax: +1 269-372-2674

Web: www.epredia.com

These instruments conform to the general safety and

performance of:

In Vitro Diagnostics Regulation (IVDR) EU 2017/746

Medical Devices Regulations 2002 (SI 2002 No 618, as

amended) (UK MDR 2002)

387718 Issue 16

4

Safety Information

Epredia instruments are designed for convenient and reliable service; however, improper

use or handling by a user may damage the instrument or cause a hazard to health. The

instrument must not be used in a manner not specified by Epredia. Correct maintenance

procedures are essential for consistent performance. It is recommended that users secure a

maintenance contract with our service department.

To remain compliant with regulatory requirements, and to ensure that mandatory safety

upgrades are performed at the earliest opportunity, it is strongly recommended that all

service activities are performed by Epredia-factory trained Engineers. Warranty may be

voided if service is performed by non-factory trained Engineers.

Maintenance or repairs that are not performed by Epredia trained Engineers with proven

training may affect the safety, performance and compliance of the equipment.

Please consult your local sales or support teams for more information about service

contracts

The following sections contain important information for the safe setup and use of

the instrument, and should be read and understood by the user before using the

instrument.

General Safety

This instrument, as supplied, conforms to IEC61010-1 and IEC61010-2-101;

however, the addition of chemicals introduces potential hazards. Good Laboratory

Practice must be employed and consideration must be given to the potential for

hazard when dealing with these chemicals.

Do not use this instrument in close proximity to strong electromagnetic radiation as

these may interfere with the proper operation. The electromagnetic environment

should be evaluated prior to operation of the device.

Good Laboratory Practice must be used when handling tissue samples to prevent

cross contamination and infection. The user should complete a risk assessment to

determine any potential hazards related to tissue handling.

•Do not introduce any source of ignition into, or near, the instrument once it has

been loaded with reagents.

•Do not remove any panels or access covers, unless specifically instructed to do

so. The instrument does not have any user serviceable parts. Potentially lethal

voltages are present inside the instrument.

•The instrument must be properly connected to a good earth (ground) via the

Mains input supply and positioned such that it is possible to interrupt the Mains

supply at the source by removing the plug from the socket.

•Use only factory approved accessories or replacement parts with this

instrument.

387718 Issue 16

5

•Only use reagents recommended in the Operator Guide.

•Disconnect the instrument from the mains supply before performing

maintenance.

•Take necessary precautions when handling glass. Wear Personal Protective

Equipment (PPE) if required.

Symbols

The following symbols and conventions may be used throughout this document and on the

instrument:

This symbol is used on the instrument, or in a document, to indicate that

instructions must be followed for safe and correct operation. If this symbol

appears on the instrument, always refer to the operator guide.

This symbol indicates that a surface is hot. If this symbol appears on the

instrument, always refer to the operator guide. Take suitable precautions

This symbol indicates that a surface is hot. If this symbol appears on the

instrument, always refer to the operator guide. Take suitable precautions.

Manufacturer.

This symbol indicates the instrument is an in vitro diagnostic medical device.

This symbol is used on the instrument, or in the document to indicate that

instructions for use must be consulted

387718 Issue 16

6

Chemical Safety

The introduction of chemicals creates potential hazards. Epredia has adopted the following

position with regard to the subject of volatile chemicals used in laboratories:

•Customers using non-specified chemicals in the instrument do so at their

own risk.

•All chemicals recommended by Epredia have auto-ignition temperatures

considerably above any surface temperature that can be reached during a

single fault failure on the instrument.

•The instrument contains no source of ignition in any areas of the instrument

where chemicals are stored, or are likely to leak into in a single fault

condition.

•The operator is fully aware of the contents of the specification documents

detailing the properties of the chemicals they are using.

•

The operator has carried out any legally required assessment of chemicals

used and is using good laboratory practice.

Environment

This instrument is required to comply with the European Union's Waste Electrical and

Electronic Instrument (WEEE) Directive 2012/19/EU. It is marked with the following symbol:

Epredia has contracts with one or more recycling / disposal companies in each EU Member

State, and this product should be disposed of or recycled through them. For further

information contact your Epredia service representative.

387718 Issue 16

7

Warranty Statement

Epredia is proud of their quality, reliability and after-sales services. We continuously strive to

improve our service to our customers.

Please ask your distributor or Epredia representative about service contracts which can help

maintain your instrument in an optimal operating condition.

Warranty provisions necessarily vary to comply with differences in national and regional

legislation. Specific details can be found in the delivery documentation or from your dealer or

representative.

Please note that your warranty may be invalidated if:

•This instrument is modified in any way, or not used as intended by Epredia.

•Accessories and reagents which have not been approved by Epredia are used.

•The instrument is not operated or maintained in accordance with instructions.

•The installation of the instrument was not conducted by a certified Epredia

representative.

Any serious incident that has occurred in relation to the device shall be

reported to the manufacturer and the competent authority of the Member

State in which the user/or the patient is established.

387718 Issue 16

8

Table of Contents

COMPANY INFORMATION .............................................................................................................. 3

SAFETY INFORMATION .................................................................................................................. 4

GENERAL SAFETY ............................................................................................................................ 4

SYMBOLS ........................................................................................................................................ 5

CHEMICAL SAFETY ........................................................................................................................... 6

ENVIRONMENT................................................................................................................................. 6

WARRANTY STATEMENT ................................................................................................................... 7

TABLE OF CONTENTS .................................................................................................................... 8

CHAPTER 1 - INTRODUCTION TO THE EPREDIA TISSUE PROCESSOR STP120...................... 10

INTENDED PURPOSE:...................................................................................................................... 10

DESCRIPTION OF THE EPREDIA TISSUE PROCESSOR STP120 ............................................................ 10

THEORY OF OPERATION ................................................................................................................. 10

Processing – dehydration, clearing and infiltration .................................................................... 10

TECHNICAL SPECIFICATIONS OF THE STP 120 .................................................................................. 11

CHAPTER 2 - REPLACEMENT AND EMPLACEMENT .................................................................. 13

TRANSPORT AND UNPACKING.......................................................................................................... 13

Emplacement........................................................................................................................... 14

Connection .............................................................................................................................. 15

Main Parts of the STP 120 ....................................................................................................... 17

Connection of the Paraffin Baths.............................................................................................. 18

Placement of the baskets......................................................................................................... 19

CHAPTER 3 - CONTROL PANEL................................................................................................... 20

CONTROL PANEL ........................................................................................................................... 20

CHAPTER 4 - PROGRAMMING...................................................................................................... 22

BASKET CYCLE .............................................................................................................................. 22

ENTERING THE PROGRAM ............................................................................................................... 23

STARTING THE PROGRAM ............................................................................................................... 25

DELAYED START............................................................................................................................ 26

STOPPING THE PROGRAM ............................................................................................................... 26

END OF THE PROGRAM ................................................................................................................... 27

TEMPERATURE DISPLAY ................................................................................................................. 27

END OF PROCESS DISPLAY ............................................................................................................. 27

CHAPTER 5 – INSTRUMENT SETUP............................................................................................. 28

SETUP MENU ................................................................................................................................ 28

CHANGING THE LANGUAGE ............................................................................................................. 30

CHANGING THE DATE AND TIME....................................................................................................... 31

WORKING WITH TWO BASKETS ........................................................................................................ 32

POWER FAILURE ............................................................................................................................ 33

EMERGENCY MOVEMENTS .............................................................................................................. 34

387718 Issue 16

9

CHAPTER 6 - MAINTENANCE ....................................................................................................... 35

CLEANING ..................................................................................................................................... 35

CHANGING THE FILTER ................................................................................................................... 36

REPLACING THE BATTERY ............................................................................................................... 37

ALARMS ........................................................................................................................................ 37

RESETTING THE UNIT ..................................................................................................................... 38

APPENDICES ................................................................................................................................. 39

APPENDIX A-REAGENTS................................................................................................................ 39

APPENDIX B-PROGRAM RECORD SHEET......................................................................................... 40

INDEX ............................................................................................................................................. 41

REVISION CONTROL FOR THIS DOCUMENT............................................................................... 42

387718 Issue 16

10

Chapter 1 - Introduction to the Epredia Tissue

Processor STP120

Intended Purpose:

The Epredia STP120 automated tissue processor is an in vitro diagnostic device, designed to

infiltrate tissue specimens with paraffin in medical, pharmaceutical research laboratories

to allow for subsequent examination and diagnosis by a technologist or pathologist. Only

qualified and trained laboratory personnel may operate the STP120.

The instrument may only be operated within the scope of its intended use as described above

and as per the instructions given in this manual.

Any other use of this instrument is considered as an improper action.

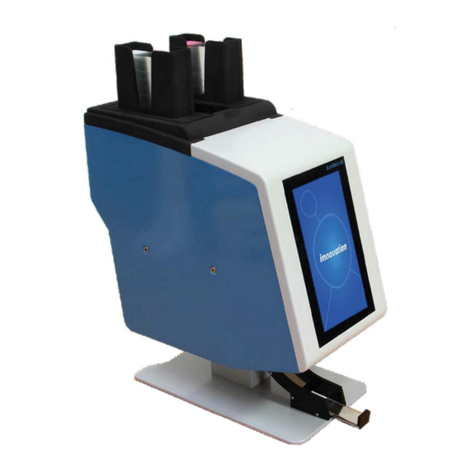

Description of the Epredia Tissue Processor STP120

The STP120 has 12 reagent positions, between which baskets containing tissue samples are

automatically transferred and processed from chemical dehydration to paraffin infiltration.

The instrument is programmable via a membrane keypad and display screen, and can store

up to 10 user configured processing protocols. Variable parameters which can be selected by

the user include; immersion time, reagent temperature and agitation.

The STP120 reduces carryover between reagent positions through centrifugal spinning of the

tissue basket above the last used reagent position.

Theory of Operation

Processing – dehydration, clearing and infiltration

The Epredia STP120 rotary movement transports tissue specimens through a sequence of

reagents to complete the process of removing water from the tissue and replacing it with

paraffin.

Samples are first transferred through progressively more concentrated dehydrants, such as

Ethanol, to remove the water. This is followed by a hydrophobic clearing agent (such as

xylene) to remove the alcohol, and finally molten paraffin which can then infiltrate the cleared

tissue.

387718 Issue 16

11

Technical Specifications of the STP 120

Sizes

Diameter of the carousel 850 mm

Height 500 – 700 mm

Diameter of the turning circle 670 mm

Weight

Including packing

145 kg

Net (fully equipped)

70 kg

Electrical installation

Rated Voltage (±10%) 100-120 V~, 50/60 Hz, 1.7A

220-240 V~, 50/60 Hz, 0.9 A

Fuses 110-120 V: (2 x T4AH 250V)

220-240 V: (2 x T2AH 150V)

Battery

Nickel-Cadmium (12V 600 mA)

Overvoltage category 2

Pollution degree II

Sound pressure < 70 dBA

Capacity

Reagent stations

Number of reagent vessels

10 (9, if 3 are for paraffin.)

Volume per reagent vessel

1.8 L

Baskets for the specimen holders

Number of baskets

1 (option of 2)

Basket capacity

120 specimen holders

Paraffin stations

Number 2 (option of 3)

Volume 1.8 L

Rated Voltage 24 V ~

Rated power per station 100 VA

Temperature range 50 – 70 °C

Hysteresis margin 0.1 – 2 °C

Temperature cut-off

80 °C (± 4 °C)

Thermal protection

Manual reset

387718 Issue 16

12

Programming

Number of programs 10 (selectable)

Programmable infiltration time per

station

from 1 s to 90 h 59 m

Rotation stirring selectable

Vertical shake selectable

Centrifugation

selectable

Centrifugation time selectable

Program start delay selectable without time limit

Environmental conditions

at a max. rel. humidity of 60% without condensation

Temperatures

from + 5 to + 40 °C

Storage temperature range from –20 °C to +50°C

Altitude up to 2000 m M.S.L.

Floor loading requirements

160,0 kg /m

2

For indoor use only

387718 Issue 16

13

Chapter 2 - Replacement and Emplacement

Transport and Unpacking

During transportation the STP 120 should always be kept in an upright position.

Inspect the packaging and the STP 120. If either is damaged or the contents do not match

the supplied packing list, inform your local Epredia representative.

Remove any support or brace holding the machine inside the packing box.

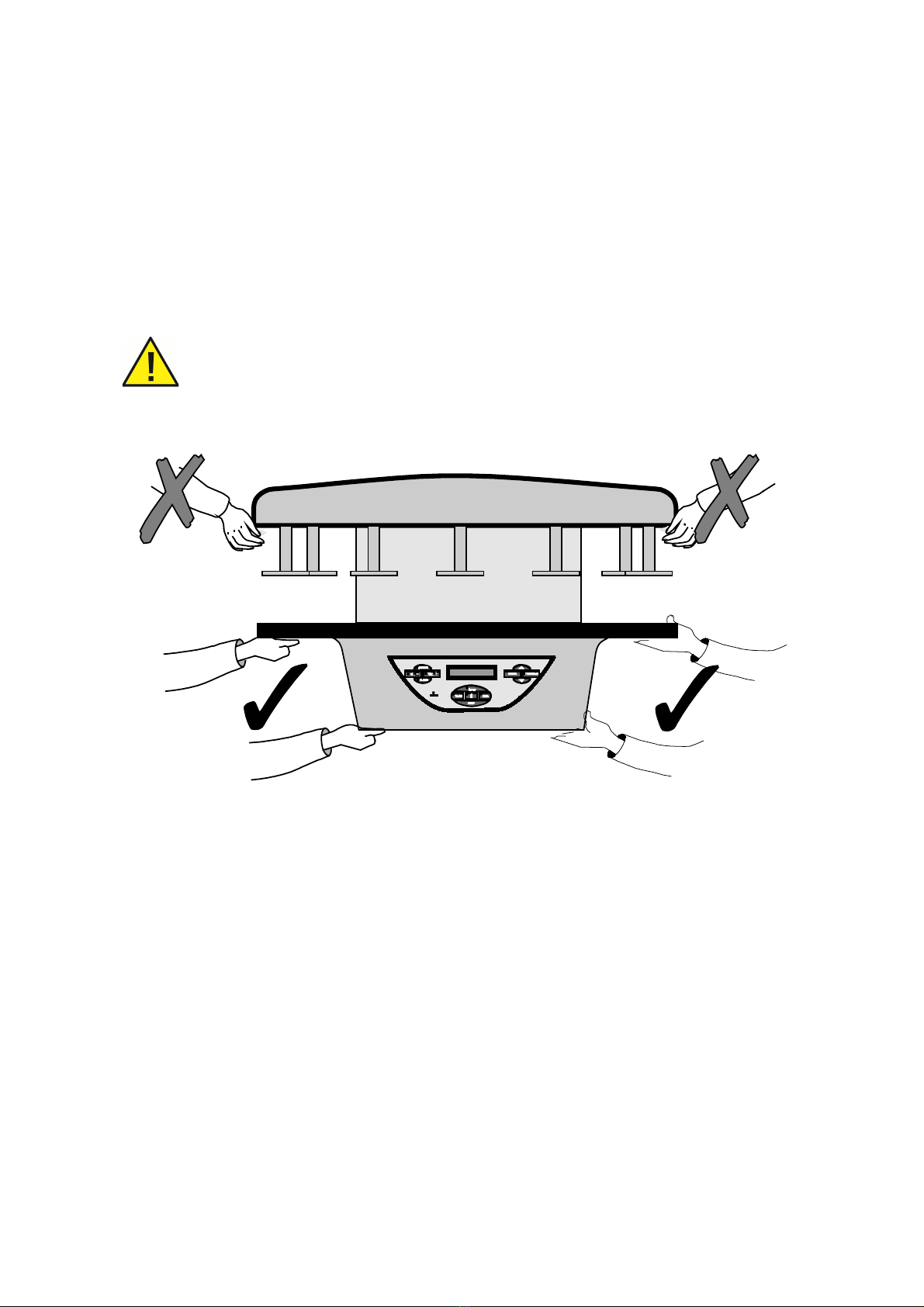

Use safe lifting practices when moving the STP 120. At least two people

are required to move the STP 120. Take care to always hold the STP 120

as shown in fig 1. Never list the STP 120 by the upper cover or the

carousel as this will cause irrepairable damage to the unit.

Fig 1 – Correct Handling of the STP 120

387718 Issue 16

14

Emplacement

Choose a suitable flat surface measuring at least 900 mm in width x 900 m depth with 750

mm of headroom.

It is absolutely necessary that the emplacement of the STP 120 has at

least 750 mm of free headroom otherwise the carousel will be irrepairably

damaged when it opens.

Make sure that:

•The surface is perfectly smooth, flat and stable.

•The site is well ventilated.

•There is sufficient surrounding space to allow easy access while safely supporting

the weight of the machine.

When selecting the emplacement for the machine, remember that the

Main ON/OFF switch is located at the rear and that it must be accessible

at all times

Manual Rotation of the Whole Unit

Apart from the automatic rotating system for the processor cover, the base of the unit is also

fitted with wheels. This enables the whole unit to be turned by hand to enable easy access to

all the reagent vessels and paraffin baths should it be placed close against a wall.

Never turn the unit holding it by the cover.

Before turning the unit, hold it by the reagent vessel support table and proceed as follows:

Use the ↑↓ button, to raise the carousel cover to its uppermost position.

Turn off the unit at the Main ON/OFF switch and unplug the power supply cable (see

next page). This will enable the unit to be turned on its axis without any risk of

damaging the power cable.

387718 Issue 16

15

Connection

The electronic unit of the STP120 is suitably protected and adequately shielded according to

EC Standards on emission and reception of interference. Nevertheless, the unit should not

be installed close to other high power equipment that could generate vibrations or strong

electrical interference.

The STP120 is supplied with a power cable for connection to a standard outlet with earth.

The electrical connection is located at the rear.

Before connecting the power cable, make sure that the STP120 is

adjusted to operate at the supply voltage

Do not replace the detachable mains supply cord with and inadequately rated mains supply

cord.

Initial Turn-On

Before assembling the baths, start the unit to raise the carousel.

Never attempt to turn, raise or lower the carrousel cover by hand or force

it in any way!

Always use the keys on the control panel to make any manual

movements and keep hands away from any moving parts.

Connect the power supply cable and start the STP 120 using the stop-start switch located at

the rear of the unit, above the plug for the power supply cable.

When the power is connected, the STP 120 automatically begins a machine test cycle and

the fume exhaust fan will being operating.

This message appears on the display

(V1.XX indicates the software version).

SPIN TISSUE

PROCESSOR V1.XX

This is followed by:

FILTER CHANGE XXXX HOURS (Refer

to 'Changing the Filter), and then:

C10 C11 C12

16º 16º 16°

This indicates the temperature of the

paraffin baths.

Note

These messages may appear in a language other than your own. If you want to change the

language now, refer to section Changing the Language. Furthermore, the date and time

perhaps do not coincide with those in your country. If you want to adjust the time, refer to

chapter Changing the Date and Time section.

387718 Issue 16

16

The display indicates (in the pre-set

language), a message like the one shown

here.

01/01

READY

12:50

Press the ↑ ↓ button once. Note that the

carousel opens to a half-way position and

the basket holder begins to turn.

When the carousel stops opening, press

the ↑ ↓ key once again to continue

opening the basket holder as far as

possible. The screen will display the

message indicating 'Take sample' and the

reagent vessel located at 'C01'.

TAKE SAMPLE

C 011

If the basket holder is not physically in the position of reagent vessel 1, press the key ↑ ↓

repeatedly to advance the basket to the position of reagent vessel No 1. Disconnect the unit

from the power supply.

Now you can place the reagent vessels and paraffin baths in position.

Connect the paraffin baths.

Before connecting or disconnecting the paraffin baths, make sure that

the unit is disconnected from the power supply by turning off the main

switch located at the rear of the unit.

Now you can turn the unit on again.

387718 Issue 16

17

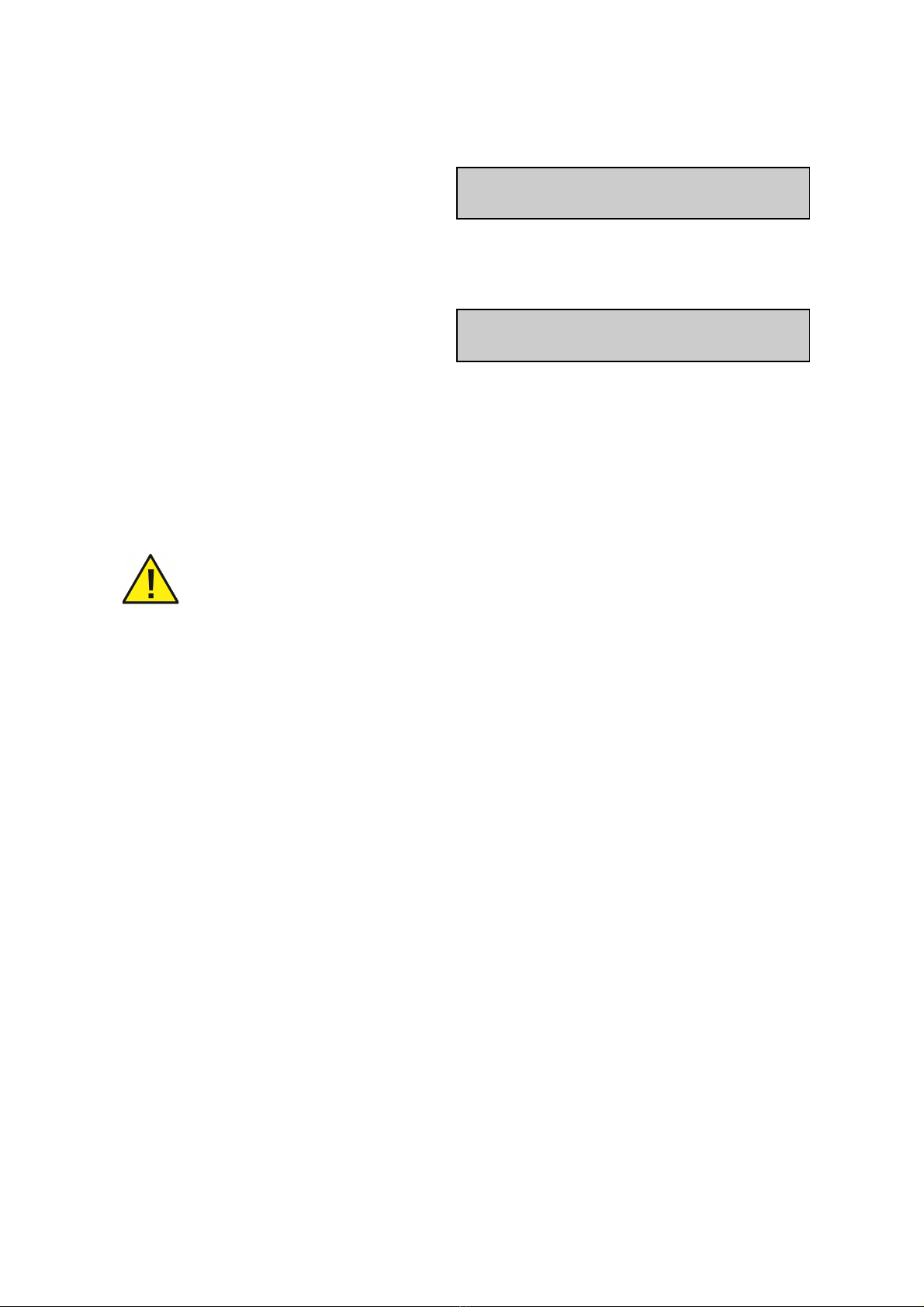

Main Parts of the STP 120

Fig 2 – Main Parts of the STP 120

The model shown in the figure 2 corresponds to the version with two basket holders, three

paraffin baths and reagent vessels.

Fig 3

Under no circumstances should the maximum fill level be exceeded as

the process will not be performed correctly and reagent or paraffin could

be spilled.

387718 Issue 16

18

Connection of the Paraffin Baths

The paraffin baths are connected from the rear of the STP 120.

Before connecting or disconnecting the paraffin baths, make sure that

the STP 120 is disconnected from the power supply by turning off the

main switch located at the rear of the unit.

Always use the following connections:

•The connection marked with the

number 10 only if a third paraffin

bath has been installed in position

10.

•The connection marked with the

number 11 only if the paraffin bath

has been installed in position 11.

•The connection marked with the

number 12 only if the paraffin bath

has been installed in position 12.

Note

The grooves in the edge of the processor table to allow connection of the cables to the

paraffin baths.

387718 Issue 16

19

Placement of the baskets

The baskets are held in position by a four

point bayonet connector.

When fitting the baskets, make sure that the

four studs fit into the four grooves on the edge;

turn the basket as far as possible inside the

groove and allow it to rest on the pivots of the

basket holder (see picture on the right).

Before beginning to process tissues, you should become familiar with the handling and

programming of the STP120. Design a small test program and perform some manual

movements without any reagents in the vessels or samples in the baskets.

387718 Issue 16

20

Chapter 3 - Control Panel

Control Panel

The control panel at the front of the STP 120 contains all the keys required for handling and

programing. Activate the keys by pressing in the centre of the corresponding icon or

indicator. Do not use sharp objects as they could damage the keyboard.

The actions of the keys:

SHAKE

Vertical shake. Pressing this

key lights the indicator light

and activates the SHAKE

function. This function enables

vertical shaking of the basket

during the stirring process

(refer to Basket Cycle).

START

Key to start the automatic operating

cycle (program). When the STP 120 is

operating in automatic mode, the pilot

beside the key is lit.

UP

When adjusting values it increases

the value displayed, or goes back

to the previous option

←

Press this key to make the

machine perform a partial

rotation, moving the basket

holder to the next station. This

is only possible when the

basket holder is in the upper

position.

STOP

Key to stop the automatic operating

cycle. If this key is pressed the STP

120 indicates for confirmation of

whether the process is to be aborted.

Once the stop is confirmed, the

program is cancelled and the STP 120

must be controlled in manual mode

using the keys ↑↓ and ← to place the

basket holder above the first reagent

vessel. The STOP key also halts any

movement of the machine at any time.

DOWN

When adjusting values it

decreases the value displayed, or

goes to the next option.

↑↓

These keys raise and lower

the basket holder, as required.

If pressed when the basket

holder is moving, it will reverse

the direction. The STOP key

stops all movement

TIMER

Allows delaying the start. Refer to

Delayed Start. When the TIMER is

active the display appears as dimmed

the pilot light of the key is lit

PROGRAM

Use this key to access the mode

for editing programs or making

adjustments.

POWER

The LED lights up to indicate

that the unit is connected to

the power supply.

A flashing LED indicates that

the unit is operating on the

emergency battery (for more

information refer to section

Power Failure).

LOCK

Pressing this key blocks all the keys

on the control panel (to prevent

accidental operation). Restore the key

actions by holding down this key for

more than two seconds.

ENTER

Validates the option or

adjustments made.

x2

This key should always be pressed

when the STP 120 is fitted with a

double basket holder (optional

accessory). For more information,

refer to section Working with two

baskets.

For more information, refer to

Chapter 4 – Programming.

Before executing the first real process with reagents and paraffin,

remember that paraffin can sometimes take a long time to melt. After a

long period of disconnection (for example the first start or after power

This manual suits for next models

3

Table of contents

Other epredia Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual