Nipro RO medical User manual

Operator´s Manual

RO MEDICAL

Description: NRO-MED-IFU-1001

Date: 06.10.2021 | Version: 12

Written by: Nipro Pure Water

Version 12| 06.10.2021 | Page 3

Table of Contents

1 General .............................................................................................. 6

1.1 Scope of supply ................................................................................... 6

1.2 Unit combinations ................................................................................ 6

1.3 Notes for the Operator.......................................................................... 6

1.4 Laws and Standards ............................................................................. 6

1.5 Symbols used in this Manual ................................................................. 7

1.6 Transport and Storage .......................................................................... 7

1.7 Model Plate ......................................................................................... 8

1.8 Warning on the Unit. ............................................................................ 8

1.9 Shutdown ........................................................................................... 8

1.10 Disposal.............................................................................................. 9

1.11 Instruction / Further Documentation ...................................................... 9

1.12 Duration of usage ................................................................................ 9

2 Intended operation ............................................................................. 10

2.1 Contraindications / side effects ............................................................. 11

3 Safety ............................................................................................... 11

3.1 Risk Assessment ................................................................................. 11

3.2 EMC .................................................................................................. 11

3.3 Emissions .......................................................................................... 11

4 Technical Data .................................................................................... 12

5 Description of the device ..................................................................... 13

5.1 Flow-Chart ......................................................................................... 13

5.2 Functional sequence ............................................................................ 14

5.3 Safety devices / Components ............................................................... 15

6 Installation......................................................................................... 16

6.1 Environmental Condition ...................................................................... 16

6.2 Assembly ........................................................................................... 16

6.3 Electrical installation ........................................................................... 17

6.4 Prefiltration (Example) ........................................................................ 18

6.5 Commissioning ................................................................................... 19

6.6 Initial commissioning ........................................................................... 20

7 Operation .......................................................................................... 21

7.1 Control Panel ..................................................................................... 21

7.2 System on / off without permeate tank .................................................. 22

Version 12| 06.10.2021 | Page 4

7.3 Device on / off with permeate tank ....................................................... 23

7.4 Emergency operation .......................................................................... 24

7.5 Operating displays .............................................................................. 25

8 Error messages / troubleshooting ......................................................... 26

8.1 Error messages .................................................................................. 26

8.2 Clear alarms....................................................................................... 26

9 Maintenance and cleaning .................................................................... 27

9.1 External Cleaning ................................................................................ 27

9.2 Maintenance Intervals ......................................................................... 28

9.3 Chemical Disinfection .......................................................................... 29

9.4 Microbiological Inspection .................................................................... 30

10 Display / Parameter ............................................................................ 31

10.1 Retrieval of the operating hours / conductivities ..................................... 31

10.2 Change the conductivity parameter ....................................................... 32

10.3 Change parameter temperature ............................................................ 33

Technical appendix ........................................................................................ 34

11 Replacement of the reverse osmosis membrane ..................................... 35

12 Service Parameters ............................................................................. 36

12.1 Adjustment of the conductivity ............................................................. 37

12.2 Setting date and time .......................................................................... 37

12.3 Summer / winter time ......................................................................... 37

12.4 Auto Start (Timer) .............................................................................. 38

12.5 Service point ...................................................................................... 39

13 Disinfection ........................................................................................ 40

13.1 Disinfection Protocol ............................................................................ 43

14 EMC manufacturer's declaration ............................................................ 44

Version 12| 06.10.2021 | Page 5

Foreword

This Operator’s Manual includes all information required for the installation and operation for the

reverse osmosis model RO medical.

Please keep this Operator’s Manual readily available and near the unit.

This Operator’s Manual applies for the units with the serial number:

© Copyright 2021

Nipro Pure Water GmbH

Werner-von-Siemens-Str.2-6

76646 Bruchsal –

Tel.: 0049 7251-32 19 7810

Rev# Date / Name Description

1 16.05.11 / N.Bürkle First edition

2 07.07.11 / N.Bürkle Disposal added

3 31.08.11 / N.Bürkle Disinfection added

4 28.02.12 / N.Bürkle Limit values added

5 28.02.14 / N.Bürkle Company name

6 20.12.19 / N.Bürkle New Design / EMC

7 10.01.20 / N.Bürkle Air pressure added

8 29.06.20 / N.Bürkle Changes accord. EN 60601

9 29.06.20 / N.Bürkle LOGO Control

10 24.02.21 / T. Barretto Cosmetic corrections

11 03.03.21/ R.Tille Water pressure input

12 06.10.21/G.Biscardi Information Service point

For the reverse osmosis type RO medical, conformity according to

EC directives is declared

0297

Version 12| 06.10.2021 | Page 6

1 General

1.1 Scope of supply

The scope of delivery includes the following parts:

1 reverse osmosis

1 connection set

1.2 Unit combinations

The unit model RO may be combined with the following devices:

* Permeate tank

* City water tank

1.3 Notes for the Operator

The operator is responsible for:

Competent and intended operation

Compliance with work safety and accident prevention provisions

Technical instruction of operating personnel

1.4 Laws and Standards

The following laws and standards are adhered to:

Council Directive 93/42 EEC Medical Devices

EN 60601

DIN EN 1717 Protection of potable water against contamination

Version 12| 06.10.2021 | Page 7

1.5 Symbols used in this Manual

Stands for a dangerous situation. Disregard can result in personal injury or

material damage.

Stands for information and valuable tips.

1.6 Transport and Storage

Protect unit against frost and moisture

Protect against strong jolting and collisions.

Only move unit upright and with an appropriate lift.

The system may be stored for a maximum of 1 year.

Version 12| 06.10.2021 | Page 8

1.7 Model Plate

1.8 Warning on the Unit.

Caution voltage. Turn mains switch off before opening housing. Fixed on

control cabinet.

1.9 Shutdown

If a unit is shutdown for more than 5 days, conservation will be necessary.

Please contact Nipro Pure Water before performing conservation.

Attention, take note of

accompanying documents

CE mark with the number of

the notified body. Here DQS

IPX 4

Protection against the

ingress of liquids. Here

splash-water protection

Protection Scheme according

to EN 1717. Here free outlet

Serial number

Year of construction

Manufacturer

Pay attention to manual

Version 12| 06.10.2021 | Page 9

1.10 Disposal

Regarding the WEEE guidelines of the European Union, the disposal of electronic devices and

electronic sub-assemblies and parts into the general garbage is not lawful. These parts must be

disposed environmentally appropriate:

If not appointed otherwise and no private disposal management is available, these devices or

possibly other environmental hazardous items can be sent back.

The filters and membrane can be disposed via the general garbage

1.11 Instruction / Further Documentation

The using personnel must be warned against the hazards during operation and must be warned

against the hazards of misusing the product.

The personnel gets the instruction of operation and the specialties of usage. Instructed adult only

are allowed to operate this device.

This instruction by the manufacturer or authorized personnel takes place during the

commissioning of the device.

Further trainings are not necessary for this device.

For qualified personnel the following documents can be made available upon request.

Circuit diagrams

Spare parts list

1.12 Duration of usage

The device is designed for a use of 10 years

Version 12| 06.10.2021 | Page 10

2 Intended operation

The unit is designed for the treatment of potable water. The pure water (permeate) thus

produced may be used for dialysis treatment.

Other applications are only possible after consulting the manufacturer and receiving their

approval.

The unit can only be maintained by the manufacturer or technicians trained by

the manufacturer.

Only original replacement parts may be used for maintenance and repairs.

Installation operations, modifications or reparations, are only allowed to be

performed by persons authorised by the manufacturer and may only be done with

original replacement parts. Improper performed reparations or modifications can

lead to hazards to the user and/or may damage the device.

The device may only be operated in perfect condition.

Before operating, check the following:

Lose or defect parts

Defect cables and/or isolations

Serious soiling

The device may only be operated with the appropriate ring line.

The device does not produce water for injections.

The device has pressurized parts.

If the temperature sensor fails, the temperature in the permeate can increase.

(Max 60°C)

The water treatment system RO medical may only be used for permeate supply

of dialysis devices, which have a temperature measurement (permeate

temperature).

The device has no direct patient contact and no patient application part.

Version 12| 06.10.2021 | Page 11

2.1 Contraindications / side effects

None

3 Safety

3.1 Risk Assessment

There will be no dangers associated with the reverse osmosis model RO medical D if the

operating instructions are followed.

The device can automatically start by way of an auto-start.

3.2 EMC

The device was developed and tested in accordance with current standards. Nevertheless,

influence through electromagnetic fields cannot be completely excluded.

3.3 Emissions

The device does not produce dust or vibrations.

The noise level is under 609 dB (A).

Version 12| 06.10.2021 | Page 12

4 Technical Data

Permeate performance

Temperature

1 Membrane

2 Membranes

3 Membranes

4 Membranes

15° C

350 l/h

700 l/h

1050 l/h

1400 l/h

Inlet water

Quality

Potable Water

Hardness

< 1 °dH

Silicate

< 25 mg/l

Chlorine

< 0,1 ppm (mg/l)

Iron

< 0,1 ppm (mg/l)

Fouling Index (S.D.I)

< 3

Temperature

5

-

25

°C

Pressure

1

-

3 bar

Connections

Water feed

1”

internal thread

Pure water connection

Hose nozzle d20

Drain

HT 4

0

Electrical data

Supply voltage

220

-

23

0

V,

1

Phase,

50

/60

Hz

Fuse

Automat 16 A

-

K

,

Fi ΔI 30mA

Current consumption

9

,

9

A

x 60 Hz

Degree of pollution

1

Ambient temperature

Storage / transport

3

-

40°C

Operation

10

-

35°C

Air pressure

795

-

1062 hPa

Display system

Conductivity

0

-

1000 µS/cm ±5%

pressure switch 0-10 bar ±5%

Flow (sight glass) 300-3000 l/h ±5%

100

-

1000 l/h

Size

RO Medical

1000x500x1

64

0

Version 12| 06.10.2021 | Page 13

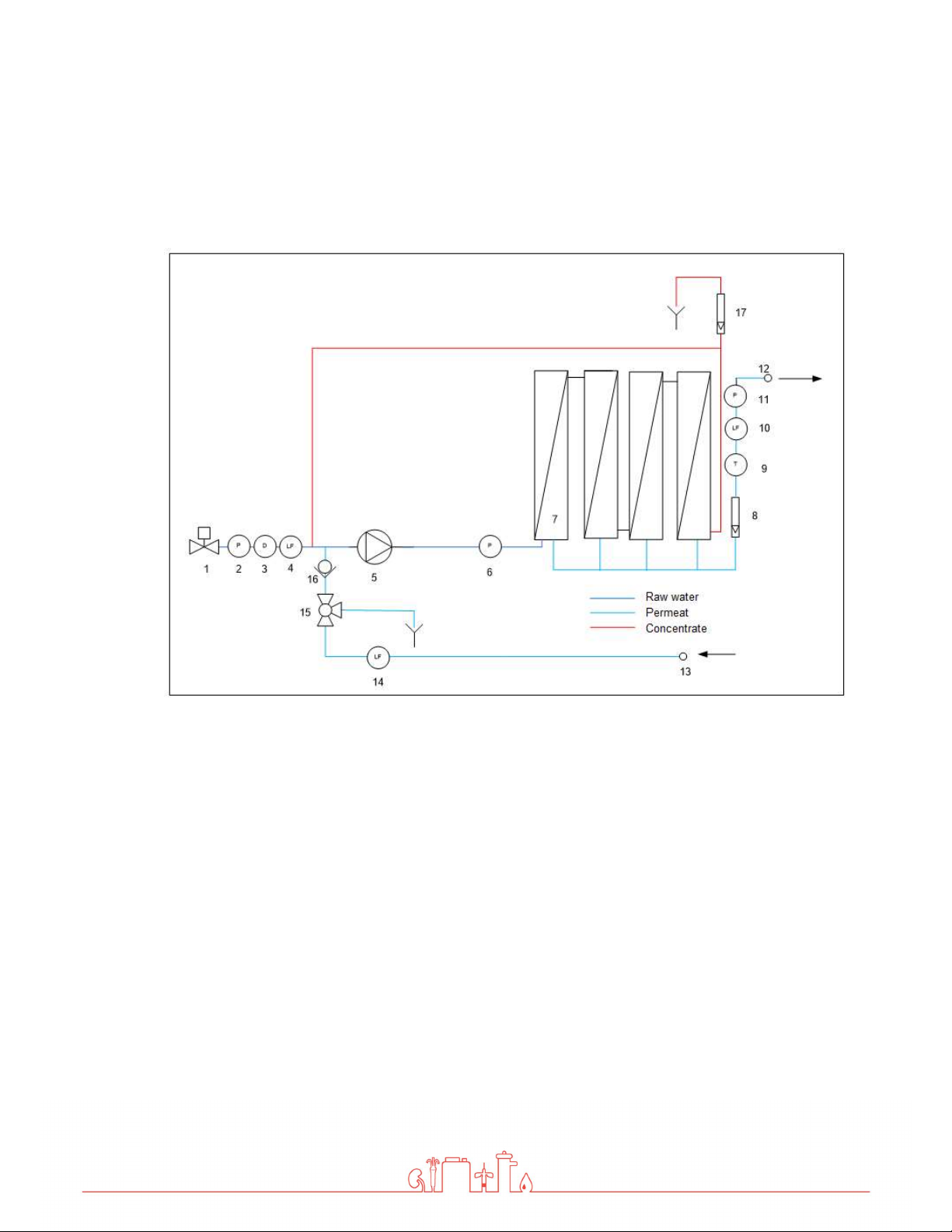

5 Description of the device

5.1 Flow-Chart

1. Magnetic valve inlet

2. Pressure switch input

3. Disinfection point

4. Conductivity input

5. Pump (pressure 10-13bar)

6. Manometer (pressure 10-13 bar)

7. Reverse osmosis membrane (1-4

pieces)

8. Permeate flow rate indicator

9. Temperature sensor

10. Conductivity probe permeate flow

11. Permeate pressure switch

12. Connection back flow hose nozzle d20

13. Connection back flow hose nozzle d20

14. Conductivity ring back flow

15. Discard three-way ball valve permeate

16. Check valve

17. Flow indicator concentrate outflow

Version 12| 06.10.2021 | Page 14

5.2 Functional sequence

If the toggle switch is turned to the ‘On‘ position, the magnetic valve (1) opens and water flows

into the system. After a short delay, the pump (4) will start.

Now the water is pressed into the reverse osmosis membrane at a pressure of 10-15 bar. The

flow is divided into a permeate and a concentrate part. The permeate content flows through the

flow indicator (7), the temperature sensor (8), the conductivity probe (9) and the pressure switch

(10) into the ring line. The unused permeate flows back into the RO medical via the connection

(12).

To save water, the concentrate portion is divided up again, one portion is given into the drain via

the flow indicator (17), the other is fed back in front of the pump.

Version 12| 06.10.2021 | Page 15

5.3 Safety devices / Components

Pressure switch

Magnetic valve

Inlet

Conductivity Probe

Inlet

Pressure pump

Manometer

Pump pressure

Main switch

Emergency

Mode switch

Fault signal lamp

Display

Disinfection port

Flow Display

Permeat

Flow Display

Concentrate

Pressure tube with

membrane

Permeat Flow

Connection

Raw water

connection

Turn on key

Pressure Switch

Inlet

Service Point

Version 12| 06.10.2021 | Page 16

6 Installation

The installation must be conducted by the manufacturer or by personnel trained

and authorized by the manufacturer.

6.1 Environmental Condition

Conditions for the osmosis room:

Relative air moisture < 90% at 20°C

Room temperature between +10°C and +35°C (frost proof)

Equipped with floor drain, water supply and electrical supply

6.2 Assembly

Bring the device into the appropriate position

Adjust machine feet until the device stands level and secure on the floor.

Do not store easily flammable materials in the vicinity of the device.

Do not store chemicals in the vicinity of the device.

Only operate the device with the necessary water pre-treatment.

Room of osmosis may not be freely accessible. (Access for instructed personnel

only)

Version 12| 06.10.2021 | Page 17

6.3 Electrical installation

The installation may only be performed by a qualified electrician.

The device must be supplied by a permanent connection, connectors are not

valid. The disconnection via the main switch at the control cabinet. The power

cord must be provided with a strain relief.

Connection cable RO Medical

For protection against a re-start of the unit, the main switch

can be locked with a padlock.

Safety class I

The device is equipped with a Protective earth terminal for

prevention against high touch current

For prevention of the hazard of an electric shock, this device

may only be connected to a power supply with protective

earth.

The power cord is fixed to the device and cannot be replaced.

Version 12| 06.10.2021 | Page 18

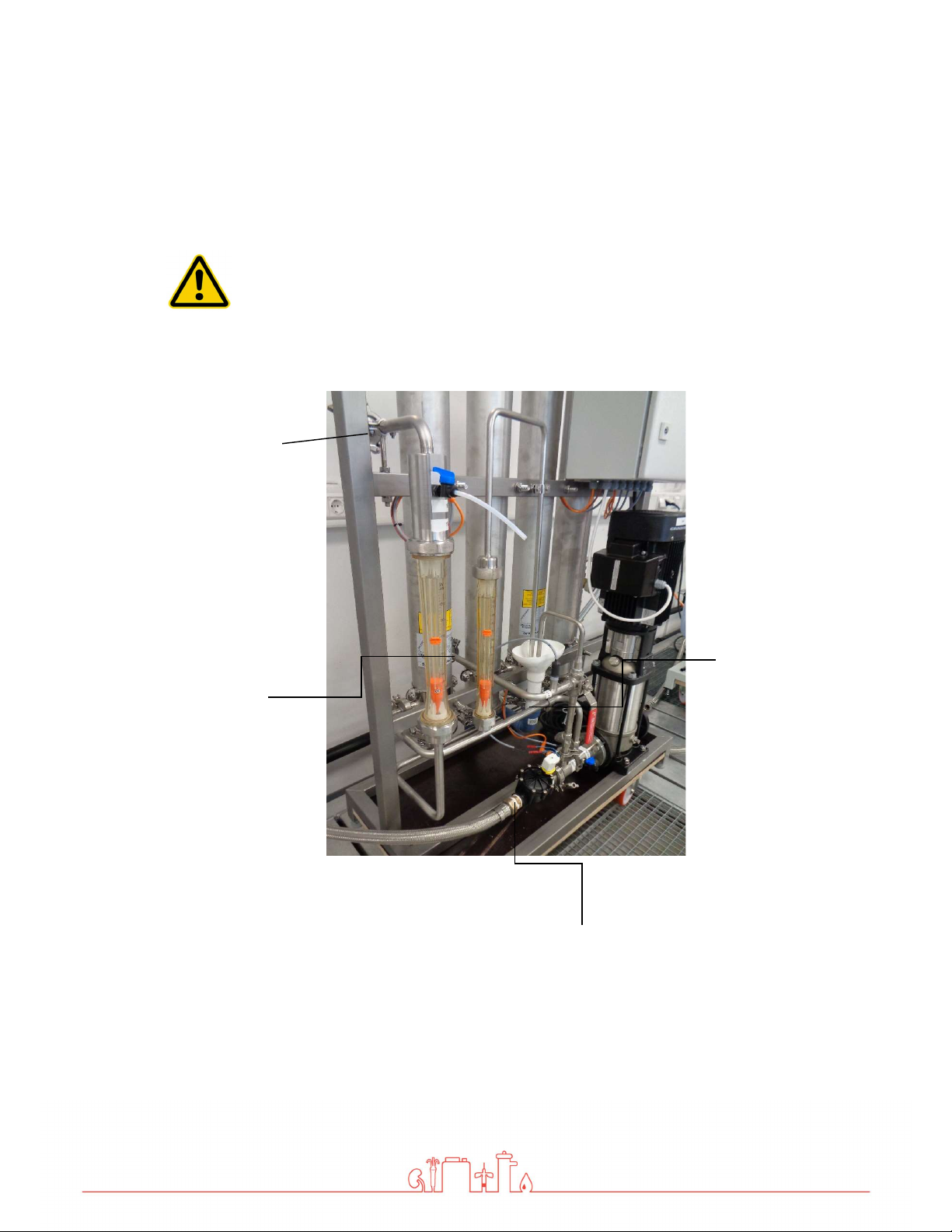

6.4 Prefiltration (Example)

Install the necessary water pre-treatment equipment first!

Only then connect the RO medical and start up

Local water works regulations and DIN EN 1717 must be followed.

The water pre-treatment must be adapted to the local potable water quality.

Version 12| 06.10.2021 | Page 19

6.5 Commissioning

Caution, device damage!

The device must be preconnected by a suitable pre-

filter and a softening system

as well as a pressure reducer.

Permeat Flow Connection (2)

Hose nozzle d20

Raw water connection (1)

1“ Internal thread

Drain water

connection (4)

HT 40

Permeat back flow (3)

Hose nozzle d20

Version 12| 06.10.2021 | Page 20

6.6 Initial commissioning

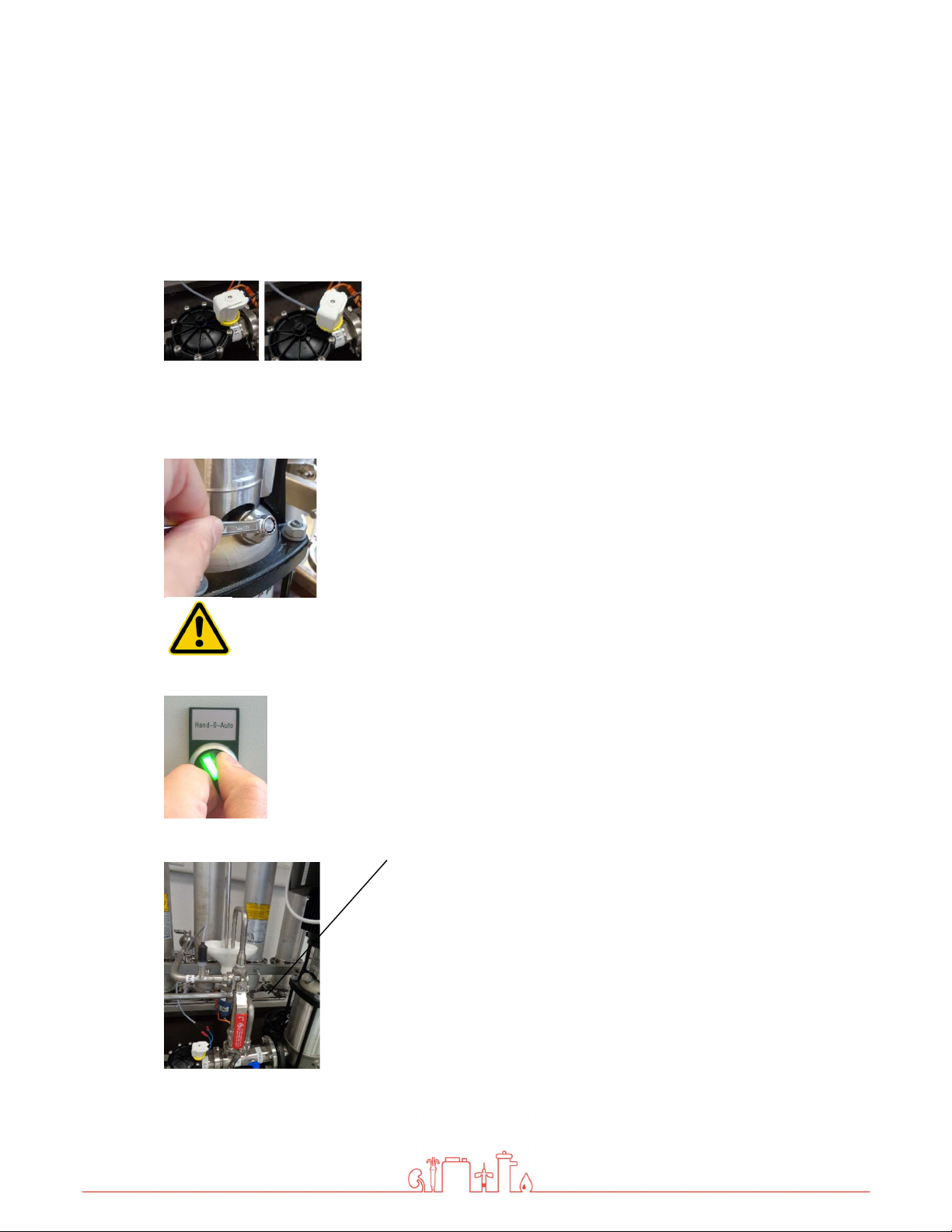

1. Connect and check the raw water connection (1),

permeate flow (2), permeate back flow (3) and waste

water (4)

2. Open the inlet valve manually. To do this, turn the white

magnet coil 45° counter clockwise.

Now water is running into

the device

.

3. Carefully open the screw for the pump venting until a

water outlet can be seen.

Then close the screw again and

reset the solenoid.

4. Make sure that the wall-mounted taps at the start and end

of the ring are open.

5.

6.

Start the device using the toggle switch.

Check all connections for leaks.

7.

8.

Open the three-way valve permeate to the drain.

Allow the device to discard permeate for at least 30

minutes.

Table of contents

Other Nipro Medical Equipment manuals