6

Correct Use of a CyClean System

Meech CyClean web cleaning systems should only be used in installations for which they are designed.

If the CyClean is used in any other way than instructed in this manual, it will be considered as improper use.

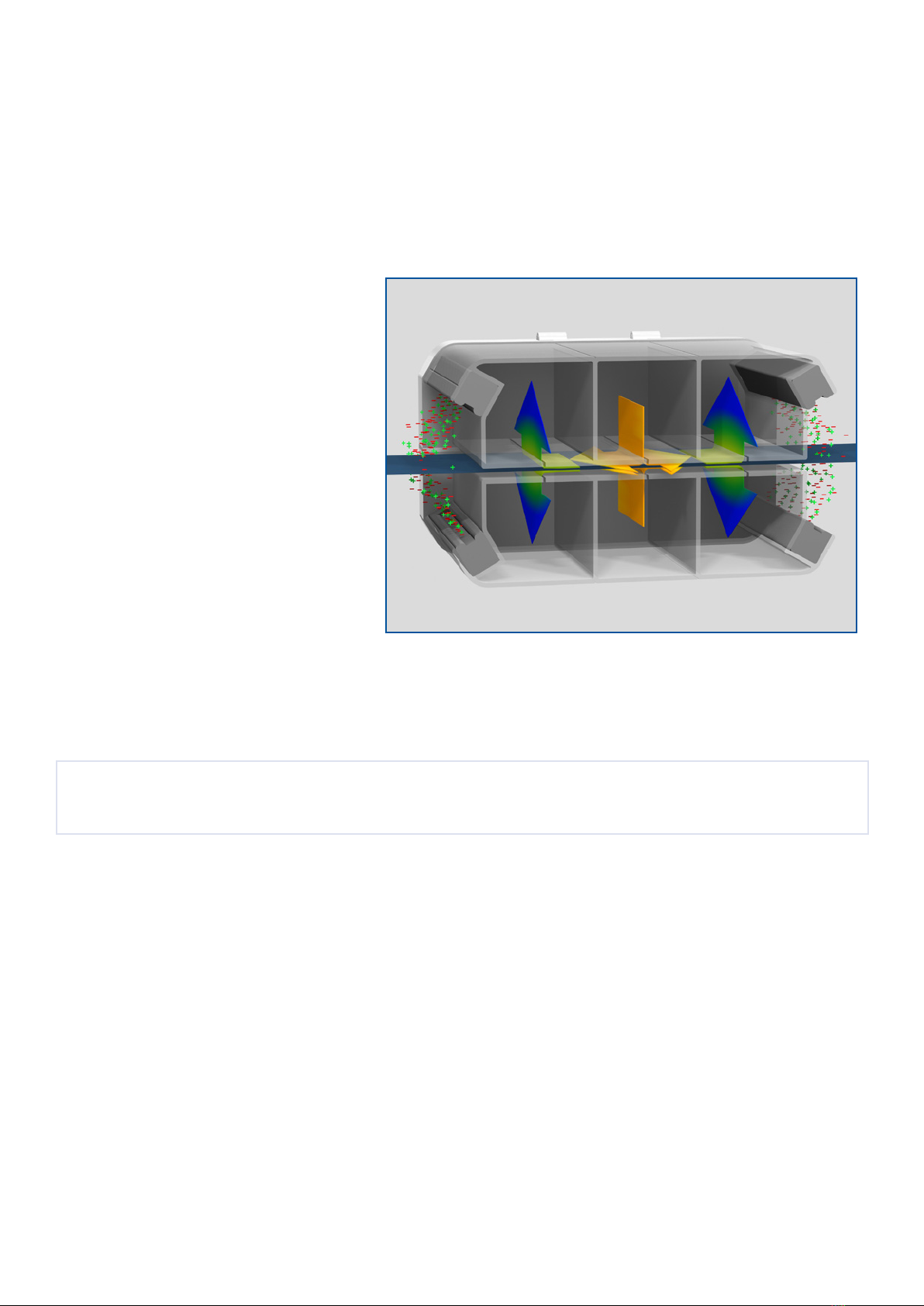

How CyClean Works

The excellent cleaning performance of CyClean is achieved from the combination of the following processes.

The web passes through a cloud of ionisation on entry to the CyClean head, which neutralises any static charges.

The web is then subject to a force of turbulent

air created by the blowing and vacuum airows

within the head unit.

High frequency micro-movements of the web

are created by the turbulent air.

The combination of the high frequency

micro-movements and turbulent air shatters

the web boundary air layer, releasing the

contamination into the vacuum airows.

As the web exits the CyClean head, it passes

through a second cloud of ionisation to prevent

re-contamination of the web.

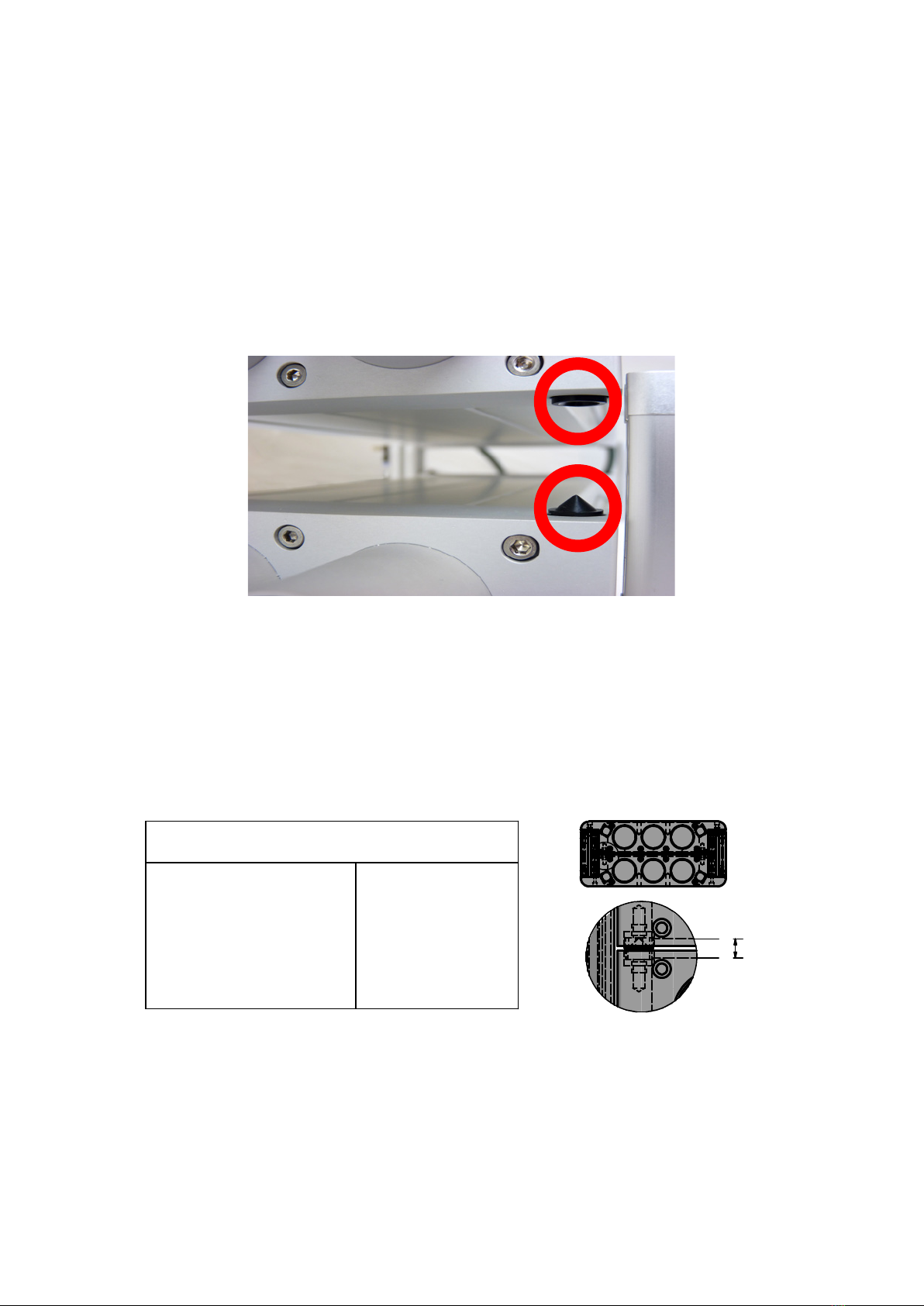

Unpacking the System

CAUTION

Observe correct manual handling procedures when removing the system from the packaging. It is likely that the system will

exceed the recommended manual handling limit.

The CyClean will be delivered in a heavy duty wooden packing crate.

On receipt of the system, check the packaging for signs of shipping damage. If found, any damage should immediately be

reported to the shipping company, the supplier of the system and Meech directly.

Inside the packing crate check the system for signs of damage. If found, any damage should immediately be reported to the

supplier of the system and Meech directly.

Before installation of the system, it is recommended that you clean it to remove any potential packing contamination.