3

CONTENTS

TAKCLEAN SYSTEM OVERVIEW 5

Models and Function

Double Sided Cleaning

Single Sided Cleaning

Correct Use of a TakClean System

How TakClean Works

UNPACKING THE SYSTEM 7

SYSTEM INSTALLATION – MECHANICAL 8

Positioning of the System

Required Space and Mounting Holes

SYSTEM INSTALLATION – PNEUMATIC 9

Compressed Air Requirement

Compressed Air Connections

Setting the Required Air Pressure

Compressed Air Circuit

SYSTEM INSTALLATION – ELECTRICAL 11

Connecting the Remote On/Off Signal From the Line

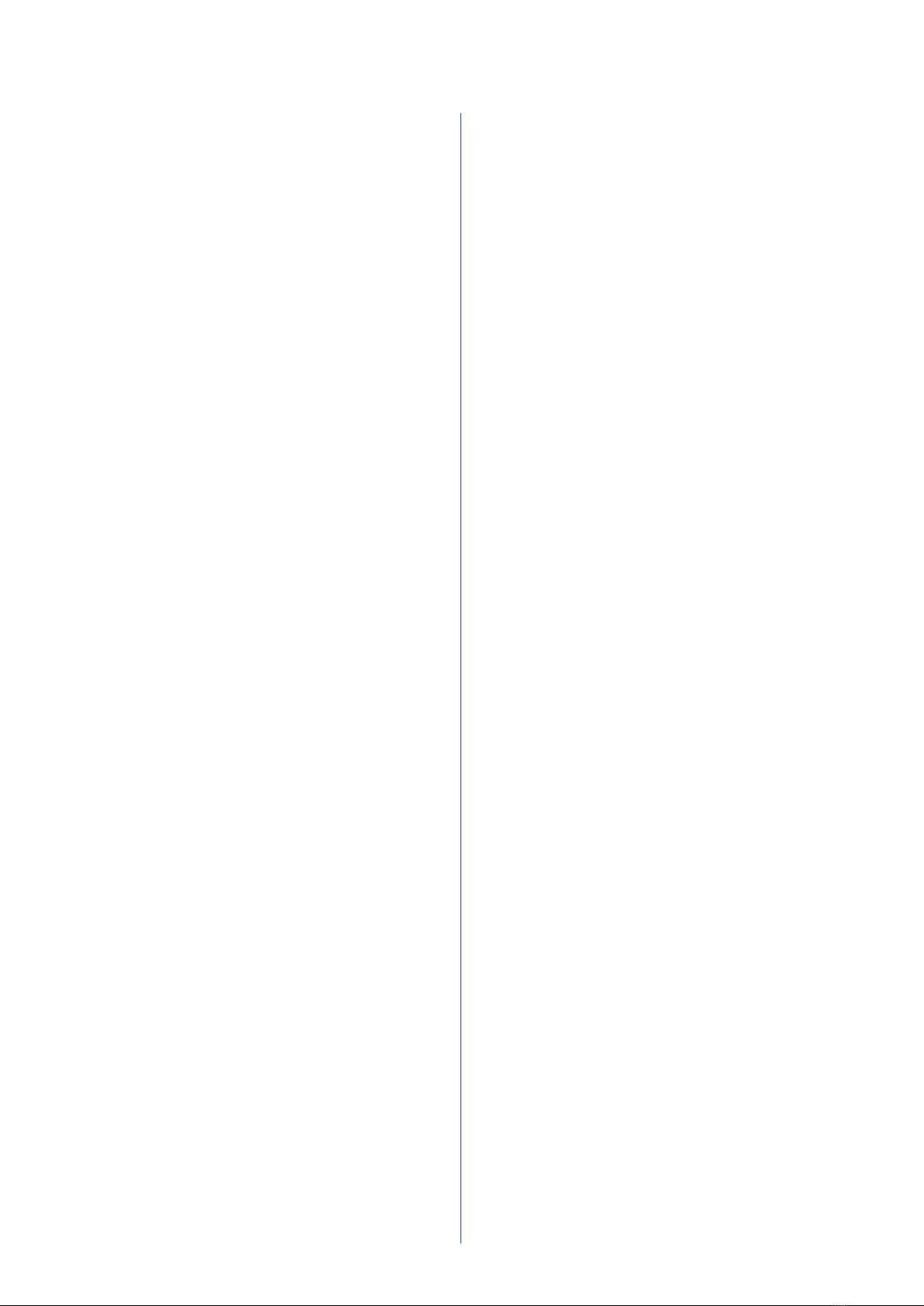

Connecting the Active Ionisation Equipment

MAINTENANCE – IONISATION EQUIPMENT 20

Fault Finding – Ionisation Equipment

SPARE PARTS AND CONSUMABLES 21

TROUBLESHOOTING 22

DRAWING PACK 24

Backplate Mounting Holes - Option 1

Backplate Mounting Holes - Option 2

Backplate Mounting Holes - Option 3

GA Double Sided System

Compressed Air Circuit

ADHESIVE ROLL MATERIAL SPECIFICATION 29

CE DECLARATION OF CONFORMITY 30

OPERATING THE SYSTEM 14

Before Use

General Operation

MAINTENANCE – ADHESIVE ROLLS 15

General Guidelines

Refreshing the Adhesive Roll

Replacing the Adhesive Roll

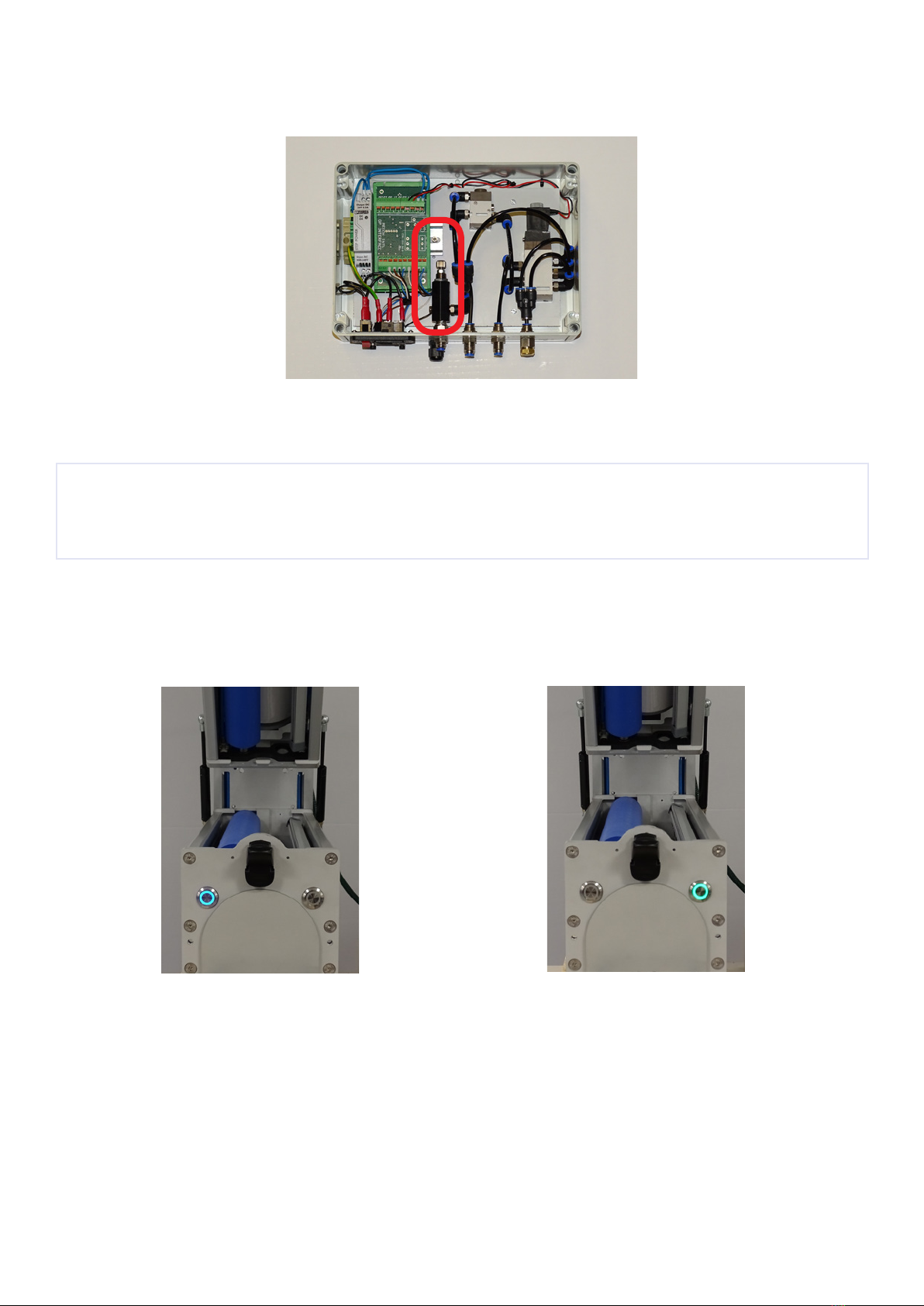

Adhesive Roller Positioning

MAINTENANCE – TransTak ELASTOMER ROLLERS 18

General Guidelines

Replacing the TransTak Elastomer Rollers