Safety Instrucons

Before using equipment, read the following safety and operang instrucons to ensure your own personal safety

and help to protect your equipment. Failure to do so could result in injury or death.

Connected equipment may require addional safety instrucons. Observe all safety instrucons for addional

equipment connected before operang.

General Safety

Before seng up the equipment:

• Read the operang instrucons carefully and ensure you understand how to use the equipment correctly.

• Installaon and tesng must only be completed by those suitably qualied.

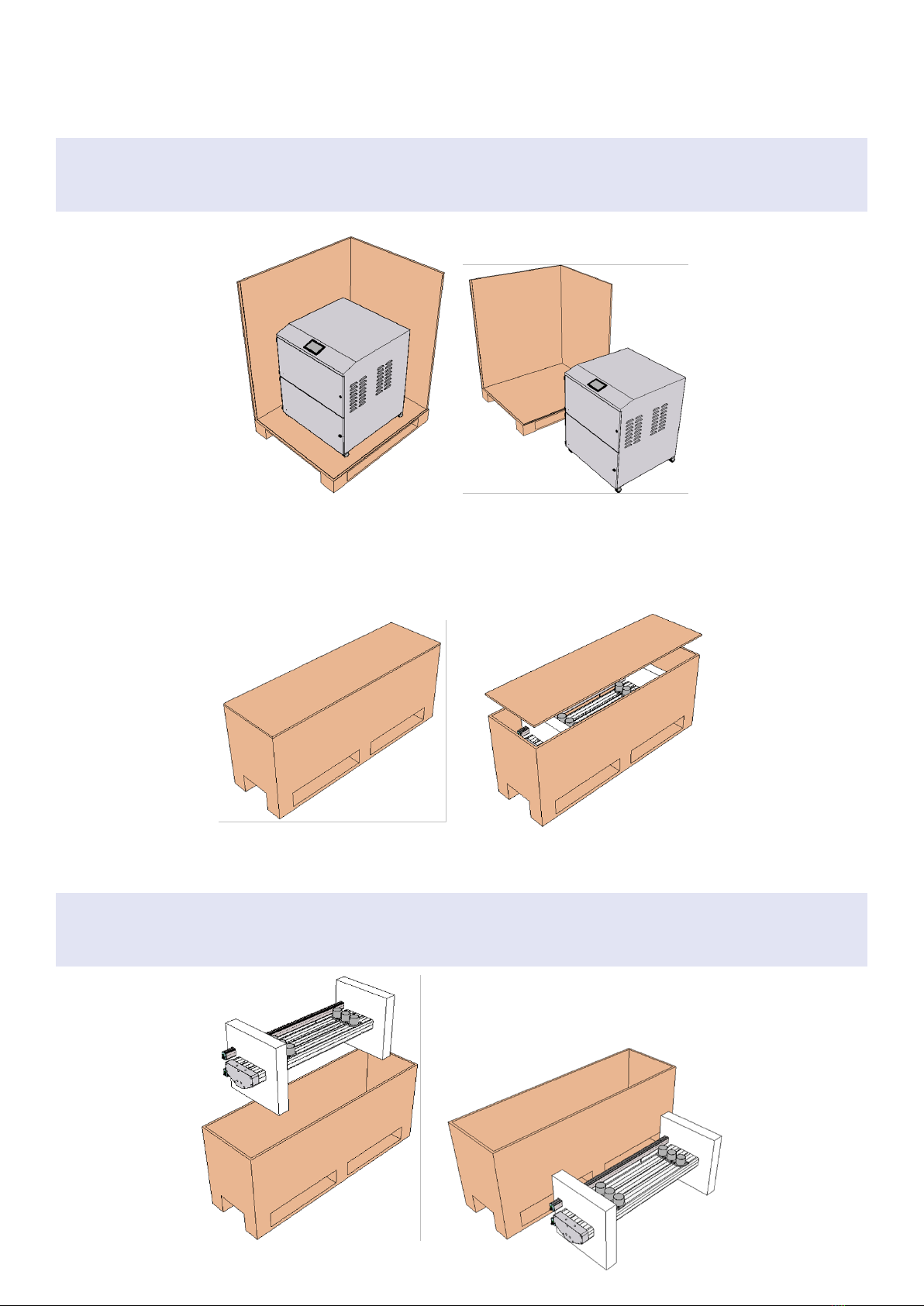

• Inspect the working environment and ensure it is clean and clear of hazards before removing equipment from

packaging and posioning the system.

• Visually check all equipment for damage. If damaged, contact your local Meech representave before

connuing.

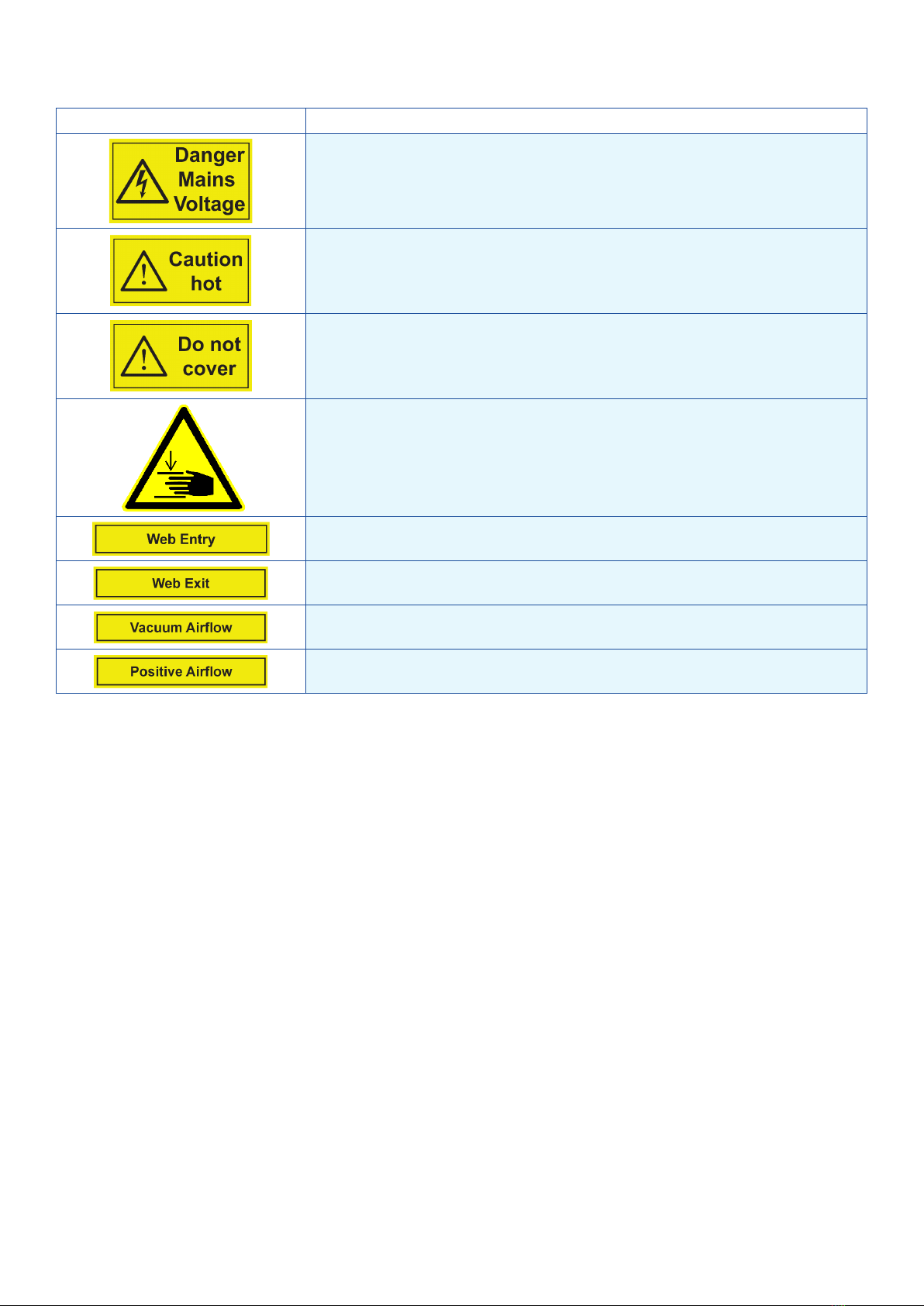

• Observe warning symbols placed on the equipment, see page 5.

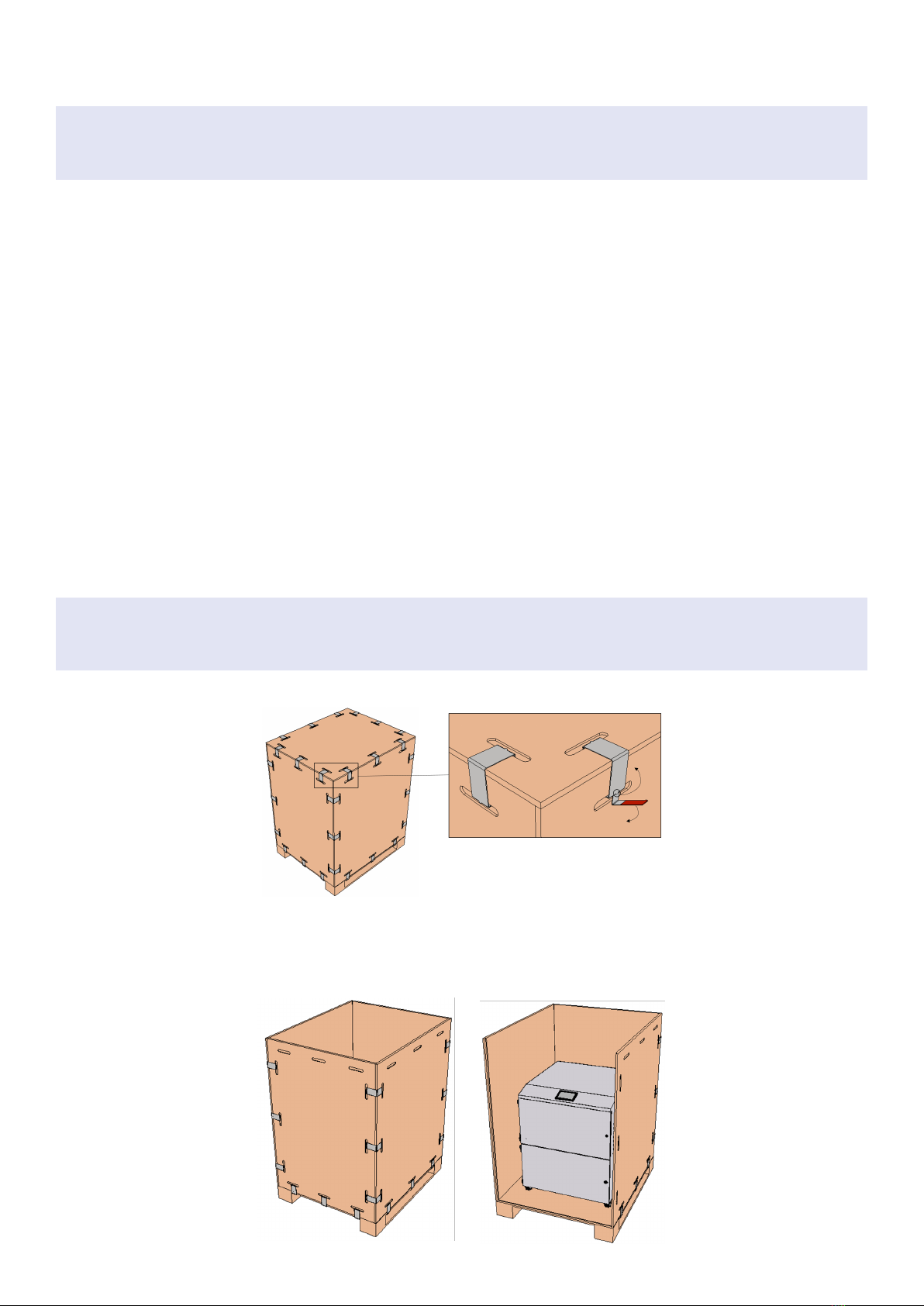

• Ensure a minimum distance of at 0.5m is kept around the Air Handling Unit (AHU) to permit adequate airow

required for venlaon. Restricng airow may damage the equipment.

• Keep all cables secured unl ready for use.

• Keep a copy of the Operang Manual close to the system at all mes.

Electrical Safety

Before installing, performing repairs or maintenance on equipment, ensure the system is electrically isolated. Failure

of this could result in injury or death.

Before working on the equipment:

• Check the equipment is electrically isolated correctly.

• Check equipment and cables for damage. If damaged, contact your local Meech representave before

connuing.

• Ensure all wiring is completed by competent personnel.

• Check all connecons in relaon to the wiring diagram.