2-1

MMP4-CAT(T4)-MX-2

26 Feb 2014

SECTION 2

System Description

Contents

DESCRIPTION

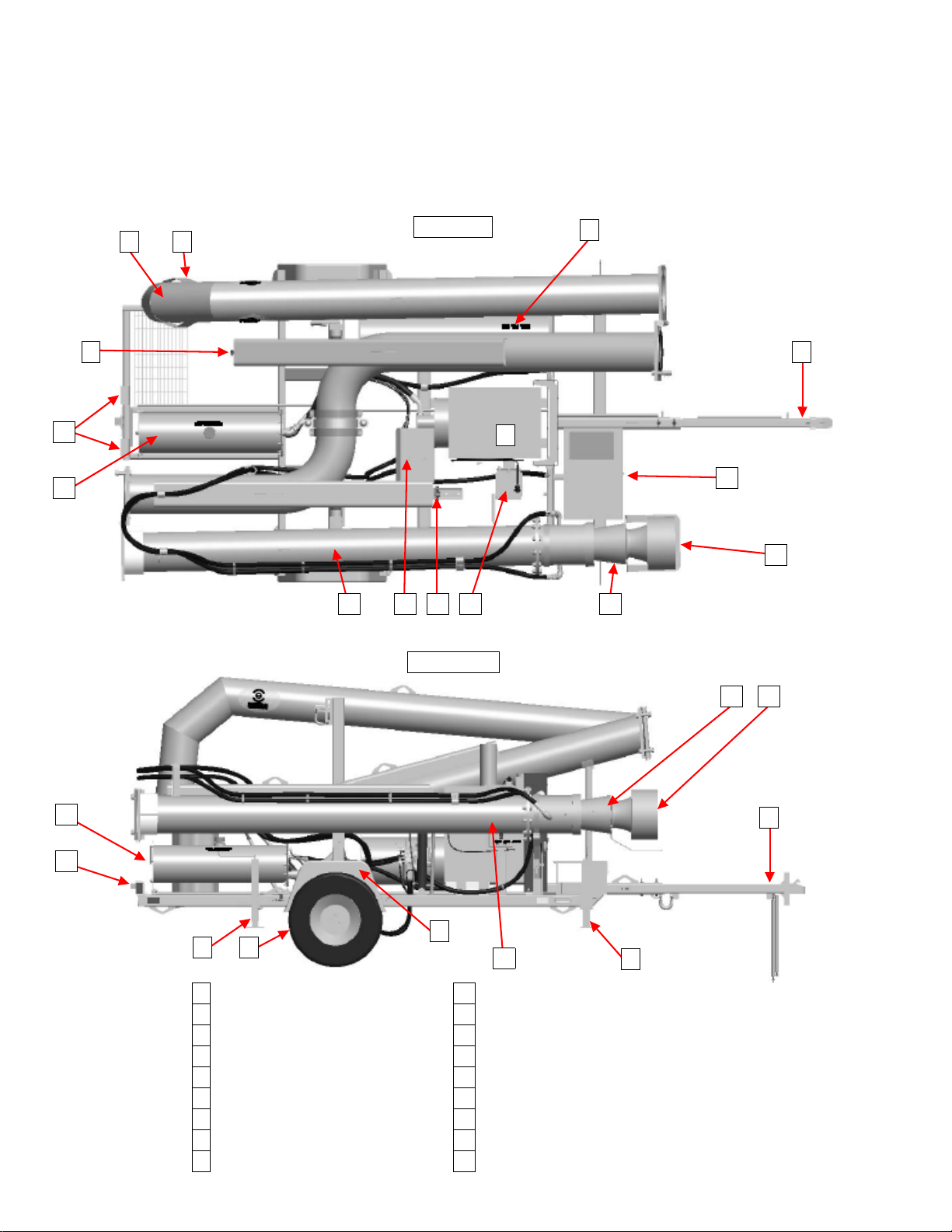

The MEGA Mobile Pump (MMP4) is a towable water

lifting station. The MMP4 may be towed by a vehicle

capable of at least a 6,000 pound (2,725 kg) towing

capacity, 1,000 pound (450 kg) tongue weight, and

equipped with the appropriate weight rated Class IV

trailer hitch with a 2 5/16 inch ball. The MMP4 can be

transported to a water holding pond and be set up

by one individual.

The MMP4 is a self-contained pumping station fitted

with a hydraulically driven 12 inch axial water pump

that has the potential to lift water 25 feet (7.6 meters)

from pump level to fill water distribution equipment

(maximum height: 17 feet or 5.2 meters above

ground level).

MMP4s are equipped with: hydraulically lifted inlet

and discharge booms with safety retaining chains

and travel locking devices, DOT rated lighting, 16

inch load range 'E' on-highway trailer tires, a fold

away hitch with safety chains, a vacuum break with

an anti-siphon discharge sock on the discharge

boom, 23 gallon (87 liter) hydraulic oil tank filled with

Chevron Clarity AW 46 hydraulic oil, a gear type

hydraulic pump driven by a Caterpillar C2.2T series

diesel engine, and a 50 gallon (190 liter) capacity

diesel fuel tank equipped with shut off valves.

The MMP4 needs a minimum of 2.5 feet (0.76 meters)

of water above the inlet of the water pump for proper

operation.

INSPECTION

1. Inspect MMP4 exterior paint for wear and

corrosion.

2. Inspect piping for damage and leaks.

3. Inspect frame, landing gear and suspension for

damage and missing parts.

4. Inspect engine assembly for loose, missing,

damaged or leaking parts.

5. Inspect all hydraulic hoses and couplings for

security, damage and leaking.

6. Inspect fuel, engine oil, anti freeze and hydraulic

oil for contamination and proper level.

7. Inspect lighting, lug nuts, fenders and hitch

safety equipment for operation, damage and

missing parts.

8. Inspect electrical system for corrosion, damage

and missing parts.

Description ........................................................................2-1

Inspection ...........................................................................2-1

Repair ...................................................................................2-2