Megacon Iso4-DIN User manual

pag. 1 / 8

INSTRUCTION MANUAL

IM264-U-M v0.1

Iso4-DIN

Multipoint earth leakage relay 4 inputs

pag. 2 / 8

CURRENTS

0.540 A

3.230 A

0.300 A

2.365 A

WARNING!

•Carefully read the manual before the installation or use.

•This device is to be installed by qualified personnel, complying to current standards, to avoid damages.

•Before any maintenance operation on the device, remove supply inputs.

•The manufacturer cannot be held responsible for electrical safety in case of improper use of the equipment.

•Products illustrated herein are subject to alteration and changes without

prior notice.

Description

•Earth leakage relay type A

•Measuring in true effective value (TRMS)

•Third harmonic filtering (settable)

•Modular DIN-rail housing, 3 modules

•Green power LED indicator (ON)

•External residual current transfomer

•Fail safe function for each four relays (settable)

•Visualization instant leakage values

•Backlighted LCD display (green, yellow, red)

•4 red indicator LEDs for tripping

•TEST and RESET by front button or remote contact

•Four independent relays to control the circuit breakers of the four channels

•Instantaneous bar-graph of current measurement for each channel

•Log tripped residual current

•RS-485 communication (Modbus RTU protocol)

Display and LED functions

Thanks to LCD display, the user can view very quickly the measurements (instant leakage values, filter TRMS, MAX values, THD, crest factor), the graph bar, the

Log, the alarms and can access to all settings.

•Green: detected current lower than threshold

•Yellow:

- detected current higher than PRE-ALARM threshold but lower than TRIP threshold

•Red:

- detected current higher than TRIP threshold and relay activation

- current leakage read off scale

- TEST, causes tripping of the relay

- open residual current transformer circuit (or not right connected)

Front keyboard

RESET key –To reset the relay after tripping, used to exit from settings menu.

TEST key –Causes tripping of the relays, to confirm a choice.

PROG keys –Used to enter into settings menu, to scroll display pages.

▲and ▼ keys –Used to switch between visualization modes, to select among possible choices and to modify settings (increment/decrement).

LED ON: presence of

auxiliary voltage

LCD display instant

leakage current, TRMS values,

MAX values, THD values, crest

factor, LOG and

channel’s settings

TEST pushbutton

RESET pushbutton

SETUP (▲and ▼ keys) used

to enter menu settings

TRIP LED inputs 1 - 4

▲and ▼ keys used to switch

between visualization

Channel input indication

pag. 3 / 8

Display indications

Correct display Pre-alarm display Trip display

(Green LCD) (Yellow LCD) (Red LCD)

Cause of the trip

Display message

Test

/ Red display

Current leakage

/ Red display

Others display messages

Pre-alarm

/ Yellow display

Current leakage over scale

OVR / Red display

Poor toroidal connection

OPEN / Red display

Parameters table

Below are listed all the programming parameters. For each parameter are indicated the possible setting range, the factory default, as well as a description of the

function of the parameter.

Press ▲and ▼keys to select the required parameter. The selected parameter is highlited with ►.

Press TEST key to activated the selected parameter. Use ▲and ▼ keys to select among possible choices and press TEST key to confirm a choice.

INPUTS menu

Configuration parameters for current inputs (for inputs 1…4).

INPUT ENABLE

Unit of measure

Default

Range

Enable

-

YES

YES - NO

If set to OFF, the toroidal current input is disabled.

3RD HARMONIC FILTER

Unit of measure

Default

Range

3RD filter

-

OFF

ON-OFF

Set to ON if the harmonic blocking filters for 3rd harmonic is used.

FAULT CURRENT

Unit of measure

Default

Range

I∆

mA

30

30…30000

Select the tripping fault current to earth.

LOG

10:07 15/02/2020

10:07 20/02/2020

10:07 22/02/2020

10:07 02/04/2020

10:07 09/05/2020

10:07 23/06/2020

THD

36.0%

25.0%

37.0%

35.0%

GRAPH

pag. 4 / 8

TRIPPING DELAY TIME

Unit of measure

Default

Range

Time

ms

20

20…10000

Select the tripping delay time.

RESET TRIP

Unit of measure

Default

Range

Reset

-

MAN

AUTO-MAN

If set to AUTO, the reset of TRIP will be automatic. If set to MAN, manual reset through the RESET key on the front.

PRE-ALARM DELAY TIME

Unit of measure

Default

Range

Time

ms

20

20…10000

Select the pre-alarm delay time.

PRE-ALARM THRESHOLD

Unit of measure

Default

Range

%

%

50

50…90

Select the pre-alarm threshold which is a function of the tripping fault current value.

PRE-ALARM RESET

Unit of measure

Default

Range

Reset

-

AUTO

AUTO-MAN

If set to AUTO, the reset of pre-alarm will be automatic. If set to MAN, manual reset through the RESET key on the front.

TRIP RELAY FAILSAFE

Unit of measure

Default

Range

Failsafe

-

OFF

ON-OFF

If set to ON, positive safety activated on TRIP relay of the channel input, in this condition the TRIP relay is normally energised; therefore in the event of the lack of

auxiliary voltage the output contacts move to the trip condition.

HYSTERESIS

Unit of measure

Default

Range

Hysteresis

%

90

50…90

Tripping fault current threshold hysteresis.

COMMUNICATION menu

Communication port parameters (COM1).

RS485

Unit of measure

Default

Range

Serial node address

-

01

01-247

Baudrate

bps

38400

4800-115200

Stop bits

-

1

1-2

Data format

-

8 bit - n

8 bit, no parity

8 bit, odd

8 bit, even

Response time

ms

10

5-100

UTILITY menu

UTILITY

Unit of measure

Default

Range

Language

-

ENG

ENG-ITA

Operating frequency

Hz

50

50-60

TIME and DATE menu

The ISO-4DIN manages the time and date, that is used for the storage of events (tripped current).

COMMANDS menu

The commands menu allows executing some occasional operations like resetting, log events clearing. Once the required command has been selected, press TEST

to execute it. To cancel the command execution press RESET key.

COMMAND

Description

Parameters to default

All setup parameters are resetted to factory default value

Reset MAX & TRIP

Clears the event trip memory and MAX

Reset TRIP

Clears the event trip memory

Reset MAX

Clears the MAX values

PASSWORD menu

The password is used to enable or lock to setting menu and command menu (RESET). For new devices (factory default), the password management is disabled

and the access is free. If instead the password has been enabled and defined (0-9999), then to get access, it’s necessary to enter the password first, specifyng

the number code.

PASSWORD

Unit of measure

Default

Range

Value

-

0

0-9999

If set to 0, password management is disabled.

pag. 5 / 8

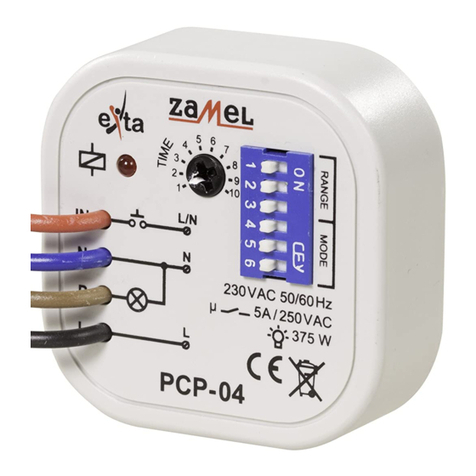

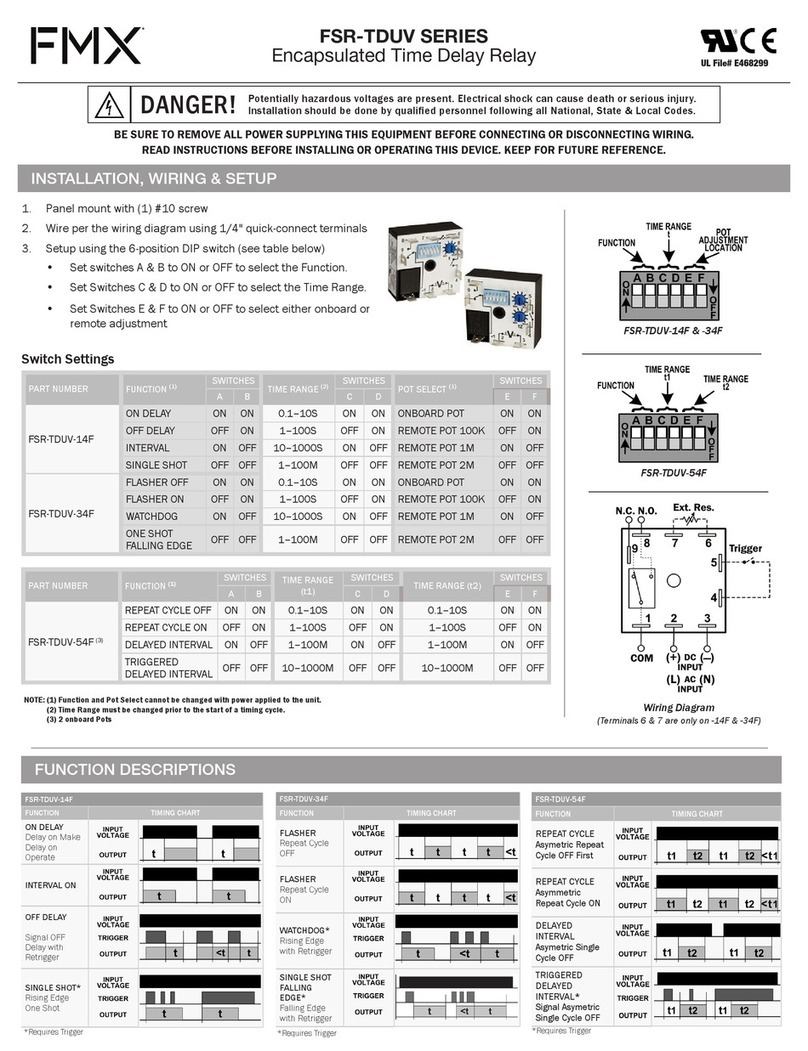

Terminals connection

N°

Description

1

Trip output relay R1

2

Trip output relay R1,R2 (COMMON)

3

Trip output relay R2

4

Trip output relay R3

5

Trip output relay R3,R4 (COMMON)

6

Trip output relay R4

7

External TEST (DI1)

8

Digital input (COMMON)

9

External RESET (DI2)

10

Auxiliary supply (neutral or phase)

11

Not used

12

Auxiliary supply (neutral or phase)

13

Input toroidal current transformer 4-S1

14

Input toroidal current transformer 3,4-S2

15

Input toroidal current transformer 3-S1

16

Input toroidal current transformer 2-S1

17

Input toroidal current transformer 1,2-S2

18

Input toroidal current transformer 1-S1

pag. 6 / 8

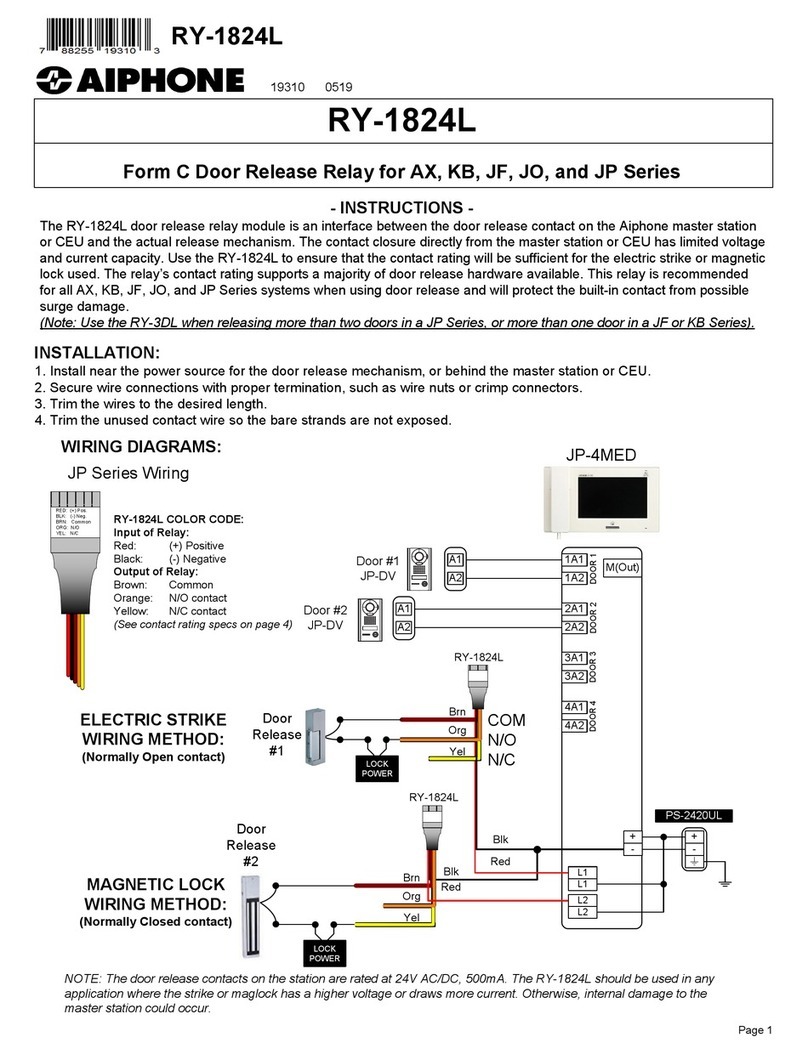

Wiring connection

RS485 connection (optional)

12 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

pag. 7 / 8

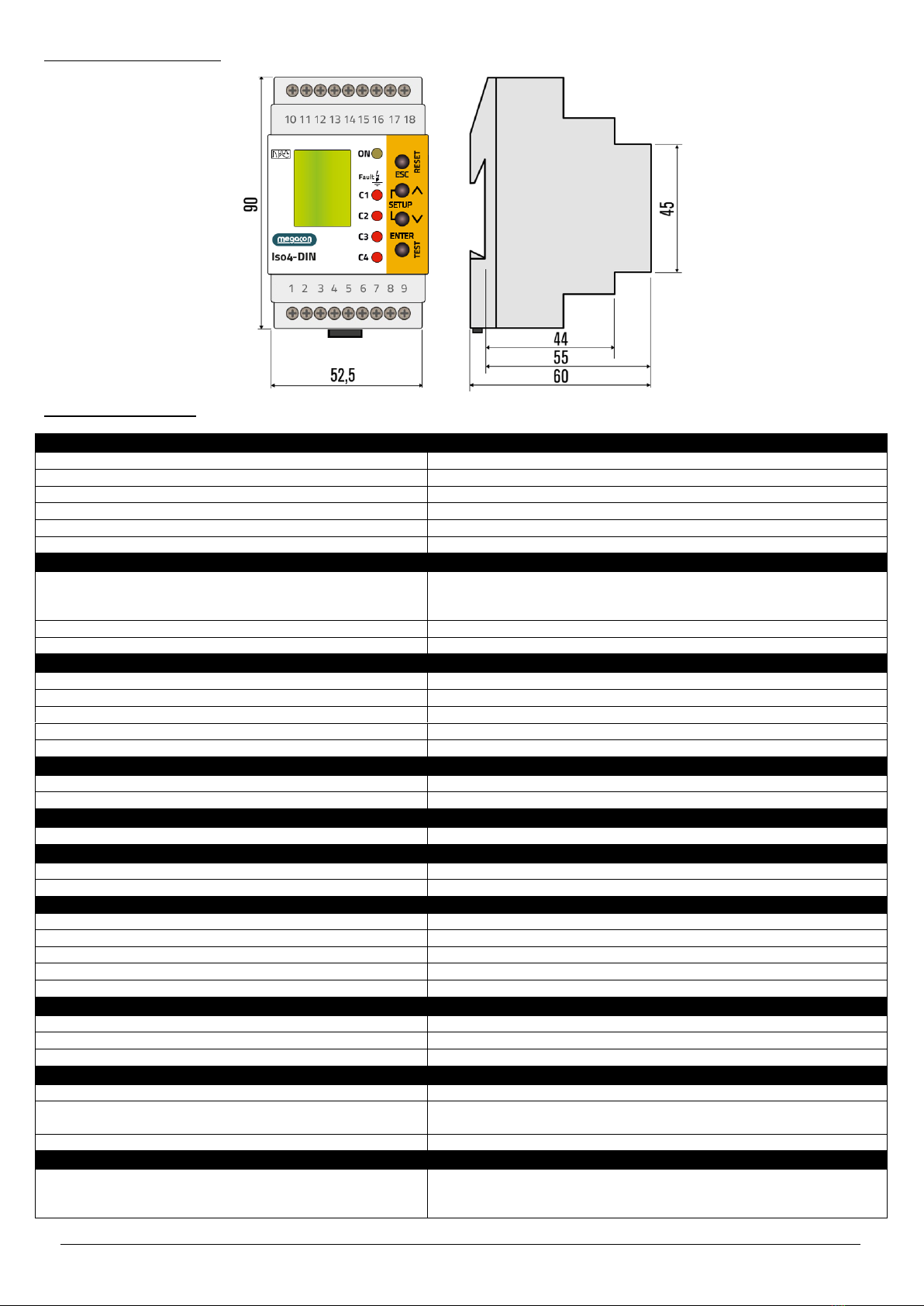

Mechanical dimensions (mm)

Technical characteristics

Control circuit

Toroidal transformer

External

Tripping type

Type A

Tripping set-point (I∆)

0,03÷30A

Prealarm set-point

50÷90%

Tripping time (t)

0,02÷10s

Resetting

Automatic or manual by pushbutton on front or remote

Auxiliary supply

Auxiliary voltage

230 VAC

115 VAC (optional)

24-48VAC/DC (optional)

Rated frequency

50/60Hz

Max power consumption

6VA

Output relay

Number of outputs

4

State

Configurable normally de-energised or energised

Rated operating voltage

250 VAC

Rated current

5A

Mechanical life

10 · 106 cycles

Digital inputs

Number of inputs

2

Rated voltage

Self powered

Display

Type

LCD

RS485 serial interface (optional)

Protocol

Modbus-RTU

Baud-rate

Programmable 4800 –115200 bps

Connections

Type of terminal

Screw (fixed)

Number of terminals

18

Conductor cross section

0,127 - 2,082 mm2

Tightening torque

0.5 - 0.6 Nm

Length of cable to strip

7mm

Ambient operating conditions

Operating temperature

-10÷60°C

Storage temperature

-20÷80°C

Relative humidity

5÷95%

Housing

Version

3 module DIN

Degree of protection

IP20 terminals

IP40 on front

Weight

200g

Certifications and compliance

Reference standards

EN 61010, EN 61000-6-2,

EN 61000-6-3, IEC/TR 60755

EN 60947-2 Annex M

pag. 8 / 8

For further details please contact:

Megacon AB

Ranhammarsvägen 20

S-168 67 Bromma, Sweden

Phone: +46 (0)8-402 42 50

www.megacon.se

Table of contents