2

Contents

SAFETY WARNINGS .................................................................................................................................................................3

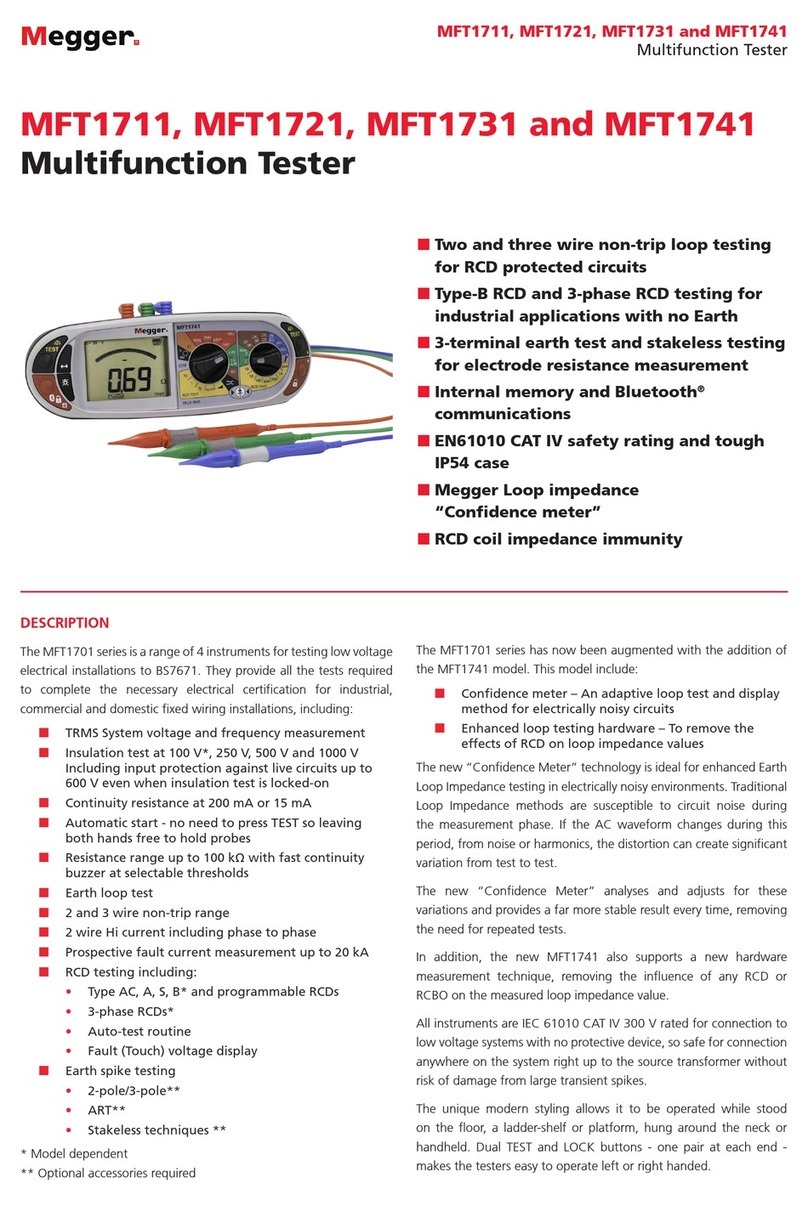

1. Introduction.............................................................................................................................................................................4

2. Overview .................................................................................................................................................................................4

2.1 Front panel and controls .................................................................................................................................................6

2.2 Waste electrical and electronic equipment.......................................................................................................................6

2.3 Battery and fuse location, fitting and replacement ..........................................................................................................6

3. Operation .......................................................................................................................................................................7

3.1 General operation – all models........................................................................................................................................7

3.2 Mode button functions...................................................................................................................................................7

3.3 Test inhibit ......................................................................................................................................................................7

4. Voltage, frequency, current and temperature measurement..........................................................................................................8

4.1 Making a voltage measurement......................................................................................................................................8

5. Continuity / resistance measurement............................................................................................................................................10

5.1 Nulling test lead resistance (up to 9.99 ohms) ...............................................................................................................10

5.2 Making a CONTINUITY measurement..............................................................................................................................11

5.3 Storing / downloading results (MFT1731 only).................................................................................................................11

5.4 Continuity Buzzer ON/OFF...............................................................................................................................................11

5.5 Switch probe (SP5)..........................................................................................................................................................11

5.6 Buzzer threshold .............................................................................................................................................................12

5.7 Measurement methods and sources of error ...................................................................................................................12

6. Insulation resistance ...............................................................................................................................................................12

6.1 Making an INSULATION measurement.............................................................................................................................12

6.2 Insulation test lock..........................................................................................................................................................13

6.3 Measurement methods and sources of error ...................................................................................................................13

7. Loop Impedance testing...........................................................................................................................................................13

7.1 Range selection and test leads ........................................................................................................................................14

7.2 Making a loop impedance measurement.........................................................................................................................15

7.3 Phase to Neutral (or Phase to Phase) testing....................................................................................................................19

7.4 Prospective Fault Current and Short Circuit calculation (PFC & PSCC) ..............................................................................20

7.5 Zmax test mode..............................................................................................................................................................20

7.6 Making a Zmax loop impedance measurement ...............................................................................................................20

7.7 Making an R1+R2 loop impedance measurement (MFT1721 only)...................................................................................21

7.8 Measurement methods and sources of error ...................................................................................................................22

8. Residual Current Device testing................................................................................................................................................22

8.1 Making an RCD measurement ........................................................................................................................................23

8.2 Selecting RCD type .........................................................................................................................................................23

8.3 ½ x I RCD current rating (No-trip test) ...........................................................................................................................23

8.4 1 x I RCD current rating (Tripping test on 30mA RCD) ...................................................................................................24

8.5 5 x I RCD current rating (Tripping test on 30mA RCD) ...................................................................................................25

8.6 Ramp Test.......................................................................................................................................................................25

8.7 Type A (DC sensitive) RCD test ......................................................................................................................................26

8.8 Type B (Pure DC) RCD test...............................................................................................................................................26

8.9 Variable RCDs (not MFT1711) .........................................................................................................................................27

8.10 AUTO RCD testing ..........................................................................................................................................................27

8.11 3 Phase RCD testing........................................................................................................................................................27

8.12 Touch voltage display......................................................................................................................................................29

8.13 Measurement methods and sources of error ...................................................................................................................29

8.14 Useful information..........................................................................................................................................................29

9. Earth resistance measurement..................................................................................................................................................29

9.1 Connection terminals......................................................................................................................................................29

9.2 Touch voltage limit..........................................................................................................................................................29

9.4 Making a measurement – Three terminal resistance measurement ..................................................................................30

9.5

9.6

10. Setup options ..........................................................................................................................................................................31

11. Warning messages...................................................................................................................................................................32

11.1 Startup warnings ............................................................................................................................................................32

11.2 Battery............................................................................................................................................................................32

11.3 Battery charger ...............................................................................................................................................................32

11.4 Fuse warning ..................................................................................................................................................................32

11.5 Invalid rotary switch setting.............................................................................................................................................32

11.6 Continuity test................................................................................................................................................................32

11.7 Insulation test .................................................................................................................................................................32

11.8 RCD Test.........................................................................................................................................................................32

11.9 RCD range selection errors..............................................................................................................................................32

11.10 Loop Test.......................................................................................................................................................................32

11.11 Earth test.......................................................................................................................................................................32

11.12 Test will not start ...........................................................................................................................................................32