7

Service IPP 200-500/HPP 108 | 10/2008

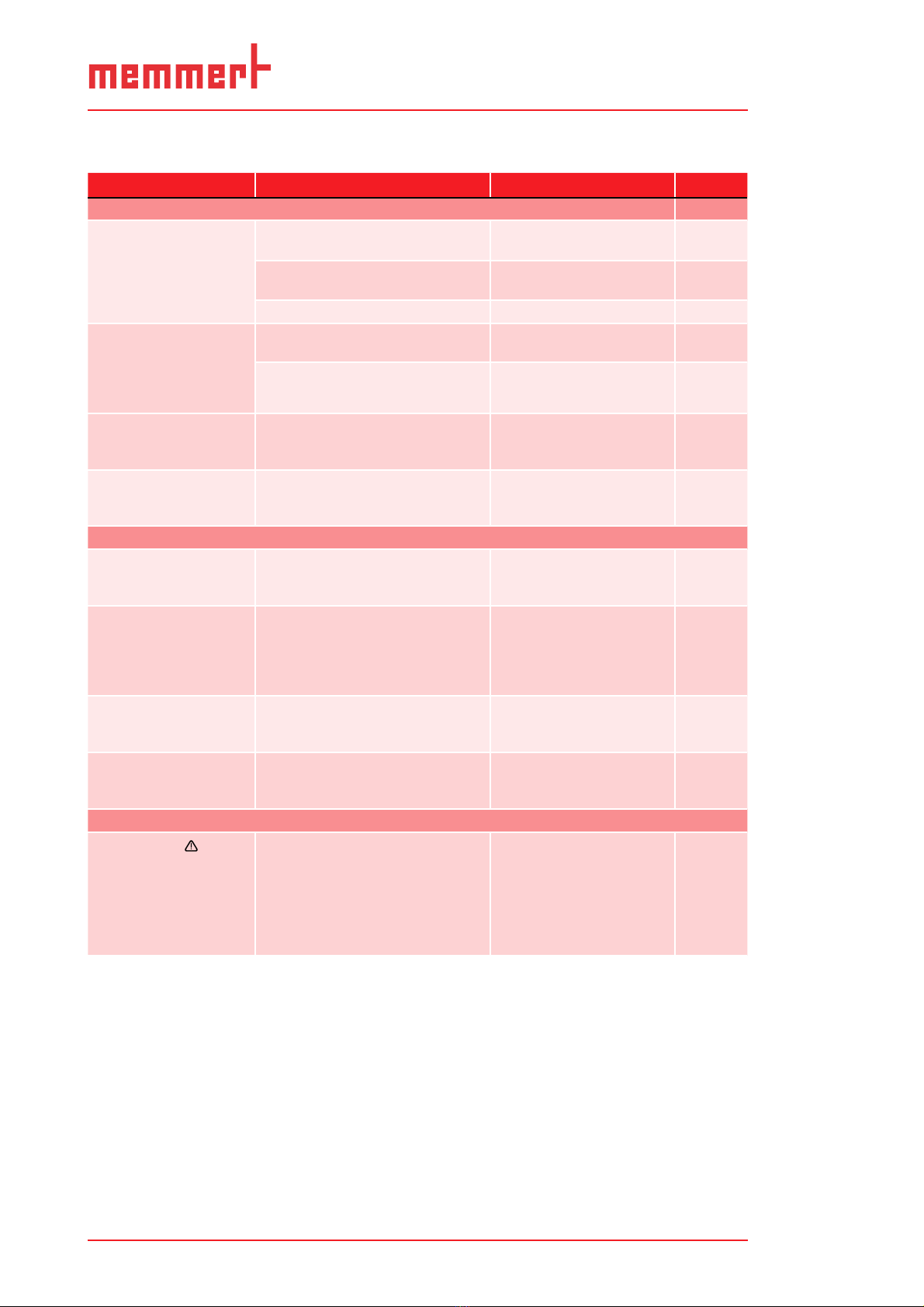

Error description Cause of error Rectifying errors Page

Error message "E-3"

alternates with display of

temperature

Pt100 temperature sensor of

monitoring controller faulty.

Monitoring controller is working

in emergency mode with the

temperature value of the Pt100

temperature sensor from the

operating controller

Replace Pt100 temperature

sensor of the monitoring

controller on plug J3

18

Error messages in timer display

Error message "E-0" Serious configuration error

(e.g. incorrect cabinet type or wrong

temperature range)

Replace controller 17

Error message "CONF" (is

displayed for only 10 sec.

after switching on)

Checksum error (error when saving

set values, e.g. air turbine speed)

The error can be rectified

by the controller after a set

value parameter has been

saved again. If the error

should continue occurring,

or cannot be rectified,

replace the controller 17

Error message "E-L1" in

the timer display

Communication with the mainboard

interrupted

Check connection cable,

replace mainboard if

necessary

13

Error messages in temperature display

Error message "E-3"

alternates with display of

monitor

Pt100 temperature sensor of

operating controller faulty. Operating

controller is working in emergency

mode with the temperature value of

the Pt100 temperature sensor from

the monitoring controller

Replace Pt100 temperature

sensor of the operating

controller on plug J4

18

Error message "E-1" Mainboard actuator Triac faulty Replace mainboard 13

Error message "E-2" Mainboard faulty Replace mainboard 13

Malfunctions of the humidifier and/or dehumidifier (only for the constant climate chambers HPP 108)

Neither humidification nor dehumidification are working properly 33

Dehumidification works, humidification doesn't work 33

Humidification works, dehumidification doesn't work 36