..........................................................................................................

1.2 Product safety and dan

ers ................................................................................................

1.3 Requirements of the operatin

personnel..........................................................................

1.4 Responsibility of the owner

.................................................................................................

....................................................................................................

1.6 Behaviour in case of malfunctions and irre

..........................................................

nts..........................................................................................

1.8 Switching off incubator in an emergency

...........................................................................

n................................................................................................................................1

n.............................................................................................................................11

2.3 Optiona

extras..................................................................................................................11

2.4 Mat

.............................................................................................................................1

..........................................................................................................

ns.......................................................................................................................1

......................................................................................................................

14

2.8 EC Declaration of Conformit

...........................................................................................15

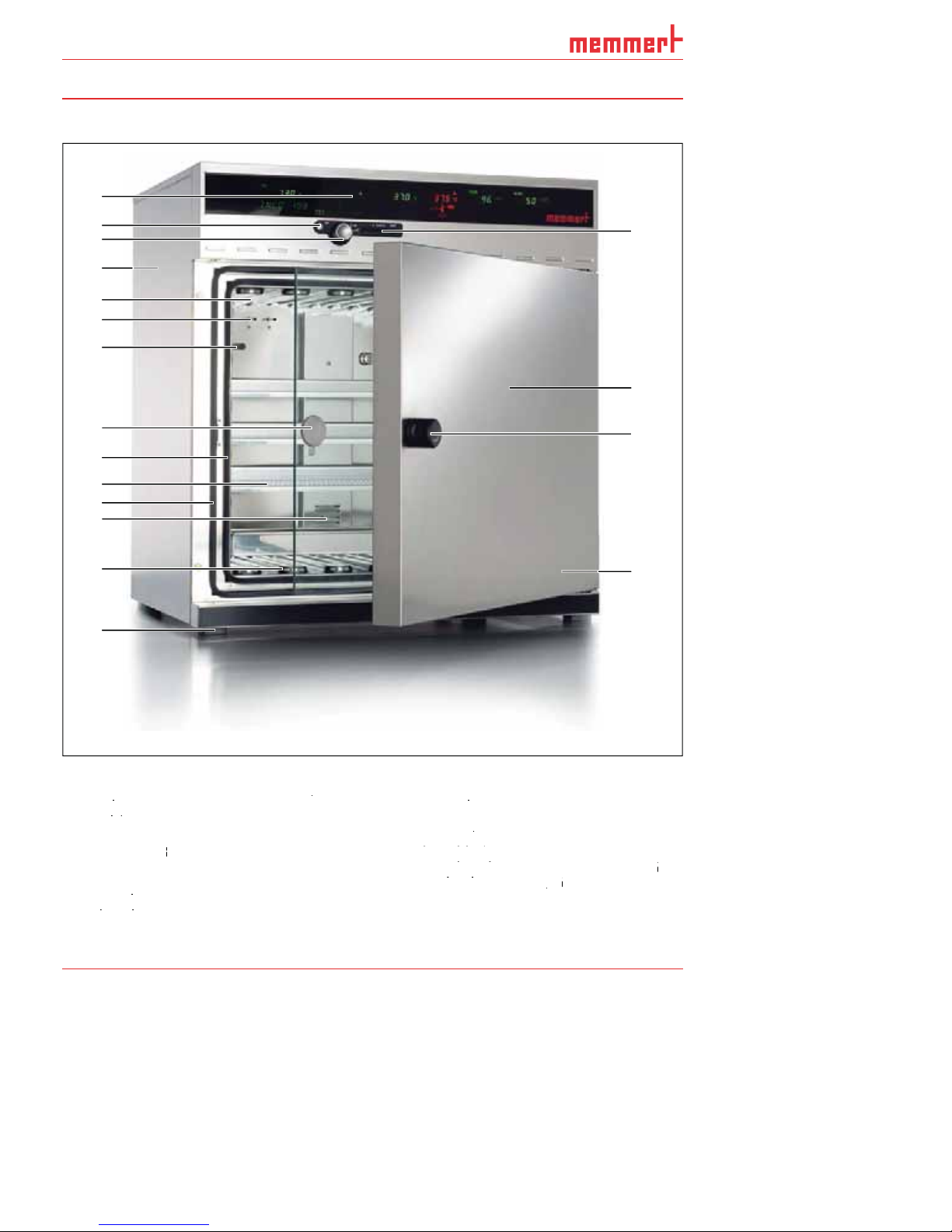

2.9 Desi

...................................................................................................15

2.1

ata....................................................................................................................1

ns...........................................................................................................1

..........................................................................................................1

ulations..............................................................................................................1

Transport............................................................................................................................1

..............................................................................................................................

.................................................................................................................................2

................................................................................................................................

........................................................................................................................

.............................................................................................................

.........................................................................................................

oor ............................................................................................................

5.3 Loading the incubator

.......................................................................................................

.......................................................................................................

...........................................................................................................

..........................................................................................................

on..................................................................................................................

parameters............................................................................................................

es...............................................................................................................2

5.10 Setting the operating mode

..............................................................................................2

on...............................................................................................................

operation...............................................................................................................

............................................................................................................

iance errors ....................................................................................................

......................................................................................................................