Merand MECAFORM VE User manual

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

1TECHNICAL

SPECIFICATIONS

MA

RC

2006

MECAFORM VE

Intermediate Proofer

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

2TECHNICAL

SPECIFICATIONS

MA

RC

2006

I. General Presentation

General safety rules

Guarantee rules

Description and function of t e equipment

- required space, electricity features, handling, production

capacity

Presentation of t e different sub-units

Description of controls

List of c eckpoints and tests to be conducted at commissioning

II. Operation Modes

Restart after sector power cut or emergency stop

Loading

Unloading

Control proofer

Cleaning

III. Malfunctioning and origins (troubles ooting)

IV. Description of operation from t e system standpoint

V. Regular maintenance

Regular maintenance c ecklist (regularity and personnel required).

VI. List of spare parts

VII. Wiring diagrams

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

3TECHNICAL

SPECIFICATIONS

MA

RC

2006

I. GENERAL PRESENTATION

General safety rules.

1- Before using MECAFORM VE, read these instructions carefully.

2 – Only bakery technicians are authorised to carry out the technical control of this

material.

3 - MERAND Mécapâte S.A shall not be liable in case of damage arising out of

failure to comply with the present instructions.

4 – Only the machines provided by MERAND Mécapâte S.A. shall fall within their

scope of responsibility, pursuant to the general selling conditions.

5 – Only professional electricians are authorized to open the switch boxes and to work

on the equipment.

6 – Never use MECAFORM VE for other purposes than those allowed.

7 – Make sure that non-authorized persons, children and animals are kept away from

all the divider components.

8 – Cut the power supply to the MECAFORM VE before any intervention.

9 – Each part must be connected to the corresponding plug.

10 – Do not look into the germicidal lamp directly (on risk of blindness).

11 - Do not clean the MECAFORM VE with steam or water jet.

12 – During all electricity works, pay attention to residual voltage.

13 – The MECAFORM VE must always be used with all the protection cases and

casing panels assembled.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

4TECHNICAL

SPECIFICATIONS

MA

RC

2006

Guarantee rules

The MECAFORM VE AUTO is guaranteed during a 12-month period as from the

acquisition of the equipment, provided that it is operated according to the present

instructions and pursuant to the general selling conditions of MERAND Mécapâte.

The guarantee will not be valid if the proofer was not operated according to the

present instructions, or if technical operation was performed by personnel not

authorized by MERAND Mécapâte.

T E GUARANTEE S ALL NOT INCLUDE ELECTRICAL COMPONENTS.

Description and function of the equipment

Required Space

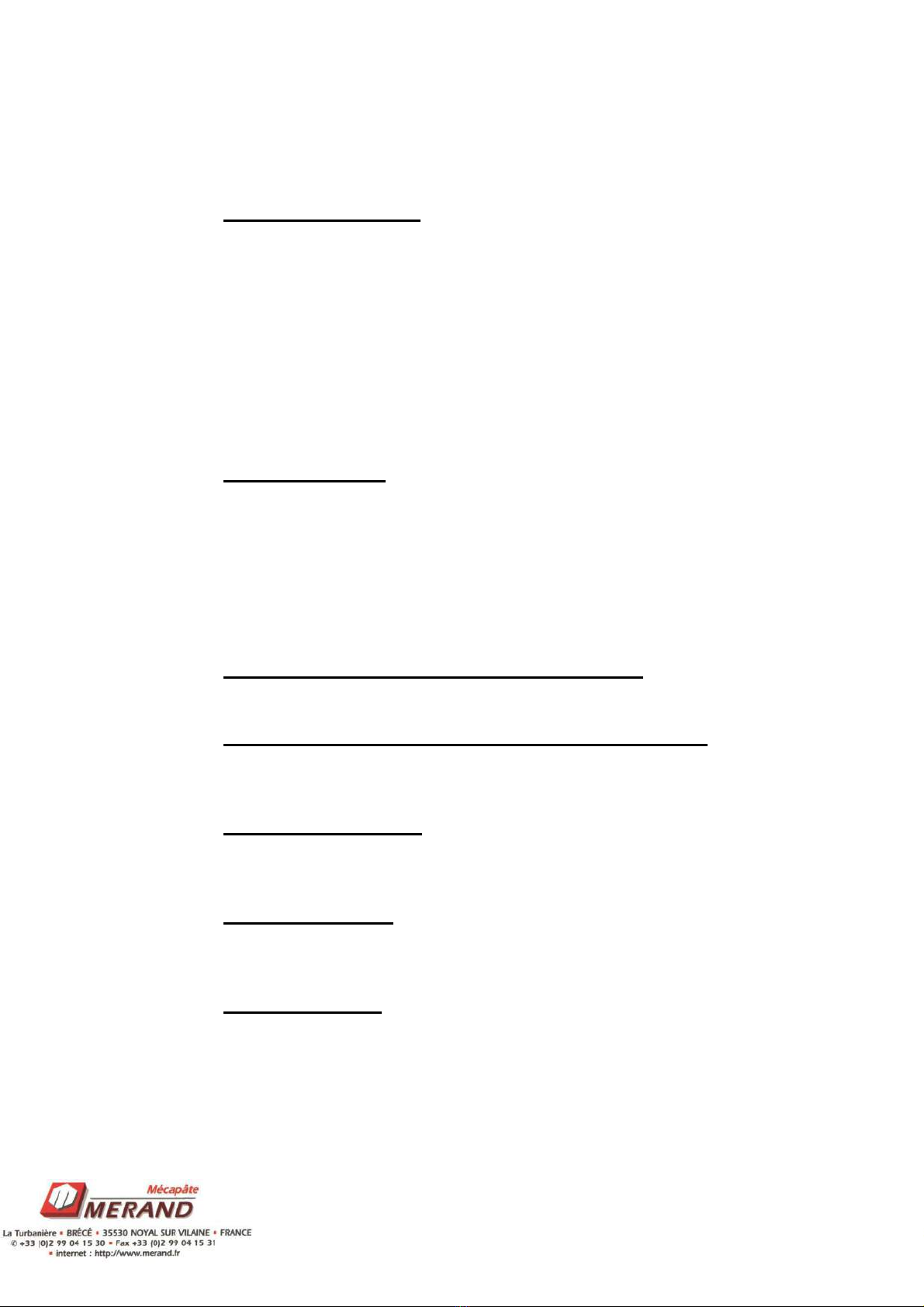

Machine Name

Ext. Enhance

m.

Top width

without

delivery belt

Top depth

Height

Estimat

ed

weight

(kg)

MECAFORM VE: 56 rectanguar 7-

pocket proofers (900 g)

56 47 7 0 0 1740 1515 2240 600

MECAFORM VE: 72 rectanguar 7-

pocket proofers (900 g)

72 63 7 0 1 1740 1515 2640 800

MECAFORM VE: 78 rectanguar 7-

pocket proofers (900 g)

78 69 7 1 0 1740 2050 2240 820

MECAFORM VE: 96 rectanguar 7-

pocket proofers (900 g)

96 87 7 2 0 1740 2585 2240 1000

Electricity features

General electric power: 6.22 KW maximum.

Voltage: 380 V.

Amperage: 20.4 A max.

Frequency: 50 z.

Protection: IP 55.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

5TECHNICAL

SPECIFICATIONS

MA

RC

2006

Handling

The MECAFORM VE intermediate proofer is equipped with four wheels, 2 with lock

to allow for movement during installation or regular maintenance. It is therefore

advisable to always move this equipment by rolling.

owever, if you need to use handling instruments to install this expansion chamber,

follow the instructions:

- Lift the equipment only from the side.

- Always use forks which are long enough to pass from one side of the proofer

to the other (to prevent the frame bottom from breaking).

- Check the position of the equipment gravity centre before lifting it

Production capacity

In loading mode, the production rhythm of the proofer is given by the

weigher.

In unloading mode, the production rhythm of the proofer is given by the

speed of the unloading belt (variable from 0 to 1800 pieces/h in the

machines equipped with the speed regulator option).

By way of information, one person alone is able to receive around 800

pieces an hour on pallets and 1200 pieces an hour on layers.

In general terms, it is important to adapt the unloading speed of the proofer

to the capacity of the moulder used.

The MECAFORM VE moulder can receive 900g rolls with 7-pocket

frames.

All this information is provided for indicative

purposes and may change subject to the dough

type and weight of rolls produced

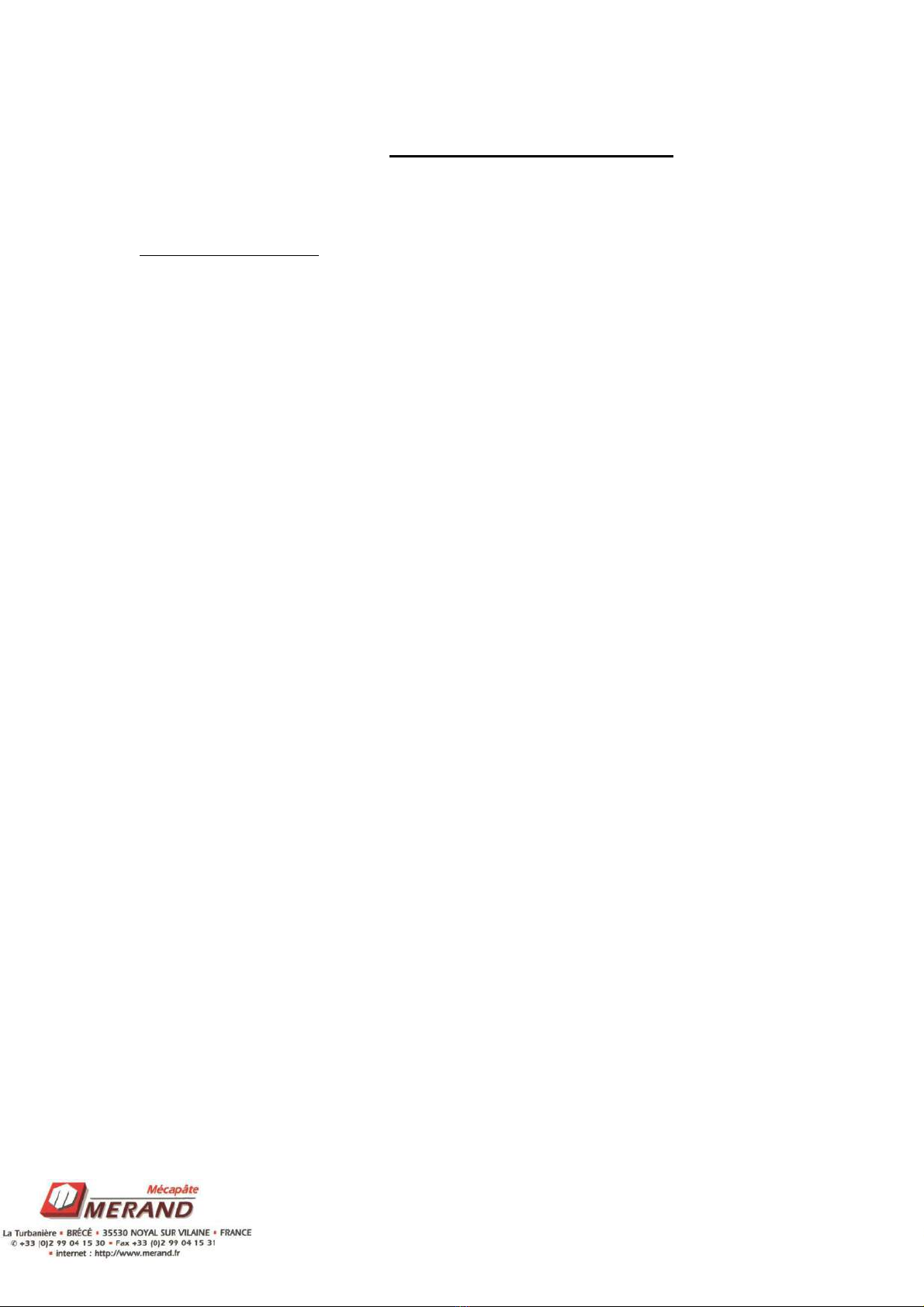

T EGO

TENO

A MO ABS

1600

Type of moulder

1500

1200

maximum rate

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

6TECHNICAL

SPECIFICATIONS

MA

RC

2006

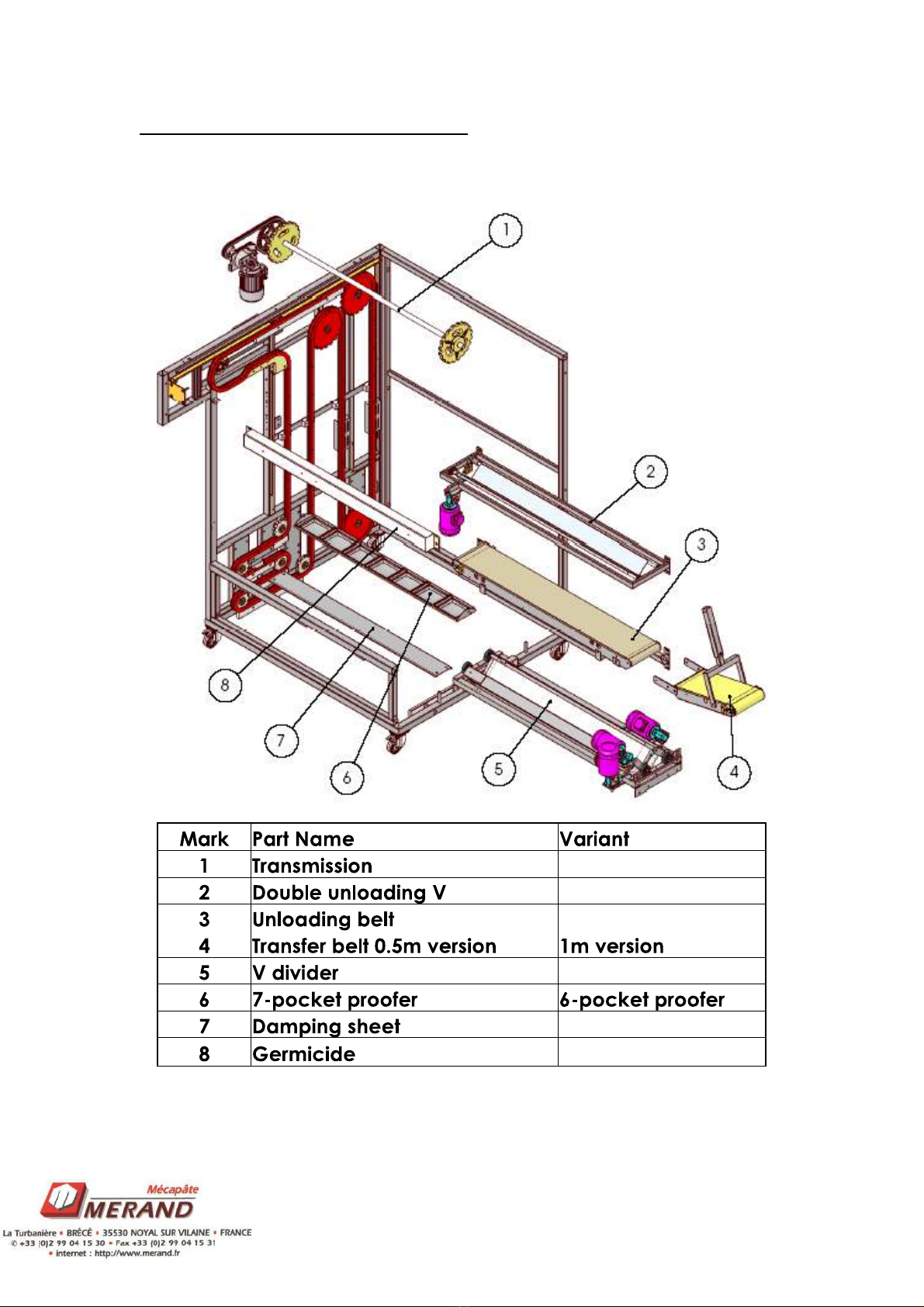

Presentation of the different sub-units

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

7TECHNICAL

SPECIFICATIONS

MA

RC

2006

0 DIV

UV

0

Special Balance

x

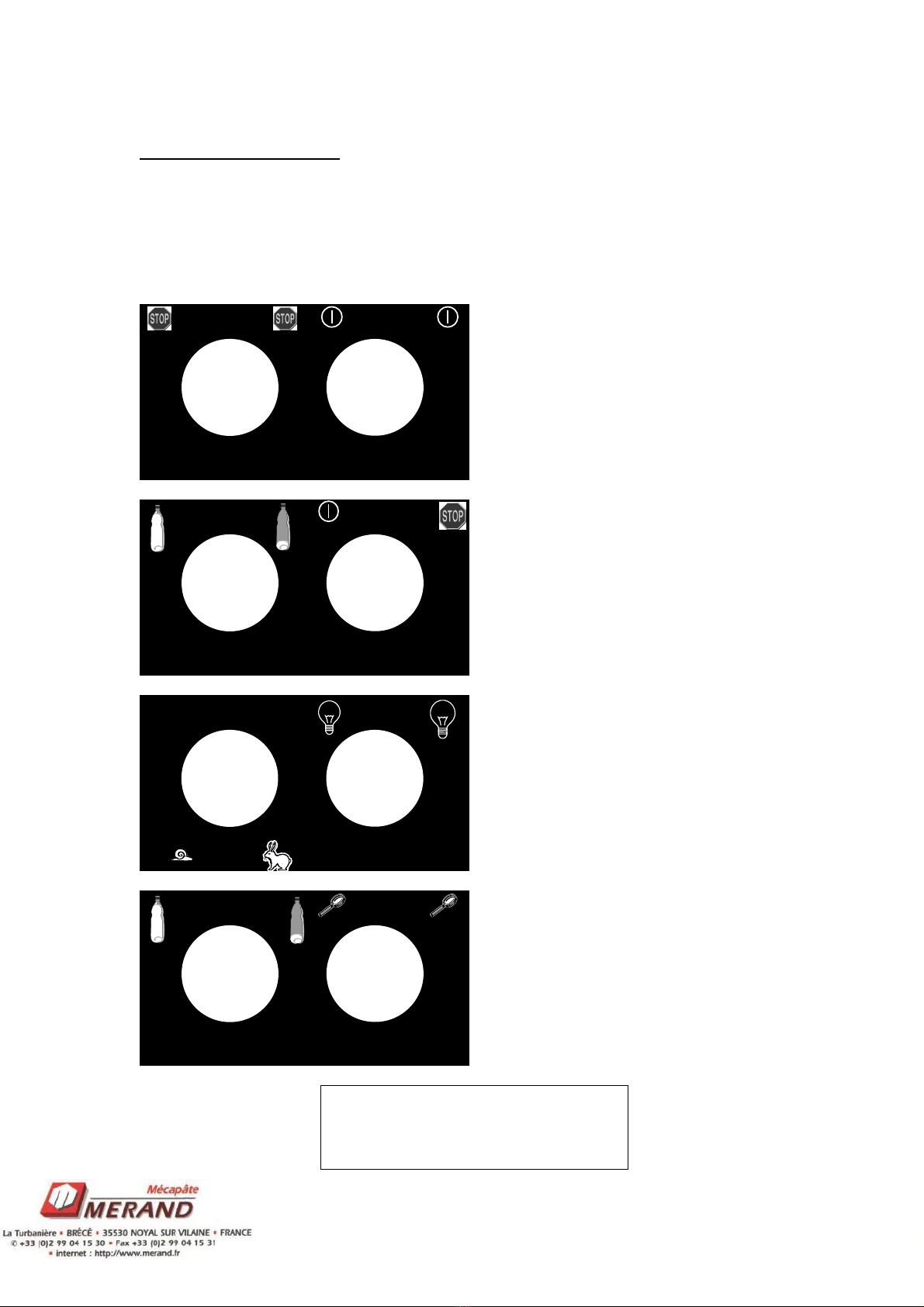

Description of controls

There follows the function of each of the buttons in the MECAFORM VE proofer

control box.

Emergency stop

General operation

Loading

0

Unloading

Weigher Start

Weigher Stop

Speed regulator adjustment

Germicidal lamp start

Germicidal lamp stop

Control proofer loading

0

Control proofer unloading

Control proofer search

The control proofer commands are

removed when equipment is fitted

with the treatment tunnel.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

8TECHNICAL

SPECIFICATIONS

MA

RC

2006

List of checkpoints and tests to be conducted at commissioning

Check the engine rotation direction of the transfer belt. If it does not rotate in the

correct direction, then reverse two phases in the power supply plug of the

MECAFORM VE proofer.

Check that all the thermal relays, circuit breakers and disconnecting switch are

correctly engaged.

Check that all cells and sensors are working properly.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

9TECHNICAL

SPECIFICATIONS

MA

RC

2006

OPERATING MODES

Restart after sector power cut or emergency stop

After restoring power, press the “general start” button so that the equipment performs

an initialization cycle. Once the initialization has been completed, the dough proofer

resumes the production mode selected before the stop.

Initialization cycle

The MECAFORM VE expansion chamber initialization cycle must be performed as

follows at each restart after a start or an emergency stop:

- Forward movement of the unloading belt up to the detection cell.

- Forward movement of the proofer support chain up to the proofer detection cell.

- Afterwards, the V divider and the Realignment V open, and the unloading belt

makes another forward movement up to the detection cell.

- Forward movement of the proofer support chain up to the proofer detection cell.

Once all these operations have been completed, the machine is in initial position and

waits for the launch of a new production cycle.

Loading

During the restart (after an emergency stop or a production start) push the “general

start” button.

Check that the weigher is well connected.

Put the “loading-unloading” selector on “loading” position – the cycle will start.

Note: An emergency stop during the loading cycle causes the re-initialization of the

expansion chamber.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

10 TECHNICAL

SPECIFICATIONS

MA

RC

2006

Unloading

Put the “loading-unloading” selector on “unloading” position – the unloading cycle

will start.

Make sure that the rotating system is well engaged.

Push the “general start” button- the unloading belt will move, and a proofer will turn

while the rolls are discharged.

Note: If you put the “loading-unloading” selector on position 0 during the unloading

cycle, the equipment will stop. To restart it, put the selector back in unloading

position.

An emergency stop during the loading cycle causes the re-initialization

of the expansion chamber.

Control proofer

During the start, after the initialization of the proofer, release the turning system, then

put the “control proofer loading-unloading” switch in loading position, then push the

“control proofer search” button. The control proofer will position itself under the V

divider, and a classic loading cycle will start.

Once the loading has been completed, put the “control proofer loading-unloading”

switch back in “0”.

For unloading, engage the turning system again, and put the “control proofer loading-

unloading” switch in unloading position; then push the “control proofer search”

button. The control proofer will position itself below the unloading belt, and a classic

loading cycle will start.

Once the loading has been completed, put the “control proofer loading-unloading”

switch back in “0”.

Cleaning

When the MECAFORM VE expansion chamber is correctly initialized, push the

“germicide” button to start a 1-hour UV lamp unloading cycle. To stop this cycle,

push the “germicide” button again.

The purpose of this function is to kill mould by means of UV light.

WARNING: Do not expose unprotected parts of the body (such as eyes and skin) to

UV light.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

11 TECHNICAL

SPECIFICATIONS

MA

RC

2006

Fan (optional)

When the selector is positioned on “fan start”, the fan located behind the equipment

will start. The purpose of this function is to extract humidity from your equipment,

allowing you to have better control of your process.

Variable flow central flour duster (optional)

By turning the potentiometer on the control unit, you may adjust the flour flow

necessary for a good flouring of proofers, before they require loading.

Treatment tunnel (optional)

By pushing the germicide start-stop button, you may combine the action of germicidal

lamps and fans. You may perform this operation throughout production, since the

frames going through the treatment tunnel are isolated from the rest of the frames.

The combined action of fans and germicidal lamps will allow you to dry pockets and

to kill mould.

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

12 TECHNICAL

SPECIFICATIONS

MA

RC

2006

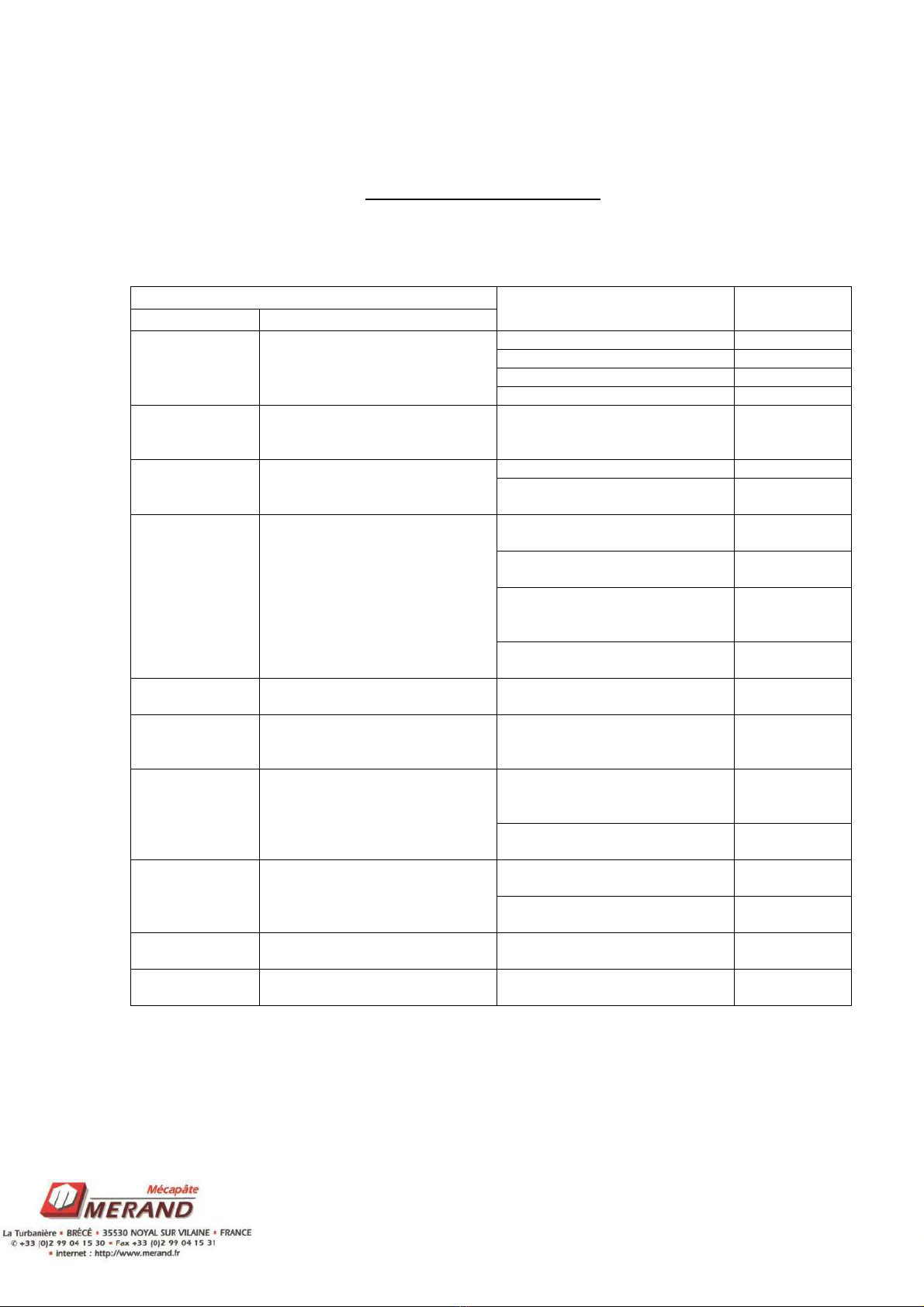

III. FAULTS AND CAUSES.

Fault

Type Description Possible origins Person

intervening

Power cut Baker

Emergency stop engaged Baker

Thermal relay disconnected Baker

Power Motor does not work

Motor out of service Technician

Power

Dough proofer motor

protection disconnected

permanently

Adjustment of thermal relay Baker or

technician

Band too tight Technician

Power

Belt motor protection

(unloading or transfer)

disconnected permanently Adjustment of thermal relay Baker or

technician

The Mécaform chain does not

turn in the right direction Technician

Drive pinions misaligned or

unlocked Technician

Quick disconnect fastener of

the gutter chain is not

properly locked

Technician

Operation Abnormal noise of Mécaform

VE

Chains wrongly tightened

(drive, gutter)

Baker or

technician

Operation The proofer does not stop at

the right place

Proofer stroke end wrongly

adjusted Technician

Operation The Mécaform does not

rotate when loaded

The drive motor torque

switch must be readjusted

(by ¼ turn)

Technician

The proofer chain does not

turn in the appropriate

direction

Technician

Operation Mécaform Ve is blocked

Faulty frame Technician

or baker

Moulder misplaced Technician

or baker

Operation The dough roll does not fall

properly into the moulder Belt position is not properly

set

Technician

or baker

Operation The V’s are not well closed Adjustment of the stroke end

position Technician

Operation Belts that countersink Adjustment of the belt

tightness

Technician

or baker

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

13 TECHNICAL

SPECIFICATIONS

MA

RC

2006

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

14 TECHNICAL

SPECIFICATIONS

MA

RC

2006

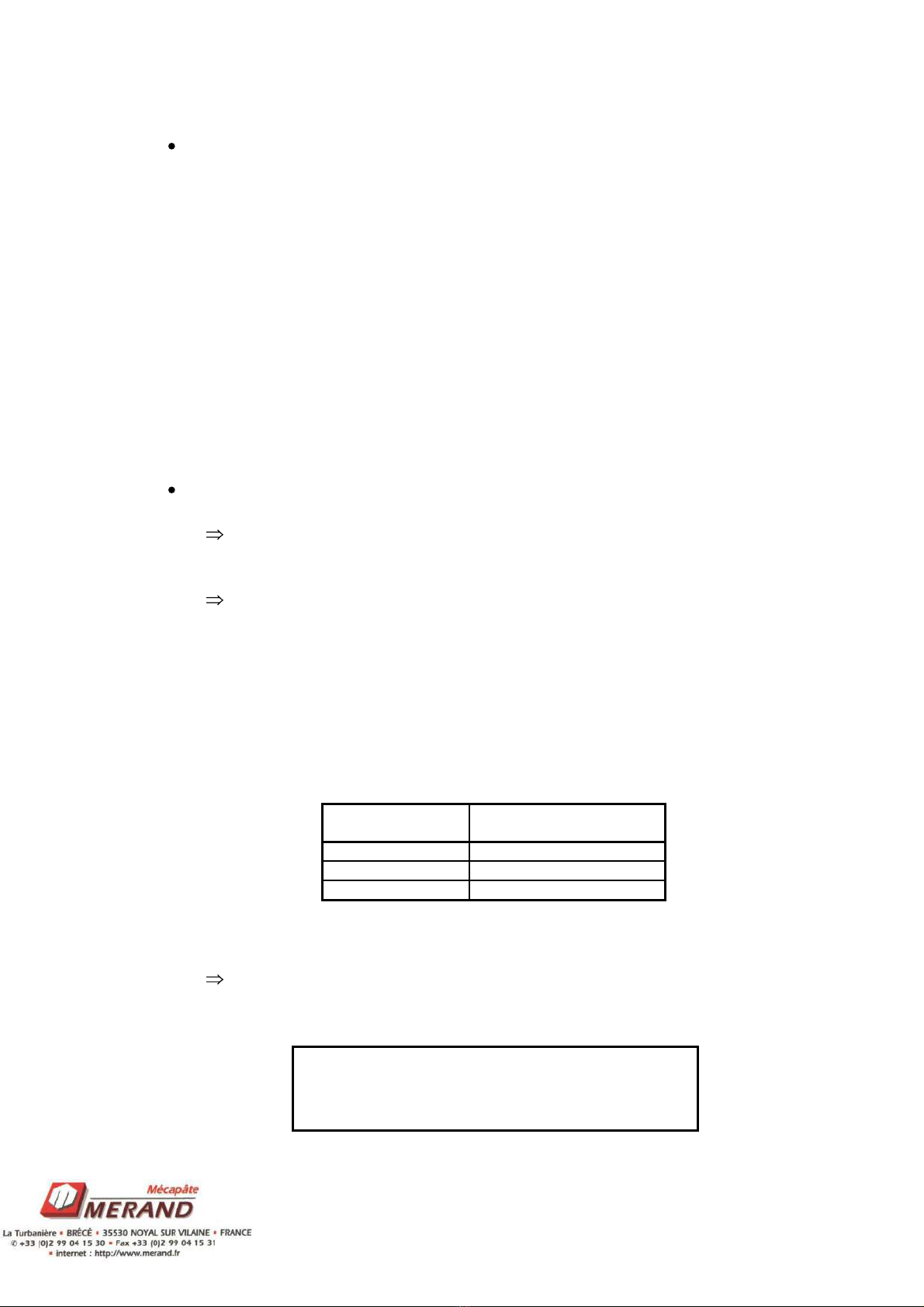

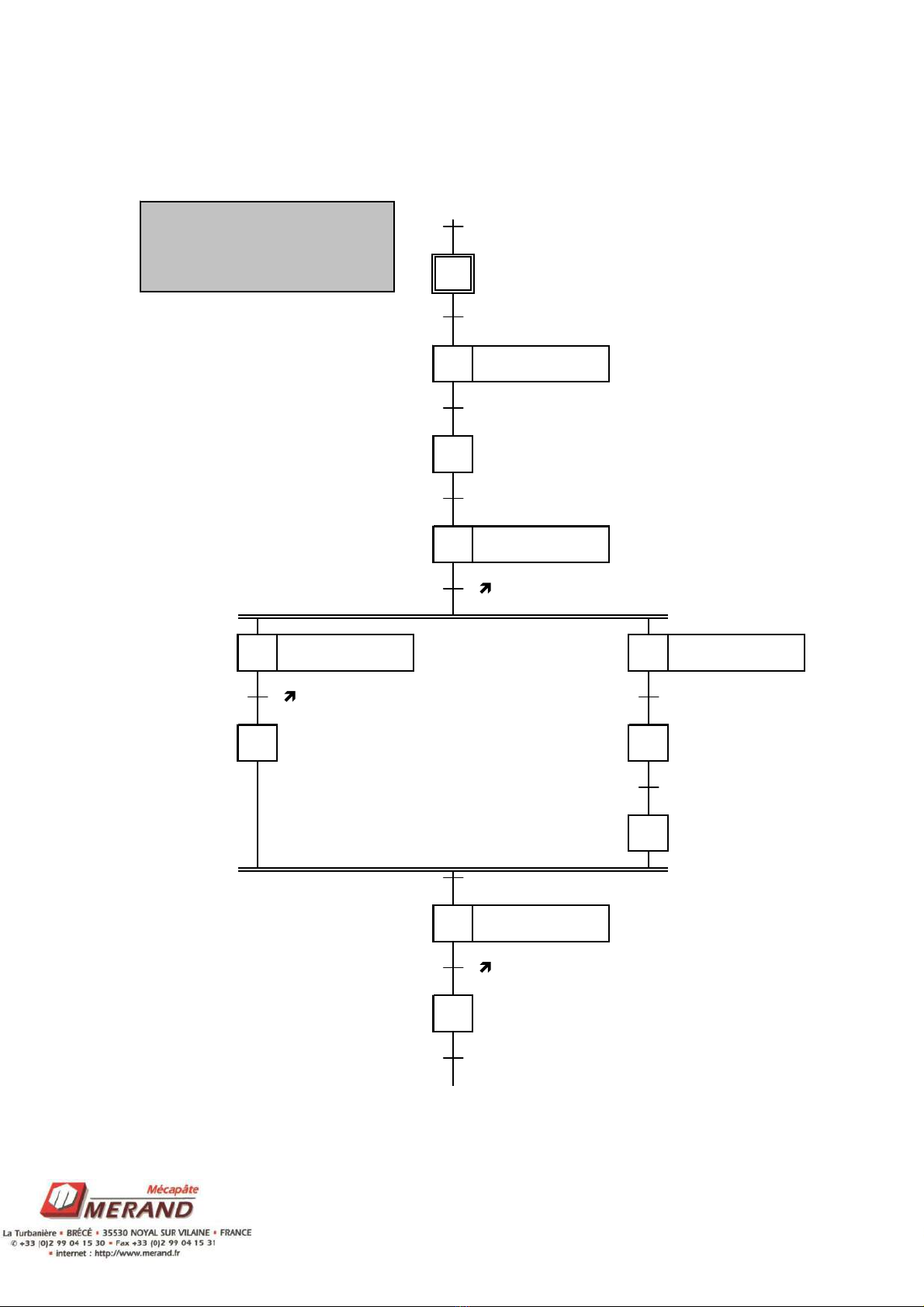

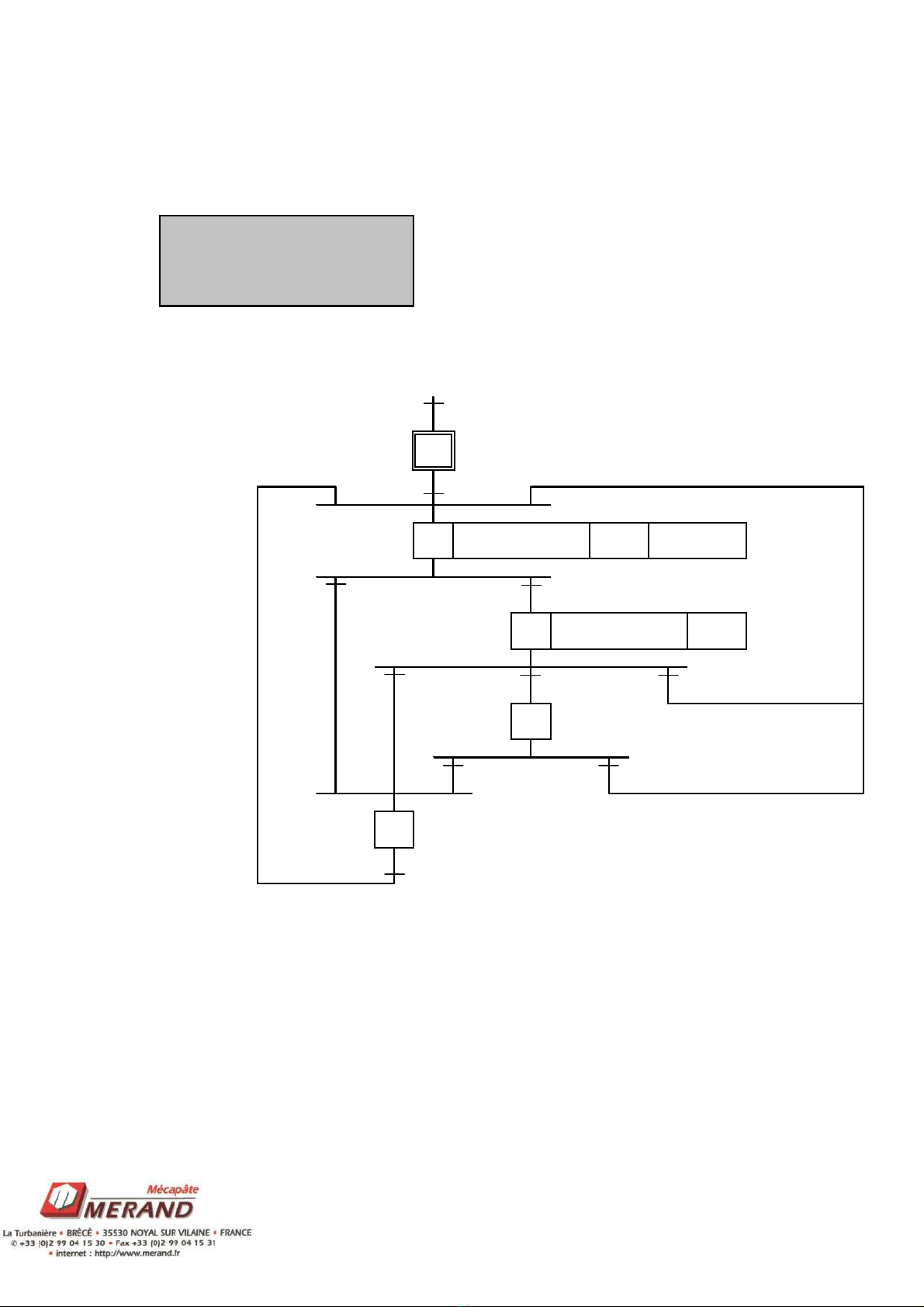

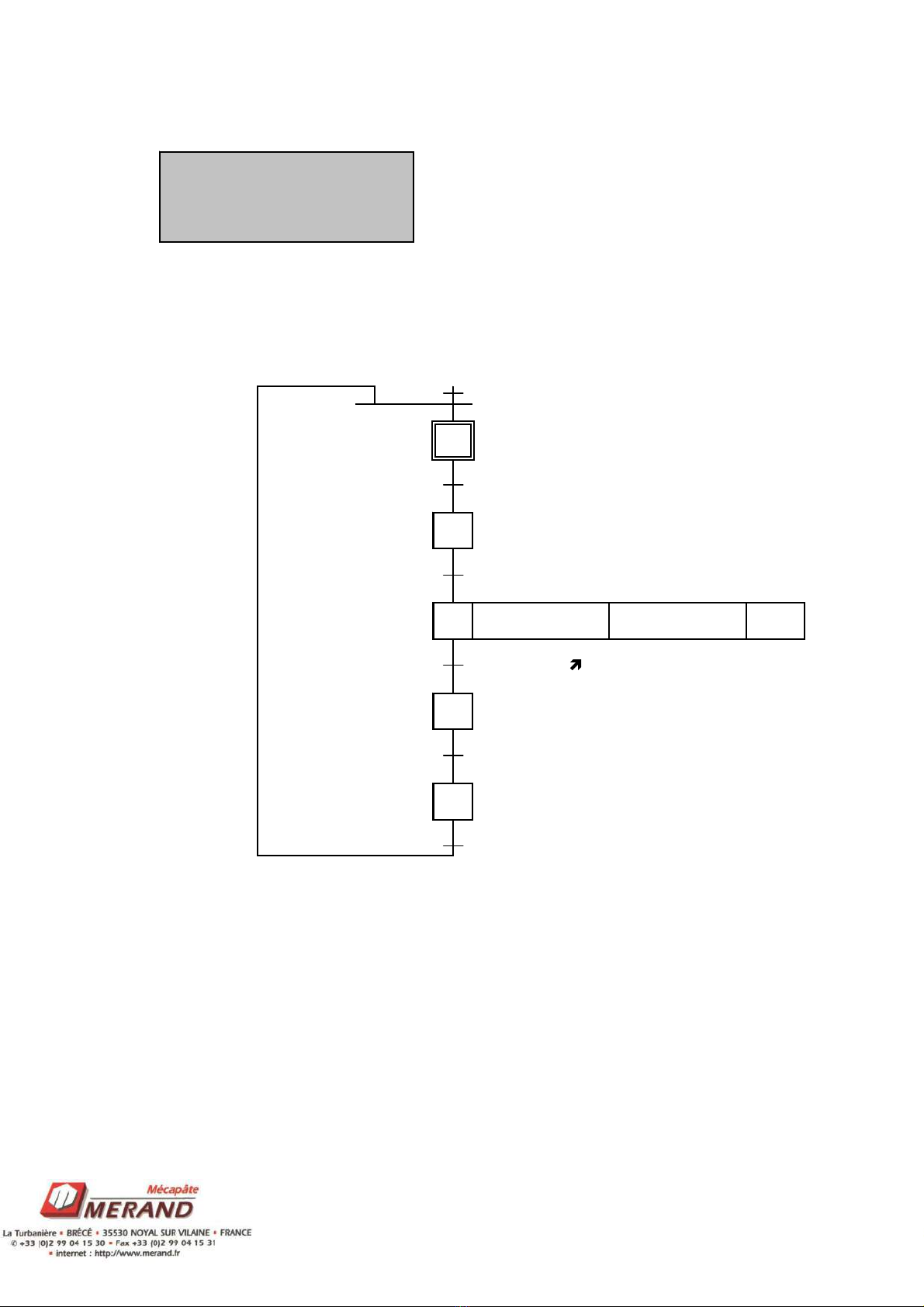

IV. DESCRIPTION OF OPERATION FROM THE SYSTEM

STANDPOINT.

G AFCET

MANAGEMENT

Faults

/Kg

%MW10

Kg.Mg

/ Init(Etp 10 grafcet init)

Init.Load./MbalT

Init.Unload./MbalT

Init.MbalT

Init.

Bp Germ

Init OK

Etp 34./Load.

/Unload.

/MbalT

Etp 74

10

11

13

14

15

16

17

12 FCT INIT. FCT LOAD. FCT UNLOAD.

FCT CTRL. PROOF.

FCT GERMICIDE

19

18 20

21

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

15 TECHNICAL

SPECIFICATIONS

MA

RC

2006

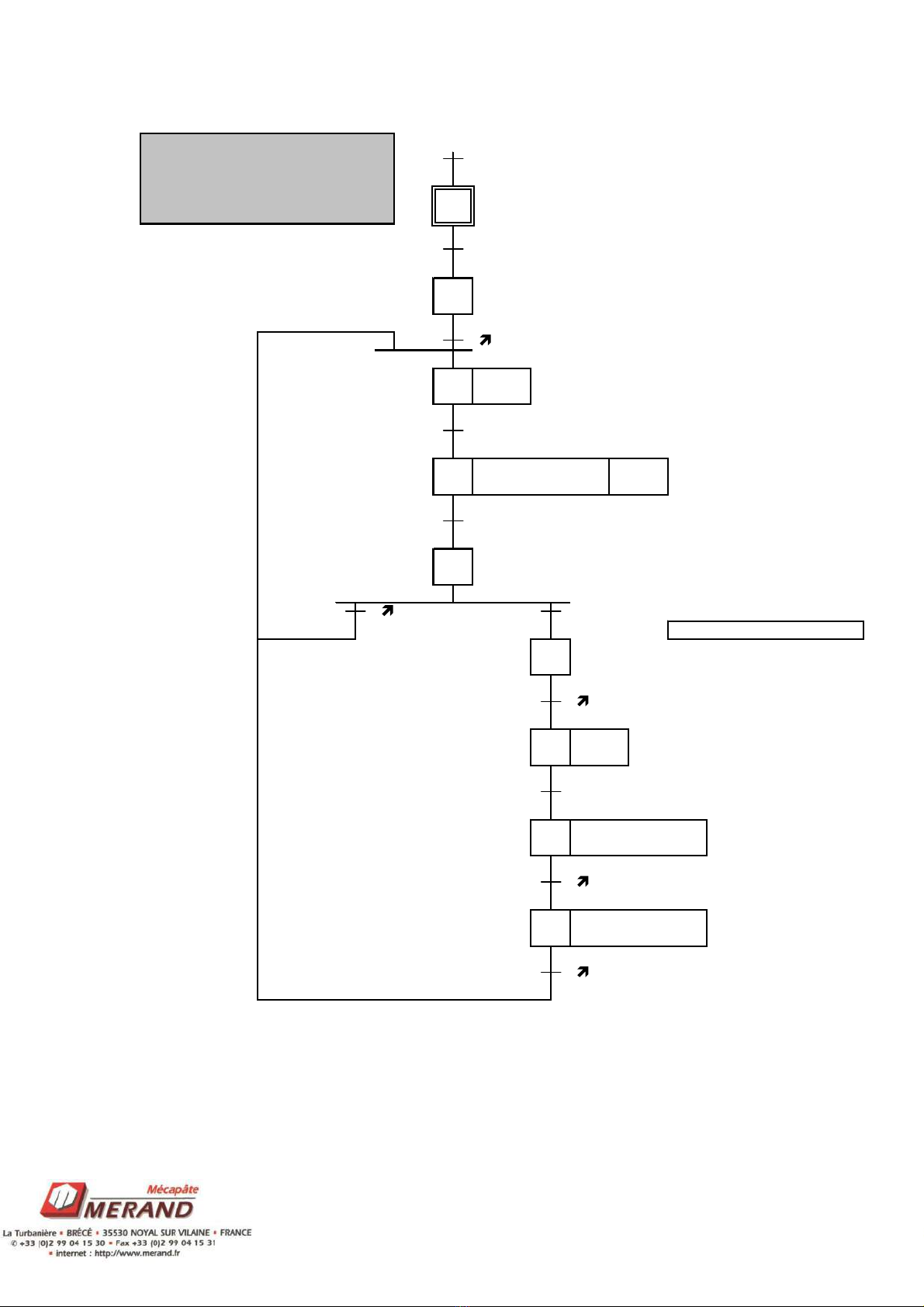

G AFCET

INITIALIZATION

/Kg

Etp 12

Cel tpvid

=1

fdc proof.

fer rev

Cel tpvid

=1

fer rev

fdc proof.

Init OK

%MW20

20

21

30

23

22

TP UNLOADING

PROOFER

26 TP UNLOAD.

25 27

24 OP. REV

28

29 PROOFER

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

16 TECHNICAL

SPECIFICATIONS

MA

RC

2006

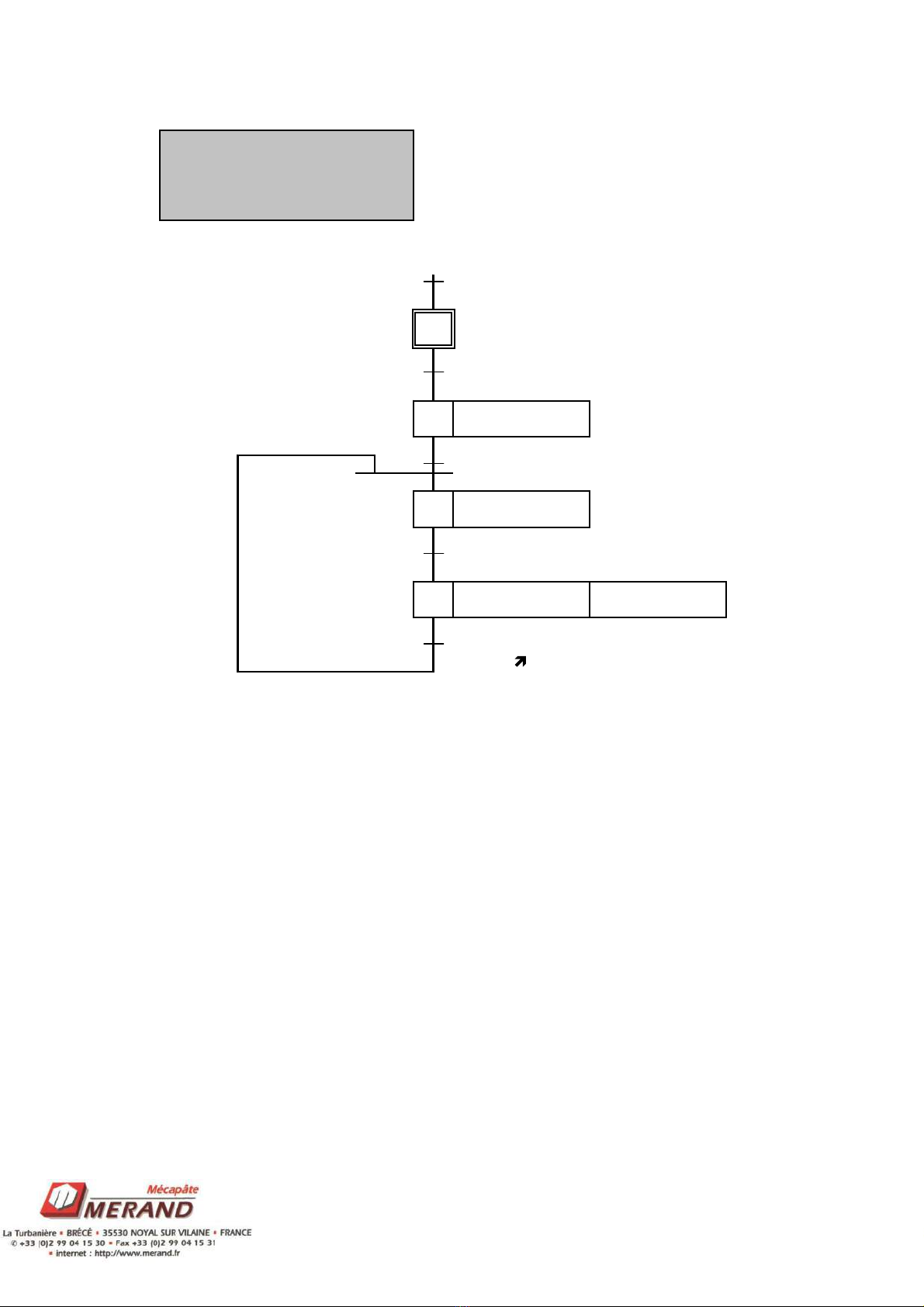

G AFCET

LOADING MGT

/Kg

Etp 14

/Loading

Apes+T1=0

/Loading

T2=0

Mpes.Loading

/Loading

Mpes.Loading

Etp 14

%MW30

30

31 G7 LOADING

32 G7 LOADING

33

34

T1

T2

WEIGHER

START

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

17 TECHNICAL

SPECIFICATIONS

MA

RC

2006

G AFCET

LOADING

/Kg

Etp 31+Etp 32

cat

T7=0

T4=0

cat.cont<X

cont>=X

X= No. of pockets to fill

cat

T7=0

fer rev

cat

OP. REV

46

T7

T4

45

48

AUTHORIZATION

PROOFER FW

42

43 FW TP REV

44

T7

47

%MW40

40

41

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

18 TECHNICAL

SPECIFICATIONS

MA

RC

2006

G AFCET

UNLOADING

/Kg

Etp 14+Etp 16+Etp72

Cel tpvid

=1

Cel tpvid.(Etp 16+Etp 72+Etp 95)

+Etp 14.

cpal.(Etp 31+Etp 32)

51

%MW50

TP UNLOADING

TP UNLOADING

52

53

50

AUTHORIZATION

FW PROOFER

TP UNLOADING

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

19 TECHNICAL

SPECIFICATIONS

MA

RC

2006

G AFCET

P OOFE FWD

/Kg

(Etp 52.(Etp16+Etp72+Etp95))

+(Etp 48.Etp 14.(Etp32+Etp 31))

fdc proofer

((Etp 52.(Etp 16+Etp 72))+(Etp 42.Etp 14)

%MW60

60

PROOFER

61

62

Non-binding document. The manufacturer reserves the right to modify all its products without prior notice

20 TECHNICAL

SPECIFICATIONS

MA

RC

2006

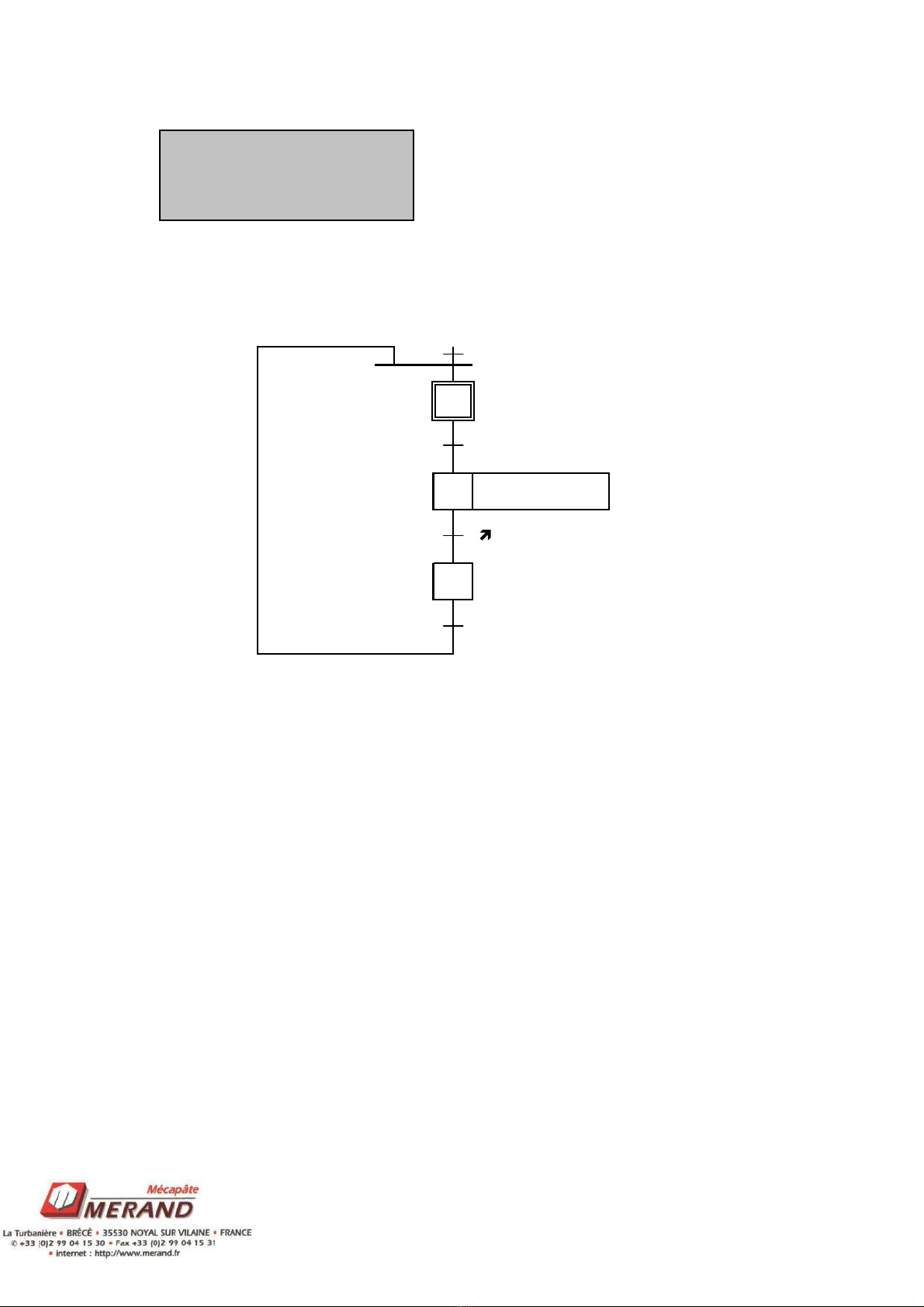

G AFCET

GE MICIDE

/Kg

Etp 20(Mgt Grafcet)

=1

T6=0+Etp 20.

Bp germ

=1

/Etp 20

%MW70

UNLOADING

CYCLE

71

72 GERMICIDE

70

T6

73

74

Table of contents

Other Merand Industrial Equipment manuals