Merlin Overdrive Supplement

MRC950EVO

ight Commercial Rolling Door Opener

Installation and Operating Instructions

Owners Copy: Please keep these instructions for future reference

This manual contains IMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTA ATION BEFORE READING THOROUGH Y

gomerlin.com.au

gomerlin.co.nz

IMPORTANT

* Chain reduction assemblies that may interfere with the safe and

proper operation of the OVERDRIVETM (MRC950EVO) must be removed.

* All hand chains must be removed prior to fitting the OVERDRIVETM

(MRC950EVO).

* DO NOT use Extension Poles with the OVERDRIVETM (MRC950EVO).

* The OVERDRIVETM (MRC950EVO) can be used on windlocked doors

based on the following conditions:

- door is professionally installed, correctly sprung and maintained to

manufacturerʼs instruction

- door size up to 18 m2

- product is only operated in normal conditions, not during adverse wind

conditions.

NOTE:

When installed on light commercial doors, the warranty covers the

replacement of the opener only. Merlin holds no responsibility for the

door or costs associated with the door in order to access the opener.

For warranty to be claimed in a light commercial application, proof

must be provided that the door has been serviced according the door

manufacturers requirements and that the door is spring balanced, is

operable by hand and opens and closes with no more than a maximum of

20 kgs of lifting weight.

1

CONTENTS PAGE

SA ETY INSTRUCTIONS . . . . . . . .1

CARTON INVENTORY . . . . . . . . . .2

TOOLS REQUIRED . . . . . . . . . . . .2

DOOR REQUIREMENTS . . . . . . . .2

PREPARE & TEST THE DOOR . .3-4

INSTALLATION . . . . . . . . . . . . . .4-5

CONNECT ELECTRIC POWER . . .5

ADJUSTMENT . . . . . . . . . . . . . . .6-7

INSTALL THE PROTECTOR

SYSTEM .....................8

WIRELESS PROGRAMMING . .9-10

BATTERY BACK UP . . . . . . . . .11-12

SPECIAL EATURES & WIRING .13

SPARE PARTS . . . . . . . . . . . . . . .14

ACCESSORIES . . . . . . . . . . . . . .14

DIAGNOSTIC CHART . . . . . . .15-16

TROUBLESHOOTING . . . . . . . . .17

MAINTAINING YOUR OPENER . .19

CARE O YOUR OPENER . . . . . 19

OPERATION O YOUR OPENER 19

SPECI ICATION . . . . . . . . . . . . . .19

WARRANTY . . . . . . . . . . . . . .20-22

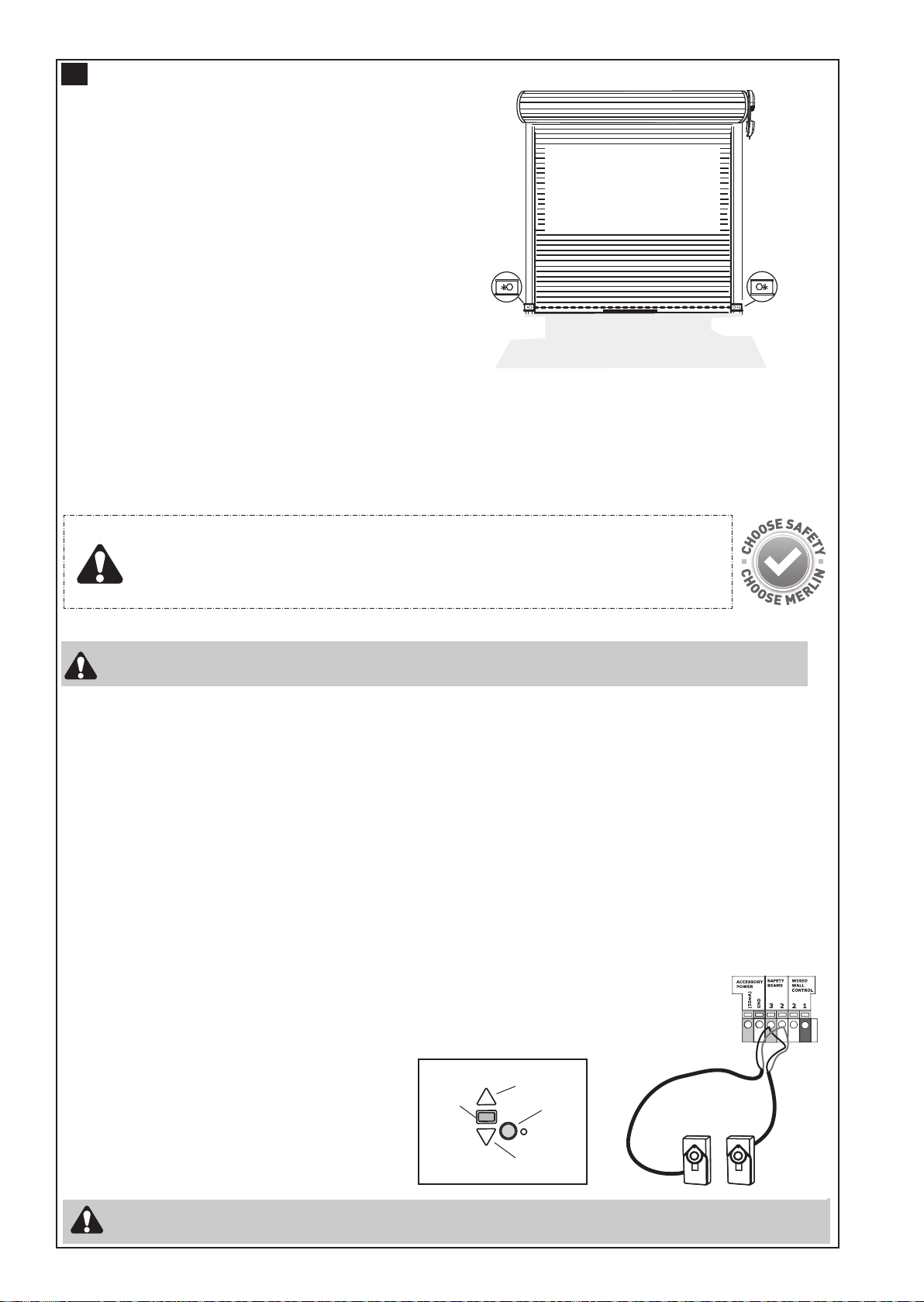

The opener must not be used on a wicket

door (door within a door).

The rotector SystemTM must be used for all

installations where the closing force as

measured on the bottom of the door is over

400 N (40 kgf). Excessive force will interfere

with the proper operation of the safety reverse

system or damage the garage door.

After installation, ensure that the parts of

the door do not extend over public

footpaths or roads.

Install the wireless wall control (or any

additional wall control) in a location where

the garage door is visible, at a height of at

least 1.5 m and out of the reach of children.

Do not allow children to operate push

button(s) or transmitter(s). Serious personal

injury from a closing garage door may result

from misuse of the opener.

ermanently fasten the Warning Labels in

prominent places, adjacent to wall controls

and manual release mechanisms as a

reminder of safe operating procedures.

Activate opener only when the door is in

full view, free of obstructions and the

opener is properly adjusted. No one should

enter or leave the garage while the door is

in motion.

Do not allow children to play near the door,

or with door controls.

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid hazard.

Disconnect electric power and battery to

the garage door opener before making

repairs or removing covers.

KEE THESE INSTRUCTIONS

WARNING

•Failureto comply with the following instructions may resultinserious personal injury or property damage.

• Read and follow all instructions carefully.

• The garage door opener is designed and tested to offer safe service provided it is installed and

operated in strict accordance with the instructions in this manual.

These safety alert symbols mean WARNING : A possible risk to personal safety or

property damage exists.

NOTE: If your garage has no service entrance door, a CM1702 outside quick release must be installed.

This accessory allows manual operation of the garage door from outside in case of power failure.

Keep garage door balanced.Do not let the

garage door opener compensate for a binding or

sticking garage door. Sticking, binding or

unbalanced doors must be repaired before

installing this opener.

Do not wear rings, watches or loose clothing

while installing or servicing a garage door

opener.Wear gloves and suitable protective

clothing where appropriate.

Frequently examine the door installation, in

particular cable, springs and mountings for signs

of wear, damage or imbalance. Do not use if

repair or adjustment is needed since springs and

hardware are under extreme tension and a fault

can cause serious personal injury.

To avoid serious personal injury from

entanglement, remove all ropes, chains and

locks connected to the garage door before

installing the door opener.

Installation and wiring must be in compliance

with your local building and electrical codes.

The safety reverse system test is very

important. Your garage door MUST reverse on

contact with a 40 mm obstacle placed on the floor.

ailure to properly adjust the opener may result in

serious personal injury from a closing garage

door. Repeat the test once a month and make

any necessary adjustments.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capablities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Automatic Drive - Keep away from the area of

the door as it may operate unexpectedly.

This opener should not be installed in a damp

or wet space exposed to weather.

START BY READING THESE IM ORTANT SAFETY INSTRUCTIONS

1. Instruction manual (this document)

2. Stop collar

3. Clamp bracket

4. Release handle, cord and risk of entrapment card

5. Transmitters (2)

6. Wireless wall button

7. Hardware bag

8. Clamp plate

9. Warning label and risk of entrapment label

10. Battery back up

CARTON INVENTORY

1

10

(or work platform,not shown)

TOOLS REQUIRED

2

1. Ladder or work platform (not shown)

2. Adjustable wrench for U-bolts already installed

on the door

3. 8mm socket, 10mm socket and 13mm extended

socket and socket wrench

4. 300mm socket extension (for minimum side-room

installations)

5. Drill and 5.5mm drill bit

6. Philips-head screwdriver

7. Marker pen

8. Hoist or similar device to safely lift & support door

(not shown)

DOOR REQUIREMENTS

3

Ensure that there is at least 45 mm from the edge of the curtain to the edge of the bracket. If the roller door

drum is on the edge of the curtain or is a smaller diameter, additional clearance may be required. ( Ensure

there is a power point near the opener.)

95mm

95mm

Minimum distance from

edge of curtain to edge of

door bracket 45mm

Alternate

clamping method

(Onto Axle only)

Preferred clamping

method

(Direct to Wall

Bracket)

The maximum allowable door height is 5.5m (light commercial door) with a maximum curtain area of 25m² (door

height in metres multiplied by the width in metres). The door must be of continuous corrugated sheet construction,

spring balanced & of a mass not exceeding 250kg. Door axle diameter must not exceed 35mm.

2

TESTING THE DOOR

4

Complete the following test to ensure your door is well

balanced, and not sticking or binding:

• Disable all locks and remove any ropes connected to the

door.

• Lift the door to about halfway and then release it. The

door should remain spring balanced.

• Raise and lower the door to determine if there are any

sticking or binding points (20 kgf is the absolute maximum

allowable to raise or lower the door in any position).

• If your door does not hold in place or the door binds, sticks

or requires excessive force to move, call a qualified door

technician before installing the opener.

Non opener side Opener side

• Install the stop collar on the opposite end to where

the opener is to be installed.

• it the stop collar hard against the boss of the door

drum. Ensure the U-bolt holding the door shaft to the door

bracket is tightly secured.

INSTALLING THE STO COLLAR

5

3

SAFETY CHECK!

Is the stop collar

installed?

YES: proceed to the next

step

NO: install the stop collar

before proceeding

INNING THE DOOR

Note: A ballooning door may delay the safety reversal

response and can compromise door security.

• To remedy any ballooning place self tapping metal screws

or rivets where the curtain leaves the roll. Secure these

through the curtain into the drum wheel at each end of the

roll.

• After determining the correct fastener location as shown, lift

the door approximately half a turn from the closed position

to allow access for drilling.

ree curtain Ballooning Add fasteners here

Door closed Door can be

lifted Door secure

6

Note: When installed on light commercial doors, the warranty covers the replacement of the opener

only. Merlin holds no responsibility for the door or costs associated with the door in order to access

the opener. or warranty to be claimed in a light commercial application, proof must be provided that

the door has been serviced according the door manufacturers requirements and that the door is

spring balanced, is operable by hand and opens and closes with no more than a maximum of 20 kgs

of lifting weight.

4

To disengage the opener

Pull the release cord down firmly,

(opener will make a clicking noise).

To re-engage the opener

Pull the release cord down firmly,

(opener will make a clicking noise).

Disable all locks and remove any ropes connected to the door.

Take care when operating the manual release as an open door may fall rapidly due to weak or

broken springs, or being out of balance.

O ERATING THE MANUAL RELEASE

8

Pull down

FIRMLY

click

Release cable

Rope

Manual release

warning label

Release handle

Overhand knot

DOWN Arrow

button

UPArrow

button

Learn

button

Learn Limits

button

• Thread one end of the rope through the hole in the top

of the red release handle so that “NOTICE” reads

right side up as shown.

• Secure with an overhand knot at least 25mm from the

end of the rope to prevent slipping.

• Thread the other end of the rope through the loop of

the manual release cable.

• Adjust rope length so the handle (when installed) will

be no higher than 1.8 m above the floor. Secure with

an overhand knot.

NOTE: Final adjustment of handle height should be

completed after the opener is installed. If it is

necessary to cut the rope, heat seal the cut end to

prevent unravelling (refer section 13).

THE RELEASE HANDLE & CORD

7

LEFT / RIGHT HAND INSTALLATION

9

LE T

(handing must be

changed during limit

setting, section 11)

RIGHT

(factory

default

setting)

Inside looking out

5

INSTALLATION ROCEDURE

NOTE: The opener can be installed on either side

of the door. The following instructions are for

RIGHT HAND INSTA ATIONS (as illustrated i.e.

inside the garage looking out). For left hand

installations, reverse the instruction terminology

(eg EFT for RIGHT etc).

Preparation:

• Place the opener in manual release mode (refer

section 8).

• Open the roller door fully. or safety, tie a rope

around the door.

• Ensure the door axle U-BOLT and door mounting

bracket on the left hand side (non opener side) are

securely fastened.

• Support the door with a door stand or similar device

to safely support the door.

• Mark the position of the door shaft on the right hand

door bracket (for reassembly purposes).

• While the door is supported, remove the right hand

axle U-Bolt and door mounting bracket from the wall.

Install the opener:

• Slide the opener over the door axle and engage the

drive legs into the door drum wheel, either side of a

spoke.

• Refit the door mounting bracket to the wall. If the

door bracket needs to be relocated due to opener

width, refer section 3.

• Clamp the opener on the door axle and door bracket

in the marked position using the clamp assembly

supplied (tighten to 25 – 28 Nm).

• If side room exceeds 95mm clamp independently to

the door axle as illustrated in section 3.

• Remove all ropes and the support stand.

• Check the operation of the door in manual mode by

raising and lowering by hand. It should operate

smoothly without sticking or binding. The disengage

handle should already be attached less than 1.8 m

above the floor (refer section 7).

Connect the power:

• Position the power cable away from the door curtain

and any moving parts.

• Plug the opener into a nearby power point and turn

ON.

• The opener courtesy LEDs should turn ON.

• The opener must now be programmed for:-

• DOOR TRAVEL LIMITS (Section 11)

• RIGHT OR LE T HAND OPERATION (Section 11)

• ORCE SETTING (Section 11)

Door stand

Rope

Tighten to

25-28 Nm

Do not allow people to walk under or

around the door during the installation

process as serious injury can occur.

10

Door stand

Rope

6

SETTING THE LIMITS FOR RIGHT OR LEFT HAND O ERATION AND FORCE

Travel limits set how far your door goes up and down. Your opener must be configured correctly for right or left

hand installation to operate correctly, if not the door will rotate in the reverse direction.

NOTE: The OVERDRIVETM (MRC950EVO) opener is factory configured for right hand installation.

Press and hold

until

FLASHING

LED

Press & release to accept

selected hand.

If required: Use DOWN button to adjust

Press and hold to drive

door up to open

Press and hold to drive

door down to closed

If required: Use UP button to adjust

Activate door to open

Close the door to test limits

Orange

LED ON &

Courtesy LEDS

on Dim

Motor will make a click &

FULL BRIGHT courtesy

LEDs will turn on

Right bank

will light up

(IF REQUIRED)

To change

press and hold

until correct

bank lights up

Left bank

will light up

for Left hand

installation

Click

Press & release to set the

UP limit

Press & release to set the

DOWN limit

The opener will operate during this procedure. Make sure the door is clear of obstruction.

Ensure your hands are away from any moving parts before activating the door.

Setting right or left hand operation:

• Ensure the door is positioned halfway and the opener

is engaged.

• Turn the power ON. After 2 seconds the Courtesy

LEDs will turn on.

• Press and hold the black (Limit) button until the

orange indicator LED starts flashing, and then

release. Either right or left courtesy LEDs will light

up.

• or right hand installations, the right side bank of

LEDs must light up, and for left hand installations,

the left hand bank must light up.

• If the incorrect bank of LEDs is illuminated, simply

press the Yellow learn button until the opposite bank

lights up.

• Press and release the Black limit set button to

accept hand. UP button will flash.

Setting the open (UP) limit:

• Press and hold the “UP” button, until the door

reaches the desired open position, and then release.

You can adjust the door by using the DOWN button

and UP button to adjust as necessary. Make sure

there is enough room for your vehicle to pass under.

• Press and release the Black limit set button to

acknowledge the Up position.

• Courtesy light flashes twice and DOWN button will

flash.

Setting the bottom (DOWN) limit:

• Press and hold the “DOWN” button until the door

reaches the desired closed position. If the door

closes too hard against the floor, use the UP and

DOWN button to adjust.

• Press and release the Black limit set button to

acknowledge the down position.

• Courtesy light flashes twice and UP button will flash.

Setting the FORCE:

• Press and release the UP button. The door will travel

to the UP limit and the DOWN button will flash.

• Press and release the DOWN button. The door will

travel to the DOWN limit.

• The indicator LED will stop flashing indicating the

force has been learned.

NOTE: The courtesy EDs will go out after 2.5

min.

• The door must travel through a complete cycle, UP

and DOWN, in order for the force to be set properly.

If the opener cannot open and close your door fully,

inspect your door to ensure that it is balanced

properly and is not sticking or binding.

11

7

Once you have completed your installation and

successfully carried out the safety reverse system test

(outlined above), install the warning labels provided

with your opener as shown.

The risk of entrapment label must be installed

adjacent to the release handle at a height of less than

1.8 m from the floor.

If required, use an eye bolt or hook (not included) to

guide the release handle rope.

The WARNING label must be installed in a prominent

place near any fixed control.

Any fixed wall control or wireless door control must be

mounted at a height of no less than 1.5 m out of the

reach of children.

Ensure the manual release instruction card is attached

to the rope as detailed in section 7.

Read the safety instructions (page 1) for further details

concerning safety.

FIXING WARNING LABELS

Operate the door in the down direction. The door must

reverse upon contact with the obstacle. If the door

stops on the obstacle, remove obstacle and repeat

limit and force setting (refer section 11).

Repeat test of the safety reverse system.

12

40mm Test obstacle

40mm

13

TESTING THE SAFETY REVERSE SYSTEM

The safety reverse system test is important.

The door must reverse on contact with a

40 mm obstacle laid flat on the floor. Failure

to properly adjust the opener may result in serious

personal injury from a closing door.

STANDARD INSTA ATION COMP ETE

8

NOTE: This accessory must be used for all

installations where the closing force as measured

on the bottom of the door is over 400 N (40 kgf).

After the opener has been installed and adjusted, the

Protector System™ accessory can be installed.

Instructions are included with this accessory.

The Protector System™ provides an additional

measure of safety against a small child or animal

being trapped under a garage door. It uses an infra-

red beam, which when broken by an obstruction,

causes a closing door to open and prevents an open

door from closing and is strongly recommended for

homeowners with young children.

Red LED

MUST BE ON Red LED

MUST BE ON

IR Beam IR Beam

IR Beams must be installed

to detect a 100 mm high

obstacle at any point along

the floor.

14

SAFETY FIRST!

Whilst Chamberlain have engineered safety features into your garage door opener, we urge you

to consider fitting IR Beams to your new garage door opener. In many countries these devices are

compulsory to assist in preventing serious injury or property damage. For your own peace of mind

and the safety of others please install this inexpensive safety device.

Door may operate unexpectedly, therefore do not allow anything to stay in the path of the door.

INSTALL THE ROTECTOR SYSTEM™ (IR BEAMS) O TIONAL ACCESSORY

Timer to close feature (TTC)

The Timer-to-close feature allows the door to automatically close after a specified time period. Prior to the door

closing, the garage door opener lights flash for 8 seconds before the door begins to close.

If the door encounters an obstruction while closing, the opener will make a second attempt to close the door. If

an obstruction occurs on the second attempt, the garage door opener will open, stop and WI NOT close until

the obstruction has been cleared and the opener has been operated again.

NOTE: The Protector SystemTM MUST be installed and operating for 5 minutes to enable this feature.

Installing and adjusting:

• Turn the opener off

• Install the Protector SystemTM using the brackets, wires and instructions provided with the product. Twist the

two white (only) wires together and terminate them into the white (2) terminal. Twist the two white/black wires

together and terminate them into the grey (3) terminal.

• Turn the opener on

With the door at the down limit, press and hold DOWN

arrow until orange LED starts blinking.

Yellow LEARN button is used to cycle through the

TTC settings:

1 x long blink = TTC O

1 x short blink = TTC 1 min

2 x short blink = TTC 5 min

3 x short blink = TTC 10 min

Press black rectangle button to set and exit.

Auto close is NOT recommended for households with young children.

12V DC

Up

Down

Yellow

Learn

Button

Black

Learn

Button

ENAB ING THE PROTECTOR SYSTEM: ( actory default – IR beams are not enabled.)

With the Protector System installed, enabled the IR Beams using the following process.

• TURN O the mains power and ensure any battery backup is also disconnected.

• PRESS and HOLD both the UP and DOWN arrow buttons.

• TURN ON the mains power to the operator.

• HOLD both arrows until the courtesy lamp flashes TWICE and remains ON.

The Protector System is now activated. Checks IRs operate correctly.

9

WIRELESS ROGRAMING (O TIONAL ACCESSORIES)

NOTE: Transmitter(s) and wall button supplied with your opener are factory programmed.

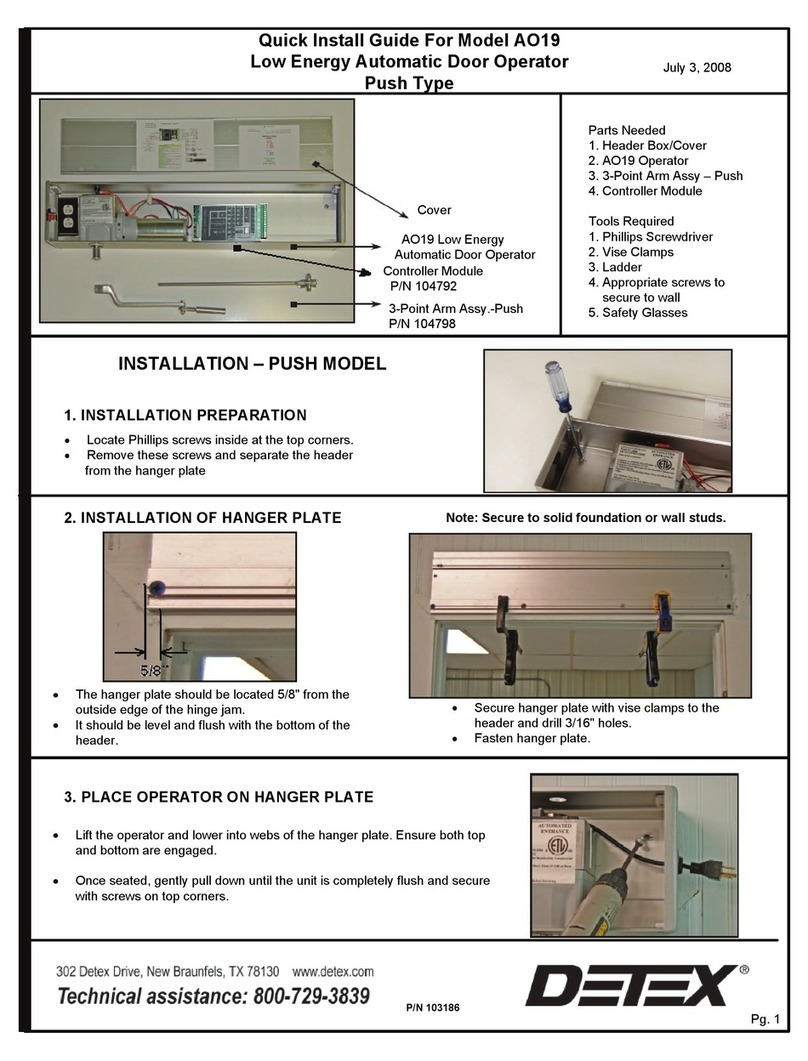

INSTALLING YOUR E128M WIRELESS WALL BUTTON

To install:

• Carefully pry open the E128M and locate the two screws for

mounting.

• Attach to the wall using the two screws and wall anchors

provided if mounting to a plaster wall. If using a recessed wall

box do not use anchors.

NOTE: Do not overtighten screws.

+

15

16

Disconnect power to the opener whilst installing

this accessory to prevent accidental activation.

Locate minimum 1.5 m above the floor.

Activate the opener only when the door is in full view, free of obstruction and properly adjusted.

No one should enter or leave garage whilst the door is in motion. Do not allow children to operate

push button(s) or transmitter(s). Do not allow children to play near the door.

Fix any wall control at a height of at least 1.5 m and within sight of the door but away from any

moving parts.

NOTE: The wall control supplied with your opener should be pre-programmed by the factory.

If adding a new wall control, program into the opener before mounting the unit as detailed in

section 16.

Press LEARN

or

LED will FLASH

TO ADD Transmitters / Wireless wall button

Press and hold down the desired

Button.

Press LEARN for 9 seconds

TO DELETE ALL REMOTES

LED on WILL TURN ON

After 9 seconds all remotes

are deleted and LED will go

out.

Release LRN button when

Courtesy LEDs

flashes once

NOTE: If adding an installed wall control (E128M)

you will need a second person to press and hold

the desired button. If not installed, program the

wall button into the opener before mounting.

ADDING transmitters using the RN “ EARN”

button

• Press and hold down the button you wish to program

to the opener.

• The orange LED on the opener will flash to indicate

it is receiving signal from the transmitter.

• Press and release the “LRN” button.

• The courtesy LEDs will flash once.

• Ensure the door is clear of obstruction, then test the

transmitter.

Deleting A transmitter codes

NOTE: This deletes all transmitters and codes

•Press and hold the LRN learn button until the orange

indicator light goes out (approximately 9 sec).

10

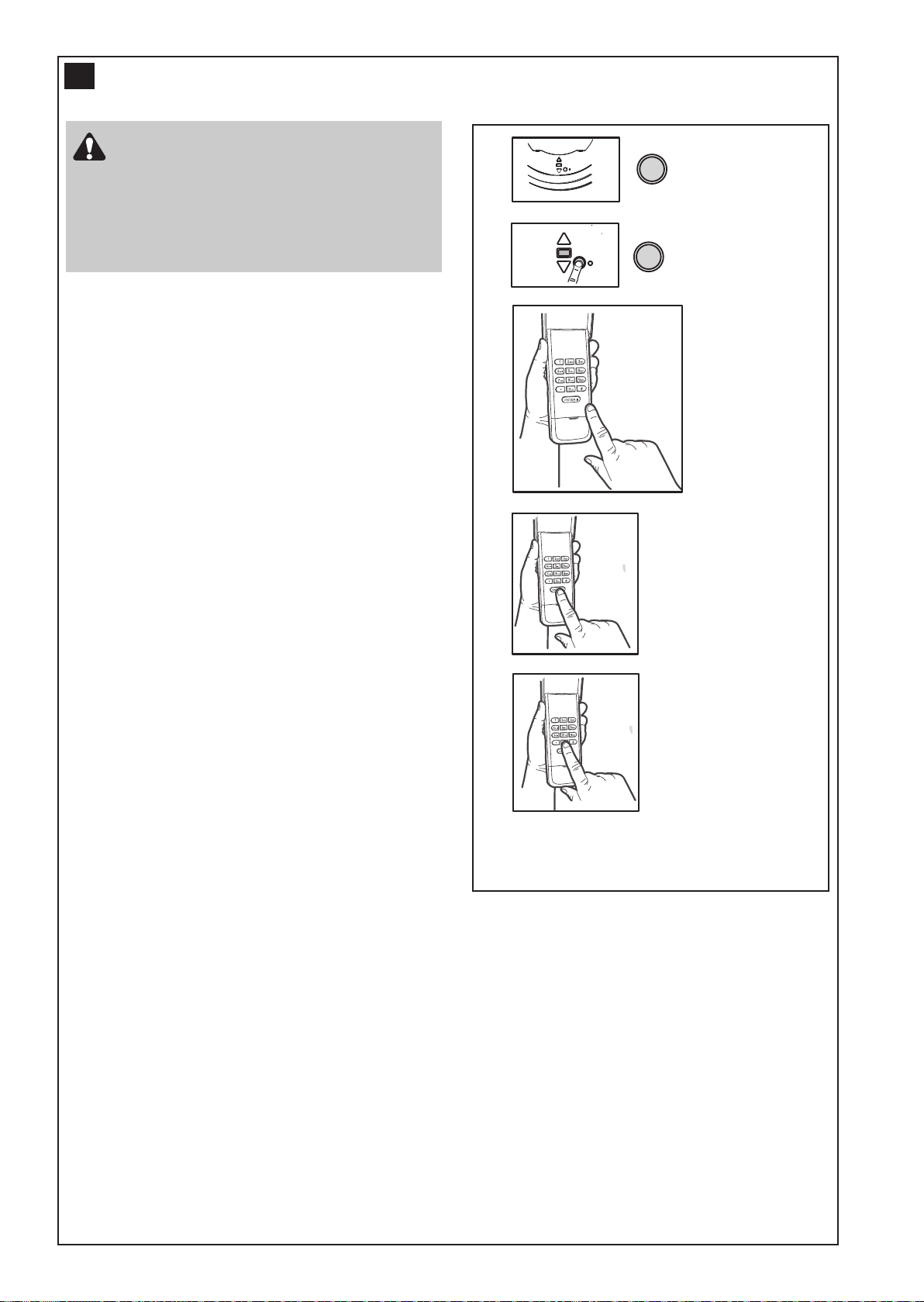

17

2

3

4

3

Press and release

the yellow

learn button

Enter a 4-digit

PIN of your

choice

? ? ? ?

____

Press and hold

the enter button

Opener light bulbs

blink

After the lights

blink release the

ENTER button

1Locate

the yellow

learn button

Activate the opener only when the door is in

full view, free of obstruction and properly

adjusted. No one should enter or leave

garage whilst the door is in motion. Do not

allow children to operate push button(s) or

transmitter(s). Do not allow children to play

near the door.

Wireless Keypad E840M

To set the keyless entry PIN:

1.Locate the Yellow Learn button on the garage door

opener.

2.Press and release the Yellow Learn button on the

garage door opener. The LED will light.

3.Enter a 4-digit personal identification number (PIN) of

your choice on the keypad.

4.Press and hold the ENTER button. Check to see if

the opener light blinks. Release the ENTER button

after the light bulb blinks.

To change an existing keyless entry PIN:

1.Enter the existing programmed PIN that you want to

change.

2.Press and hold the # button until the light bulb blinks

twice.

3.Enter the new 4-digit PIN of your choice, then press

the ENTER button. The light bulb will blink once.

4.To test, enter the new PIN, then press the ENTER

button. The garage door opener will activate.

KEYLESS DEVICE ROGRAMMING (O TIONAL ACCESSORIES )

11

18

To prevent possible SERIOUS INJURY

or DEATH from electrocution,

disconnect ALL electric and battery

power BEFORE performing ANY service or

maintenance.

1. Installation instructions for mounting the BBU.

After the opener has been installed, position the BBU

next to the opener on a structural support (joist) within

BBUʼs cord length.

Attach the BBU to the support by using the wall or

ceiling mount holes on either side of the BBU and the

1” (25mm) screws (provided).

2. Connect the BBU to the Opener.

Disconnect the opener from the electrical outlet.

Connect the BBU cord into the connector on the

bottom of the opener (see picture below). Connect the

opener into the electrical outlet.

Turn the power ON. After 2 seconds the Courtesy

LEDs will flash 5 times.

After 20 seconds, the green diagnostic LED (see

picture next page) will begin to flash indicating the

BBU is charging.

IMPORTANT NOTE: Installation of the BBU when

permanent electrical power is not available (such as a

new construction and the electricity is not installed)

may damage the battery.

Unplug the BBU after testing to prevent damage.

BATTERY BACKU UNIT E475M12V

OPERATING INSTRUCTIONS

1. Test the installed BBU with the opener.

To test the BBU, disconnect the opener power cord

from the electrical power outlet.

A solid orange LED indicates the BBU is operating

on battery power.

A flashing orange LED indicates the BBU is

operating on battery power and that the battery

charge is low.

To test the BBU is functioning properly, open and

close the garage door.

Re-connect the opener power cord back into the

electrical outlet.

Verify that the green LED is flashing on the opener

(indicates that the BBU is now charging).

Test completed.

2. Charge the battery.

Allow the battery 24 to 48 hours to fully charge

before using the BBU system.

A fully charged BBU supplies 12V DC to the opener

for one to two days of normal operation during an

electrical power outage. If the battery voltage drops

too low, the battery will disconnect and the opener

will no longer operate under battery power.

After the electrical power has been restored, the

battery will recharge within 48 hours. Under normal

usage the battery will last 3 to 5 years.

To obtain maximum battery life and prevent damage,

disconnect the battery backup when the opener is

not in use for an extended period of time.

NOTE: Door operation may be limited until the

battery is fully charged.

Battery Backup

Unit (BBU)

12

Diagnostic LED

"-" NEGATIVE LABEL

"+" POSITIVE LABEL

15AMP FUSE

"+" POSITIVE TERMINAL

"-" NEGATIVE TERMINAL

BATTERY TO BE PLACED INTO

THE HOUSING WITH THE

TERMINALS AS SHOWN

RETAINING BRACKET

19

Battery Backup Unit (BBU) Diagnostics

GREEN ED:

All systems are normal.

• A solid LED light indicates the battery is fully

charged.

• A solid LED light indicates the battery is fully

charged.

NOTE: Battery does not have to be fully charged to

operate the motor unit.

ORANGE ED:

The motor unit has lost power and is operating off the

BBU.

• A solid LED indicates the opener is activating the

door and is operating off the BBU.

• A flashing LED indicates the battery is low.

• Once the power is restored the BBU will recharge. is

indicated by a flashing green LED.

RED ED:

An error has been detected and the BBU will

automatically shut off. The BBU will attempt to restart

by reconnecting to the battery. If the error is still

present it will shut itself off again. This process will

repeat every 5 minutes or until the error has been

resolved. This is used to prevent further draining of the

battery.

• If a red LED remains on when the power is restored

please call for service.

Replace Battery

• Unplug the BBU from the opener and remove the

screws holding the BBU to the wall.

• Remove the battery retaining bracket.

• Withdraw the battery from the housing and

disconnect the terminals.

• Reinstall the new battery in the reverse process,

taking care to connect the positive and negative

terminals correctly.

• Reconnect the BBU to the opener as in step 2 of the

previous page.

BATTERY BACKU UNIT E475M12V - CONTINUED

13

S ECIAL FEATURES (O TIONAL ACCESSORIES)

1. 12 VDC power output for external devices

2. The Protector SystemTM IR Beams - C77

3. Standby Power Unit (battery backup E475M-12V, included accessory)

20

rx

white/black

white

white/black

white

12 vdc

gnd

External

Device

Keyswitch or

push button

com

no

12V DC

TY ICAL WIRING DIAGRAM OVERDRIVETM (MRC950EVO) -

Information for Service ersonnel

21

1

3

2

12V DC

MOUNTING THE EVERCHARGE

STANDBY POWER UNIT (SPU)

• The SPU can be mounted to either the ceiling

or a wall within 0.9 m (3') of the opener.

• Position the SPU as desired to a structural

support (ceiling joist or wall stud).

• Attach the SPU to the support using the

mounting holes on either side of the SPU.

• Secure the SPU using the 1-1/2" lag screws

(2) provided with the SPU unit.

• Connect the SPU cord into the connector on

the bottom of the opener.

• ollow all instructions included with the

E475M-12V unit to test for proper operation

and testing of the SPU.

14

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualified persons

in order to avoid hazard.

001A6621

041A6811-3

041B0603

001A6528

041B0640

001B6451-3S

041A7460

041D7403

041B0029

041B0641-2

026B0166

204D0250

22 S ARE ARTS

041A6811-3 Mount plate sub assembly (including motor)

041B0029 Sungear kit - Aluminium

041B0603 Front upper housing

041B0640 Base housing

041D7403 Service logic board

041A7460 Removable cover sub assembly

041B0641-2 Hinged access cove

204D0250 230V 105VA transformer

026B0166 Power Cord

001A6621 Clamp & bolt assembly

001B6451-3S Handle & pull rope assembly

001A6528 Absolute Position Encoder (APE)

13

12

8

7

9

16

E840M

E128M

760E

E1702M

774ANZ

E940M E943M E945M

10 11

45

E950M

E138M

23

E960M

E475M-12V

DMK1

23

NOTE: Only genuine Merlin accessories are approved for use with this opener. Generic compatible accessories are NOT approved for

use with this opener.

ACCESSORIES

(1) Model E128M Wireless wall button

(2) Model E138M Wireless wall button

(3) Model E960M 4 Channel remote control

(4) Model E950M 4 Channel remote control

(5) Model E940M 1 Channel visor remote control

(6) Model E943M 3 Channel visor remote control

(7) Model E945M 3 Channel mini remote control

(8) Model E840M Keyless entry system

(9) Model 774ANZ The rotector SystemTM

(10) Model E1702M Quick release lock

(11) Model 760E Outside keyswitch

(12) Model DMK1 Outside quick release (brick fix)

(13) Model E475M-12 V Standby ower Unit (battery back up)

DIAGNOSTIC UP DOWN SYMPTOM POSSIBLE CAUSE POSSIBLE RESOLUTON

CODE ARROW ARROW

1-1 1 FLASH 1 FLASH The garage door opener will The Protector System is not Check the Protector System is

not close and the lights will

flash installed, connected, or installed and aligned correctly,

wires may be cut both LEDs are ON with no

obstruction between the beams.

1-2 1 FLASH 2 FLASHES The garage door opener will The Protector System wire Check the Protector System is

not close and the lights will shorted or reversed installed and aligned correctly,

flash both LEDs are ON with no

obstruction between the beams.

1-3 1 FLASH 3 FLASHES Wall mounted door control The wires for the door control Check the door control wiring is

will not function are shorted or the door correct

control is faulty

1-4 1 FLASH 4 FLASHES The garage door opener will Misaligned or obstructed Check the Protector System is

not close the door and the Protector System installed and aligned correctly,

lights flash both LEDs are ON with no

obstruction between the beams.

1-5 1 FLASH 5 FLASHES The garage door opener clicks Internal fault Contact service centre

but no movement

The opener runs approximately Communication error to Contact service centre

150-200 mm and stops and/or

reverses travel module

Your garage door opener is programmed for self-diagnostic capabilities. The UP and DOWN arrows on the garage door opener flash the diagnostic codes.

DIAGNOSTIC CHART

TM

TM

TM

TM

TM

TM

2-1 2 FLASHES 1 FLASH The garage door opener will not PCB memory corrupt Reset opener by turning the mains

OFF for 20 seconds

Retest Opener

operate

2-2 2 FLASHES 2 FLASHES The garage door opener will not Reset opener by turning the mains

OFF for 20 seconds

Retest Opener

operate

2-3 2 FLASHES 3 FLASHES The garage door opener will not

operate in battery mode Recharge battery

Reset opener by turning the mains

OFF for 20 seconds

Contact customer service

PCB Voltage test failure

Battery failure - if fitted

15

16

DIAGNOSTIC UP DOWN SYMPTOM POSSIBLE CAUSE POSSIBLE RESOLUTON

CODE ARROW ARROW

3-3 3 FLASHES 3 FLASHES The garage door opener fails to Battery LED flashing green, Recharge Battery, contact

operate and the battery LED is charging circuit stops and starts service centre.

constantly flashing green to drain causing battery charging

status

4-1 4 FLASHES 1 FLASH Door is closing, stops and Obstruction, binding or sticking Remove obstruction, service door.

reverses door

4-2 4 FLASHES 2 FLASHES The door stops while opening Obstruction, binding or sticking Remove obstruction, service door.

for no apparent reason door

4-3 4 FLASHES 3 FLASHES The door reverses for no Obstruction, binding or sticking Reset limits & force, service door.

apparent reason or after touching door

the floor

4-4 4 FLASHES 4 FLASHES The door reverses for no apparent Obstruction, binding or sticking Reset limits & force, service door.

reason or after touching the floor door

4-5 4 FLASHES 5 FLASHES The opener runs approximately Communication error to travel

150-200 mm and stops and/or

reverses module Reset limits & force contact

service centre

4-6 4 FLASHES 6 FLASHES The door reverses for no apparent Safety sensors were temporarily Remove obstruction, or realign

reason while travelling down obstructed or misaligned sensors

My garage door opener light(s) will not turn off when the door is open:

The garage door opener is equipped with a feature that turns the light on

when the safety reversing sensors have been obstructed. If staying on

continually - Contact Customer Service Centre.

* Reprogram the remote control.

* If the remote control will still not activate the door check the diagnostic

codes to ensure the garage door opener is working properly. My neighbour's remote control opens my garage door:

* Ensure the antenna wire is hanging down from the garage door opener. Erase the memory from your garage door opener and reprogram the

remote control(s).

These are additional troubleshooting issues that will not show up in the diagnostic codes:

My remote control will not activate the door:

2-4 2 FLASHES 4 FLASHES The garage door opener will not

operate by remote controls PCB radio receiver failure Reset opener by turning mains OFF

for 20 seconds, recode transmitters

2-5 2 FLASHES 5 FLASHES The garage door opener will not

operate PCB possible internal failure Reset opener by turning mains OFF

for 20 seconds, retest opener.

17

8. The door opens but will not close or reverses

while closing:

• Is something obstructing the door? Pull the manual

release handle. Operate the door manually. If it is

unbalanced or binding, call a trained door systems

technician.

• Clear any ice or snow from the garage floor area where

the door closes.

• Repeat the limit and force setting in section 11.

Repeat safety reverse test after adjustments.

9. The opener strains to operate door:

• The door may be out of balance or the springs may

be broken. Close the door and use the manual

release to disconnect the door. Open and close the

door manually. A properly balanced door will stay in

any point of travel while being supported entirely by

its springs. If it does not, disconnect the opener and

call a trained door systems technician.

10. The opener motor hums briefly, then will not

work:

• Check that the door is not in manual release mode

(refer section 8).

• The garage door springs may be broken. See above.

• If the problem occurs on the first operation of the

opener, door may be locked. Disable any door locks.

11. The opener will not operate due to power

failure:

• Use the manual release handle to disconnect the

door. The door can be opened and closed manually.

When power is restored, re-engage the opener (refer

section 8).

• If a Battery Back up Unit is connected, the opener

should be able to operate up to 20 times without

power.

12. The UP and DOWN arrows on the control panel

are flashing in sequence:

Check the diagnostic code on previous page

TROUBLESHOOTING

1. The opener will not operate from either the

ACTIVATION arrows or the transmitters :

• Does the opener have electric power? Plug a lamp into

the outlet. If it does not work, check the fuse box.

• Have you disabled all door locks? Review installation

instruction warnings on page 1.

• Is there a build-up of ice or snow under the door? The

door may be frozen to the ground. Remove any

restriction.

• The garage door spring may be broken. Have it

replaced.

2. Opener operates from the transmitter, but not

from the wired wall control terminals:

• Are the wiring connections correct?

3.The door operates from the ACTIVATION arrows

but not from the wireless wall control or

transmitter:

• Program the opener to match the transmitter code

(Refer to section 16). Repeat with all transmitters.

4. The transmitter has short range:

• Change the location of the transmitter in your car.

• Check to be sure the antenna on the bottom of the

opener extends fully downward.

• Some installations may have shorter range due to a

metal door, foil backed insulation, or metal garage

siding.

5. The garage door opens and closes by itself:

• Be sure that all transmitter push buttons are off.

• If the wired wall control terminals are installed, remove

the bell wire from the wired wall control terminals and

operate from theACTIVATION button or transmitter . If

this solves the problem, the wired wall control is faulty

(replace), or there is an intermittent short on the wire

between the wired wall control and the opener.

• Clear memory and re-program all wireless wall

controls and transmitters.

6. The door reverses and stops before opening

completely:

• Is something obstructing the door? Is it out of balance,

or are the springs broken? Remove the obstruction or

repair the door.

7. The door reverses for no apparent reason and

opener lights blink 10 times after reversing:

• Check the Protector SystemTM (IR Beams), if

installed. If the red light on the beam is flashing, the

alignment is incorrect.

DISAB ING THE PROTECTOR SYSTEM:

If the Protector System is no longer required, it is

necessary to deactivate the opener so that normal

operation can occur.

With the IR beams REMOVED.

• TURN O the mains power and ensure any battery

backup is also disconnected.

• PRESS and HOLD both the UP and DOWN arrow

buttons.

• TURN ON the mains power to the operator.

• HOLD both arrows until the courtesy lamp flashes 3

times and remains ON.

The Protector System is now deactivated. The door

should operate normally.

18

Battery of the remote control:

The batteries in the remote have an extremely long life.

If the transmission range decreases, the batteries must be replaced. Batteries are not covered by the warranty.

Replacing battery (CR2032):

RE LACE BATTERIES IN REMOTES

12VDC

Pb Cd Hg

To prevent SERIOUS INJURY OR DEATH: observe the fo owing instructions for the battery

- NEVER a ow sma chi dren near batteries.

- If battery is swa owed, immediate y notify doctor.

- Danger of exp osion if battery is rep aced improper y.

- Rep acement on y by identica or equiva ent type.

- Dispose of o d battery proper y. Batteries shou d not be treated as househo d waste. A consumers

are required by aw to dispose of batteries proper y at the designated co ection points.

- Never recharge batteries that are not meant to be recharged.

- Do not short-circuit batteries or take them apart.

- If necessary, c ean contacts on batteries and contacts

before oading.

- Never expose batteries to excessive heat such as sunshine, fire or the ike!

To replace battery for E945M & optional remote control transmitters - E943M & E940M, use a

screwdriver blade to pry open the case as shown. Insert battery positive side up.

To replace battery for optional remote control transmitter E950M, turn remote control around and open

the case with a screwdriver. Lift cover and lift control board below. Slide battery to one side and

remove. Observe polarity of battery!

Assemble again with a new battery in reverse process.

or

Carefully

RemoveBattery

(CR2032 x 1)

Table of contents

Other Merlin Door Opening System manuals

Popular Door Opening System manuals by other brands

Besam

Besam Swingmaster MP Installation, adjustment and maintenance instructions

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

Dorma

Dorma MUTO COMFORT M DORMOTION 50 Mounting instruction

ADL

ADL LIGHT Assembling instructions

RYTEC

RYTEC Bantam Installation & owner's manual

TPG

TPG AXIM PR-7000 Series Technical support

DEUTSCHTEC

DEUTSCHTEC TL240 installation manual

Assa Abloy

Assa Abloy Adams Rite EX89 Preparation guide

Assa Abloy

Assa Abloy SARGENT 2900 FIREGUARD installation instructions

Assa Abloy

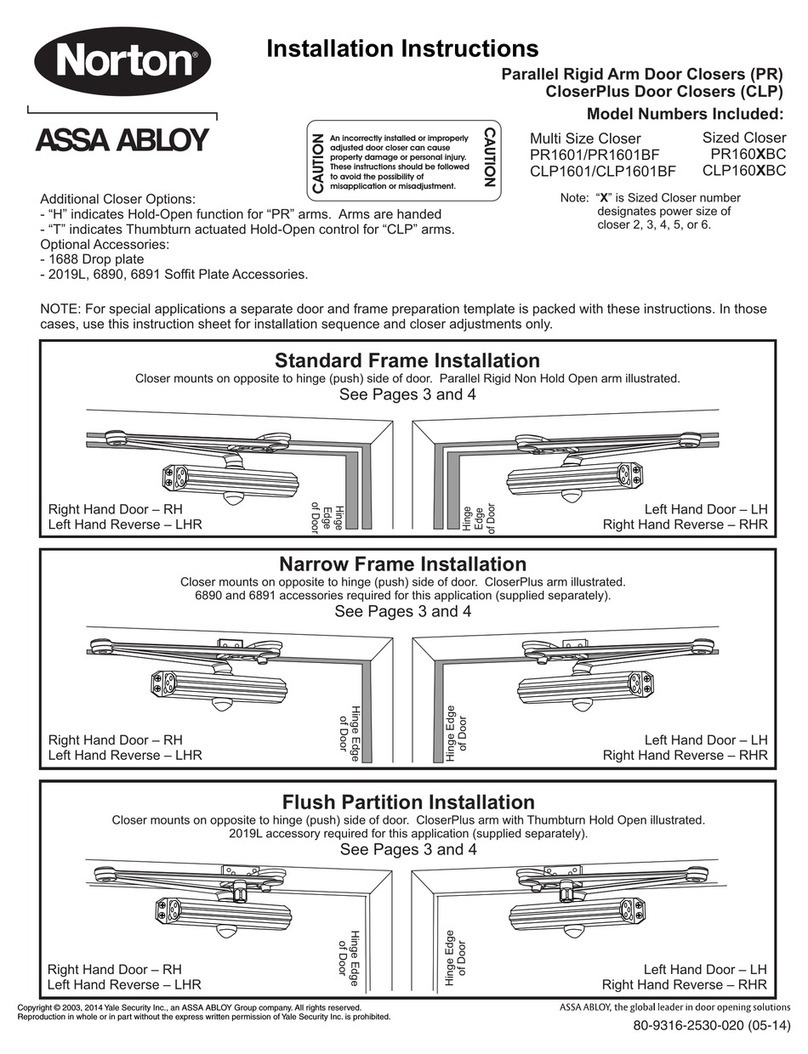

Assa Abloy Norton PR1601BF installation instructions

Dormakaba

Dormakaba 8900 TDE installation instructions