Table of Contents

Introduction ...................................................................................................................................... 4

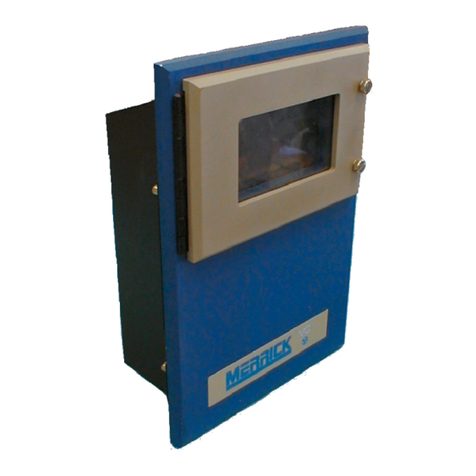

Controller Enclosures ...................................................................................................................... 5

Panel Mount................................................................................................................................. 5

Wall Mount ................................................................................................................................... 5

Door Mount .................................................................................................................................. 6

Installation........................................................................................................................................ 7

Physical Installation ..................................................................................................................... 7

Panel Mount ............................................................................................................................. 7

Wall Mount................................................................................................................................7

Door Mount............................................................................................................................... 7

Card Stack Assembly ...................................................................................................................... 8

Connections ................................................................................................................................. 8

Card Stack with Revision 11 or newer CPU Board .............................................................. 9

Card Stack with Revision 10 or older CPU Board .............................................................. 10

Controller Disassembly .............................................................................................................. 11

Controller Reassembly............................................................................................................... 11

CPU Board..................................................................................................................................... 12

New CPU Board (Rev 11 or Newer) .......................................................................................... 12

Communication Ports ............................................................................................................. 12

COM 1 RS-232 J7 .............................................................................................................. 12

COM 1 RS-485 4 WIRE J6................................................................................................. 12

COM 2 RS-232 J4 .............................................................................................................. 13

COM 2 RS-485 4 WIRE J5................................................................................................. 13

Board Features .......................................................................................................................... 13

Option Switch Settings ........................................................................................................... 14

LED Display............................................................................................................................ 14

JTAG/Service Port (J8) .......................................................................................................... 14

Old CPU Board (REV 10 or older) ............................................................................................. 15

Communication ports ............................................................................................................. 15

Comm 2 (RS-232)............................................................................................................... 15

Board Features....................................................................................................................... 16

Jumper Settings.................................................................................................................. 16

Printer Operation (Old CPU Only) ...................................................................................... 16

HPAD Board .................................................................................................................................. 18

Straps......................................................................................................................................... 18

HPAD 1/2 Determination............................................................................................................ 18

PCIO Board ................................................................................................................................... 20

PCIO 1/2 Determination............................................................................................................. 20

Connections ............................................................................................................................... 21

Analog I/O Current/Voltage Strapping ....................................................................................... 21

Analog Input............................................................................................................................... 21

AIN Adjustments..................................................................................................................... 22

Analog Outputs .......................................................................................................................... 22

MC3 Hardware Manual i