MERRICK MC3 90.10.EX User manual

MC³ 90.10.EX

MasterSet Controller

Operation and Maintenance Manual

Version ß

Merrick Industries, Inc

10 Arthur Drive

Lynn Haven, FL 32444

Ph. +1 850.265.3611

Fax +1 850.265.9768

Web http://www.merrick-inc.com

Revisions

Version Date Description

Z02/06/03/ldd New

All trademarks referenced are the property of their respective owners.

PROPRIETARY NOTE

The information in this manual, including technical data and copies of drawings, embodies information proprietary to

Merrick Industries, Incorporated. This manual is provided to the user of equipment purchased from Merrick Industries, Inc.

for use only in operation or maintenance of such equipment. Such information in this manual is not to be used, disclosed,

copied, or reproduced in whole or part for any use other than that indicated above, or for any other purpose detrimental to

the interests of Merrick Industries, Inc. Patents owned by Merrick Industries, Inc. have been issued or are pending on at

least some of the information in this manual, and unauthorized use of this subject matter of such patents is a violation of

such patents and is prohibited.

MC³ 90.10.EX O&M Manual -i-

TABLE OF CONTENTS

INTRODUCTION ....................................................................................................................2

MANUAL CONVENTIONS ..........................................................................................................2

Important points...............................................................................................................2

Buttons............................................................................................................................2

Screens...........................................................................................................................2

SAFETY................................................................................................................................2

In General .......................................................................................................................2

Electrical Precautions.......................................................................................................2

Solving Problems.............................................................................................................2

Technical Support ............................................................................................................3

SYSTEM CONCEPTS ............................................................................................................4

HARDWARE OVERVIEW...........................................................................................................4

Installation.......................................................................................................................4

Enclosures ......................................................................................................................5

Electronic Cards ..............................................................................................................6

SOFTWARE OVERVIEW ...........................................................................................................8

Application Software ........................................................................................................8

BIOS...............................................................................................................................8

Register Database ...........................................................................................................8

Digital I/O Mapping...........................................................................................................8

RUNNING & CONTROLS .......................................................................................................9

INITIAL SETUP.......................................................................................................................9

MAIN DISPLAY.......................................................................................................................9

MASTER SETPOINT..............................................................................................................10

Local.............................................................................................................................10

Analog ..........................................................................................................................11

Ratio .............................................................................................................................11

Serial ............................................................................................................................11

FAULTS..............................................................................................................................12

WARNINGS .........................................................................................................................12

GRAPH SCREEN..................................................................................................................13

ACTION MENU.....................................................................................................................13

Recipe Select ................................................................................................................13

Start/Stop Feeders .........................................................................................................13

Reset Sub-Total.............................................................................................................14

Reset Master Total.........................................................................................................14

Diagnostic Display .........................................................................................................14

Settings.........................................................................................................................14

RECIPE MENU.....................................................................................................................14

Feeder Amount ..............................................................................................................15

Recipe String.................................................................................................................15

FEEDER DISPLAY.................................................................................................................15

FEEDER SETTINGS...............................................................................................................16

Feeder Numeric.............................................................................................................17

Feeder Strings ...............................................................................................................18

PRINTER MENU ...................................................................................................................19

Print Line Editing and Printout Selection ..........................................................................19

SETTINGS MENU................................................................................................................21

MC³ 90.10.EX O&M Manual -ii -

ENTERING NEW VALUES.......................................................................................................21

Units Select...................................................................................................................21

Design Capacities ..........................................................................................................22

Decimal Points...............................................................................................................22

Comm Parameters .........................................................................................................22

Comm 1 Numeric...........................................................................................................23

Comm 2 Numeric...........................................................................................................24

Limit Switches................................................................................................................24

Panel Meter...................................................................................................................25

Display Parameters........................................................................................................25

EMT Parameters............................................................................................................25

Date/Time .....................................................................................................................26

Analog Input ..................................................................................................................26

Analog Input Source Settings..........................................................................................26

Analog Input Numeric.....................................................................................................26

Analog Input Cal ............................................................................................................27

Analog Outputs..............................................................................................................28

Analog Output Cal..........................................................................................................28

DIGITAL IO .........................................................................................................................29

Digital Inputs..................................................................................................................29

Digital Outputs...............................................................................................................31

DIAGNOSING PROBLEMS ..................................................................................................34

DIAGNOSTIC DISPLAY...........................................................................................................34

Feeder Diagnostics........................................................................................................34

Analog I/O Diagnostics...................................................................................................34

Communication Diagnostics............................................................................................34

DF1 and Modbus Diagnostics.........................................................................................35

Digital I/O Diagnostics....................................................................................................35

Register Monitor ............................................................................................................36

Misc. Data.....................................................................................................................36

Faults............................................................................................................................36

Warnings.......................................................................................................................36

DIAGNOSTIC SETTINGS.........................................................................................................37

Password Settings .........................................................................................................37

Quick Setup...................................................................................................................37

Register Editor...............................................................................................................37

SOLVING PROBLEMS.........................................................................................................38

SYMPTOMS.........................................................................................................................38

Unit does not power up...................................................................................................38

Controller Fails to Boot Up. .............................................................................................38

LCD Display too dark or too light .....................................................................................38

No analog Input .............................................................................................................38

External Totalizer problems ............................................................................................38

No Serial Communications .............................................................................................38

Hang Message Appears .................................................................................................39

HARDWARE CALIBRATION AND TESTING ......................................................................39

Analog Outputs..............................................................................................................39

Analog Inputs ................................................................................................................39

CONTROLLER HARDWARE................................................................................................40

LTI BOARD.......................................................................................................................40

EMT..............................................................................................................................40

Encoder ........................................................................................................................40

Serial Communications...................................................................................................40

PCIO BOARD .....................................................................................................................41

MC³ 90.10.EX O&M Manual -iii -

Digital Inputs..................................................................................................................41

Digital Outputs...............................................................................................................41

Analog Inputs ................................................................................................................41

Analog Outputs..............................................................................................................42

LCD Board ....................................................................................................................42

CPU BOARD ......................................................................................................................42

Communication Ports.....................................................................................................42

Printer Operation ...........................................................................................................44

BACKPLANE BOARD.............................................................................................................44

DC Style Backplane Board .............................................................................................45

AC Style Backplane Board..............................................................................................45

STORAGE...........................................................................................................................47

STORAGE ON RECEIPT FROM FACTORY ..................................................................................47

Storage Longer than 6 Months........................................................................................47

Storage up to 6 Months ..................................................................................................47

STORAGE FOLLOWING USE...................................................................................................47

OPERATION AFTER STORAGE................................................................................................47

SPARE PART LIST..............................................................................................................48

SPARE PARTS LIST ..............................................................................................................48

ACCESSORIES.....................................................................................................................48

I/O System ....................................................................................................................48

Spare I/O Plugs and Miscellaneous.................................................................................48

APPENDIX A.......................................................................................................................49

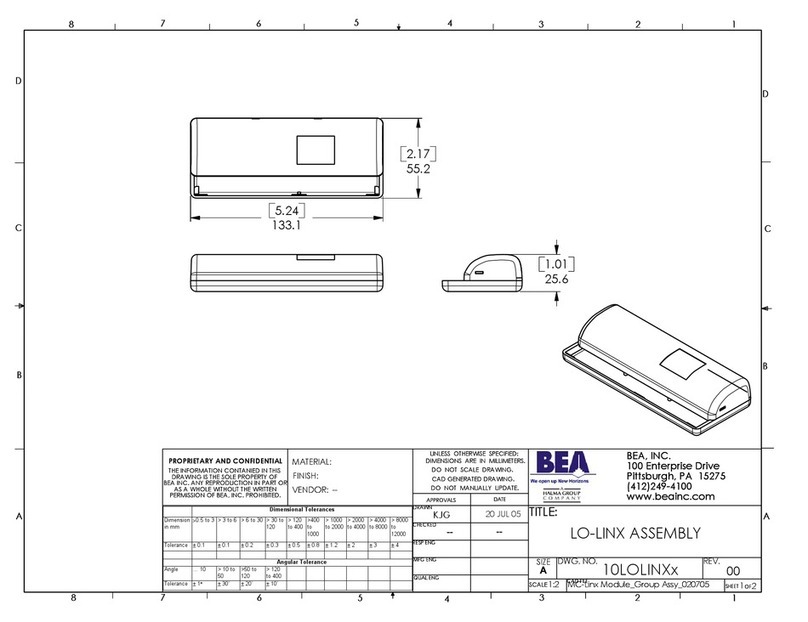

PANEL MOUNT -DIMENSIONS ................................................................................................49

WALL MOUNT –MOUNTING DIMENSIONS.................................................................................50

DOOR MOUNT -DIMENSIONS.................................................................................................51

INDEX .................................................................................................................................52

MC³ 90.10.EX O&M Manual -1-

MC³ 90.10.EX O&M Manual -2-

INTRODUCTION

Manual Conventions

Important points

NOTE: Any additional information that may be useful follows the note marker.

CAUTION: Be careful, certain settings may cause problems.

WARNING: Follow the directions prescribed in the warning. Serious problems can occur if the

recommendations are not followed.

Buttons

Button graphics will be shown to the right of the corresponding information regarding the function

for the button.

Screens

A graphic of this size and type will show the functions and/or information available in many of the

different screens.

Safety

The Merrick MC³ Controller is used for the control of process weighing equipment. As such, it is

normally responsible for the control of a process and is not intended as a motor control device. To

insure personnel safety please read the following instructions and precautions carefully.

In General

Observe all standard precautions that pertain to moving machinery.

Observe all standard precautions that pertain to electrical drives and electrical controls.

Pay particular attentions to special notes and precautions that appear throughout this manual.

Please read and become familiar with this entire manual before attempting service or repair of the

Merrick MC³ Controller. If you have any questions or problems, please call the Merrick Customer

Support Department for assistance.

All trademarks referenced are the property of their respective owners.

Electrical Precautions

Before undertaking work on the electrical system, the drives, or the Controller, from the main-

disconnect switches and lock boxes insure power is disconnected. Work should never be

performed on the Controller with power on the unit. It is recommended to disconnect the power

from the controller before attempting any service procedure.

Verify that all grounds called for on the wiring diagrams are in place and are securely connected.

Proper grounding not only helps insure your personal safety, but is also necessary for the proper

operation of the controller.

If it is necessary to work in or near areas of live high voltage, always keep one hand clear of the

machine, the cabinet, or any other conductors to avoid the possibility of electrical shock traveling

across your chest. NEVER undertake any electrical work in areas with wet or flooded standing

areas.

WARNING: NEVER impair or disable the function of a fuse or a circuit breaker.

CAUTION: IF IN DOUBT ABOUT ANY PROCEDURE CONTACT THE MERRICK CUSTOMER

SUPPORT DEPARTMENT.

Solving Problems

Included in this manual is a troubleshooting section to assist in solving technical problems

(section Diagnosing Problems on page 34or section SOLVING PROBLEMS on page 38).

MC³ 90.10.EX O&M Manual -3-

Technical Support

Merrick provides customer technical and spare part support 24 hours a day, seven days a week.

Our normal business hours are Monday through Friday 7:30 AM until 4:30 PM Central Standard

Time. During normal hours call 1-888 MERRICK (637-7425) and ask for service. The call will be

routed to the next available phone support technician.

After normal hours and on holidays and weekends, technical assistance is available by calling 1-

888 MERRICK extension 7878. Follow the instructions and be sure to enter the area code and

the phone extension where you can be reached. Someone will return your call as soon as

possible.

When you call Merrick for Technical Support, please have your machine serial number or a

controller serial number. This information will better help us to serve you.

MC³ 90.10.EX O&M Manual -4-

SYSTEM CONCEPTS

The MC³ 90.10.EX MasterSet Controller was designed to connect multiple MC³ Feeder

Controllers together to provide a central point for control and data collection in a total feeding

system. A MasterSet System contains an MC³ MasterSet Controller with a FastComm 422 Serial

Port Card installed, one or more MC³ Feeder Controllers capable of communicating using

Modbus RTU protocol, and the associated communications hardware needed to provide an

interconnecting serial communications loop with multi-drop capability.

Features:

The MasterSet Controller provides the following features:

1. Display of combined system Feedrate and Total

2. Reset-able Recipe, Sub-Total and Master Total

3. MasterSetpoint Control through blending recipes

4. MasterSetpoint methods of Local, Analog, Ratio and Serial

5. Storage of 100 recipes for up to 32 Remote Controllers

6. Configurable alarming system for the entire MasterSet System

7. Display of Individual Feedrate, Speed, Load, Total, Sub-Total and other data

8. Digital and Analog Outputs representing MasterSet System variables and states

9. Ability to print information on a printer

Hardware Overview

The MC³ Controller has been designed to control many different types of feeding, weighing and

metering equipment. This allows for easier maintenance and simplified training.

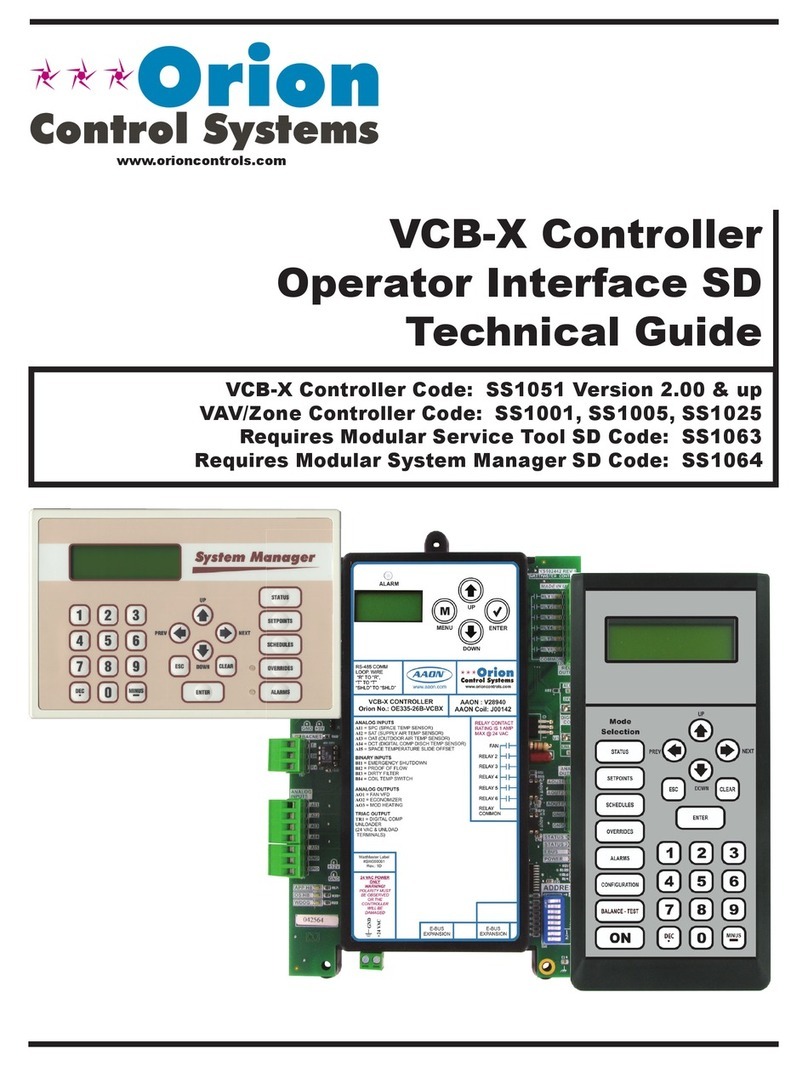

The Standard Merrick MC³ 90.10.EX Controller consists of an Enclosure, an LCD Display, Card

Stack and a Power Supply.

Installation

Carefully unpack the controller and inspect it for obvious damage because of shipping or

handling. If the unit appears to be damaged in any way, contact the Merrick Service Department

for assistance.

Insure that the power is disconnected from the power supply. Make the wiring connections to the

controller, following the instructions on the electrical connection diagram. In order to maintain the

weatherproof integrity: of the Wall Mount enclosure, liquid-tight conduit and conduit connectors

must be used when running the wires. It is recommended to penetrate the enclosure from the

bottom.

Verify all wiring connections before applying power to the controller.

NOTE: Before any deviation from the supplied wiring diagrams, Merrick must first be consulted to

insure safe and proper operation of the controller. See Technical Support on page 3for

contacting the Merrick Customer Support Department.

MC³ 90.10.EX O&M Manual -5-

Enclosures

Panel Mount

The Merrick MC³ Panel Mount Controller is designed for mounting in a control panel. It is suitable

for use in environments that are generally clean, and within the temperature range of 32º to 122º

F (0º to 40º C). It must be protected from water or significant dirt or dust.

The panel mount enclosure consists of a rectangular box with a hinged door on the rear covering

the I/O connections, a removable top cover, a system-grounding bar and a sliding tray. The slide

tray allows the Card Stack Assembly to be slid out of the back of the enclosure for easier

maintenance while the controller is mounted into a panel. The Display assembly is mounted on

the front bezel. The top cover may be removed for easier access to the boards. Access to the

terminal blocks for interconnection with other equipment is obtained by unscrewing the rear

cover.

Installation

Cut panel to dimensions provided in Panel Mount -Dimensions on page 49. Care must be used

when cutting due to tight tolerances for the panel mount bezel. Also, insure there is adequate

clearance around the controller for maintenance and ventilation. Install the controller into panel

using the mounting brackets provided.

Wall Mount

The Merrick MC³ Wall Mount Controller is designed to be weatherproof, and can generally be

mounted anywhere where the temperature range is within 14º to 104ºF (-10º to 40ºC). Merrick

MC³ 90.10.EX O&M Manual -6-

recommends that the controller should be located out of direct sunlight and away from dripping

water and must be protected from heavy rain.

The wall mount enclosure is available in NEMA-4 or NEMA-12 boxes. NEMA-4 box includes

gaskets and a window kit over the touch screen to provide extra protection.

Installation

Mount the controller on a vertical surface, Use dimensions provided in Wall Mount –Mounting

Dimensions on page 50 for placement of hardware used to secure enclosure to surface. Make

sure there is adequate clearance around the unit for swinging open the door and for

maintenance.

Door Mount

A door mount enclosure is available that separates the power-supply and Backplane boards from

the controller. This style includes a window for protection from the elements. It also adds two

fans to the cover of the enclosure to improve air circulation for better cooling.

The Merrick MC³ Door Mount Controller is designed for mounting in a control panel. It is suitable

for use in environments that are generally clean, and within the temperature range of 32º to 122º

F (0º to 50º C). It must be protected from all but incidental water or significant dirt or dust.

Installation

Mount the controller in the panel. Cut panel to dimensions provided in Door Mount -Dimensions

on page 51. Insure there is adequate clearance around the controller for maintenance and

ventilation. Install the controller into panel using the mounting brackets provided.

Electronic Cards

Backplane Board

Most of the Digital I/O connections to the MC³ will be made through the Back plane Board. The

Back plane mounts vertically in the rear access cover on the Panel mount type enclosure. On the

Wall mount enclosure, the boards are mounted directly below the Card stack assembly. When

the Door Mount controller is used, the boards are normally placed on a panel inside the cabinet.

There are two types of Back plane cards available, a dry contact enclosure input card (BPLN) and

an AC input card (BPAC). The BPLN card has four dry contact inputs and 7 relay (N/O) outputs.

MC³ 90.10.EX O&M Manual -7-

The BPAC card has four AC inputs and 8 Relay outputs. The relays 1-7 are N/O types with relay

8 having the capability of being selected to N/O or N/C.

Up to four Back plane boards may be connected to the MC³ Controller when two (2) PCIO boards

are in the card stack assembly.

Card Stack Assembly

The Card Stack assembly consists of one (1) CPU Board, one (1) FastComm 422/4-104

Communication Board, one (1) or two (2) PCIO boards and one (1) LTI board. The Card Stack

Assembly in the panel mount enclosure is mounted to the slide tray. The slide tray is kept in place

by a pair of guides that are mounted on the enclosure and with catch screws on the back of the

enclosure. In the wall mount enclosure, the Card Stack Assembly is securely attached to the

mounting plate. All boards are connected electronically by way of an industry standard PC-104

interface bus.

Fastcom 422/4-104

The Fastcom 422/4-104 is a 4-port RS-422 serial communication board. All feeders to be

controlled by the 90.10.EX software must be attached to one of ports on this board.

CPU Board

The CPU Board contains the Intel 386EX Microprocessor and associated support circuitry for a

bus interface, serial interface and memory support. The newest CPU module includes both

available communication ports providing RS-232 and RS422/485 from both ports. The CPU

board is the bottom board of the card stack.

The RS-485 Serial Communications port is a feature that provides the circuitry necessary for the

MC³ Controller to communicate with other serial devices such as a SuperBridge or Personal

Computer. For more information regarding MC³, Serial Communications see the Merrick

Communications Specification Manual. This specification lists some hardware options and

interconnection examples and describes the Merrick Communications Protocol in detail.

PCIO Board

The PCIO Board provides the circuitry for two (2) isolated analog outputs; one (1) isolated analog

input, sixteen (16) digital outputs and eight (8) digital inputs. An additional PCIO Board is

available as an option giving the controller a capability of having four (4) isolated Analog Outputs,

two (2) isolated Analog Inputs, thirty-two (32) Digital outputs and sixteen (16) Digital inputs. Two

(2) racks of digital inputs and outputs can be connected to the PCIO board.

LTI Board

The LTI Board contains the circuitry required to process incoming synchronization pulses, outputs

for an AC and DC Electromechanical Totalizer (EMT) and an interface to the Display assembly.

Power Supply Assembly

The power supply is mounted on the front of the slide tray on the panel mount enclosure. On the

wall mount enclosure, the power supply is mounted under a protective metal panel. The power

supply for the door mount is normally attached to the cabinet away from the controller.

Display Assembly

The Display Assembly consists of a Touch Keypad, LCD Board and LCD Display.

LCD Board

This board is used to interface the LCD Display and the Touch Keypad to the LTI Board and

provides the proper voltage for the backlight of the LCD Display. There is a potentiometer for

adjusting the contrast of the LCD Display. In addition, on specific LCD Boards containing an

LS220 type inverter there is a Brightness Adjust potentiometer.

LCD Display

The LCD Display is a 240 horizontal by 128 vertical pixel resolution monochrome graphical

display. The display works in conjunction with the Touch Screen to provide a Graphical User

Interface (GUI).

MC³ 90.10.EX O&M Manual -8-

Touch Keypad

The Touch Keypad is mounted directly to the bezel of the MC³ Panel Mount Controller. It

consists of a four by eight touch cell array. The Touch Keypad works with the LCD Display to

provide a way for you to interface with the controller.

Software Overview

The MC³ software consists of three (3) primary parts consisting of the BIOS (Basic Input / Output

System) a register database and the actual application software. The software has been

designed to utilize the hardware fully without requiring a large amount of training to operate. The

user interface has been designed to provide you with maximum flexibility with minimum input.

Application Software

Application Software is written for each specific type of "job" that the controller is to perform. This

software will allow you to turn on and off different modes of operation, which allows you to

configure the software for your specific process

BIOS

The BIOS is the portion of the software that directly manipulates the hardware. It is the interface

between the application and the hardware.

Register Database

The Register Database is a set of variables used in the software application. It is provided to

allow structured access through Serial Communications to variables used in the MC³. A numeric

listing of registers for each application is available from Merrick. Procedures for using Serial

Communications to access the register list are also provided in the Merrick Serial Protocol

Specification.

Digital I/O Mapping

The MC³ allows configuration of the digital inputs and outputs to the system's requirements. By

allowing mapping of the I/O, the MC³ gives a great degree of flexibility in design of the system.

CAUTION: This feature is a very powerful tool that should be used with extreme care. For most

installations, the default settings should be used.

MC³ 90.10.EX O&M Manual -9-

Running & Controls

Initial Setup

1. Slaves must be set to use Modbus/RTU. This usually is accomplished by setting the Comm

Protocol Value to 2 then cycling power to use the protocol. Default Line Parameters -Baud

Rate 9600, 8 Data Bits, 1 Stop Bit, Even Parity.

2. One digital input in the slave must be properly configured.

Input Setting

External Input 1 Run Permission

3. Five digital outputs must be mapped in the slave.

Output Setting

External Output 1 Fault

External Output 2 Warning

External Output 3 Ready

External Output 4 Running

External Output 5 Good Feedrate

4. The total number of recipes used must be entered into the design parameters.

5. The total number of feeders (slaves) must be entered into the design parameters.

6. There are several parameters from the feeders (slaves) that need to be entered into the MC³

90.10.EX.

Parameter

Port # that the slave feeder is attached to

Controller number for the slave feeder

Type of feeder (Belt feeder, Loss-In-Weight

Feeder, Flowmeter)

Unit settings for each feeder.

Design Feedrate

Design Weight/Load

Design Speed (if not used use default of 100%)

Main Display

The main screen displays the following parameters:

The current selected recipe

The current feedrate of all feeders that are a part of the current recipe

The current setpoint (The method, ex. Local, is displayed within an indicator box.)

The total of the current selected recipe

A Sub-Total of all recipes

MC³ 90.10.EX O&M Manual -10 -

The Master Total of all recipes.

Below the Fault and Warning buttons there are several text indicators that provide additional

information regarding the state of the controller.

The first line displays whether the process is running or stopped.

The second line displays the current setpoint method.

Local Analog R Ratio Serial

The third line displays whether there is a Blocking condition (Feeder Block logical input is

enabled) or if the Run Permission logical input is enabled. If neither condition is detected the line

is cleared.

The fourth line Displays the running condition of the controller.

Ready –All feeders associated with the current recipe are online AND

There are no fatal communication errors AND

All feeders are ready (The associated Ready output for each feeder is enabled.) AND

The Feeder Block logical input is disabled AND there are no FAULTS.

In Control –The Ready (same as above) logical output is enabled AND Run Permission logical

input is enabled.

Good Feed –All feeders associated with the current running recipe are feeding good. (The

associated output for Feed Good is enabled in each running feeder.) AND

The In Control logical output is enabled (same as above). AND

The feedrate is within the feedrate and deviation limits set in the Limit Switch Menu. AND

The recipe is running (the Running logical output is enabled). AND

there are no Warnings or Faults.

If none of these conditions are present the line will be cleared.

Master Setpoint

Touching this button provides access to the Setpoint Screen. A Setpoint Password may be

saved to restrict access to this screen. See the section Password Settings on Page 37 for setting

and modifying password.

On the Setpoint Screen, the Setpoint Mode Button at the top left will indicate the Setpoint Mode.

Touching the Setpoint Mode Button will change the Setpoint Mode to the next mode in the order

of the list:

Local

When this mode is selected, direct entry of the Feedrate setpoint is available. This setpoint is in

engineering units for feedrate.

MC³ 90.10.EX O&M Manual -11 -

Analog

This Setpoint mode allows the setpoint value to be input through the Analog Input in relation to

the Maximum Feedrate. For example, if a 50% input signal (12mA when the input is 4-20mA) is

being read from the Analog Input, and the Maximum Feedrate Capacity is 40.00 lb/min, then the

Setpoint will be 20.00 lb/min.

Ratio

This method scales the External Feedrate setpoint as a percentage of the incoming analog input

signal. Scaling is the same as Remote Analog. This allows multiple systems to be connected to a

single signal with each system assigned a particular percentage of the signal as a setpoint.

For example, three systems are to be used configured to provide material to a process using one

analog input for control. System number one provides 25%, system number 2 provides 35% and

system number 3 will provide 40% of the material needed for the total process. When the

setpoint changes for the process all three systems will properly scale for the new setpoint.

Serial

This setpoint mode allows the MC³ Controller to receive a setpoint from a remote device through

the serial port such as a computer or a PLC/SuperBridge Controller. This method requires that

the remote device be connected to the controller via a serial port.

NOTE: When the controller is to be used in SuperBridge or any other system, which transmits

setpoint information using Serial Communications, the Remote Serial mode must be selected.

The rules and format of the data exchange is described in a separate publication, Merrick

Serial Protocol Specification.

MC³ 90.10.EX O&M Manual -12 -

Faults

The Fault button is used to indicate an error has occurred. A Fault condition will stop all feeders.

The system will not restart until the Fault condition has been cleared. A Fault will also prevent the

system from starting. Up to 16 Logical Inputs and Outputs may be selected to give you a Fault

indication.

This button will remain displayed until the conditions that caused the Fault have been removed

and the Fault acknowledged. To view the Fault screen, touch . There is an active indicator

to the left of the text ( = ON = OFF). Any Fault that occurs will be saved until acknowledged

by you and will be displayed with a to the left of the active indicator. If there are no Faults, this

button will be hidden from the main screens. You may still access this screen from the action

menu.

Use and to move the selection box to the Fault you want to acknowledge.

is used to acknowledge a Fault selected by the selection box. is used to acknowledge

all Faults. If the error that caused an indication has not been corrected the Fault button will

continue to be displayed on the main screens and the Fault will continue to be indicated on this

screen.

Warnings

The Warning button is used to indicate a problem has occurred. Up to 16 Logical Inputs and

Outputs may be selected to give you a warning indication. A Warning condition will not stop the

system.

This button will remain displayed until the conditions that caused the Warning have been

removed and the Warning acknowledged. To view the Warning screen, touch . There is an

active indicator to the left of the text ( = ON = OFF). Any Warning that occurs will be saved

until acknowledged by you and will be displayed with a to the left of the active indicator. If

there are no Warnings, this button will be hidden from the main screens. You may still access

this screen from the action menu.

Use and to move the selection box to the Warning you want to acknowledge.

is used to acknowledge a Warning selected by the selection box. is used to

acknowledge all Warnings. If the problem that caused an indication has not been corrected the

MC³ 90.10.EX O&M Manual -13 -

Warning button will continue to be displayed on the main screens and the Warning will continue

to be indicated on this screen.

Graph Screen

This button displays a trend screen that graphically compares the current feedrate to the setpoint.

Also displayed on this screen is the Sub-Total (ST), Master Total (MT), Feedrate (FR), and

Setpoint (SP).

Action Menu

This menu allows you to change the current recipe, start and stop the feeders, reset the Sub-

Total or Master Total, access to the Settings Menu, Diagnostic Menu, Recipe Menu and the

Feeder Display menus.

Recipe Select

This button allows selection of the recipe to be used. Immediately to the right of the Recipe Select

button the controller displays the currently selected recipe number and the name (string)

associated with the recipe number directly below.

If a recipe is currently running the button will not be displayed. To change the selected recipe the

system must be stopped either by removing Run Permission or touching the Stop Feeders button.

Start/Stop Feeders

These buttons are used to start and stop the Feeders that are attached to this controller when the

logical input Run Permission is enabled. A status message associated is displayed directly to the

right of these buttons.

If a Fault occurs, this controller will stop all feeders and the text message “Faults Present” will

be displayed. The Start/Stop feeder buttons will be hidden until the Fault has been cleared.

If the logical input Feeder Block is enabled, this controller will stop all feeders and the text

“Controller Blocked" will be displayed. The Start/Stop Feeder buttons will be hidden until the

input is turned off.

If Run Permission is turned off, this controller will stop all feeders and the text message “No Run

Permission" will be displayed. The Start/Stop Feeder buttons will be hidden until the input is

turned on.

Table of contents

Other MERRICK Controllers manuals

Popular Controllers manuals by other brands

EasyIO

EasyIO FS-20 installation guide

Reach Technology

Reach Technology SLCD+ manual

Simplex

Simplex RTL-TH DIGITAL Installation and operating instructions

Linear Technology

Linear Technology LTM4620A Demo Manual

Becker

Becker Centronic SunWindControl SWC545-II Assembly and operating instructions

Kinco

Kinco KS Series manual