MES SQA-V Gold User manual

and

SQA-V

S e r v i c e M a n u a l

V e r s i o n 2 . 4 8 / 2 . 4 9 / 2 . 6 0

Catalog #7501

Rev: Dec 2019

and

SQA-V

Service Manual Dec_2019

2

Table of

Contents

SECTI N I: Introduction

Automated Test Results 4

Technology 4

Automated System 4

Visualization System 5

SECTI N II: System Specifications

Sperm Quality Analyzer –SQA-V Version 2.48/2.49 6

SECTI N III: System verview

Front Panel 9

Keypad 9

Rear Panel 9

Side Panel 9

Rear Panel Assembly 10

Front Panel Assembly 10

Schematic of the SQA-V system 10

SECTI N IV: System Components and Accessories

SQA-V Capillary 11

SQA-V Slide Adaptor 11

Cleaning and Accessory Kits 11

SECTI N V: Electronic Self- Test and Auto-Calibration

Start Up 12

Prior to testing a sample 12

SECTI N VI: Getting Started / Set Up

Getting Started / Set Up 13

SECTI N VII: Troubleshooting

verview 13

SECTI N VIII: Technical Support and Part Replacement Instructions

pening the SQA-V 13

Closing the SQA-V 14

Printer (Thermal) 14

Printer (Impact) 15

Keypad 15

Power Supply (PSU) 16

Replacement of PSU 17

Power Inlet 19

Fan Assembly 19

peration Monitor (lower LCD screen) troubleshooting 20-23

Replacing the SQA-V processor 23-24

Focus Knob 25

Video System troubleshooting 26-28

Visualization LED 28

CCD Cleaning or Replacement 29-31

Video Screen replacement 31

Video Control Board Replacement 32

Surge Protector troubleshooting 32-33

Capillary Sensor troubleshooting and replacement 34-35

ptical Board to LED Board Cables replacement 35-36

Visualization System Upgrade (VSU) 36-37

SECTI N IX: Error Messages

Stabilization Failed 38

Self-Test Failed 38

Electronic Noise 38-39

Concentration out of Range 39

Sample size out of Range 39

I-Button warning screens 39-40

and

SQA-V

Service Manual Dec_2019

3

Communication Error

40

SECTI N X: Appendixes

C

leaning Instructions

41

Loading I-Button Tests 42

I-Button troubleshooting 43

Power Supply Troubleshooting Flowchart 44

and

SQA-V

Service Manual Dec_2019

4

SECTION I: Introdu tion

The SQA-V is a high performance analytical medical device that combines state-of-the-art

technology in electro-optics, computer algorithms and video microscopy. The system

performs a precise, 75-second semen analysis. The SQA-V runs a self-test and auto-

calibration on start-up and also runs external quality controls. The SQA-V incorporates

two systems: An automated system and a visualization system which allows

flexibility to analyze all types of semen samples.

Automated

Test Results

WHO 5

th

Semen Parameters with SQA

-

V Abbreviation in Bra kets

Sperm Concentration

(SPERM C NC.)

M/ml Velocity

(VEL CITY)

mic

/sec

Total Motility

(T TAL M TILITY <PR+NP>)

% Sperm Motility Index

(SMI)

#

Progressive Motility

(PR G. M TILITY <PR>)

% Total Sperm Number / ejaculate

(SPERM #)

M

Non-progressive Motility

(N NPR G. M TILITY <NP>)

% Total Motile Sperm / ejaculate

(M T. SPERM)

M

Immotility

(IMM TILTIY <IM>)

% Total Progressively Motile Sperm /

ejaculate (PR G. SPERM)

M

Sperm Morphology

(normal forms, %)

(M RPH. N RM. F RMS, WH 5

th

)

% Total Functional Sperm / ejaculate

(FUNC. SPERM)

M

Motile Sperm Concentration

(MSC)

M/ml Total Morphologically Normal

Sperm / ejaculate (M RPH. N RM.

SPERM)

M

Progressively Motile Sperm

Concentration (PMSC)

M/ml Postvasectomy: Motile, Immotile

and Total Sperm/Scan

(#SPERM/SCAN: M TILE,

IMM TILE and T TAL)

#

Functional Sperm Concentration:

Progressively Motile Sperm with Normal

Morphology (FSC)

M/ml Postvasectomy: Motile, Immotile

and Total Sperm/sample volume

(#SPERM/SAMPLE V LUME:

M TILE, IMM TILE AND T TAL)

M

Te hnology

Automated System

Motility Channel

Light disturbances caused by moving sperm cells are detected and translated into

analog signal peaks.

The greater the number of motile sperm cells in the field of view, the higher the

peak.

The slower the sperm velocity the broader the signal peaks.

The average analog signal is mathematically proportional to MSC.

Con entration Channel

Sperm concentration is measured in the cuvette section of the SQA-V testing

capillary.

An infrared light wavelength specific to sperm cells is maximally absorbed by

sperm cells and minimally absorbed by other seminal fluid components.

In the final calculation of sperm concentration the SQA-V algorithm makes an

adjustment to account for the infrared light absorption of the seminal fluid

components.

and

SQA-V

Service Manual Dec_2019

5

Step 1: The capillary is inserted into the measurement compartment.

Step 2: Sample concentration is evaluated in the "tall" 10 mm chamber of the

capillary by measuring the amount of opti al absorption of light as a

beam traverses the seminal fluid.

Step 3: Motility is detected in the "thin" 0.3 mm section of the capillary by

analyzing light modulations aused by sperm motion.

Step 4: This information is then digitized and routed to the microprocessor that

applies algorithms to extract the required clinical semen parameters and

performs internal self-testing and calibration.

Visualization System

LED light source

bjective lens 20X

Total system magnification: 300X – 500X

Focal depth: Approximately 30 microns

Color video camera with resolution 700 TVL

Accommodates both: a testing capillary and the SQA-V slide adaptor

and

SQA-V

Service Manual Dec_2019

6

SECTION

II

: System Spe ifi ations

Sperm Quality

Analyzer

Dimensions:

40 Height x Width 30 x 15

-

25 cm Depth

Weight: 4.5 kg

AC power supply: 100 to 250 VAC, 50/60 Hz, 24W

Fuse rating: 2A 250V

Power stability requirements: Voltage fluctuations ± 5% nominal

Measurement Compartment

Sour es of radiant energy - two LEDs for motility and spectrophotometry

channels

Dete tor system - two photo detectors - Motility and ptical Density

Visualization Compartment

LED illumination source

Video camera: sensor size - ¼”; resolution: 700 TV lines

bjective: Standard, 20X

Signal utput (analog): PAL or NTSC standard

Zoom system for magnification transition between 300X and 500X

Focus knob

Display(s)

perational LCD screen with white backlight (resolution: 240 x 128 pixels)

Video LCD screen (4” diagonal, resolution: 960 x 240 pixels)

Use monitor On/Off key on the keypad to independently operate the video

display

Printer

SW version 2.49:

Built-in, Serial impact dot matrix printer

Copier paper roll

58mm width

Ink ribbon cartridge (Citizen)

SW version 2.48, 2.60:

Built-in thermal printer (CASHIN )

Thermal paper roll (CASHIN )

Keypad

Operational keys: n/ ff (Power), Test, Print, Service, Archive, Delete,

Enter, four cursor buttons, Esc, ten numeric buttons (0-9), F (function key)

and . (decimal dot)

Video ontrol keys: Zoom In/ ut, Illumination High/Low (light source

intensity) and Monitor n/ ff (video monitor)

Front Panel

Built-in printer

Visualization compartment

LCD video monitor and controls

Focus knob

LCD operational display

Measurement compartment

Multi-button keypad

I-Button port

and

SQA-V

Service Manual Dec_2019

7

Rear Panel

Power inlet with fuse-holder (2 fuses: 250V, 2A)

RCA Video connector

RS232 communication port

Spe imen Testing Supplies

Measurement apillary: Disposable, plastic, positive displacement testing

capillary. (Testing depth of capillary section: 300-micron; Cuvette section:

10 mm).

Standard laboratory slide: 20 micron depth, 22 x 22 mm cover-slip.

Operating System

Control: Keypad

Analysis Time: Normal Test – 75 seconds; High Sensitivity/Postvasectomy

Test – 5 minutes (9 minutes in version 2.43).

Software: Resides on flash memory and drives all man-machine interface

functions, runs algorithms for test measurements (according to WH

guidelines), and operates visual and automated screens. System can be

upgraded from a PC CD-R M.

Sample Testing Temperature: Calibrated for room temperature only

20-25° C / 68-77° F. Motility results will be impacted by heating the specimen.

Motility hannel input signal: Analog, up to 5V.

Spe trophotometer hannel input signal: Modulated (1 kHz) analog, up to

5V.

Quality Control

Internal: Electronic Self-Test and Auto-Calibration.

External: Counts can be run on the SQA-V automated and visualization

systems using commercially available assayed control material: "QwikChe k-

beads™" (product of Medical Electronic Systems) or Stabilized Sperm as a

non-assayed control in version 2.45 and higher.

PC Compatibility

Minimum requirements for V-Sperm software

PC: 1 GHz processor, Pentium 3

RAM: 256 MB

AGP-video display ard with at least 16 MB of RAM memory

Video olor: At least 16 bit (65,535)

CD ROM drive

200 MB free hard disk spa e for image capturing

Video resolution: Minimum 640 x 480

Operating system ompatibility: Windows XP, VISTA, Windows 7,

(Windows 10 pending)

Ports: ne serial; two USB ports

Monitor: 15" color

Required Software

V-Sperm software for SQA-V system and I-button set-up, ar hive and

CONTROL reporting also permits user to benefit from many features such as

real time visualization interface between PC and SQA-V visualization system,

data analysis, video/picture capture and archives test records.

Ex el/Word for exporting files and lips

and

SQA-V

Service Manual Dec_2019

8

Operational Temperature and Humidity

System is operational at 15-38

º

C.

NOTE: SQA-V operates in a wide range of ambient temperatures however the

system is calibrated to measure semen samples at room temperature:

20-25

º

C (68-77

º

F).

NOTE: Variations in ambient temperature may impact the accuracy of test

results because of the effect of temperature on human semen.

System is fully operational at up to 80% humidity and 26°C.

Maintenan e S hedule

Daily cleaning of measurement compartment (refer to User Guide –

"Cleaning") or with each 10-15 tests and/or spillage. USE NLY the

MANUFACTURER supplied cleaning kit, brush and solution to clean the SQA-V

or the system may be damaged and/or inoperable!

Manufa turer Re ommendations

perate the SQA-V away from devices that may cause electronic noise (cell

phones) or other devices causing vibrations such as centrifuges.

Turn system OFF at the rear-panel when not in use for extended period of

time.

When running High Sensitivity or Post-vasectomy tests do not interrupt test

cycle nor interfere with system or testing capillary in any way – this test

requires complete stability of the system during the 5-minute testing cycle.

Variations in ambient temperature can affect semen samples. The SQA-V

(HUMAN) is calibrated to test samples at room temperature: 20-25ºC (68-

77ºF). All VET SQA’s are calibrated with internal heaters.

Semen is considered a biologically hazardous material and is subject to

individual laboratory protocols for handling such materials.

Fa tory Default Settings

Chamber standard: 2 (Neubauer)

Morphology: WH

Date format: DD/MM/YY

Time/Date: Manufacturer's local time/date

Controls (all levels/types): Exp date 01/01

and

SQA-V

Service Manual Dec_2019

9

SQA

-

V

System

SECTION III: System Overview

Front Panel

NOTE: The

TEST button of

the SQA-V

keypad is only

active in the

CALIBRATION

mode

The ARCHIVE

button on the

keypad is

inactive- the

archive is

managed

through the

V-Sperm G LD.

Keypad Navigation

Use NUMERIC keys to enter data; ARROW keys to move to the next field

Press ENTER to select menu options, confirm data entries and to move to

the next screen or field

Use the ESC button to return to the previous screen or field

Rear Pane

l

Side Panel

The side panel has an I-Button port (with clip in

newer SQA-V’s starting with Serial Number

1333)

Refer to the Appendix Section for instructions on

how to load I-button tests.

Printer and paper Visualization

ompartment:

A ommodates both a

slide and the SQA-V

testing apillary

Automated

Measurement

ompartment

Fo us knob

Video display

and ontrols

Keypad

Operational

display

I-Button with lip Zoom magnifi ation

X300 – X500

Ventilation slots

Devi e label

Power inlet and

main On/Off

swit h

RS232 COM port

Video output

onne tor

Rear panel s rew

Fuses box

and

SQA-V

Service Manual Dec_2019

10

Assemblies

The

rear panel

a

ssembly

The rear panel assembly contains the

following sub-assemblies:

Motherboard

Power Supply Unit

Surge Protector (starting with SN#

1270)

AC Power Inlet Assembly

Cooling Fan

Printer

Communication Port

Video Board Assembly (till SN#1317

T-Jack Video Adaptor (for SN# 1318-

1410)

Video splitter (starting with SN#

1411)

The

front panel a

ssembly

The front panel assembly includes the

following:

perational Display

Video screen

Keypad

Power Indicator LED

Visualization Compartment

Visualization Compartment Cover

Measurement Compartment

Focus control knob

S hemati of the SQA-V

+1.5 to +1.8 VDC

+5 VDC

+5 VDC

+12 VDC

+3 VDC

+12 VDC

+12 VDC

+2 VDC

AC

100-230 V,

50/60 Hz

Main switch

+12 VDC

+5 VDC

-12 VDC

+12 VDC

Mother Board

Fuse

2A x 2

On/Off LED

Visualization LED

Video Monitor

Printer

Backlight PCB

Operational

Monitor

+3.5 VDC Backlight LEDs

LED’s Board Optical Board

Chassis

JP1

GND

J8

J3

J10

Video Splitter

+12 VDC

J9J17

J14

J1

J7

I-Button Port

J18

789

F0 .

123

45 6

J11

Keypad

J13

Video

camera

+1.7 VDC

Capillary

sensor

Surge

protector

FAN

DC Motor

-16 VDC

-13 VDC

+5 VDC

J1 J2

J3

JP1

JP5

+1.5 to +1.8 VDC

JP6

J2

J1

Control Board

+12 VDC

J1 J3

CN4

Main

Power Supply

CN1

CN2

+5 VDC

and

SQA-V

Service Manual Dec_2019

11

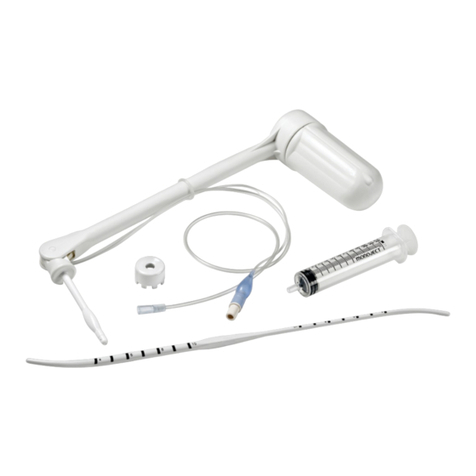

SECTION IV: System Components and A essories

Testing

Capillary

Can be used in both measurement chambers of the SQA-V.

Disposable, designed to collect and test samples in a biologically safe manner.

Motility is measured in the 0.3 mm (thin) "Capillary Section."

Concentration is measured in the 10 mm (tall) "Cuvette Section."

S

lide

Adaptor

For use with a standard laboratory slide 76 x 25.6 mm and 22 x 22 mm cover-slip

in the visualization ompartment of the SQA-V to visually assess semen

samples

Cleaning Kit

Daily cleaning is recommended or after testing 10-

15 specimens.

See the detailed cleaning instructions in the

Appendix Section

NOTE: nly use the manufacturer’s cleaning kit or

the SQA-V can be damaged

A essories

Kit

Each kit contains:

Slide Adaptor

Power Cables

Communication Cable

Printer Paper

Printer Ribbon (only for SW version 2.49)

Instructional Guides

and

SQA-V

Service Manual Dec_2019

12

Ele troni

SECTION V: Ele troni Self-Test and Auto-Calibration

Self

-

Test

and Auto-

Calibration

A

series of tests

are automati ally run on the SQA

-

V

to he k

the

alibration and

internal operating system. Tests are run when the SQA-V is first turned-on and

also prior to ea h semen analysis test.

Start-up:

Stabilization and auto alibration: Checks system stability and reference

ranges. The system sensors are analyzed for several minutes to ensure that the

values are within a very narrow acceptable range. nce the system is stable for 30

seconds it will pass stabilization and auto calibration. The system will fail if it is not

stable for at least 30 seconds and a warning message will be displayed.

System noise: The level of electronic noise in the system is measured to ensure

that noise thresholds are accurately defined to ensure effective measurement of

electronic signals. The system will use this measurement prior to running a test

and will automatically adjust the noise level thresholds to ensure accurate

readings.

Self-test: The system produces electronic signals that simulate motility and

concentration in order to check the performance of the system and verify that the

calibration settings are consistent with the factory specifications. The

SQA-V will report failures (see section on error and warning messages) and

"freeze" the system if the system is not within the established ranges.

Prior to testing a sample:

Auto alibration verifi ation: Reference values are read again. The

concentration and motility parameters are measured (without a testing capillary).

System noise: Measures the electronic noise level of the system to ensure that

noise thresholds are accurately defined in the system to ensure effective

measurement of electronic signals. The system will use this measurement prior to

running a test and will automatically adjust the noise level thresholds to insure

accurate readings.

Ele troni spikes: Checks for any measurement points that are out of range

electronically. More than three such points will fault the system and a warning

message will be displayed.

The following pro edure details how the user an do ument the system

parameters to prepare for te hni al support if the system fails (see se tion of this

user guide on Error Messages and Warning Messages).

How to run a copy of the system parameters version 2.48/2.49 G LD:

From the MAIN MENU select: SERVICE>PRINT SQA-V DEFAULT

SETTINGS>SELF TEST DATA

All other versions:

Remove any testing capillaries from the system.

Turn the SQA-V on from rear panel and from the front keypad.

When the MAIN MENU appears or when a FAILED SELF TEST message appears

press the SERVICE key on the keypad to enter the SERVICE menu.

Select USER.

Press the PRINT key on the keypad to generate the required printout.

Refer to the table below. Enter numbers in the "SQA-V Value" olumn that

orresponds to #1 - #10 from the SQA-V system parameters printout. Compare

the values. If the value from the SQA-V is within range mark the "Pass" olumn.

If not, mark the "Fail" olumn.

and

SQA-V

Service Manual Dec_2019

13

# Parameter

Software version

2.45,2.46, 2.48, 2.49 SQA-V Value Pass Fail

1. Ref 1 150 – 350 mV

2. LED Cur 1 5 – 25 mA

3. Amplitude 50 – 100 mV

4. Zero Level 500 - 525

5. Ref 2 2500 – 3500 mV

6. LED Cur 2 10 – 32 mA

7. C NC. 1 0 – 1 M/ml

8. C NC. 2 50-150 M/ml

9. C NC. 3 300-600 M/ml

10.

Count (Internal

Data, Item #12) 26 - 36

SECTION VI: Getting Started / Set-Up

Please refer to the relevant SQA-V User Guide for start-up and set-up instructions (based

upon the software version of the SQA-V).

NOTE:

Turn off the

power supply

to the SQA-V

and disconnect

the power

supply cable

from the back

of the device

before opening

the SQA-V.

nly a

qualified, MES

certified

distributor is

authorized to

open the SQA-

V without

voiding the

warranty.

SECTION VII: Troubleshooting

verview: The following sections describe how to troubleshoot and repair potential

problems that may occur with the SQA-V. Theses section will discuss how to provide

support for three types of issues: Te hni al, Self-test, Clini al

PLEASE NOTE:

Only a qualified MES distributor who has been trained to perform te hni al

support is authorized to open the SQA-V.

Opening SQA-V devi e without authorization may ause to the alibration

orruption and will VOID THE WARRANTY.

The ele tro-opti al board should NEVER be tou hed when the SQA-V is

opened – it will ause damage to the SQA-V alibration.

SECTION VIII: Te hni al Support/Part Repla ement

1. Opening the SQA-V

Turn off the main switch located on

the rear panel and disconnect

the SQA-V from the mains.

Using a Philips screwdriver, unscrew

all the screws on the rear panel.

Opening SQA-V rear panel

and

SQA-V

Service Manual Dec_2019

14

2.

Closing the SQA

-

V

Grip each panel from the side and

gently push them back together

making sure that all cables and

connectors are free and not

“pinched” between the panels.

Use a Phillips screwdriver to tighten

all screws of the rear panel.

Printer

Se tion 1:

SW version

# 2.48 and

2.60

NOTE: Use only

paper rolls

supplied by the

SQA-V

manufacturer,

otherwise the

printer can be

damaged.

3.

Thermal Printer (Part # V

-

E

-

01428

-

00)

ISSUE: The printer is not working

Check the following (SQA-V is powered on):

Thermal printer has a roll of paper loaded

properly

Printer paper is not jammed in the printer

Press the FEED button, if the paper does not

advance please proceed to the steps below

pen the SQA-V device (Device is switched off):

Remove the printer from rear panel

Check the cable connected between the printer

and the main board (location J3) and verify that

is not damaged or disconnected

If the cable is .K. but printer is not working,

please proceed to printer replacement

instructions below

Replacing the thermal printer:

Disconnect the printer cable

Remove the two screws holding the printer

bracket

Pull the printer gently out of its bracket

Replace the printer with new one

Assemble the bracket, reconnect the cable to

the printer and main board (location J3)

Attach the printer to the SQA-V rear panel

Close the SQA-V according to the instructions

from “Closing the SQA-V” section above

NOTE: For

devices with SW

version 2.48 and

2.60 with old

impact printer

If you have device with SW version 2.48 or 2.60 and

the impact printer has failed or damaged, MES would

highly recommend replacing it with newer printer

version - thermal printer (Part # V-E-01428-00).

Press the feed button

Che k the ables onne ted

to the printer

Remove two s rews

holding the bra ket

and

SQA-V

Service Manual Dec_2019

15

S

e tion

2:

SW version

# 2.49 and

Pro

NOTE: Use only

paper rolls

supplied by the

SQA-V

manufacturer,

otherwise the

printer can be

damaged.

4.

Printer (Part #

PCD

-

0171)

ISSUE: The printer is not working

Check the following (SQA-V is powered on):

Printer has a roll of paper loaded properly

Printer ribbon (ink) is not dry

Printer paper is not jammed in the printer

Press the FEED button, if the paper does not

advance please proceed to the steps below

pen the SQA-V device (Device is switched off):

Remove the printer from rear panel

Check the cable connected between the printer

and the main board (location J3) and verify that

is not damaged or disconnected

If the cable is .K. but printer is not working,

please proceed to printer replacement

instructions below

Replacing the printer:

Disconnect the printer cable

Replace the printer with new one

Reconnect the cable to the printer and main

board (location J3)

Attach the printer to the SQA-V rear panel

Close the SQA-V according to the instructions

from “Closing the SQA-V” section above

Keypad

5.

Keypad (Part # PCD

-

0201)

ISSUE: The Keypad is not working

pen the SQA-V

Verify that the keypad cable is connected firmly

to the Main board at J11 location (connector is

not loose)

Confirm that the cable is connected in the

correct orientation: The golden stripe on the

cable connector should be facing the rear panel

If the cable is connected properly and the

keypad is still not working- replace the keypad

Repla ing the keypad: Disconnect the keypad

cable connector from location J11 on the main

board

Using a flat

screwdriver,

carefully peel

off the faulty

keypad from

the front

panel. Clean

the surface

with alcohol

and let it dry

for a few

minutes.

Pull out the

faulty keypad cable through the slit in the front

panel

Press the feed button

Che k the printer able

Verify firm onne tion of

keypad able

Verify the able orre t

orientation

Pull the old Keypad Cable

and

SQA-V

Service Manual Dec_2019

16

Insert the new keypad cable into the slit in the

front panel

Please note: DO NOT onne t urrently the

keypad

Attach the keypad to its designated location on

the front panel by gradually removing the paper

while pressing it firmly into place from one side

to the other.

Please note: DO NOT bend the keypad during this

pro ess otherwise ele tri al wires/ onne tors

will be damaged

Plug the keypad connector to the J11 location on

the main board

Please note: The golden stripe on the able

onne tor should fa e the rear panel (the fan

side)

Close the SQA-V using 4 screws on the rear

panel

Power

Supply

Unit (PSU)

Notes:

1. Turn off the

main n/ ff

switch and

disconnect the

device from the

mains before

opening.

2. Refer to the

Appendix section

for instructions

on how to

address power

supply problems.

6.

Power Supply

Unit

–

PSU

ISSUE: The main switch is ON but the power

indicator does not light up and the fan is not working.

Check the fuses in the fuse box located inside

inlet on the rear panel of the SQA-V.

Replace the fuses if they are burned out.

Reconnect the power cord and turn the unit

back on.

If the unit still does not work, check the

input/output voltage of PSU as instructed below.

How to he k the input onne tor:

Check the voltage in the input connector of the

main PSU using a multimeter

The measured voltage between black and red

wires should be about 220 Volt AC

If no voltage is evident, replace the power inlet

(see paragraph 8)

If voltage is being supplied to the input

connector, check the output connector.

Plug the keypad onne tor

and verify orre t orientation

Atta h the new keypad

Keypad able slit

Che k the voltage in the

input onne tor

Che k the fuses

and

SQA-V

Service Manual Dec_2019

17

Note:

Before checking

the input\ output

connectors of

the main PSU,

turn on the SQA-

V from the

switch on the

rear panel.

How to he k the output onne tor:

Disconnect the output cable from the

motherboard.

Check the voltage on

the

output connector of the main PSU using a

multimeter:

Black wire: GND

Red wire: +5V±0.3

Purple wire: +12V±0.8

White wire:

-11.3V to -13.3V: New PSU

-16.1V to -12.7V: ld PSU

If there is no voltage on the output connector,

or if the voltage is out of the range – please

replace the faulty PSU. If the problem persists -

contact support services.

Power Supply

Unit (PSU)

Note:

Turn off the

main n/ ff

switch and

disconnect the

power cord from

the device inlet

before opening.

7.

Repla ement of the

Power Supply

Unit

ISSUE: The power supply and/or cables are not

working.

PLEASE N TE: The instructions depend on the SERIAL

NUMBER (SN#) of the SQA-V.

SN# 1329 and below – follow the instructions in

SECTI N 1

SN# 1330 and above – follow the instructions in

SECTI N 2

SECTION 1:

SN #1329

and below,

Old PSU P/N:

PSD-0492

1.

pen the SQA

-

V

2. Disconnect the two cables of the faulty PSU:

Input connector- location P1

utput connector- location P2

3. Place the SQA-V on its rear side

4. Using a #1.5 Philips screwdriver, remove the three

screws that connect the PSU to the rear panel

5. Replace the faulty PSU

6. Secure the new PSU to the rear panel using the

same three screws

7. Re-connect the input and output cable connectors

to the new PSU

8. Close the SQA-V

If the problem persists - Contact Customer Support

Che k the voltage on output

onne tor

Uns rew the

Power Supply Unit (PSU)

Dis onne t the ables

Old version PSU

(SN #1329 and below)

and

SQA-V

Service Manual Dec_2019

18

SECT

ION 2:

SN# 1330

and above,

PSU part #:

FPE-E-

00146-00

1.

pen the SQA

-

V

2. pen protective black cover of faulty PSU

3. Disconnect the two cables of the PSU:

Input connector- location CN1

utput connector- location CN2

4. Using a #1.5 Philips screwdriver open four

screws holding the faulty PSU

5. Replace the faulty PSU

6. Secure the new PSU to the rear panel using the

same three screws

7. Re-connect the input and output cable

connectors to the new PSU

8. Close the SQA-V

9. If the problem persists - Contact Customer

Support

Dis onne t the ables

Dis onne t the ables

and

SQA-V

Service Manual Dec_2019

19

Power Inlet

8.

Power Inlet

(

Part#

AP

-

9081001)

ISSUE: There is no power supplied to the PSU from the inlet.

Notes:

1. Turn off the

power supply and

disconnect the

power cord from

the back of the

SQA-V device

before opening.

2. Refer to the

Appendix section

for a flow chart of

power supply

problems and

solutions.

1. pen the SQA-V

2. Gently remove the rubber cover of the power

inlet until the connectors are exposed

3. Disconnect the three terminals from the power

inlet

4. Unscrew the power-inlet screws at the rear

panel of the device.

5. Gently pull out the power inlet from the rear

panel

6. Insert a new power inlet and reconnect the

terminals

7. Put the rubber cover back on the power inlet

Fan Assembly

9.

Fan Assembly

ISSUE: The main power switch is N, the power indicator is lit,

but the fan is not rotating.

For SQA-V of SN 1329 and below: use part# KHD-08-000856

For SQA-V of SN 1330 and above: use part #V-H-00575-00

Note:

When replacing the

fan, do not change

the direction of

airflow. Install the

new fan in the

same direction and

orientation as a

replaced fan.

1. pen the SQA-V

2. Verify that the both sides of cable connecting

the fan are plugged firmly

3. Verify that the voltage between black and purple

wires on output connector of PSU is +12V±0.8

(see paragraph 6 – “How to check the output

connector”)

4. If no power is evident, replace the main PSU

(see paragraph 7)

5. If the voltage is as described above, replace the

fan + cable:

Disconnect the fan cable from PSU and from

main board

Unscrew the four fan screws

Replace the fan assembly (fan+ cable) by

new one

Screw the new fan to the rear panel of the

SQA-V using four screws

Reconnect all the disconnected cables

Note:

The fan on

veterinary systems

work only when the

system reaches a

certain internal

temperature and

requires cooling.

Remove the rubber over

to expose the onne tors

Dis onne t the terminals

Uns rew the power inlet

s rews

Gently pull the power

inlet out the rear panel

Uns rew the four fan s rews

and

SQA-V

Service Manual Dec_2019

20

Operation

Monitor

10.

O

peration Monitor

-

ISSUE #1:

LCD S reen (P/N: V-MA-00615-00)

The SQA-V is N, power indication LED is functioning and the fan is working, but the LCD

screen ( peration Monitor) is not illuminated although data is displayed on the screen.

PLEASE N TE: The instructions depend on the SERIAL NUMBER (SN#) of the SQA-V

SN# 2228 and below – follow the instructions in SECTI N 1

SN# 2229 and above – follow the instructions in SECTI N 2

SECTION 1: SN

#2228 and

below

Note:

Turn off the SQA-V

and disconnect the

power cord from

the back of the

device before

opening the SQA-V.

WARNING:

D N T T UCH the

backlight lamp and

inverter board while

SQA-V is on! There

is a risk of HIGH

V LTAGE shock!

1. pen the SQA-V

2. Turn on the SQA-V and check the input and

output cables of the inverter board: verify they

are connected properly and the connection is not

loose

3. Check the voltage on purple wire of PSU output

connector and verify that it is within the range

(refer to Power Supply Unit section, paragraph

#6). If the measured voltage is K but the

screen doesn’t light up, replace the faulty

inverter board (Item#AS-9084111):

Turn the SQA-V off and disconnect the

cables connecting the inverter board to the

main board and LCD screen

Using a Phillips screwdriver, remove the two

screws that secure the faulty inverter board

Replace the faulty inverter board with a

new one and secure it with the two screws

Re-connect the cables of the inverter board

If the problem persists, contact MES Customer

Support.

SECTION 2: SN

#2229 and

above

NOTE:

Turn off the SQA-V

and disconnect the

power cord from

the back of the

device before

opening the SQA-V.

1.

pen the SQA

-

V.

2. Turn on the SQA-V and check the input and

output cables of the Backlight PCB: verify they

are connected properly and the connection is not

loose

3. Using multimeter check the voltage on J3

connector of Backlight PCB. If the supplied

voltage is not +3.5V±0.1 replace the Backlight

PCB:

Turn the SQA-V off and disconnect the data

cables connecting the Backlight PCB to the

LCD screen and to the mother board

Disconnect the backlight power cable

Using a Phillips screwdriver, remove the two

screws that secure the faulty Backlight PCB

Replace the Backlight PCB with a new one

and secure it back with two screws

Re-connect all the cables to the new

Backlight PCB

4. If the measured voltage is +3.5V±0.1 – replace

the peration monitor (refer to section below for

detailed instructions)

5. If the problem persists after replacing of

Backlight PCB and/or perational monitor,

contact MES Customer Support

Ba klight PCB

Ba klight

power able

Data Cables

Dis onne t both ables

Remove both s rews

Che k voltage on J3 onne tor

Other manuals for SQA-V Gold

2

This manual suits for next models

1

Table of contents

Other MES Medical Equipment manuals