MES SQA-iO User manual

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 1

Service Manual

Version: 187.5.1

Catalog#: IO-ML-01678-00

Rev: August 2021

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 2

Table of

Contents

SECTION I: Introduction

Automated Test Results 3

Technology 4

SECTION II: System Specifications and Requirements

System Components 4

Measurement Compartment 4

USB Port 5

Testing Capillary 5

Maintenance Schedule 5

Testing and Operting Requirements 6

Operating Temperature/Humidity/Altitude 6

SECTION III: Quality Control

Internal QC 6

Printing the Service Report 7

SECTION IV: Troubleshooting

Troubleshooting 7

SECTION IX: Appendixes

Cleaning the SQA-iO 8

Troubleshooting Guide 9

Filling the Testing Capillary with a Normal Volume Sample 11

Filling the Testing Capillary with a Low Volume Sample 13

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 3

SECTION I: Introduction

The SQA-iO is a high-performance PC-based analytical medical device that tests FRESH

semen samples. The device works with a computer application that contains the device,

patient, sample, test results and facility information.

After collection and preparation, a ~1 ml semen sample is withdrawn into an SQA capillary

disposable delivery system, inserted into the SQA-iO where key parameters are collected,

and sample test results are processed utilizing proprietary technology and algorithms. The

testing process takes approximately 75 seconds.

The system runs an automatic self-test and auto-calibration upon start up and checks

device stability before each sample is run.

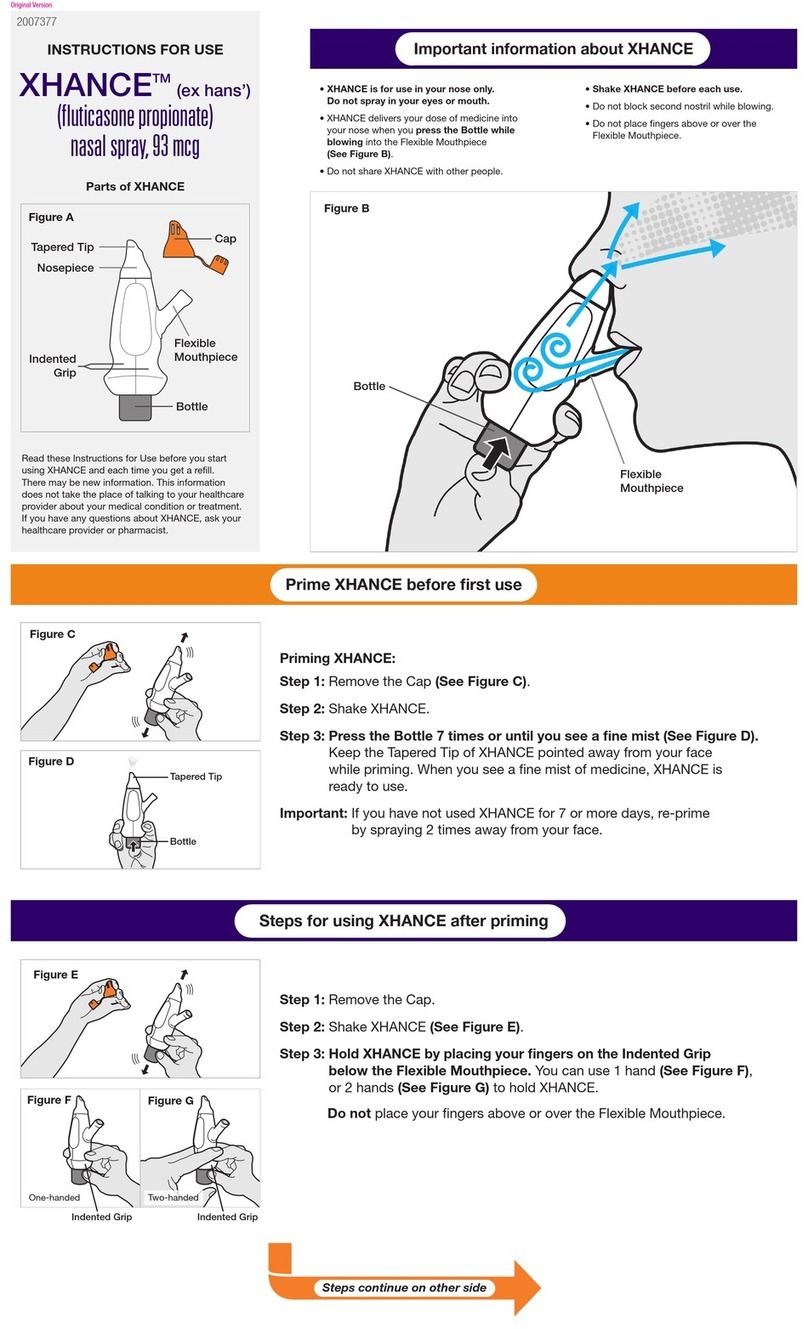

Automated

Test Results

and

Reportable

Range

SQA-iO Reportable Range

Sample

Type

Conc.

(M/ml)

Motility

(%)

PMSC

(M/ml)

Morph Norm

Forms (%)

MSC

(M/ml)

Fresh

<2 - 400

0 - 100

0 - 400

2 - 30

<0.2 - 400

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 4

Technology

Motility Channel

Light disturbances caused by moving sperm cells are converted into analog signals.

Proprietary algorithms interpret the signals and report motility.

Concentration Channel

Based on spectrophotometry analysis of the semen samples and application of

proprietary algorithms.

1. The capillary is inserted into the measurement compartment.

2. Sample concentration is evaluated in the "tall" 10 mm chamber of the capillary.

3. Motility is detected in the "thin" 0.3 mm section of the capillary.

4. This information is then digitized and routed to the microprocessor that applies

algorithms to extract the required clinical semen parameters.

Analog to

Digital

Converter

Semen

parameters

extraction

algorithms

Self-Test

and QC

KeyPad

Microcontroller

Operational

Monitor

#1 #2

#3

#4

Concentration

detector

Motility

detector

Concentration

LED

Motility

LED

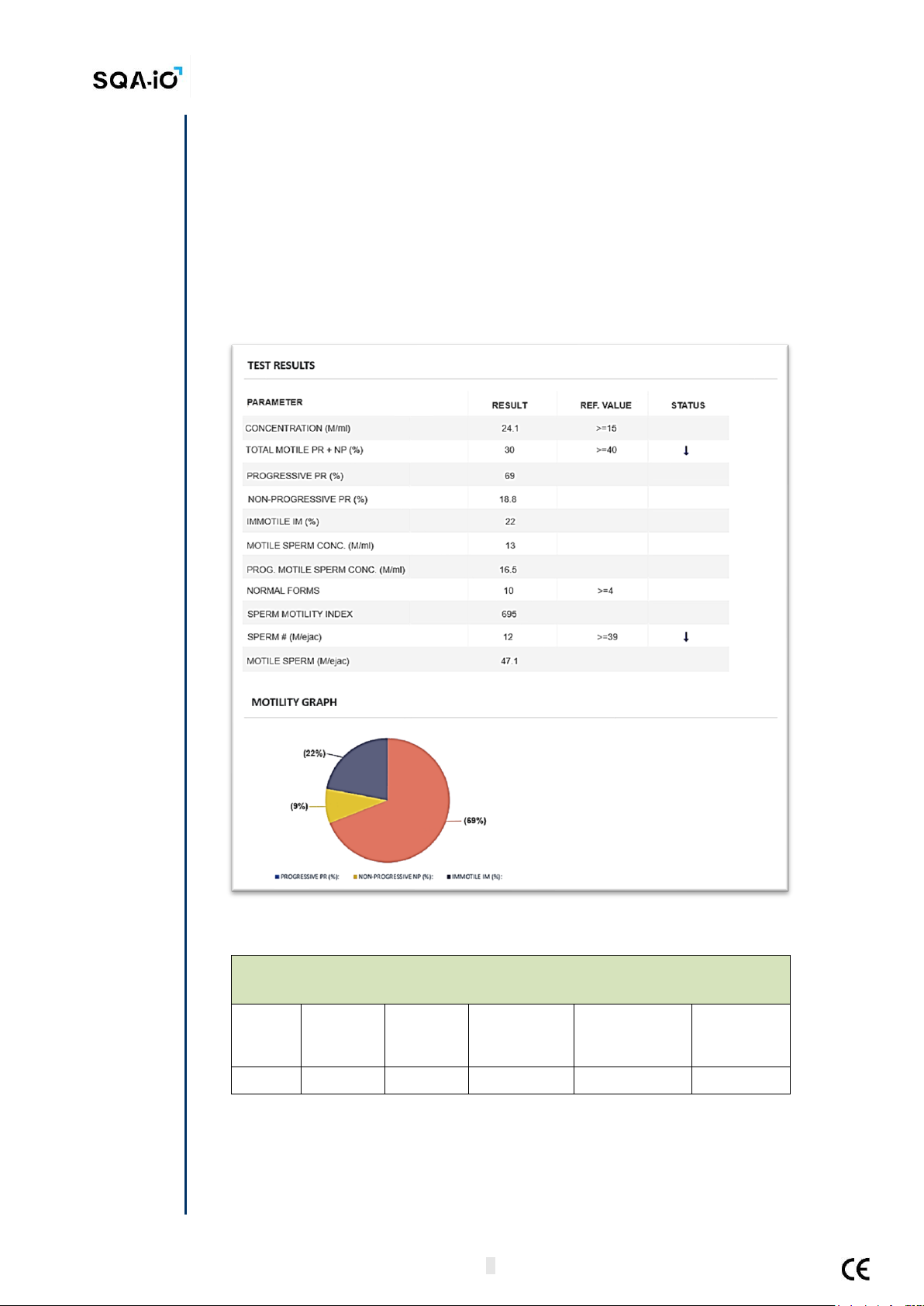

SQA-iO Device

Overview and

System

Components

Measurement

Compartment

SECTION II: System Specifications and Requirements

•Dimensions: 8 X 9.5 X 10.5 cm

•Weight: 0.350 Kg

•Power supply: 5V DC (USB)

•Noise level: 0 [dBA]

•Device power consumption: 1.7 [BTU/hour] = 0.5 [Watts]

Minimum requirements:

•PC: Intel Core i5 M520 2.4GHz or equivalent

•RAM: 4GB

•Monitor Screen: Color, Wide screen –minimum resolution 1024 x 768

•Operating system compatibility: Windows 7 Professional x32 or above

•Communication Ports: one USB port

•Internet Access: 5mb per second

Front Panel: Measurement Compartment (Capillary insertion for testing)

Capillary

chamber

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 5

USB Port

Testing

Capillary

Maintenance

Requirements

•Sources of radiant energy: Two LEDs (motility and concentration channels)

•Detector system: Two photo detectors (Motility and Optical Density)

•Analysis Time: 75 seconds

•Software: Resides on flash memory

•Motility channel input signal: Analog, up to 5V.

•Concentration channel input signal: Modulated (kHz) analog, up to 5V

•Calibrated for testing human semen only at room temperature

Rear Panel: USB connection port

•USB PORT: 1 connector for USB 2.0B male connection cable

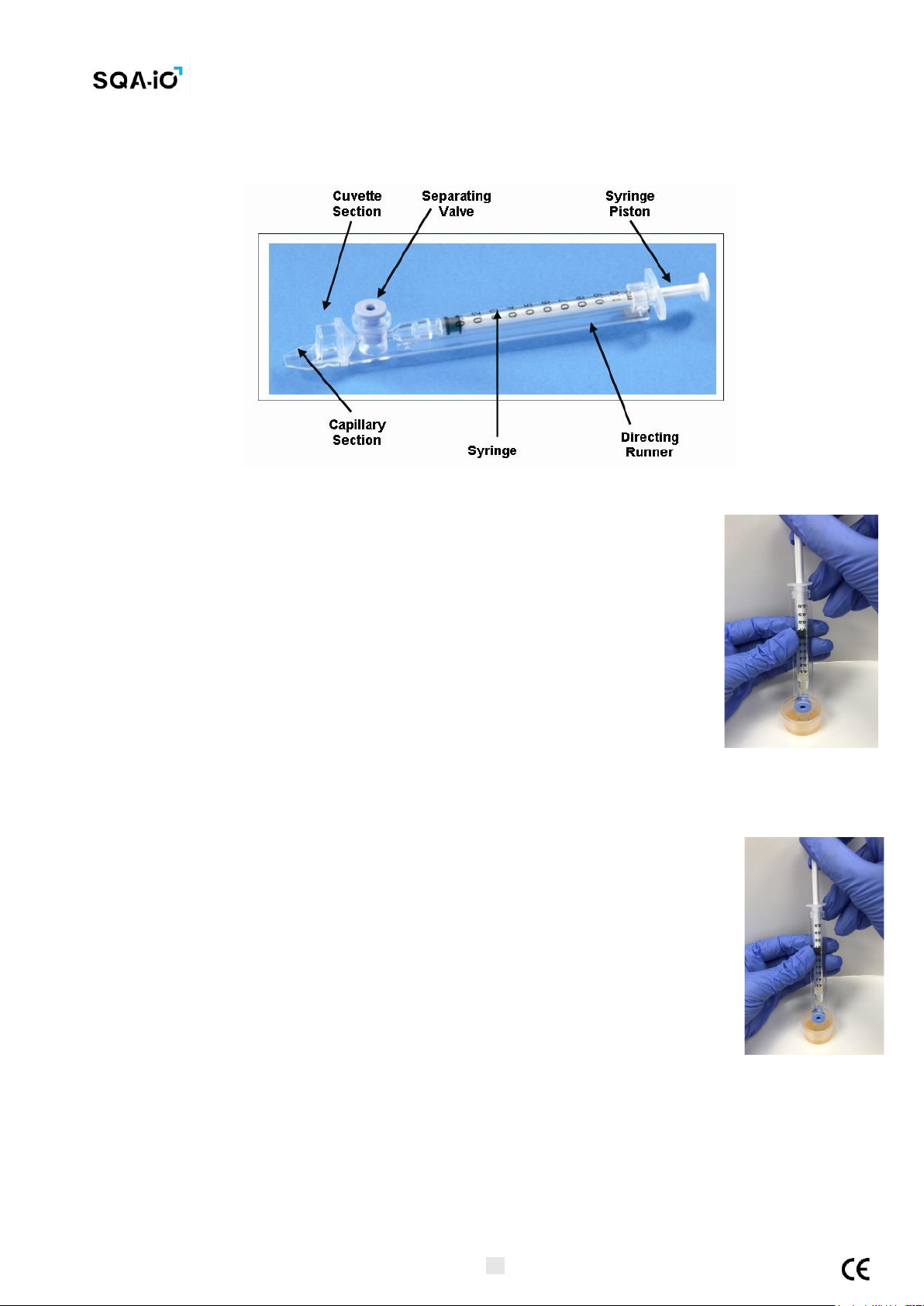

Testing Capillary: Sample delivery system

•Normal sample: Requires approximately 0.5cc of semen

•Short samples: Requires approximately 20µl

•Single-use design for testing semen in a biologically safe manner

•Motility parameters are measured in the 0.3 mm (thin) "capillary” section

•Concentration is measured in the 10 mm (tall) "cuvette” section

•Use only manufacturers’ certified testing capillaries for testing

•Filling and insterting the testing Capillary: Refer to the Appendix section

Maintenance Schedule

•Measurement compartment cleaning:

oDAILY: When running samples

oAFTER EVERY 10-15 tests and/or for ANY spillage

oUse only manufacturer’s cleaning kit/supplies to prevent damaging the device

oRefer to the “Cleaning the Capillary Compartment” Appendix in this manual

for detailed instructions

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 6

Testing and

Operating

Requirements

Ambient

Condition

Restrictions for

Operation

Quality

Controls

Overview

PASS/FAIL QC

Results

Controls Run at

Start-up

Manufacturer’s Recommendations

•The SQA-iO is sensitive to vibrations during the testing cycle. Operate away from

devices that cause electronic noise or vibrations such as centrifuges.

•Un-plug the device when not in use for an extended period of time.

•Ambient temperature limitations: The SQA-iO is calibrated to conduct tests at room

temperature: 20-25ºC (68-77ºF). This is the recommended range for room

temperature maintenance of semen samples prior to testing for up to 1 hour following

collection.

•Sample processing limitations: The device is calibrated to test semen samples at

room temperature. Heating samples in ANY WAY will impact results. Do not heat

samples.

•Semen is considered biologically hazardous material and is subject to

individual laboratory protocols for handling such materials. At a minimum,

it is recommended to:

oWear laboratory coat, mask and gloves when handling semen

oDispose of samples post testing in designated hazardous waste containers

oRequire that only personnel trained to work with biologically hazardous

materials test and handle semen samples.

Operating Temperature, Humidity and Altitude

•Maximum operational humidity is up to 80% for temperatures of up to 31ºC with

decreasing linearly to 50% humidity at 38ºC.

•Operates in a wide range of ambient temperatures (15-38ºC) however the system is

calibrated to measure semen samples at room temperature:

20-25ºC (68-77ºF).

•Intended for indoor use at a maximum altitude of 2000m, mains supply fluctuations

±10%, Overvoltage Category II, Pollution Degree II.

IMPORTANT NOTES:

•Humidiy exceeing the limitations above may impact test results due to condensation

on the optical detectors. Assess ambient humidity and temperature prior to device

operation.

•Ambient temperatures exceeding the limitation above may impact the accuracy of

semen motility test results because of the known effect of temperature on human

semen.

SECTION III: Quality Control

Internal Controls: A series of tests are automatically run when the SQA-iO is turned on and

prior to testing. These internal QC tests check the calibration settings and the internal

operating system.

Internal Controls are run @ SQA-iO Start-up: PASS/FAIL results are reported

on the SQA-iO home screen along with troubleshooting information

•Stabilization and autocalibration: System stability and reference parameters are

checked to ensure they are in proper range by analyzing the system sensors. Once

stable for 30 seconds the device passes stabilization and autocalibration. A warning

message is displayed on the home screen if there is a failure.

•System noise: Measures the electronic noise level of the system to insure effective

measurement of electronic signals.

•Self-test: Electronic signals simulating motility and concentration measurements

verify that the calibration settings are consistent with factory specifications.

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 7

Controls Run

Prior to

Sample

Testing

Printing the

Service

Parameter

Report

•Autocalibration verification: Reference parameters of the concentration and

motility channels are measured again (without a testing capillary).

•System noise: Measures the electronic noise level of the system to insure

effective measurement of electronic signals. The system automatically adjusts the

noise level threshold to insure accurate readings.

•Electronic spikes: Checks for measurement points that are out of range.

Instructions for printing the SQA-iO SERVICE parameters to prepare for

technical support:

If a Self-Test failure occurs, the related status icon in the SQA-iO HOME SCREEN will turn

red. Click on the RED icon to view instructions for how to resolve the problem:

SECTION IV: TROUBLESHOOTING

The SQA-iO troubleshooting guide is focused on app access and function. The

SQA-iO device cannot be opened for service so it is important to follow the cleaning

and use instructions for optimal and continued success using the device.

Please refer to the appendix section for a TROUBLESHOOTING GUIDE.

Support is available through your local distributor online. Please contact them

directly for questions concerning the device that are not outlined in this service

manual.

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 8

Appendix 1: SQA-iO Cleaning Instructions

APPENDIX 1: Cleaning the SQA-iO

When to clean: WEEKLY

•Or if SELF-TEST or any other failure occurs

•Or if System becomes contaminated with semen

Cleaning kit components:

Long cleaning brush (provided in the SQA-iO device kit)

Fibrous material cleaning paddles (single use)

Sponge-tipped drying paddles (single use)

Cleaning fluid (single drop dispenser)

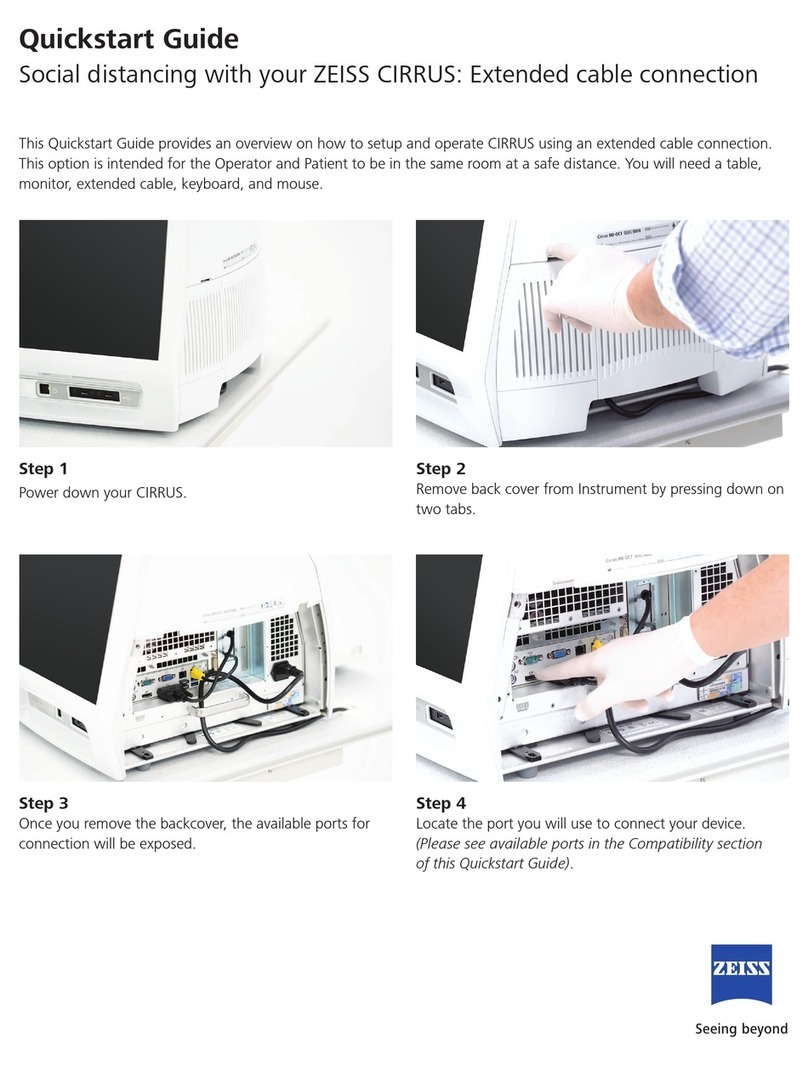

CLEANING: STEP 1

•Insert the long brush supplied in your device kit (bristle side

down) into the chamber of the SQA-iO in the same way a

testing capillary would be inserted (Fig 1 and 2).

•Pull the brush out, applying downward pressure to sweep or

‘dust off’ the optics (you will feel a ‘shelf’ in the back/top

section of the chamber) –(Fig 2 and 3)

CLEANING: STEP 2

1. Use a Fibrous material cleaning paddle (Fig 4) supplied in your

TEST KIT

•Moisten with only ONE drop of cleaning fluid.

•Shake off excess fluid.

•Insert into the measurement compartment fibrous material

facing down and move the cleaning paddle in and out 5 times

(Fig 5).

•Then, insert into the measurement compartment fibrous

material facing up and move the cleaning paddle in and out 5

times (Fig 5).

2. Dry the testing chamber using a sponge-tipped drying

paddle that is supplied in your TEST KIT.

•Insert it into the testing chamber and leave it for 10 –15

seconds (Fig 6).

•Leave the drying paddle in place, DO NOT move it in and out.

Fig.1 Long Cleaning Brush

Fig. 2 Clean the chamber

Fig. 3 “Dust off”

Fig. 4 Fibrous cleaning paddle

Fig. 5 Insert cleaning paddle down and up

Fig. 6 Dry the testing chamber with sponge

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 9

APPENDIX 2: TROUBLESHOOTING GUIDE

TROUBLESHOOTING OPERATING ERRORS: This table describes what to do when a problem occurs with the SQA-iO

app access or when running a test or receiving an error message. It is important to note: If the SQA-iO case is

opened by the user, it is no longer under warranty.

ISSUE

POSSIBLE FAILURE SOURCE

SOLUTION

Computer

connectivity

1. USB connection error

indicated on the app header

/ pop-up warning.

Remove and reconnect the USB cable –follow the pop-up

warning instructions that can be activated by clicking the USB icon

found in the app header or click the ‘Disconnected’ button on the

app home screen.

2. USB connection failure after

installation

Display of Step 2 of the installation process where the user is asked

to connect the USB cable. If it fails, please report using online

support by clicking on the link to the troubleshooting page.

3. Driver error after login/sign-

up

Download and reinstall the driver by going to step 2 of the

installation process. If it fails, please report using online support.

Cannot

Sign-up

1. Missing required information

Fill in the mandator fields that are missing information. This is

indicated by red explanation text when clicking on the ‘Register’

button.

2. Did not accept Terms and

Conditions

3. User already exists

The email entered to “Register” is already in use. Select another

email or may require a password reset (see ‘Cannot Login’ below)

Cannot Login

When clicking on the ‘Login’

button a warning that user email

or password is incorrect/missing

Reset the user password: Request an email with a link to reset the

password when receiving message “Forgot email?”

Self-test

failure

A failure is indicated by a red

warning icon on the HOME page.

Click the red icon indicating a failure. Observe the normal range

value.

1. Clean the test chamber using ONLY MES cleaning kit.

2. Remove and reconnect USB cable.

3. Reboot the device.

If problem persists, refer to MES customer support:

https://www.sqa-io.com/#/contact-us/contact-us

The testing

capillary

won’t go into

the SQA-iO

The testing capillary may have

been inserted upside down or

blue piston is not fully pushed in.

Refer to the Appendix section of this guide for instructions on how to

correctly prepare and insert the capillary into the SQA-iO device.

Low Test

Credit

A red button is shown when the

test credit balance is below 10.

Click the "Tests Remaining" button on the HOME screen to enter a

new code for test credits or contact SUPPORT to order a new test kit

with a new test credit code. If the credit balance is 0 the "Test

Patient" section on the navigation bar is disabled.

Cannot start

testing / the

START TEST

button is

disabled

1. No test credits remain

•Add test credit from a new testing kit using the unique code

provided.

•Order a new test kit by going to SUPPORT

2. Information missing in

mandatory fields

Fill in all fields that are mandatory as indicated by an asterisk: *

3. The SQA-iO is not connected

Remove and reconnect the USB cable per the pop-up instructions

(and based on the red USB icon shown on the header bar).

Connection is

lost during a

test

Loss of internet connection

The USB connection indicator will turn RED and a pop-up warning

will tell the user to reconnect and navigate back to the data entry

screen. Start must be pressed again. The patient information is

saved and the system will return to the data entry screen. Test

credits will not be charged.

Test results

are not

logical

Test results appear to be out of

range.

Go to the Service page and follow the instructions:

1. Clean the test chamber using ONLY MES cleaning kit.

2. Remove and reconnect USB cable and reboot the device.

If problem persists, refer to MES customer support:

https://www.sqa-io.com/#/contact-us/contact-us

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 10

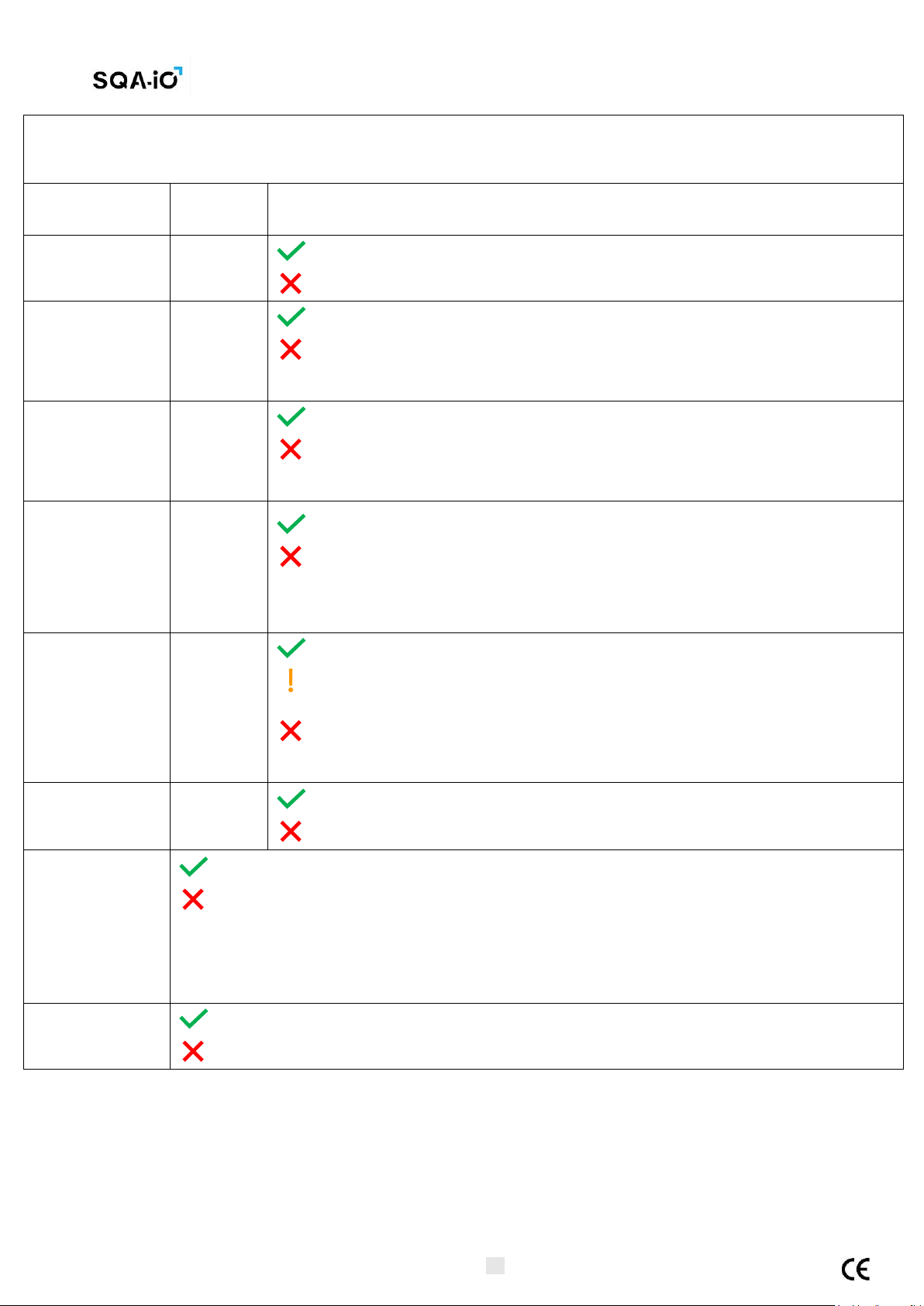

TROUBLESHOOTING PARAMETERS OUT OF RANGE: This table describes what to do when a problem occurs with the

service data key parameters. It is a detailed description of the Self-test failure that occurs on the HOME page. To solve

the issue, navigate to the SERVICE page, follow the instructions below, and rerun the Self-test. If the problem persists,

contact customer support.

PARAMETER

ACCEPTA

BLE

RANGE

DESCRIPTION/SOLUTION

REFERENCE 1

(REF 1)

150 –350

mV

Reference 1 passed the self-test

Reference 1 failed the self-test

LED CURRENT 1

(LED 1)

5 –20 mA

LED Current 1 passed the self-test

LED Current 1 failed the self-test

Suggestion: Clean the device

AMPLITUDE

50 –100

mV

Amplitude passed the self-test

Amplitude failed the self-test

Suggestion: Clean the device

ZERO LEVEL

500 –525

Zero Level passed the self-test

Zero Level failed the self-test

Suggestion: Clean the SQA-iO. Maintain ambient temperature between 20 –25°C / 68

–77°C

REFERENCE 2

(REF 2)

OPTIMAL:

2800 –

3500

PASSED:

2500 –

2800

Reference 2 passed the self-test

Reference 2 passed the self-test but is not in the optimal

range

Reference 2 failed the self-test

Suggestion: Clean the device

LED CURRENT 2

(LED 2)

10 –32

mA

Led Current 2 passed the self-test

Led Current 2 failed the self-test

AUTO-

CALIBRATION

AND

STABILIZATION

Auto-Calibration and Stabilization passed (Zero Level parameter is stable)

Auto-Calibration and Stabilization failed

Suggestion:

•Remove testing capillary from the measurement compartment

•Remove the SQA-iO from sources of vibrations (centrifuge)

•Clean the device

SELF-TEST

Self-test passed (The key system parameters are in range)

Self-test failed

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 11

APPENDIX 3: Filling the Testing Capillary with a Normal Volume Sample

Sample size, collection and preparation instructions:

1. Sample volume should be at least .5 ml. If sample volume is less than .5 ml

the sample can be run as a short sample following the instructions in

Appendix 2.

2. The sample must be collected without partners, gels or creams and tested

within 1 hour of collection for accurate results.

3. Do not heat or refrigerate the sample, maintain an test at room temperature

4. The semen sample must be completely liquefied and well mixed prior to

aspiration: Gently mix by rotating the sample collection container.

WARNING: Do not shake or use a pipette to mix the sample otherwise air

bubbles will form and test results will be inaccurate.

Figure 1

5. Carefully check that the liquefied, fully mixed specimen is free of air bubbles (or that there is an

adequate amount of sample below the air bubbles) before immersing the capillary into the specimen.

Filling the capillary:

1. Push the syringe pump fully into the syringe. Place only thin part of the

capillary into the bottom of the sample while angling the sample container at

about 45 degrees (Figure 1).

2. Placing two fingers below the syringe pump’s head pull the syringe pump back

slowly while keeping the tip of the capillary well below the sample level

and below any surface bubbles (Figure 1). Continue to aspirate the sample

until it appears in the Luer adaptor (Figure 2).

Figure 2

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 12

3. Check the capillary after filling (Figure 3), visually confirm that the sample

has completely filled the thin section (without a meniscus) and the cuvette

section. A small level of sample should appear in the syringe. Tap on the

syringe to make sure there are no air bubbles in the sample. If, after

tapping, some air bubbles appear below the Luer adaptor, dip the capillary into

the semen sample again and aspirate a small quantity of semen to draw the air

bubbles into the syringe.

4. Quickly (to avoid wicking) wipe the outer surface of the capillary - both

top and bottom (Figure 4) with a delicate wipe (Kimwipes, etc.). It is important

to remove all semen from the exterior of the capillary in order to keep the SQA-

iO clean. Visually confirm that the capillary chambers are still full following the

cleaning process. If some of the sample has been depleted (meniscus formed in

the thin part of the capillary) fill the capillary part from the cuvette section by

slightly pushing in the piston.

Figure 4 Wipe the tip

Fig 3 Inspect for bubbles

5. Slowly and carefully push-in the blue piston until it is level with the plastic

(Figure 5).

Figure 5: Push in the blue piston

6. The capillary is now ready.

7. Insert the testing capillary into the measurement compartment with the

blue stopper down. Push it in as far as it will go to ensure that the capillary is

properly seated.

Service Manual Version 187.5.1

AUGUST 3, 2021 SQA-iO Service Manual 13

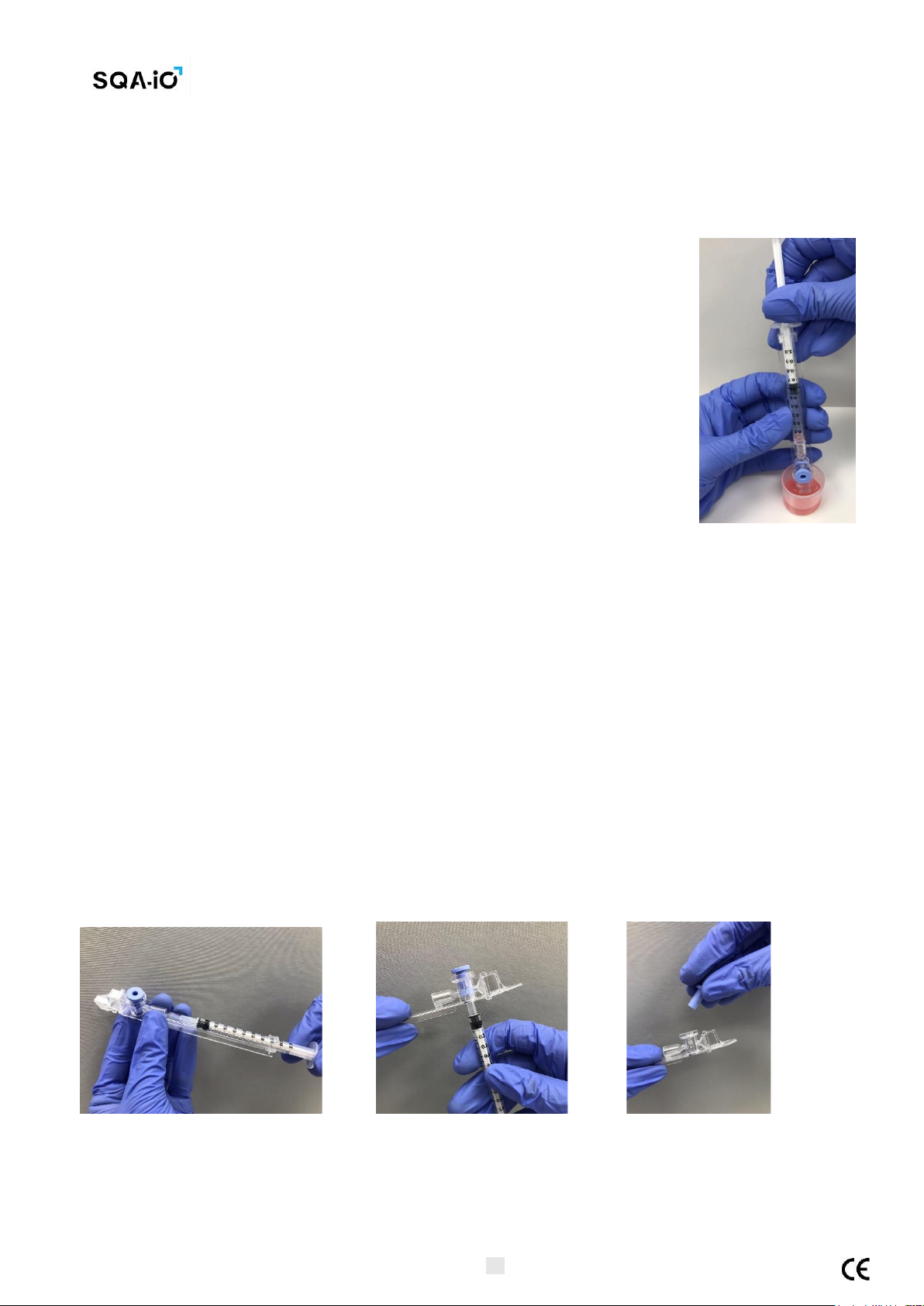

APPENDIX 4: Filling the Testing Capillary with a Low Volume Sample

Sample size and preparation:

1. A sample as small as 10 microliters can be tested for motility parameters by filling ONLY the thin section

of the testing capillary.

2. The sample must be collected without partners, gels or creams and tested

within 1 hour of collection for accurate results.

3. Do not heat or refrigerate the sample, maintain and test at room temperature

4. The semen sample must be completely liquefied and well mixed prior to

aspiration: Gently mix by rotating the sample collection container.

WARNING: Do not shake or use a pipette to mix the sample otherwise air

bubbles will form and test results will be inaccurate.

Filling the capillary:

1. Push the syringe piston in fully. Place only the thin part of the capillary

into the bottom of the sample (Figure 1).

2. Pull the piston back slowly without withdrawing the capillary from the

sample. Fill only the (thin) capillary chamber with 10 microliters of

semen (Figure 1). Aspirate the sample until it just appears in the cuvette

section while keeping the tip of the capillary well below the sample level and

well below the level of any bubbles covering the liquid.

3. Withdraw the capillary tip from the semen sample and visually inspect to

ensure that the sample has completely filled the thin section (no meniscus).

4. Quickly (to avoid wicking) wipe the outer surface of the capillary - both

top and bottom with a delicate wipe (Kimwipes, etc.). It is important to

remove all semen from the exterior of the capillary in order to keep the SQA-

iO clean.

5. Visually confirm that the thin chamber of the capillary is still full of semen

after completing the cleaning process. If some of the sample has been

depleted push-in the piston slightly until the first drop appears on the

capillary tip and then fill the capillary again from the sample container.

Figure 1

Removing the blue piston:

6. The blue piston must now be removed:

•Detach the entire syringe from the hub (Figure 2)

•Use the syringe tip to firmly push-out the separating valve from the underside of the capillary

(Figure 3).

•Completely detach the separating valve (Figure 4). The capillary is now ready to be inserted into

the SQA-iO

Figure 2: Detach the syringe Figure 3: Push the piston out Figure 4: Remove the piston

PLEASE NOTE: Test Low Volume samples as soon as the sample is aspirated into the capillary.

Table of contents

Other MES Medical Equipment manuals