MES SQA-Vision User manual

V e r s i o n 1 0 9 . 1 3 . 4

C a t a l o g # : V S - M L - 0 1 0 9 1 - 0 0

R e v : J a n 2 0 2 0

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 2

Table of

Contents

SECTION I: Introduction

Automated Test Results 3

Tec nology 4

SECTION II: System Specifications and Requirements

Sperm Quality Analyzer – SQA-Vision 5

SECTION III: System Overview

Front Panel 7

Rear Panel 7

Side Panel 8

T e C assis Assembly 8

T e Cover Assembly 8

Sc ematic of t e SQA-Vision Mot erboard 8

SECTION IV: System Components and ccessories

Testing Capillary 9

Cleaning and Accessories Kit 9

SECTION V: Self- Test and uto-Calibration

Start Up 9

Prior to testing a sample 10

SECTION VI: Getting Started / Set Up

Getting Started / Set Up 10

SECTION VII: Troubleshooting

Overview 11

SECTION VIII: Technical Support and Part Replacement Instructions

Opening t e SQA-Vision 11

Closing t e SQA-Vision 11

Keypad 12

Power issues 13

Power Supply Unit (PSU) 13

Power Inlet 14

Fan Assembly 14

Operation Monitor (LCD Screen) 15

Focus Knob and Field Of View Knob 18

Surge Protector Replacement 18

Capillary Sensor Troubles ooting and Replacement 19

Camera Replacement 21

Optical Board to LED Cable Replacement 23

SECTION IX: ppendixes

C

leaning t e

SQA

-

Vision

2

4

Replacing t e Processor

2

5

Power Supply Troubles ooting Flowc art

2

7

Parameters Out Of Range: Troubles ooting 28

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 3

SECTION

I

: Introduction

T e SQA-Vision is a ig -performance PC-based analytical medical device t at combines

tec nology in optoelectronics, computer algorit ms and video microscopy. T e SQA-Vision and

a fully integrated TOUCH-SCREEN work

toget er to provide user friendly semen analysis testing.

Samples are run in t e SQA-Vision testing device and all data entry and user interface is

computer based.

FRESH, POSTVASECTOMY, WASHED, SWIM-UP, DENSITY GRADIENT and FROZEN semen

samples as well as LONGEVITY testing can be performed on t e SQA-Vision. Additionally MANUAL

testing can be performed utilizing t e on-screen MANUAL COUNTER. T e ig resolution

visualization component of t e SQA-Vision permits assessment of oligospermic specimens and

poor quality IVF samples.

W en results fall below t e automated dynamic range of t e system, a LOW QUALITY COUNTER

opens automatically to permit manual sperm counting. Debris and round cell assessment is

performed using t e DEBRIS/ROUND CELLS SCANNER. % Normal morp ologically is assessed

automatically along wit ot er semen parameters. Vitality and Morp ology differentials can be

assessed manually using t e en anced visualization system and on-line counters.

T e analysis time varies according to t e type of sample being tested: Normal quality samples –

75 seconds; Low quality – 2 additional minutes; Post vasectomy – 5 minutes.

T e system runs a self-test and auto-calibration upon start up. It also runs latex beads or

stabilized sperm external quality controls.

utomated

Test Results

and

Reportable

Range

utomated Test

Results

Concentration M/ml Motile Sperm Concentration (MSC)

M/ml

Total Motile

PR+NP % Progressively Motile Sperm Concentration

(PMSC)

M/ml

Progressive PR %

Functional Sperm Concentration (FSC)

(Progressively motile sperm wit normal

morp ology)

M/ml

Non-progressive

NP % Velocity

mic

/sec

Immotile IM % Sperm Motility Index (SMI)

#

Normal forms

(WHO 5

t

) %

TOT LS PER SEMEN VOLUME

Sperm #

M/ejac

Functional Sperm

M/ejac

Motile Sperm

M/ejac

Morp ologically Normal Sperm

M/ejac

Progressively

Motile Sperm

M/ejac

POSTV SECTOMY

Motile, Immotile

and Total Sperm M/ml # Motile, # Immotile and # Total

Sperm/semen volume M

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 4

Technology

utomated System

Motility Channel

Lig t disturbances caused by moving sperm cells are detected and translated into

analog signal peaks.

T e greater t e # of motile sperm cells in t e field of view, t e ig er t e peak.

T e slower t e sperm velocity t e broader t e signal peaks.

T e average analog signal is mat ematically proportional to MSC.

Concentration Channel

Sperm concentration is measured in t e cuvette section of t e SQA-testing capillary.

An infrared lig t wavelengt specific to sperm cells is maximally absorbed by sperm

cells and minimally absorbed by ot er seminal fluid components.

In t e final calculation of sperm concentration, t e SQA-Vision algorit m makes an

adjustment to account for t e infrared lig t absorption of t e seminal fluid components.

SQ -Vision Reportable Range ( utomated Results)

Sample

Type

Sperm

Conc.

M/ml

Motility

%

Morp

%

MSC

M/ml

PMSC

M/ml

Motile /

Immotile /

Total Sperm

M/ml

Fres <2 - 400 0 - 100 2 - 30 <0.2 -

400 0 - 400

-

Was ed <2 -

200+ 0 - 100 2 - 30 <0.2 -

200+

0 -

200+ -

Swim-up,

Density

Gradient,

Frozen

- - - <0.2 -

200+

0 -

200+ -

Post-Vas - - - - - 0 - 400

#1: T e capillary is inserted into t e measurement compartment.

#2: Sample concentration is evaluated in t e "tall" 10 mm c amber of t e capillary by

measuring t e amount of optical absorption of light as a beam traverses the

seminal fluid.

#3: Motility is detected in t e "t in" 0.3 mm section of t e capillary by analyzing light

modulations caused by sperm motion.

#4: T is information is t en digitized and routed to t e microprocessor t at applies

algorit ms to extract t e required clinical semen parameters and performs internal

self-testing and calibration.

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 5

SQ

-

Vision

SECTION

II

: System Specifications and Requirements

Dimensions: 32 X 30 X 24 cm

Weig t: 7 Kg

AC power supply: 100-240 VAC, 50-60 Hz, 20 VA

Front Panel

Displays: LCD display

Testing: Measurement and Visualization compartments

Ot er: Multi-button keypad, Focus knob, FOV (Field Of View) knob

Keypad

Operational keys: I-Button, Service, Enter, Esc, Delete, four cursor buttons and ten

numeric buttons (0-9).

Video control key: Zoom In/Out

Measurement Compartment

Sources of radiant energy - two LEDs for motility and concentration c annels

Detector system - two p oto detectors - Motility and Optical Density

Operating System

nalysis Time: Normal Test – 75 seconds; Low Quality – 2 additional minutes;

Postvasectomy (automated) – 5 minutes

Software: Resides on flas memory. System can be upgraded from a PC CD-ROM

Motility channel input signal: Analog, up to 5V.

Concentration channel input signal: Modulated (kHz) analog, up to 5V.

Rear Panel

Power inlet w/fuse- older (fuses: 250V,2A), RS232 connector, 2 USB 2.0 B-Type Male,

On/Off switc of t e blue surrounding LEDs (located on bottom side of t e panel).

Left Side Panel

Power On/Off switc

I-Button port

Visualization Compartment

W ite LED illumination system wit max luminous intensity – 35,000 mcd.

Digital Camera, max resolution: 1280 x 1024 pixels, ig resolution of "live" and "frozen"

images provided by capturing a ig # of FPS (frames per sec).

Objective: Standard, x40, c romatic aberration correction.

Zoom system for smoot magnification transition between x1188 and x1725

Focus adjustment knob

Field of View Stage knob

SQ -Vision

Maintenance Schedule

Daily: Clean measurement compartment daily w en running samples and after every 10-

15 tests and/or for ANY spillage. Follow manufacturer’s cleaning instructions using

manufacturer cleaning kit (Refer to t e appendix section “Cleaning t e Capillary

Compartment” in t is User Guide).

ONLY use the Manufacturer’s cleaning kit and cleaning brush or damage will

occur to the SQ -Vision film and the system will not operate!

Manufacturer Recommendations

Operate t e SQA-Vision away from devices t at may cause electronic noise or ot er

devices causing vibrations suc as centrifuges.

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 6

Turn t e system OFF w en not in use for an extended period of time.

W en running Postvasectomy tests do not interrupt test cycle nor interfere wit system

or testing capillary in any way – t is test is ig ly sensitive to any motion and requires

complete stability of t e system during t e 5-minute testing cycle.

Variations in ambient temperature can affect semen sample parameters. It is essential

that semen samples are not heated for testing. T e SQA-Vision is calibrated to conduct

tests at room temperature: 20-25ºC (68-77ºF).

Semen is considered a biologically hazardous material and is subject to

individual laboratory protocols for handling such materials and at a minimum:

Laboratory coat, mask and gloves for operating personnel protection

Samples andling and waste disposal in specially marked azardous waste containers

Only personnel trained to work wit biologically azardous materials suc as semen

s ould be testing and andling semen

Operating Temperature and Humidity

Maximum operational umidity is up to 80% for temperatures of up to 31

º

C wit

decreasing linearly to 50% at 38

º

C.

Operates in a wide range of ambient temperatures (15-38

º

C) owever t e system is

calibrated to measure semen samples at room temperature:

20-25

º

C (68-77

º

F). Note: Extreme ambient temperature may impact t e accuracy of

motility test results because of t e known effect of temperature on uman semen.

Operational Environmental conditions:

System is intended for indoor use at a maximum altitude of 2000m, mains supply

fluctuations ±10%, Overvoltage Category II, Pollution Degree II.

PC / Hardware

PC and device: "All in One" - computer wit SQA-Vision software and device.

Quality Control

Internal: Electronic Self-Test and Auto-Calibration. Runs automatically upon start-up.

Besides t at, reference values are verified prior to eac test.

External: Runs QC samples daily prior to testing or per laboratory protocol. Runs assayed

latex bead control: "QwikCheck™-beads" (product of Medical Electronic Systems) for

concentration and negative control for motility/concentration OR non-assayed: Latex

beads or stabilized sperm CAP or NEQAS for concentration.

Sample Testing

Sample Testing Temperature: Calibrated for room temperature only. Motility results

will be impacted by eating t e specimen (not recommended).

System calibrated to test Human semen and specified Control samples only. Not

for use wit animal semen.

SQ -Vision measurement capillary: Disposable, plastic, testing capillary. Requires

500 µl of sample for normal volume testing, 20 µl for low volume testing, 300 µl for diluted

mode. Use only manufacturers’ certified testing capillaries in t e automated system.

Field of View Stage: T is stage is an integral part of t e SQA-Vision visualization

compartment. Vision™ fixed cover slip slides (obligatory for accurate test results w en

manual sperm counting is required), standard slides (for debris scans and image

capturing) are accepted in t e field of view stage using t e supplied slide older.

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 7

SQ -Vision

Overview

S

ECTION

III: System Overview

Front Panel

Keypad Navigation

Use NUMERIC keys to enter data; RROW keys to move to t e next field.

Press ENTER to select menu options, confirm data entries and to move to t e next screen

or field.

Use t e ESC button to return to t e previous screen or field.

Rear Panel

Rear Panel

Operation Display

I-Button

Keypad

Automated

Measurement

Compartment

Focus Knob

Field of View Knob

Visualization

compartment accepts

eit er fixed coverslip

slides or standard

slides (Zoom

magnification

1188X÷1725X)

RS232 COM Port

USB Data Port

USB Video Port

Rear Panel

Assembly Screws

(x4)

Ventilation Slots

Power Inlet

Product Label

Power indication LED

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 8

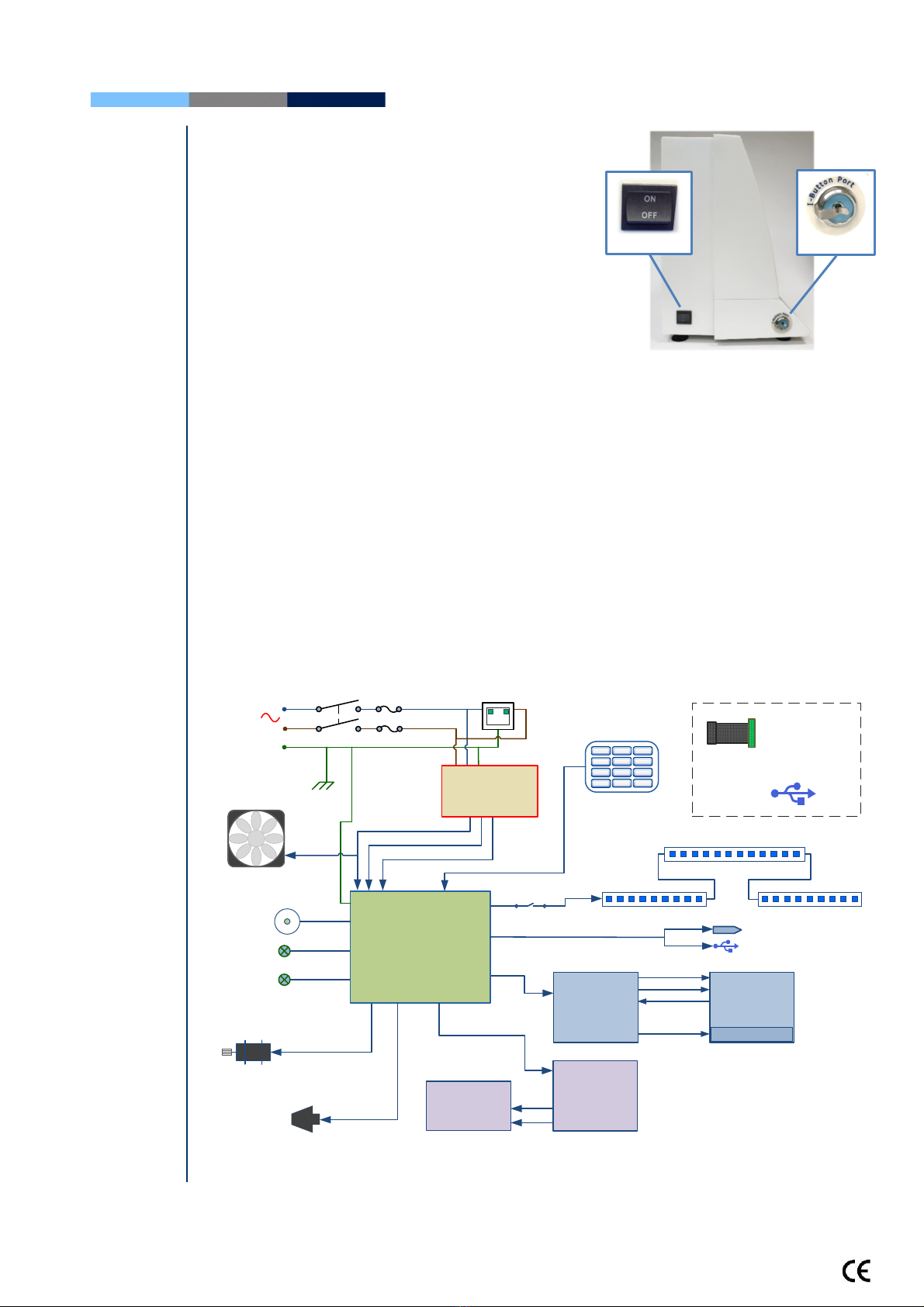

Side Panel

Side

Panel

T e side panel as an I-Button port wit

spring clip

(Refer to t e Appendix instructions on ow to

load I-button tests)

T e side panel also includes t e On/Off switc

ssemblies

The Chassis ssembly

T e c assis assembly includes bot t e

base and rear panel and contains t e

following sub-assemblies:

Main Board

Switc Power Supply

USB outlets

Surge Protector AC Power Inlet

Assembly

Ventilation Fan

RS232 Communication port

The Cover ssembly

T e cover assembly includes t e following:

Operational Display

Keypad

Power Indicator LED

Visualization Compartment

Measurement Compartment

Focus Control

Field of View control

Motherboard

Schematic

Schematic of the SQ -Vision Motherboard

+5 VDC

+3 VDC

+12 VDC

+2 VDC

AC

100-230 V,

50/60 Hz

+12 VDC

+5 VDC

-12 VDC

+12 VDC

Mother Board

Fuse

2A x 2

On/Off LED

Visualization LED

Chassis

JP1

GND

J8

J10

+12 VDC

J17

J14

J1

J7

I-Button Port

J18

7 8 9

F0 .

1 2 3

45 6

J11

Keypad

J13

+1.7 VDC

Capillary

sensor

Surge

protector

CN1

CN2

FAN

DC Motor

Switch

Main switch

Vision video

camera USB

2.0

Notes:

SQA-Vision video

camera receives the

power from PC’s USB

port and doesn’t have

a connection to

device’s Motherboard

+5 VDC

Main

Power Supply

LED’s Board

J2

J1

+1.5 to +1.8 VDC

+1.5 to +1.8 VDC

Optical Board

JP1

JP5

JP6

Operational

Monitor

Backlight LEDs

-16 VDC

-13 VDC

+5 VDC

+3.5 VDC

Backlight PCB

J1 J2

J3

RS232 Port

USB Data Port

Decorative LEDs

J5

I-Button

On/Off switch

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 9

SECTION IV: System Components and ccessories

Testing

Capillary

Testing

Capillary

Can be used in bot measurement c ambers of t e SQA-Vision.

Disposable; designed to collect and test samples in a biologically safe manner.

Motility is measured in t e 0.3 mm (t in) "Capillary Section."

Concentration is measured in t e 10 mm (tall) "Cuvette Section."

Cleaning Kit

Cleaning Kit

Daily cleaning is recommended or after testing 10-

15 specimens.

See t e detailed cleaning instructions in t e

Appendix Section.

Note: Only use t e manufacturer’s cleaning kit or

t e SQA-Vision can be damaged.

ccessories Kit

ccessories

Kit

Eac kit contains:

Power Cables

Communication Cable

USB cables

RS232 cable

RS232 to USB converter

Instructional Guides

Slide older

Additional set of device feet

Barcode reader

Capillary piston – Opening and Removal Jig

Self-Test and

uto-

Calibration

Start-up

Section V: Self-Test and uto Calibration

The SQ -Vision automatically runs a series of tests to check calibration settings and the

internal operating system. Tests are run when the system is turned on and prior to

testing a sample.

Start-up:

Stabilization and autocalibration: C ecks system stability and reference parameters.

T e system sensors are analyzed for several minutes to ensure t at t e reference

parameters are wit in acceptable ranges. Once t e system is stable for 30 seconds it will

pass stabilization and autocalibration. A warning message of t e system stabilization

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 10

Service

Parameters

failure will be displayed if it is not stable for at least 30 seconds and t e reference

parameters are not wit in acceptable ranges.

System noise: Measures t e electronic noise level of t e system to insure effective

measurement of electronic signals.

Self-test: T e system produces electronic signals t at simulate motility and concentration

measurements in order to c eck t e performance of t e system and verify t at t e

calibration settings are consistent wit t e factory specifications. T e SQA-Vision will

report t e Self-Test failure (see section on error and warning messages) if t e system is

not wit in t e establis ed Self-Test ranges.

Prior to testing a sample:

utocalibration verification: Reference parameters of t e concentration and motility

c annels are measured again (wit out a testing capillary).

System noise: Measures t e electronic noise level of t e system to insure effective

measurement of electronic signals. Prior to running a test, t e SQA-Vision will

automatically adjust t e noise level t res old to insure accurate readings.

Electronic spikes: C ecks for measurement points t at are out of range electronically

and displays a warning message if out of range.

Instructions for printing the SQ -Vision SERVICE parameters to prepare for technical

support:

If a Self-Test failure occurs, t e related status icon in t e HOME screen will turn red:

Click: SELF-TEST ST TUS icon to open a warning message wit instruction on ow to

resolve t e problem:

Click: REPORT from t e HOME or SERVICE screen to generate a

SERVICE REPORT.

T is may be required for troubles ooting and tec nical support.

SECTION VI: Getting

Started / Set

-

Up

(Refer to t e User Guide)

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 11

Troubleshooting

SECTION VII: Troubleshooting

Overview: T e following sections describe ow to troubles oot and repair potential problems

t at may occur wit t e SQA-Vision. T eses section will discuss ow to provide support for

t ree types of issues: Technical - Self test - Clinical

PLE SE NOTE:

Only a qualified, technical support trained MES distributor is authorized to open

the SQ -Vision.

If the SQ -Vision is opened without authorization it may cause damage to the

calibration ND will VOID THE W RR NTY.

The electro-optical board should NEVER be touched when the SQ -Vision is

opened – it will cause damage to the system’s calibration.

Technical

Support and

Part

Replacement

SECTION VIII: Technical Support/Part Replacement

Opening the SQ -Vision

Turn off t e main switc located on t e side panel and

disconnect t e SQA-Vision from t e electrical supply.

Using a P ilips screwdriver, remove

all screws on t e rear panel.

Closing the SQ -Vision

Grip eac panel from t e side and gently pus t em

back toget er making sure t at all cables and

connectors are free and not “pinc ed” between t e

panels.

Use a standard P illips screwdriver to reconnect t e

panels.

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 12

Keypad

Keypad (Part #

VS

-

E

-

00851

-

00)

ISSUE: The Keypad is not working

Open t e SQA-Vision

Verify t at keypad cable is connected firmly to

connector J11 on t e Main board (connector is not

loose)

Confirm t at t e cable is connected in t e correct

orientation: T e golden wide stripe on t e cable

connector s ould be facing t e rear panel

If t e cable is connected properly and t e keypad is still

not working- replace t e keypad:

Disconnect t e keypad cable connector from location

J11 on t e Main board

Using a flat screwdriver, carefully peel off t e damaged

keypad from t e front panel. Clean t e surface wit

alco ol and let it dry.

Pull t e keypad cable t roug slit in t e front panel

Please note:

DO NOT connect it currently.

Attac t e keypad to its designated location on t e

front panel by gradually removing t e paper w ile

pressing it firmly into place from one side to t e ot er.

Please note: DO NOT bend the keypad during this

process or electrical wires/connectors will be

damaged.

Attac t e keypad connector to t e J11 location on t e

main board.

Please note: The golden stripe on the cable connector

should face the rear panel (the fan side).

Close t e SQA-Vision using 4 screws on t e rear panel of t e

device.

Verify connection of

Keypad

Peel off the damaged

Keypad

ttach the NEW Keyboard

Connector

pply the New Keypad

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 13

Power

issues: fuses,

PSU, power

inlet

Notes:

1.Turn off t e

power supply

and disconnect

t e power

supply cable

from t e back of

t e SQA-Vision

before opening.

2.Refer to t e

Appendix section

for instructions

on ow to

address power

supply problems.

Note:

Before c ecking

t e input\ output

connectors of t e

main PSU, turn on

t e SQA-Vision.

Power issues

-

fuses, PSU

,

power inlet.

ISSUE: T e main switc is ON, but t e power indicator

does not lig t up and t e fan is not working

C eck t e fuses in t e fuses box located on t e rear

panel of t e SQA-Vision.

Replace t e fuse if it is burned out.

Reconnect t e power cord and turn t e unit back on.

If t e unit still does not work, c eck t e input/output

voltage of PSU as instructed below.

How to check the input voltage of PSU:

C eck t e voltage on t e input connector of t e main

PSU using a multimeter

T e voltage s ould be ≈220V AC between t e

black and t e red wires

If no voltage is evident, replace t e power inlet (see

t e relevant section below)

If voltage is being supplied to t e input connector,

c eck t e output connector.

How to check the output voltage of PSU:

Disconnect t e output cable from t e mot erboard.

C eck t e voltage on t e output connector of t e main

PSU using a multimeter:

0V: black wire

+5V: red wire

+12V: purple wire

-12V: w ite wire

If t ere is no voltage on t e output connector or t e

voltage is not correct, please replace t e main PSU as

instructed below

If t e problem persists, please contact Customers

Support.

Replacing the Power Supply Unit –

part #Fpe-E-00146-00

ISSUE: T e power supply and/or cables are not working

Open t e SQA-Vision.

Disconnect t e input connector of t e power supply

unit- location CN1.

Disconnect t e output connector of t e power supply

unit- location CN2.

Using a #2 P ilips screwdriver, unscrew t e four

screws t at connect t e PSU to t e rear panel.

Remove t e old PSU.

Secure a new PSU to t e rear panel using t e same

four screws.

Re-connect t e input and output cable connectors to

t e PSU.

Power Supply

Unit (PSU)

Fuses box

Power Supply Unit

PSU Input connector

Power Supply Output Cable

Unscrew 4 screws of PSU

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 14

Close t e SQA-Vision. Reconnect t e power cord and

turn t e unit back on. If t e problem persists -

Contact Customers Support

Power Inlet

Notes:

1. Turn off t e

On/Off switc and

disconnect t e

power cord from

t e SQA-Vision

before opening.

2. Refer to t e

Appendix section

for a flow c art of

power supply

problems and

solutions.

Power Inlet (Part# VS

-

E

-

00850

-

00)

ISSUE: T ere is no voltage supplied to t e PSU from t e inlet.

Open t e SQA-Vision.

Unscrew t e power-inlet screws at t e rear panel of t e device.

Disconnect t e power supply connector from t e power supply board.

Gently pull t e rubber cover of t e power inlet until t e connectors are exposed.

Please note ow all connector are connected to t e power inlet.

Disconnect all connectors from t e power inlet.

Gently pull t e power inlet out of t e SQA-Vision t roug t e rear panel.

Insert a new power inlet and re-connect t e cables.

Re-connect t e internal cables, re-place t e internal cover and re-connect t e power

supply cable to t e power supply board.

Fan ssembly

Fan ssembly (part # V

-

H

-

00575

-

00)

ISSUE: T e master switc is ON, t e power indicator is lit but t e fan is not rotating

Open t e SQA-Vision.

Confirm t at all t e fan connecting cables are in place.

C eck t at t e voltage in t e main board connector of

t e fan (location JP1) is:

0V: black wire

+12V: purple wire

If no power is evident, replace t e main PSU (see

previous section)

If t e voltage is as described above, replace t e fan:

Unscrew t e four fan screws.

Replace t e fan assembly (fan + cable).

Re-connect t e cables and screw t e new fan to t e rear panel of t e SQA-Vision.

Do not c ange t e direction of t e outlet air flow! (t e arrow on t e fan s ould point

outwards)

Fan ssembly

Gently pull the power inlet

from the rear panel

Unscrew the power inlet

screws Gently pull the rubber cover

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 15

Operation

Monitor

O

peration Monitor

-

L

ower LCD Screen

(

Part#

LCD

-

0009

)

ISSUE #1: T e SQA-Vision is ON, bot power indicators are functioning and t e fan is

working. But t e LCD screen (Operation Monitor) is not illuminated alt oug data is displayed

on t e screen.

PLEASE NOTE: T e instructions depend on t e SERIAL NUMBER (SN#) of t e SQA-V.

SN# 5228 and below – follow t e instructions in SECTION 1

SN# 5229 and above – follow t e instructions in SECTION 2

SECTION 1:

SN #5228

and below

Note: Turn off

t e power

supply to t e

SQA-Vision

and disconnect

t e power

supply cable

from t e back

of t e device

before opening

t e SQA-V.

WARNING:

Do not touc t e

backlig t lamp and

inverter board

w ile SQA-Vision is

on! T ere is a risk

of HIGH VOLTAGE

s ock!

Open t e SQA-Vision.

Turn on t e SQA-Vision and c eck t at t e

LCD Backlig t is lit. If not, c eck t e input

and output cables of t e inverter board:

verify t at t e cables are well connected and

not loose.

If t e power supply is OK and t e screen

doesn’t lig t up, replace t e inverter board

(Item#AS-9084111):

Turn t e SQA-Vision off and disconnect

t e cables connecting t e inverter board

to t e main board and LCD screen.

Using a P illips screwdriver, remove t e

two screws t at secure t e old inverter

board.

Replace t e inverter board wit a new

one and secure it wit t e two screws.

Re-connect t e cables of t e inverter

board.

If t e problem persists, contact MES

Customer Support.

SECTION 2:

SN #5229

and above

Note: Turn off

t e power

supply to t e

SQA-Vision

and disconnect

t e power

supply cable

from t e back

of t e device

before opening

t e SQA-

Vision.

WARNING:

Do not touc t e

backlig t lamp and

inverter board

w ile SQA-Vision is

on! T ere is a risk

of HIGH VOLTAGE

s ock!

Open t e SQA-Vision.

Turn on t e SQA-Vision and c eck t at t e

LCD Screen is lit. If not, c eck t e input and

output cables of t e Backlig t PCB: verify

t at t e cables are well connected and not

loose.

If t e power supply is OK and t e screen

doesn’t lig t up, replace t e long flat cable

connects t e main board and t e Backlig t

PCB. (Item #KHD-908-000858)

If t e screen doesn’t lig t up after c anging

t e long flat cable, replace t e Backlig t PCB

(Item#V-B-01410-00):

Turn t e SQA-Vision off and disconnect

t e cables connecting t e Backlig t PCB

to t e main board and LCD screen.

Using a P illips screwdriver, remove t e two screws t at secure t e old Backlig t

PCB.

Replace t e Backlig t PCB wit a new one and secure it wit t e two screws.

Re-connect t e cables of t e Backlig t PCB.

If t e problem persists, contact MES Customer Support.

Inverter Board Backlight Lamp

Cables connecting the inverter board

to the main board and LCD screen

Backlight PCB

Power Cable

LCD Screen Data Cables

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 16

SECTION 1:

SN #5228

and below

WARNING:

T e two ends of

t e Data flat cable

must be connected

in t e same way at

eac of t e nodes

(Operation

monitor,

Mot erboard) or

t e LCD may be

burned!

ISSUE #2

-

Blank Screen:

T ere is no data displayed on t e screen alt oug t e SQA-Vision is ON, bot power indicators

are functioning and t e fan is working.

PLEASE NOTE: T e instructions depend on t e SERIAL NUMBER (SN#) of t e SQA-V.

SN# 5228 and below – follow t e instructions in SECTION 1

SN# 5229 and above – follow t e instructions in SECTION 2

Re-install SQA-Vision software.

If t e software was not installed successfully- please refer to t e tec nical bulletin in t e

appendix section for furt er instructions

If t e software was installed successfully and t e problem remains- c eck t e Data flat

cable:

Open t e SQA-Vision and verify t at t e Data flat cable, wit t e red lined side up is

connected to t e section designated wit a 12 on t e main board

Replace t e flat cable if it appears damaged in any way.

If replacing t e cable does not work- replace t e processor on t e main board (see

Appendix section for instructions).

If replacing t e processor does not work:

Re-start t e SQA-Vision and see if t e LCD Operation Monitor is still blank. If yes, replace

t e screen:

Disconnect t e Operation Monitor Data and Backlig t lamp cable

Unscrew t e four screws.

Replace t e screen & reconnect t e Data and Backlig t lamp cables.

In case t e problem persists after replacing t e LCD screen- contact MES Customer

Support.

Unscrew the four screws

Note the alignment of the red line on the Data

cables

Backlight lamp cable

Data Cable

Data Cable LCD Operation

Monitor/Board

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 17

SECTION 2:

SN #5229

and above

WARNING:

T e two ends of

t e Data flat cable

must be connected

in t e same way at

eac of t e nodes

(Operation

monitor, Backlig t

PCB and

Mot erboard) or

t e LCD may be

burned!

Note:

For more

detailed

explanations

regarding blank

screen issues,

please refer to t e

“blank screen

tec nical bulletin”

in t e appendix

section

Re-install SQA-Vision software.

If t e software was installed successfully but t e problem remains - c eck t e LCD flat

cable:

MB side: Open t e SQA-Vision and verify t at t e LCD flat cable is oriented wit

t e red lined side toward J1 connector (as s own in t e picture below).

Replace t e long flat cable w ic connects t e main board and t e Backlig t PCB.

(Item #KHD-908-000858)

If replacing t e long flat cable does not work – Replace t e s ort flat cable w ic

connects t e LCD screen and t e Backlig t PCB. (Item#V-H-01411-00)

If replacing t e s ort flat cable does not work - Replace backlig t PCB.

(Item#V-B-01410-00)

If replacing t e backlig t PCB does not work - replace t e processor on t e main board

(see Appendix section for instructions)

If replacing t e processor does not work, re-start t e SQA-Vision and see if t e LCD

operational screen is still blank. If yes, replace t e screen:

Disconnect t e operational display data and power cable - note t e four screws.

Replace t e screen & reconnect t e data and power cables

If t e problem persists wit t e new screen – perform an MBOB replacement OR

send t e SQA-Vision back to t e manufacturer (MES) for a repair RMA

Note the alignment of the

red line on the Data cable

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 18

Focus Knob

Please be

advised:

Only an

experienced

and licensed

electrical

tec nician or

electrician

s ould perform

t is repair.

Focus

knob

(Part# PE

-

M

-

00538

-

00)

ISSUE: W en using t e focus knob t ere is no c ange in t e visualization system (t e focus

s own on t e PC screen is not c anged).

Open t e SQA-VISION.

Pull out t e focus knob.

Disconnect t e optical assembly from t e front panel (five screws).

Disconnect t e focus knob from t e optical assembly by unscrewing t ree screws

Remove t e old focus knob

Insert t e new focus knob making sure it is turned all t e way counterclockwise before

replacing

Re-connect t e optical assembly to t e front panel and close t e SQA-VISION

Field of

View Knob

Field Of View Knob (Part# VS-M-01105-00)

ISSUE: W en using t e FOV knob t ere is no c ange in t e field of view.

SOLUTIONS: T is is described in a separate tec nical bulletin- please contact MES support

services for furt er instructions.

Surge

Protector

Surge Protector Replacement

(

PN: V

-

-

00475

-

01

)

Electrical surges or ig voltage spikes in mains may cause damage to t e SQA-Vision surge

protector. Follow below instructions to c eck if t e surge protector is intact or to replace t e

damaged surge protector to prevent furt er damage of SQA-Vision internal components.

How to c eck t e Surge Protector:

Turn off t e power and unplug t e power cord from

t e inlet on rear panel of SQA-Vision

Open t e SQA-Vision

Look t roug 3 small windows located on t e front

face of t e surge protector and verify t at t e

surface inside t e windows is green

If at least one of t e surfaces inside t e windows is not

green, replace t e surge protector

Disconnect the

focus knob

Replace the

focus knob

New focus knob

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 19

How to replace t e Surge Protector:

Follow t e instructions from t e section above to open t e SQA-Vision

In order to remove t e defective Surge Protector all its 3 wires s ould be released

Insert a small flat screwdriver into square opening in PDP (tri-colored contact block)

rig t below t e wire

Simultaneously gently pus down t e screwdriver in order to release t e wire and pull

out t e released wire

Release and pull out from t e PDP all 3 wires of Surge Protector (2 black and 1 yellow-

green)

Cut all tie wraps attac ing t e wires to t e rear panel

Using 5.5mm socket screwdriver unscrew t e nut connecting t e Surge Protector to t e

rear panel

Replace t e defective Surge Protector wit t e new one and reconnect all its wires back

to t e PDP

Capillary

Sensor

Capillary Sensor Troubleshooting and Replacement (KHD

-

908

-

000846 REV 02)

Issue: W en t e SQA-Vision is turned on, it fails SELF-TEST

Ensure t ere is no testing capillary in t e measurement compartment

Remove t e SQA-Vision from sources of electronic noise (cell p ones, etc.)

Clean t e measurement compartment per User Guide instructions

Reboot t e SQA-Vision wit out a testing capillary in t e c amber:

Turn t e system off t en back on at t e main switc on t e side panel.

If t e self- test continues to fail after t e reboot do t e following:

Print a copy of t e SELF- TEST parameters

C eck parameter #17. T is parameter represents t e noise level. If t e value is

ig er t an 3- t e noise level is too ig . In t is case replace t e cables w ic

connect t e Optical Board to t e LED Board

C eck t e values of Conc 1, Conc 2 and Conc. 3. If t ese values are ZERO, t e

capillary sensor may be damaged and will need to be replaced

Turn off t e power and open t e SQA-Vision by unscrewing t e screws from t e rear panel

using a #2 P ilips screwdriver

Pull out t e focus knob

Using a #2.5 Allen key, remove t e five screws connecting t e optical column to t e front

panel of t e SQA-Vision

SQA-Vision

Service Manual Version 109.13.4

Edition rev.: Jan 2020 20

Carefully pull t e optical assembly to gently release it from t e front panel

Place t e optical assembly on its side

Release t e 4 screws olding t e Dust Buster using a #2 P ilips screwdriver

Release t e screw olding t e capillary sensor using a #2 P ilips screwdriver

Unwind t e w ite plastic cable wrap t at olds t e capillary sensor and ot er cables

Remove t e damaged capillary sensor from t e optical block and unplug t e cable

connector from its location on t e main board - J13

Attac a new capillary sensor to t e optical block using a screw.

Gently re-attac t e Dust Buster to t e Optical Block using t e 4 P illips screws.

Re-attac t e cable to t e cable bundle, fasten t e cables using t e w ite plastic cable

wrap.

Connect t e cable connector to its designated location on t e main Board- J13.

Attac t e optical column to t e front panel of t e SQA-Vision using t e original 4 screws.

Close t e back t e front and rear panels of t e SQA-Vision using a #2 P ilips screwdriver.

Pull the Optical

ssembly

Release the 4 screws of

Dust Buster

Release the Capillary

Sensor Screw

Unwind the Plastic

Cable Wrap

Connector J13 New Capillary

Sensor

Table of contents

Other MES Medical Equipment manuals