IMO 3/20

IMO-349 EN 3

1. INTRODUCTION

Thank you for choosing METSO product. Each product is fully

inspected after the production to oer you thehighest quality.

In order to fully utilize the product, we strongly recommend

users to read this manual carefully and understood.

This manual provides information on installation; operation

and maintenance procedures and related instructions for the

RMEBS make VAQ113 SPOOL VALVE.

The aim of this literature is to support the use of products in

correct manner, and all the technical information provided in

the catalogue.

The manual should be given to the end user.

The manual can be changed or revised without any prior

notice. Any changes in product’s specication, structure, and/

or any components may not result immediate revised version

of the manual.

The manual should not be duplicated or reproduced for any

purpose without any consent of RMEBS Manufacturers &

Engineers Private Limited, INDIA.

Manufacturer Warranty

For the safety, it is vital to follow instructions in the manual.

It is not RMEBS’s liability for any damages which caused by

users’negligence.

It is not RMEBS’s liability for any damages or accidents which

resulted by any alteration or modication of the product and

parts. If alteration or modication is necessary, please contact

the RMEBS directly.

RMEBS warrants the product from the date of original

retail purchase of the product for one (1) year, except as

otherwise stated.

RMEBS warranty will not cover the products that the

product have been subjected to abuse, accident, alteration,

modication, tampering, negligence, misuse, faulty

installation, lack of reasonable care, repair or service in any

way that is not contemplated in the documentation for the

product, or if the model or serial number has been altered,

tampered with, defaced or removed; damages that occurs in

shipment, failure due to power surge, and cosmetic damage.

Improper or incorrectly performed maintenance or report

voids this Limited Warranty.

For detailed warranty information, please contact :

RMEBS MANUFACTERURS & ENGINEERS PRIVATE LIMITED,

Manapada road, Dombivli (e), Maharashtra, India, Pin - 421204

1.1 Denitions

WARNING:

IF NOT OBSERVED, USER INCURS A HIGH RISK OF SEVERE DAMAGE

TO PRODUCT AND/OR FATAL INJURY TO PERSONNEL.

CAUTION: If not observed, user may incur damage to

product and/or injury to personnel.

NOTE: Advisory and information comments provided to

assist maintenance personnel to carry out maintenance

procedures.

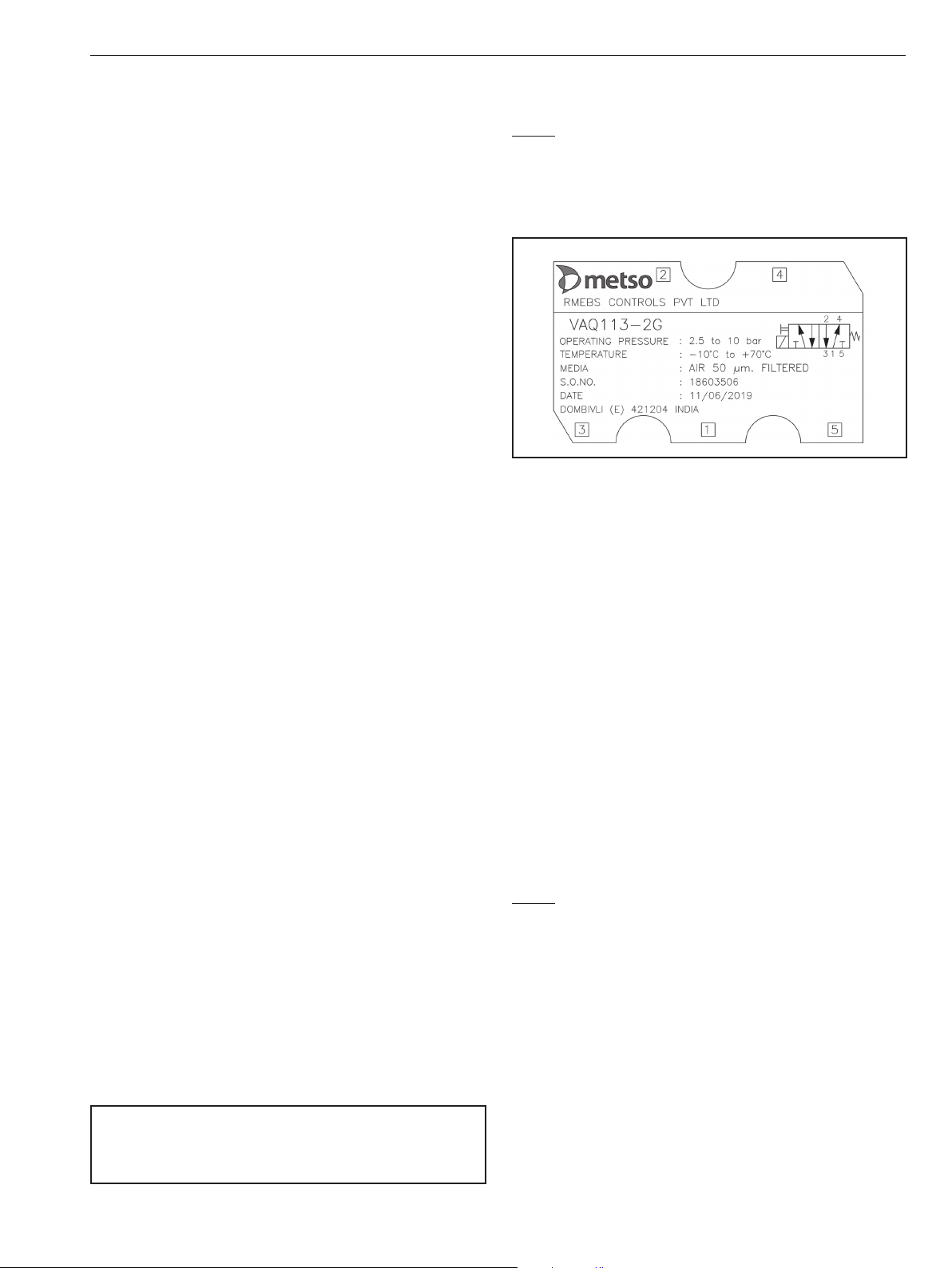

2. LABEL DESCRIPTION.

Label of the VAQ113-2G denes the precise feature. This

description is written below the RMEBS logo and is as follow.

Model no.: VAQ SPOOL VALVE 5/2 valve.

2 1/4", 3- 3/8", 4 – 1/2" .

13 2 Position, solenoid

operated spring return.

External air pressure 3 to 10 bar.

Temperature -10°C to +70°C

S.O. NO. Sales order number.

DATE Date of manufacturing.

Dombivli – 421204 INDIA Brief address.

3. INSTALLATION PROCEDURE

CAUTION: Blow out air lines and ttings before installation.

Use dry and oil free air. Do not dismantle the VAQ113 while

operation is in line. Do not allow dirty air or uids to get into

the VAQ113. Use lter unit (lter size 40µm, 3°C) for dust and

moisture removal.

NOTE: Ensure the installation meets the legal and regulatory

requirements of the country and state of use. The VAQ113

assembly should be left in the original packing until it is

required for the use.

1. Hemp laments, jute or even teon ribbons are

normally not required, As the part connections are

accurately threaded. By chance, if any of these or any

other tightening medium get into the operational area

inside the VAQ113, possible damage of the VAQ113

could not be ruled out.

2. Clean all pipes and tube ttings thoroughly with suitable

means. As even when brand new pipes are tted, unclean

interior are quite covered with dirt and dust.

3. Avoid impact on the VAQ113.These may happen during

transportation/ erection/ mishandling.