Met One 200L User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Models200L, 205,

205A, 2090, A2100,

A2120, A2200, A249,

A2210,A2212,A2420

Laser Particle Counters

Operating Guide

Met

One

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

© Copyright Met One, Inc., Grants Pass, Oregon 97526

All rights reserved. Printed

in

the United States of America.

No part of this publication may be reproduced

in

any form without

the prior written permission of Met One, Inc.

Major revisions of this manual will be indicated by a new revision

date and part number. Minor corrections or additions may

be

made at any time without changing the manual date or

part number.

Publsihed January 1990, part number 701063

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

How

to

Use this Manual

·Where to Start

. . .

If

you have just received a new particle counter, read the following sections

of

this

manual.

If

the particle counter is ·already set

up

andworking; you·can

..

skip ·section

1.

Sectio.n

1,

Getting Started, read

...

• Unpacking and Initial Inspection

• Initial Power Turn-on

Section

2,

Operation, read

...

• Counting Particles

• Using the Front-Panel

• Setting Programmed Functions

After reading these sections, you can use the rest

of

the manual

as

.a reference. Each

section

of

the manual has an introduction that tells you what you will find in that

section. The manual also has

an

AppendixA that contains supplemental information

that may be helpful

if

problems occur with the particle counter. ·

Manual Conventions

This manual shows front-panel nomenclature in capital letters. For example, the

"enter" key will appear

as

ENTER in the manual. Some keys also contain labeled

lights. For example, the COUNT MODE key has two lights labeled "CUM" and

"DIFF". The names of these keys are followed by the names

of

the lights. For

example, COUNT MODE: CUM/DIFF.

Each section

of

this manual has its own series of page numbers that are prefixed with

the section number. For example, Section

1,

Getting Started, is numbered 1-1, 1-2,

1-3, etc. and Section

2,

Operation, is numbered 2-1, 2-2, and 2-3, etc.

Instruments Covered

by

this Manual

This manual covers the latest versions of the instruments listed on the title page.

Manual effect from earlier versions

of

counters

is

covered in Appendix A,

Supplemental Information.

lV

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

WARRANTY

Prior

to

shipment,

each

MET

ONE

instrument

is

thoroughly inspectedand tested to applicable

specifications~

However,

should

equipment failure occur, MET ONE assures its customersthat promptservice

and

support

will

be

available.

All

equipment originally manufactured

by

MET

ONE

which

is

found to be defective

will

be

repaired

or

replaced subject to the following considerations:

TERMS

AND

CONDITIONS

All

units/components,

properly packed for handling, should

be

shipped freight prepaid to

the

MET ONE

designated Service Center. Equipment

will

be returned to the customer's/user's site freight prepaid

and

invoiced.

Fuses,

lamps, pumps, hoses

and

filters

are

excluded from

the

standardreplacement clause,

but

are

covered

separately

on

a limited exchange basis

and

will

be

exchanged

up to 30 days after shipment of the

equipment.

COVERAGE

Throughout

the

lifetime of

the

equipment, MET ONE

will

readily provide on-site

or

in-plant service

at

reasonable

rates

comparable to those of other manufacturers

in

the

industry.

During

the

first year, the

returned

unit/part

will

be repaired

and/or

replaced at MET ONE's option, with no

charge

for' labor

or

parts

not

excluded by warranty. Warranty commences with equipment shipment.

MET

ONE

reserves

the right to replace parts under warranty with re-manufactured items.

On

certainitems,

extended

warranty

is

available.

NON-MET

ONE

MANUFACTURED

EQUIPMENT

Equipment provided but not manufactured

by

MET ONE

is

warranted

and

will

be repaired to

the

extent and

according

to

the

current conditions of

the

respective equipment manufacturer's warranty.

ON-SITE

WARRANTY

REPAIR

SERVICE

Any service provided at

the

customer's location

will

be charged at

the

current warranty service rate.

SERVICE

CONTRACTS

On-site service contracts

are

available at substantial savings. Please request a quotation from a MET ONE

sales

or

service representative.

GENERAL

Under

the

MET ONE

Standard

Warranty, Warranty Extension

or

On-Site Service Contract,

the

customer

is

responsible for

all

charges

caused

by

modifications

or

additions to MET ONE equipment

not

approved

in

writing by MET ONE,

or

if

in MET ONE's opinion

the

equipment has been subjected to abnormal use.

"_Abnormal

use"

for purposes ofthis warranty

is

defined asany use to which

the

equipment

is

subjected other

than

that

use

specified

or

intended as evidenced by purchase

or

sales representation.

Other

than

the above,

no

other

warranty,

expressed

or

implied, shall apply to any

and

all

such

equipment furnished

oz:

sold by MET

ONE, INC.

The remedies described herein shall be the purchaser's sole

and

exclusive remedies under this warranty.

Except for

the

express warranties

stated

above, MET ONE disclaims

all

warranties

on

the

MET ONE

hardware

and

software

products

furnished hereunder, including

all

impliedwarranties of merchantabilityand

fitness.

The

stated

express warranties

are

in

lieu of all obligations

or

liability

on

the part of MET

ONE

for

damages, including but not limited to special, indirect

or

consequential damages of any kind,

or

loss of

revenue

or

other

financial loss, arising out of the use of MET

ONE

products. MET ONE's maximum liability

under

the

express

warranties contained

in

this sectionshall not,

in

any case, exceedthe total price paid by the

purchaser

for

the

specific items involved.

RE\'

:2

84

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Contents

How to Use this Manual

..........................................

iv

Where to Start

.............................

·

.........

·.

.

1v

.

Manual

Conventions

.......

,

..............................................

,

..

,

.....

,.,iv

.

.

·Instruments' Covered

b:V

thi'S'Mariiial

..

:··.

: :

.........

:.·.

..

.

..

. . . . .

iv

-Safety

~.

~-

.........

·.-

.....

~

......

·

...........

·

....

.-

......

·

.,:

..

·

..

~

.......

;

.....

:

vn1

Laser Safety Information . . . . . . . . . . . . .

..

.. .

..

. .

..

. .

...

... . . .

..

.

...

. . ix

Electrostatic Discharge . . . . . . . . . . . . . . . . .,.

...

. . • . ...

..

. . ....,.

..

. . . x

Section 1: GETTING STARTED

~

' I ' '

:;,

:'·••

'•

,..

'

·.·

..

, ....

~

•:,

'

.'.

''

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....

. . . . . . . . 1-1

'Introducing the Particle Counter

....

~

. . . . . . . . . . . . . . . . . . . . . . . . 1-2

Accessories

............

·;

...........

·

.......

·.

.

..

. . . . .

...

. . . 1-2

Options

...............................

·

.....

"

..........

:·

..

~_

.................

··

..

,

.....

1-2

Specifications

(All

Counters)

......

~

...

:.·

..

>·

..

"~

...

:

..

:

..

..

:

.......

;

...

1-3

.ModeL200L Specifications

...........

~··.

·

..

,.

·;

..

;

•.

·...:..

:~

...

..

·

..

J<i;".l-3

..

Models 205 and.205A Specifications

.........

~

...

,

.................

;.

1.,.4

Model.209D.Specifications-

........•...

:....

,~

.......••......

~

.~

......

,.1-4

Model A249 Specifications

..............................

:·

1-5

Model A2120 Specifications

..............................

;

..

~:·

1-5

..

Model A2210 Specifications

...........

·

.................

:··

1-6

Model A2420 Specifications

..............

~

..................

.

:.~:

1-6

Unpacking and Initial Inspection

.............................

, .1-7

Initial Power Turn-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Section

2:

OPERATION

-Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Countin·g Particles .'.'

:·

·

.....................................

~

2-2

Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Front-Panel Keys and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting Programmed Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7

Time, Date, and Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Sample and Hold Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Alarm Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Number

of

Count

Cycles

...............................

2-10.

v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 2: OPERATION (Continued)

Using the Option Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Fed-Std-209D Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

EPROM Part Number Identification

.......................

2-16

Options/Serial Port

rable

Printouts . . . . . . . . . . .

..

. . . . . . . . . . . . 2-17

Printing Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Interpreting the Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Setting Printer Modes

.................................

2-22

Changing Print Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Printing Serial Buffer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

)Using Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

RH/Temp and

Air

Velocity· Accessory Probes

................

2-26

External Printer Option

................................

2-27

High-Pressure Diffuser Accessory . . . . . . . . . . . . . . . . . . . . . . . . 2-28

A Sample Count Using All Functions

........................

2-30

Section 3: PERFORMANCE' VERIFICATION '

Vl

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Recording the Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

If

the Counter-Doesn't Meet Specifications

...................

3-3

Test Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Airflow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Laser Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Calibrate Mode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Zero Count/Purge Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Pulse Height Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Comparison Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Probe Sensitivity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

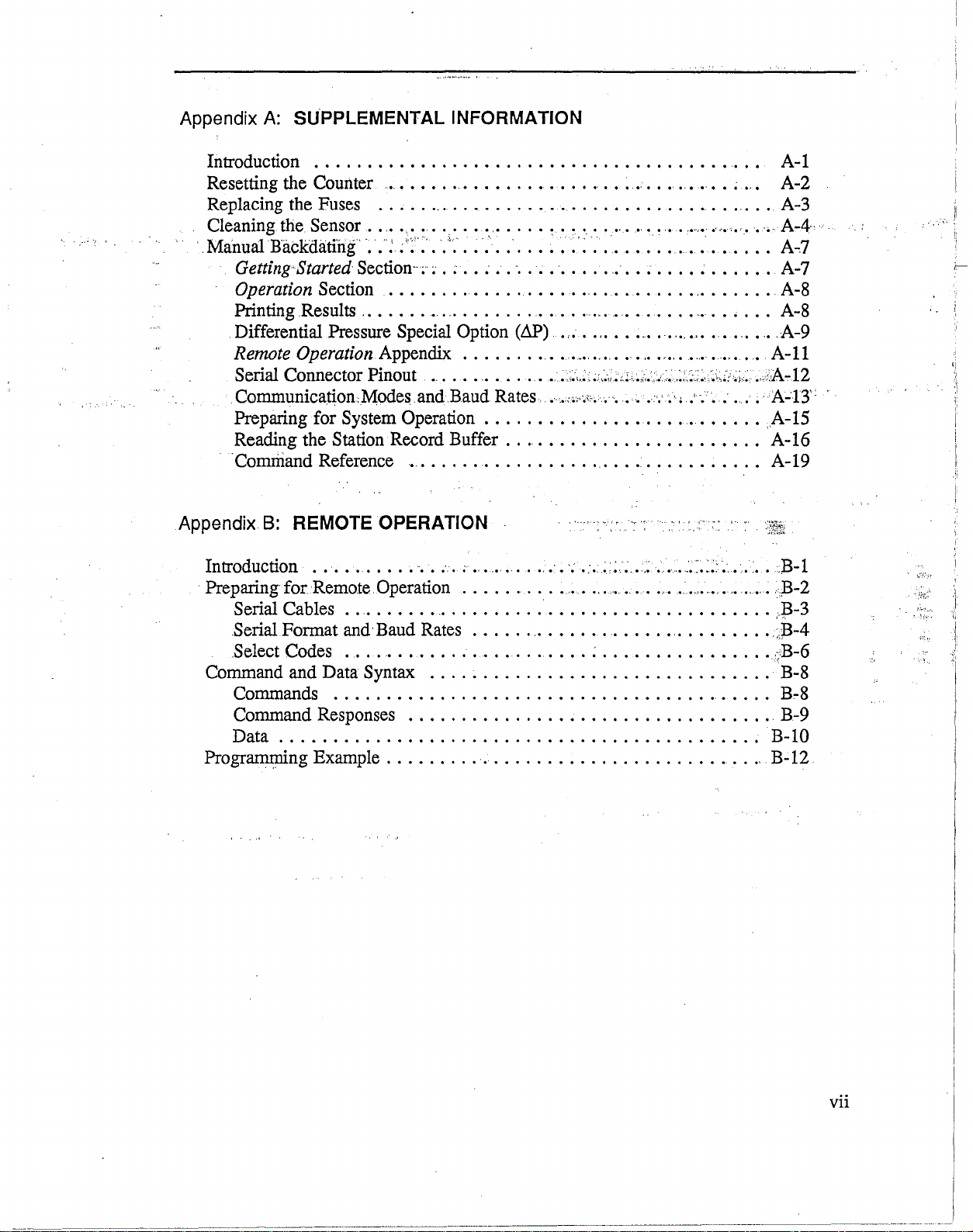

Appendix

A:

SUPPLEMENTAL INFORMATION

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. .

A-1

Resetting the Counter

................................

;

..

.

A-2

Replacing the

Fuses

. . . . .

...

. . . . . . . . . . . . . . . . . . . . . . . . . . . ... . .

A-3

Cleaning the Sensor

...................

~·

.

~

...............

,

..........

,........ A-4

..

··

· Manual Backdating··

..

~

;'·~··:·

..

'~-

..

: .

......

.':

.................

A-.7

....

.-

!'

Getting·Started

Section··

; ; . : . .

.·

. .

·.

.

·.

. . . . . . .

..

: . . . . . . . . . . . A

-7

Operation Section

........................................

A-8

Printing

.Results

................................................

, . . .

A-8

Differential Pressure Special Option

(LlP)

........•........•.•...•......

A-9

Remote Operation

Appendix

........................

.-

.............

A-ll

Serial Connector Pinout

.............

;;;~

..

;;;.,~;,;,.;

...

;,

..

<.<

•.

::.:.;>~·~;·:;;.~

...

<A.,.l2

Communication,Modes.and.Baud Rates

..

··'~'''''•

.....

<·

••

·l

:·.·

••·

•••

A-13"

Preparing for System Operation

..........................

.A-15

Reading the Station

Record

Buffer

........................

A-16

·comrriand Reference

..................................

A-19

Appendix

B:

REMOTE OPERATION , . '

~;

' r

.•

,.

·~

Introduction

............

.-.;

.......

...:.·:

.;

..

:;

~

...

.:

...........

::'~·

......

.

:S-1

Preparing forRemote Operation

.........................................

)3-2

Serial Cables

....................•.....................

,..J3-3

.Serial

Format and·Baud

Rates

.............................

:,B-4

.Select

Codes

........................

:

..................

;B-6

Command

and Data Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-8

Commands

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . .

B.,.8

Command

Responses

...................................

B.-9

Data

.............................................

B-10

Programming Example

.........

·

...........................

B-12.

Vll

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

•'·f.•,;..

Safety

Cautions

and Warnings. are used throughout this manual. Familiarize·yourselfwith

the·.

meaning

of

each before operating the particle counter.

..

j..;

viii

WARNING

A WARNING indicates a hazard for you. It calls attention

to

a

procedure which,

if

not correctly performed

or

adhered to, could

result in injury. Do not proceed beyond a WARNING until the

indicated conditions are fully understood and met.

CAUTION

A CAUTION indicates a hazard for the particle counter. It calls

attention to a procedure which,

if

not correctly performed or

adhered to, could result in damagg to·the counter;,

Do

not

proceed beyond a CAUTION symbol until the indicated

conditions are fully understood and met.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

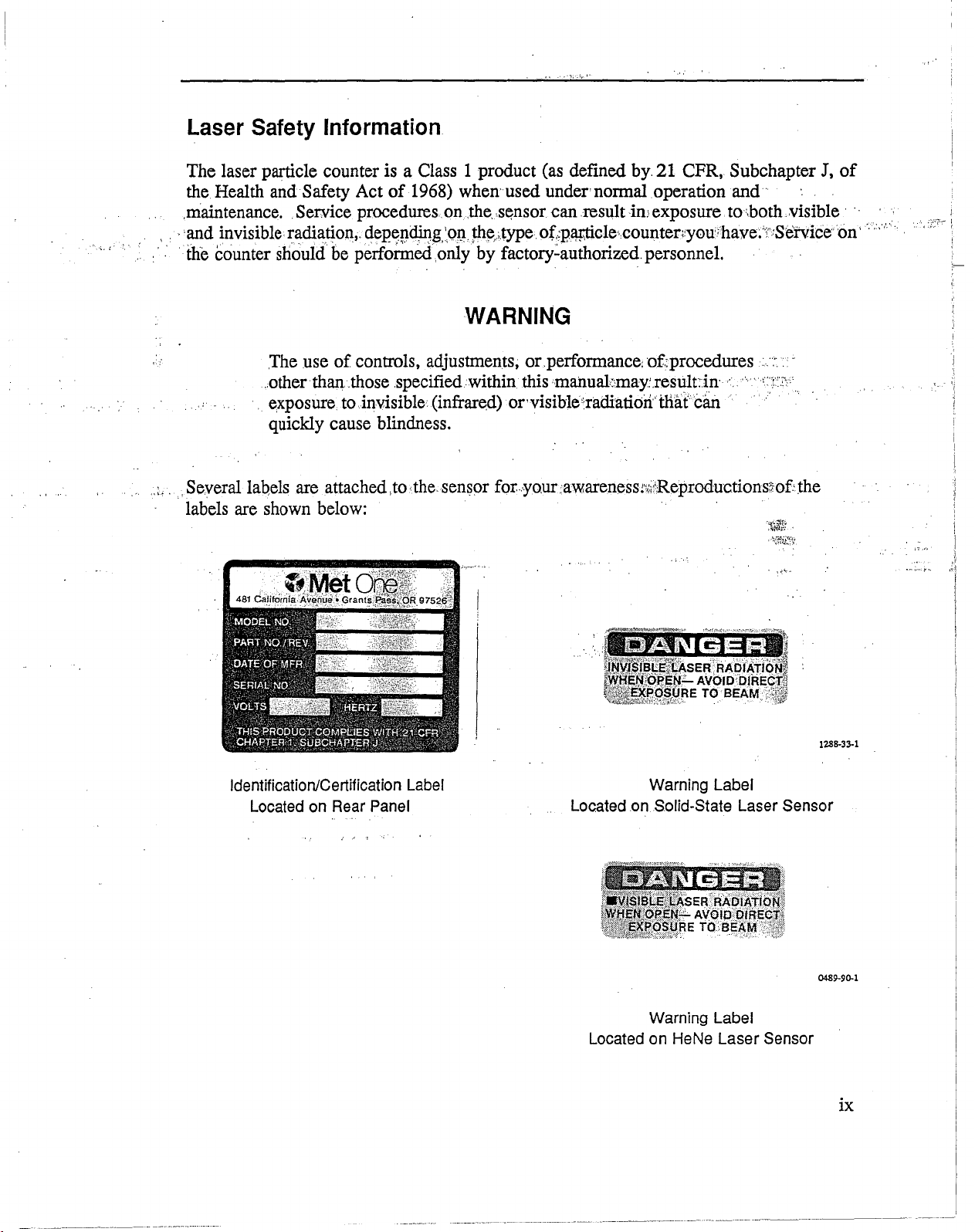

,:;'

,.,,,;,•·

laser

Safety Information

The

laser particle counter is a Class 1 product (as defined

by.

21

CFR, Subchapter

J,

of

the Health and Safety

Act

of

1968) when· used under·normal operation

and

.maintenance. .Service procedures on

..

the

..

s~nsor

can

resultinJexposure tO\both.visible · ·

>·and

invisible

r~diation,.

depf?.pdin,g,'9J,1.

#l~,;.type.

of,:p~cle··

counterty0u'•have;'·c:SetviCe·

on'

·.

··

.'

.

the

counter should be performed only

by

factory:authorized. personnel.

WARNING

.The

use

of

controls, adjustments, or.perfonnance:

of.:

procedures .

:~.

··

.other than

..

those .specified

within

this martual,:may:.resultin ·.

··

·

':(?

·

·. e,xposure toinvisible

(infrar~d)

.

Or'

visible':radiatioti'

tliat

can

.·

quickly cause blindness.

..

,. ,.Severallabels are attached,to the.sensor for:yo.ur awareness;',;i:'ReproduGtionsowfthe

labels are shown below: ·

Identification/Certification Label

Located on Rear Panel

.

,.,

.....

!288-33-1

Warning Label

Located

.on

Solid-State Laser Sensor

0489-90-1

Warning Label

Located on HeNe Laser Sensor

lX

I

'

',

;;i-'(·~r

I

..

'"'•'

!

:-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Electrostatic Discharge

Electrostatic discharge (ESD) can damage or destroy electronic components in those

counters using solid-state laser sensors (see "Specifications"

in

Section 1 for type

of

sensor in your counter). Therefore, all service or maintenance work should be done at

a static-safe work station. A static-safe work:station can

be

'c'reated by doing the

following:

• ;use a grounded conductive table mat and resistor-isolated wrist-strap combination

• 'Earth-ground all test instruments to prevent a buildup

of

static charge

··

WARNING

Using a wrist strap without an isolation resistor will increase the severity

of

an

electrical shock.

CAUTION

The laser driver board, mounted on the laser sensor

of

the particle counter, contains

wire leads from an extremely.static-sensitive laser diode.

Do

not touch the laser driver

board

or

any attached cables unless you are ESD protected.

X

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

' ..

;:'I

••,

Gaseous

Safety

Information

Sevaalprecautions should

be

considered

when

bandJing

certain

types

of

gases

and

gases

.

under

pressure.

Take extreme care

when

doing

.any.

procedures preceeded

by

or

contaitring a warning.

. ' '

·.')'

'

'.

~

-.' . .

..

"•

"~

,

..

·-

-~

[

,.

WARNING··•

· Do·nota:ttempt.tosamplereactivegases.withthe.particle.coonter

...

·.

·Reactive

gases

create anexplosion hazarddn

..

the;:counter~,o:

•.Contact the

factory for moreinformation.

WARNING

Installin the high. diffuserbackwardswill INCREASE· · sure

g pressure . . '

..

.

pres

. ,

.instead

of.

diffusing

it~g

the

high~;pressure;:diffusento·aplode~.··

·

··:·'5"

o~·i,;.;.,

"~'

.

'.,

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.<\

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

.

·,.,

..

Section 1

GETTING STARTED

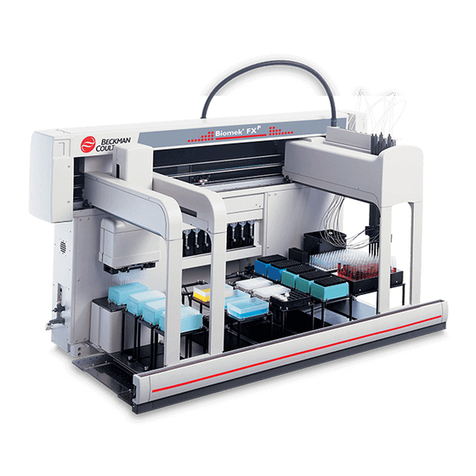

Introduction

This section describes,getting theparticlec

counterreadyfor:

use;'dncluding)(unpacking,

initialinspection, and turning the,,counter on,

but

frrsbyou will:be,introduced'

tO

:the,,,,

counter and its options, accessories, and specifications.

0889-142

Figure 1-1. Typical Laser Particle Counter

1-1

!"_:·· . ,

...

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

} :

Getting Started

Introducing the Particle Counter

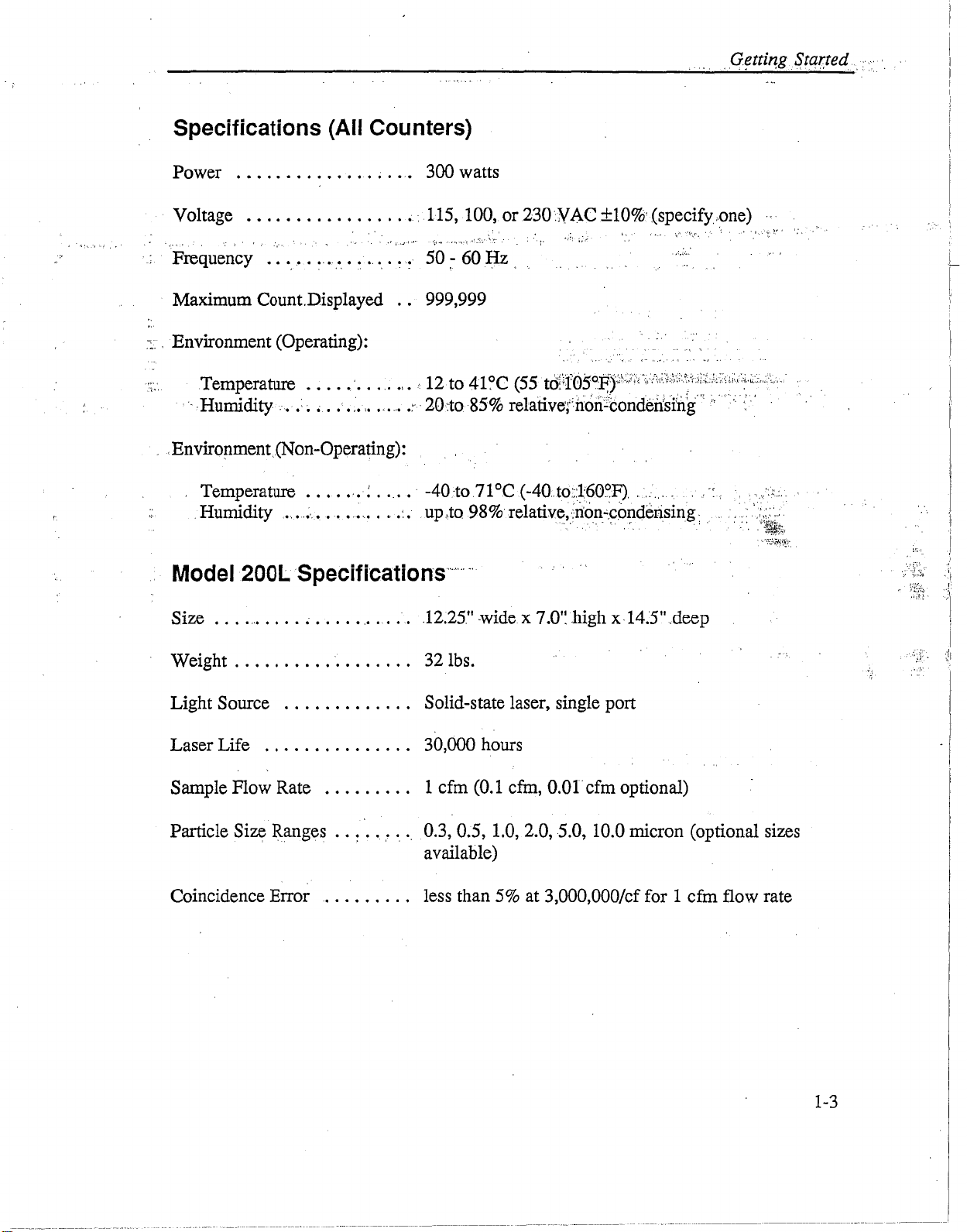

The particle counter measures airborne particles in six size ranges

at

the same time, and

displays the number

of

particles in each range as a cumulative

or

differential count.

The

counter is a state-of-the-art laser-based microprocessor-controlled instrument.

It

provides adjustable count alarms, automatic calibration verification, and

computer-controlled operation through a serial port.

The counter's laser and optical lenses create a laser beam that is used to detect particles.

The

airborne particles pass through the laser beam, deflecting bursts

of

light onto a

solid-state photo diode that converts the light to

an

electrical pulse. The size

of

the

pulse is proportional to particle size. The microprocessor and its associated circuitry

sorts

and

counts these.pulses.

Accessories

RH/Temp and

Air

Velocity Probes

High

Pressure.

Diffuser

Instrument Cart

Carrying Case

Options

Plug into the counter rear panel. The RH/femp probe monitors

relative humidity.(lO to

90%)

and.temperature.(specify,Q to··.

100°F,

or

-IS· to 38°C): The·

air;

velocity··'probe monitors air ·

velocity·(specify·so to 120 feet/minute,

or410

to 616

mm/second). The particle counter displays the reading

of

either

probe.

Allows the particle counter to measure in pressurized systems

(30-150 psi). Connects in series with particle counter inlet.

Allows easy movement

of

counter between sampleJocations.

Protects the counter during shipment or storage.

The

following option can be installed when you order your counter

or

any time

thereafter

if

you return your counter to the factory.

External Printer

1-2

Provides same printouts

as

built-in printer, but at distances

removed from counting area. Replaces built-in printer.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Getting Started

...

··

·

' ' '

~

I

..

I ' ' '

.t

' ' : •

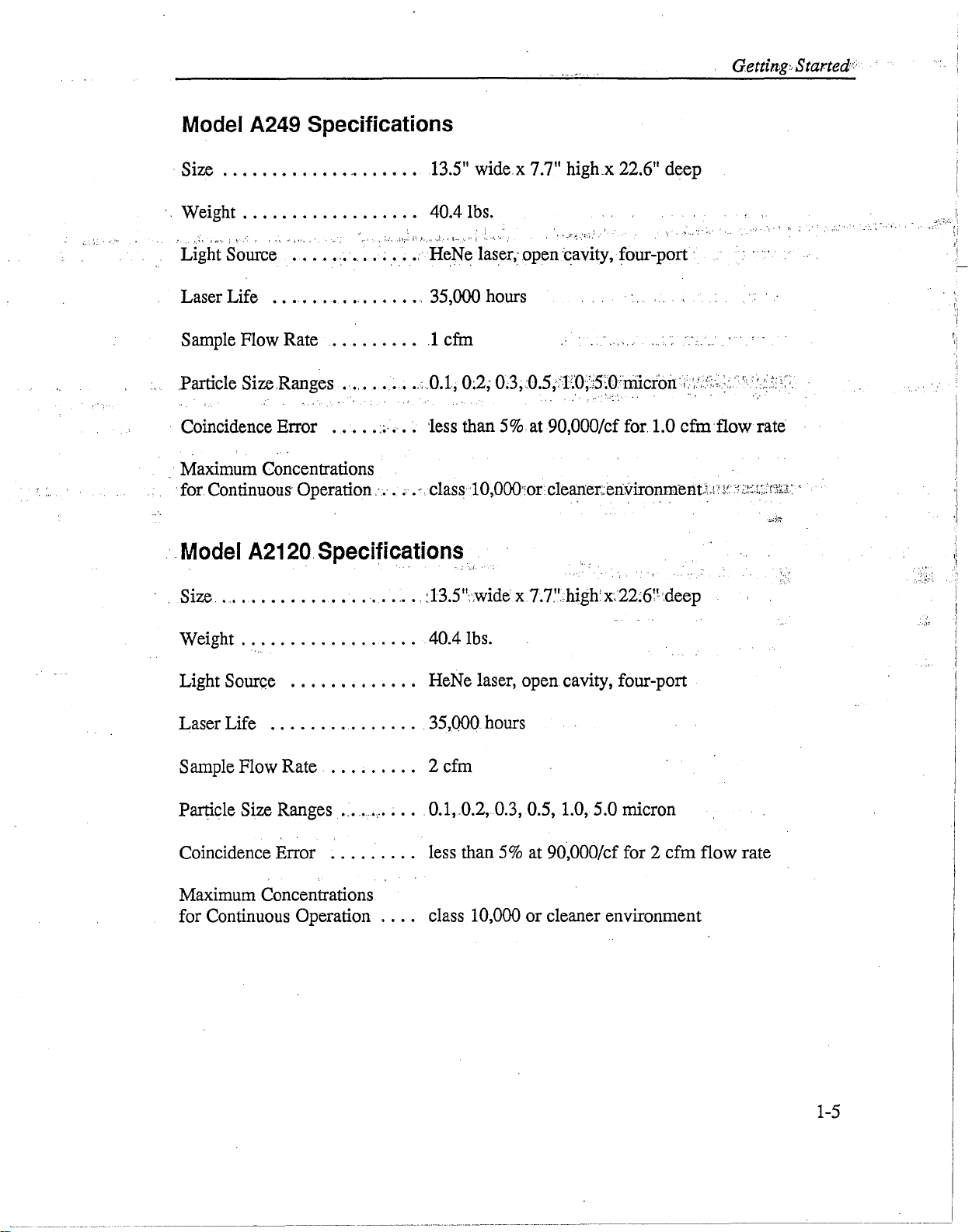

Specifications (All Counters)

Power

..............

, . ... 300 watts

Voltage

................

, . 115, 100, or

230N

AC

±10%

(specify.one)

:,. ' '

..

,._,

.....

Frequency

...........

~

. . . . . 50 -60

Hz

Maximum Count.Displayed 999,999

...

Environment (Operating):

Temperature

.....

·

.....

,. , 12 to 41?C (55

td!if05°~}'':;t;,.~;.:,,;;,:,,::'.':;ii:,;,,,,\.~;

..

<:·

·.Humidity

..

:. ,

...........

.: 20

:to

85% relative·(iloriicondelisin{

:,

· i · ·

,Environment{Non-Operating):

Temperature

......

: .

...

· -40.to.71°C

(-40.to·;:160~F).

..

. . .

..

,

.........

'

Humidity

..............

:.

up

.,to

98%relativ~

•.

irion.:.coJ?.derising:

..

.,,

..

'

\~

.' '

...

·:·

..

·,·~-\r

··'•;(.~::n\~::.

Model 200L Specifications

........

Size

.........

, . . . . .

..

. . . . .12.25" wide x 7

.o·~

high x 14.5".deep

Weight . . . . . . . . . . . . . . . . . .

32lbs.

Light Source . . . . . . . . . . . . . Solid-state laser, single port

Laser Life . . . . . . . . . . . . . . . 30,000 hours

Sample Flow Rate . . . . . . . . . 1 cfm (0.1 cfm,

0.01

cfm optional)

Particle Size Ranges

..

:

...

· . . 0.3, 0.5, 1.0, 2.0, 5.0, 10.0 micron (optional sizes

available)

Coincidence Error

.........

less than 5% at 3,000,000/cf for 1 cfm flow rate

1-3

~!';

I •

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Getting Started

Models 205 and 205A Specifications

Size

.....................

12.25" wide x 7.0 high x 22.0" deep

Weight

..................

38 lbs.

Light Source

..............

HeNe laser, open cavity, single port

Sample Flow Rate

..........

1 cfm (0.1 cfm, 0.01 cfm optional)

Particle Size Ranges:

:~Model205

.............

0.16, 0.2, 0.3, 0.5, 1.0, 5.0 micron

Model 205A

...........

0.2,

0.3~

05; 1.0, 2.0, 5.0 micron

Coincidence Error

..........

less than 5% at 130,000/cf for 1 cfm flow rate

M~imum

Concentrations

for Continuous Operation

.....

class 10,000

or

cleaner environment

Model

2090

Specifications

Size

.....................

13.5" wide x 7.7" high x 22.6" deep

Weight . . . . . . . . . . . . . . . . . . 40.4 lbs.

Light Source

..............

HeNe laser, open cavity, single port

Laser Life . . . . . . . . . . . . . . . . 35,000 hours

Sample Flow Rate . . . . . . . . . . 1 cfm

Particle Size Ranges

........

0.1, 0.2, 0.3, 0.5, 1.0, 5.0 micron

Coincidence Error

..........

less than

5%

at 830,000/cf for 0.1 cfm flow rate

Maximum Concentrations

for Continuous Operation

.....

class 10,000 or cleaner environment

1-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model

A249

Specifications

Size

............•.......

13.5" wide.x 7.7'' high.x 22.6" deep

·.

Weight . . . . . . . . . . . . . . . . . . 40.4 lbs.

: , •

I,

''

'

,_.

.,

i

~

• '

''

\

•'

t

''

o , ' - ,

. .

;

:,

.i';·:

,,

'··"

,1

.•

j,.,

•••

:.

'·

~

..

, • '• .

~

..

'·:.

··-.

-. .::<·

Light Source

..........

;

..

.:

HeNe

laser;open'cavity, four-port ·

Laser Life

.................

35,000 hours . '

(.

Sample Flow Rate

.........

J cfm

•':'···

.Particle SizeRanges

.........

:.0.1, 0;2;

OJ,

..0.5;\'E0;';5~0;niicioi1

;_

·

'

'-·"

..

Coincidence Error

.....

:;-

•..

'less than

5%

at90,000/cf for.l.O

cfm

flow rate

Maximum Concentrations

r

..

·for.Continuous· Operation:

...•.

·'·class

lO,OOO·,or

cleaner;en::VironrnenVc/:!t';;};.L;;.\t'frJ·:'

·.Model

A2120

Specifications

·~·'·

Size

......................

:13.5":·wide x

7~7''.high'x.22;6~~·.deep

Weight . . . . . . . . . . . . . . . . . .

40.4lbs.

Light

Sourc:e

.............

ReNe laser,

open

cavity, four-port

Laser Life . . . . . . . . . . . . . . . 35,000. hours

Sample Flow Rate . . . • . . . . . 2 cfm

Particle Size Ranges .

..

.

....

. . . 0.1, .0.2, 0.3, 0.5, 1.0,

5.0

micron

Coincidence Error

.........

less than 5% at 90,000/cf for 2

cfm

flow

rate

Maximum Concentrations

for Continuous Operation

....

class 10,000

or

cleaner environment

1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

;,

..

,

Getting Started

Model A221 0 Specifications

· Size

.....................

13.5" wide x 7.7" high x 22.6" deep

Weight

..................

40.4lbs.

Light Source

..............

HeNe laser, open cavity, single port

Laser Life

.·

...............

35,000 hours

Sample Flow Rate

..........

0.1 cfm

Partiicle Size Ranges

........

0.1, 0.2, 0.3, 0.4, 0.5, 1.0 micron

Coincidence Error

..........

less than 5% at 800,000/cf for 0.1 cfm flow rate

Maximum Concentrations

for Continuous Operation

.....

class 10,000 or cleaner environment

Model A2420 Specifications

Size

.....................

12.25" wide x 7.0" high x

14.5"

deep

Weight

..................

36lbs.

Light Source . . . . . . . . . . . . . . Solid-state laser, two-port

Laser Life . . . . . . . . . . . . . . . . 30,000 hours

Sample Flow Rate

..........

2 cfm

Particle Size Ranges

........

0.3, 0.5, 1.0, 2.0, 5.0,.10.0 micron (optional sizes

available)

Coincidence Error

..........

less than 5% at 100,000/cf for 2 cfm flow rate

1-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Unpacking and Initial Inspection

The counter.is thoroughly.inspected·and

..

tested.

at

the:factory and

is

ready:for use·upon··

receipt. When received, inspect the shipping.carton for damage.· Ifthe:carton is · ·

damaged, notify.the carrier.and.save,the

~lUton

for,

carri~r,inspe,ction;·:

1

,~nspect.the,.,,.·

..,

'·

·

counterfor

brokeri'parts·;·scratches~"dents·;o-r.other

damage.

.

..

.

·..

·

If

the

c~on

is

not.damaged~

keep.it for reshipment. .Forexample,·you

11?-ay..

want to ·

. reuse the.cartonwhen you.return.the counter

for

the annualfactory'cilibration.

NOTE

.,

__

.,

.,

'·''

•.

,.r,

•'·

•.

··

.

•: ;

,/'

•.'

I

-·

•;~

'

;·.,'

'

Shipping the•counter out

of

ih~

U.S.A. requires an export license.

Contact the factory for more information.

,.

. . ·

___

:,.,;;,.-:

'•'

•1'.

·'.·-.,

..

1-7

i

:1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

10

Table of contents

Other Met One Laboratory Equipment manuals