Met One BAM 1020 Installation manual

Met One Instruments, Inc.

1600 NW Washington Blvd.

Grants Pass, OR 97526

Telephone: (541) 471-7111

Facsimile: (541) 471-7116

www.metone.com

BAM 1020 Particulate Monitor Operation Manual - © Copyright 2016 Met One Instruments, Inc. All Rights Reserved

worldwide. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated

into any other language in any form without the express written permission of Met One Instruments, Inc.

BAM 1020

PARTICULATE MONITOR

OPERATION MANUAL

BAM 1020-9800 REV W

BAM 1020-9800 Manual Rev W.docx Page 2

Table of Contents

1INTRODUCTION 4

1.1 About This Manual..................................................................................................... 4

1.2 Technical Service....................................................................................................... 4

1.3 BAM: Beta Attenuation Monitor.................................................................................. 5

1.4 Beta Radiation Safety Statement............................................................................... 5

1.5 BAM 1020 US-EPA Configurations............................................................................ 6

1.6 BAM 1020 Other Configurations ................................................................................ 6

1.7 BAM 1020 Specifications ........................................................................................... 7

2SITE SELECTION AND INSTALLATION 8

2.1 Unpacking, Inspection, and Evaluation Testing ......................................................... 8

2.2 Enclosure Selection and Temperature Control........................................................... 8

2.3 Site Selection and Inlet Positioning Criteria ............................................................... 9

2.4 Mounting Options in a Walk-In Shelter....................................................................... 9

2.5 BAM 1020 Installation Instructions........................................................................... 10

2.6 BAM 1020 Power and Electrical Service.................................................................. 19

3INITIAL SETUP OF YOUR BAM 1020 20

3.1 Power Up ................................................................................................................. 20

3.2 Warm-up Period....................................................................................................... 20

3.3 The Main Menu and Using the Keypad and Display ................................................ 20

3.4 Filter Tape Loading.................................................................................................. 22

3.5 Self-Test................................................................................................................... 23

3.6 Initial SETUP Settings Considerations..................................................................... 24

3.7 Initial Leak Check and Flow Check.......................................................................... 25

3.8 Starting a Measurement Cycle................................................................................. 25

3.9 Accessing the Flow Statistics Screen....................................................................... 25

3.10 The OPERATE Menus............................................................................................. 26

3.11 The NORMAL Operation Screen.............................................................................. 26

3.12 The INSTANTANEOUS and AVERAGE Operation Screens ................................... 27

4THE MEASUREMENT CYCLE 28

4.1 The One-Hour Cycle Timeline.................................................................................. 28

4.2 Automatic Span Checks During The Cycle .............................................................. 29

4.3 Filter Tape Use......................................................................................................... 30

5FLOW SYSTEM and FLOW CALIBRATIONS 31

5.1 Flow System Diagram.............................................................................................. 31

5.2 Flow Control and Flow Reporting Types –Standard or Actual Flow........................ 31

5.3 Total Flow (QTOT) and Flow Rate (LPM) Conversions.............................................. 32

5.4 About Leak Checks, Nozzle Cleaning, and Flow Checks......................................... 32

5.5 Leak Check Procedure............................................................................................. 33

5.6 Nozzle and Vane Cleaning Procedure..................................................................... 34

5.7 Field Calibration of the Flow System –Actual Flow Mode ....................................... 36

5.8 Field Calibration of the Flow System –Standard Flow Mode................................... 38

6SETUP MENU DESCRIPTIONS 39

6.1 CLOCK Setup Screen.............................................................................................. 40

6.2 SAMPLE Setup Screen –Range, Sample, and Timing Settings.............................. 40

6.3 CALIBRATE Setup Screen –Flow and Calibration Settings..................................... 42

6.4 EXTRA1 Setup Screen ............................................................................................ 44

6.5 ERRORS Setup Screen for the Analog Output........................................................ 44

BAM 1020-9800 Manual Rev W.docx Page 3

6.6 PASSWORD Setup Screen...................................................................................... 46

6.7 INTERFACE Setup Screen...................................................................................... 47

6.8 SENSOR Setup Screen for External Met Sensors................................................... 47

6.9 HEATER Setup Screen –RH Control Settings ........................................................ 49

6.10 QUERY Setup Screen –Custom Data Array Setup................................................. 50

6.11 REPORTS Setup Screen –Daily Data and Dynamic Ranges.................................. 52

6.12 HJ 653 Setup Screen –Chinese Data Formatting ................................................... 53

7MAINTENANCE, DIAGNOSTICS and TROUBLESHOOTING 54

7.1 Met One Recommended Periodic Maintenance Table............................................. 54

7.2 BAM 1020 Error and Alarm Descriptions ................................................................. 55

7.3 Comparison of BAM 1020 Data to Integrated Filter Sampler Data........................... 59

7.4 Power Up Problems and Electrical Safety Considerations....................................... 60

7.5 Basic Problem and Cause/Solution Table................................................................ 61

7.6 Nozzle Component Service and O-ring Replacement.............................................. 64

7.7 Performing the 72-Hour Zero Filter Background Test .............................................. 65

7.8 The TEST Menu System –Overview....................................................................... 67

7.9 COUNT Test Menu –Beta Detector Count Tests .................................................... 67

7.10 PUMP Test Menu –Manual Pump and Nozzle Tests .............................................. 68

7.11 TAPE Test Menu –Manual Filter Forward/Backward Tests..................................... 68

7.12 DAC Test Menu –Analog Output Test..................................................................... 68

7.13 CALIBRATE Test Menu –Span Membrane Mass Tests.......................................... 69

7.14 INTERFACE Test Menu –Relay I/O Channel Tests................................................ 70

7.15 FLOW Test Menu..................................................................................................... 70

7.16 ALIGN Test Menu –Tape Transport Motor and Photosensor Tests........................ 70

7.17 HEATER Test Menu................................................................................................. 71

7.18 FILTER-T Test Menu –Filter Temperature Sensor Tests........................................ 71

7.19 RH Test Menu –Filter Humidity Sensor Test and Calibration.................................. 72

8EXTERNAL DATA LOGGER INTERFACE SYSTEM 74

8.1 Analog Concentration Output Signal........................................................................ 74

8.2 Early Cycle Mode Option For Analog Data Collection.............................................. 75

8.3 Telemetry and Error Relays ..................................................................................... 76

8.4 Interfacing a Digital Data logger with the BAM 1020................................................ 79

9DIGITAL COMMUNICATIONS AND DATA RETRIEVAL 80

9.1 Direct Serial Port Connections and Settings ............................................................ 80

9.2 Using Met One Comet Communications Software................................................... 81

9.3 Downloading Data Using Simple Terminal Programs .............................................. 82

9.4 System Menu and File Descriptions Using a Terminal Program.............................. 83

9.5 Printer Output Port Functions................................................................................... 89

9.6 Modem Option.......................................................................................................... 90

9.7 BAM 1020 Firmware Upgrades................................................................................ 90

9.8 Resetting the Data Pointer for New Data Collection................................................. 93

9.9 Data Collection Using the Query Output or Bayern-Hessen Protocol ...................... 93

10 ACCESSORIES and PARTS 96

10.1 Consumables, Replacement Parts, and Accessories............................................... 96

10.2 BX-500 Series Meteorological Sensor Configurations ........................................... 101

11 THEORY OF OPERATION 103

11.1 Converting Data Between EPA Standard and Actual Conditions........................... 104

BAM 1020-9800 Manual Rev W.docx Page 4

1 INTRODUCTION

1.1 About This Manual

This document is organized with the most important information toward the front of the

manual, such as site selection, installation, setups, and field calibrations.

Toward the back are sections that provide in-depth information on subjects such as theory,

diagnostics, accessories, and alternate settings. These sections provide valuable information

which should be consulted as needed. Electronic versions of this manual are also available.

This manual is periodically revised for maximum accuracy, and to incorporate new features or

updates. Below is a brief description of the BAM 1020 manual revision history:

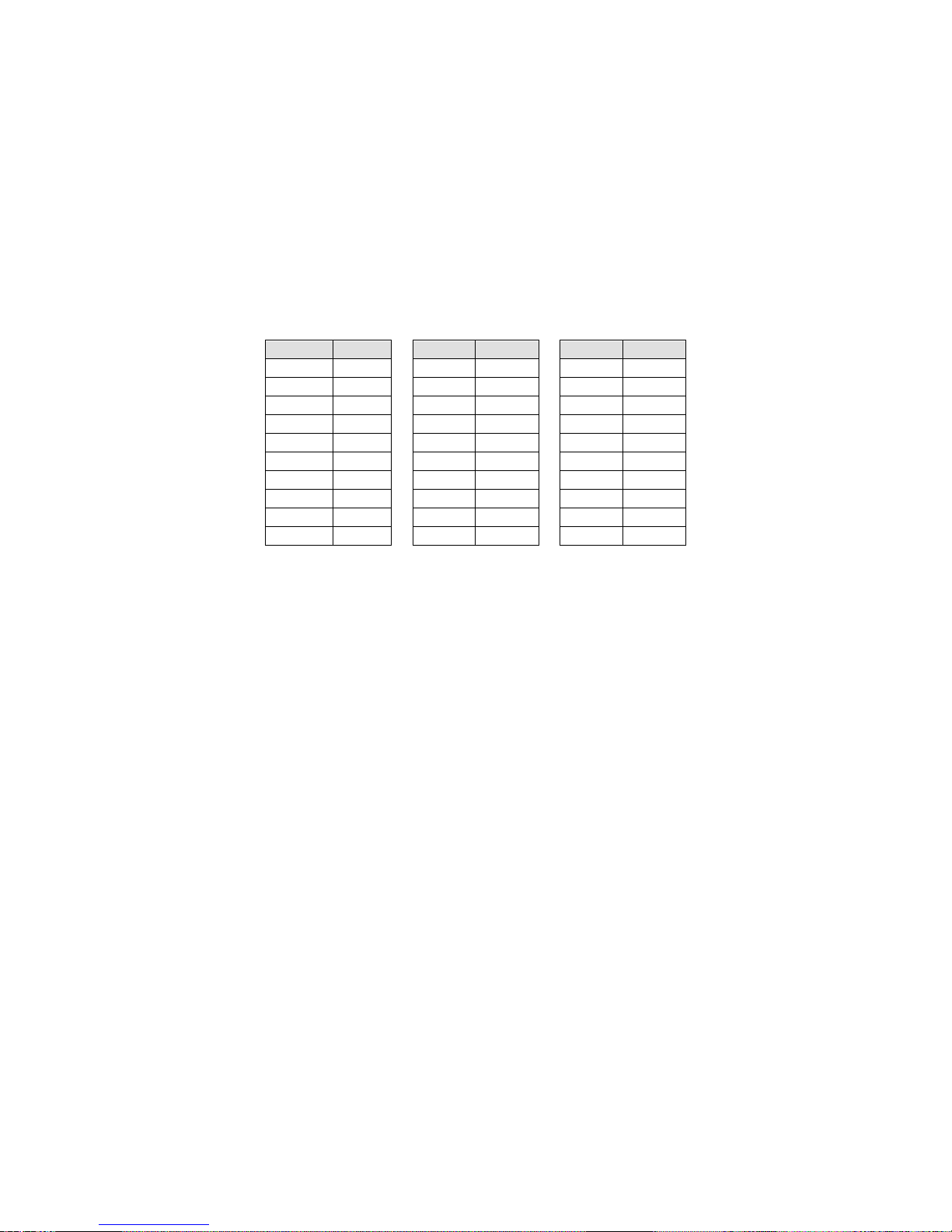

Rev

Released

Manual Description

A-E

1998-2006

Obsolete revisions of the manual. These are only suitable for older BAM 1020 units with

firmware Rev 2.58 or earlier. Users of these units should acquire a newer manual revision.

F

March 2007

Complete re-write of the entire manual to accompany the EPA PM2.5 FEM candidate

modifications for the BAM 1020. Extensively corrected, reorganized, and updated all

sections. Applies to all BAM 1020 units of all vintages. All BAM 1020 units using revision 3.0

or later firmware must have a Rev F or later manual.

G

May 2008

Minor revisions for the official sales release of the EPA designated PM2.5 FEM version of

the BAM 1020. Added final PM2.5 designation requirements and installation drawings.

Other minor revisions throughout the manual. Applies to all BAM 1020 units. All BAM 1020

units using revision 3.2.5 or later firmware should have a Rev G or later manual.

H

June 2010

Revisions to incorporate information about the PM-Coarse designated version, and to add

information about new firmware features up to firmware rev 3.6. Additional maintenance

procedures added.

J

Sep 2011

Minor revisions to zero filter test instructions.

K

Oct 2012

Added electrical safety requirements and smart heater configurations in section 2. Added

report processor and firmware compatibility details. Firmware features up to version 3.7.

L

Dec 2015

Designation update, minor changes to reflect functionality changes

M

June 2016

General Rewrite. Correction of errors, removal of unnecessary information.

N

July 2016

Correction of several formatting errors..

P

Oct 2016

Minor changes to reflect functionality updates.

Q

Feb 2017

Clarification of Zero Background Test instructions..

R

Aug 2017

Correction of minor errors..

T

Oct 2017

Updated replacement parts table..

U

Nov 2017

Minor changes to reflect functionality updates.

W

Feb 2018

Minor changes to reflect functionality updates.

1.2 Technical Service

Technical Service representatives are available during normal business hours of 7:00 a.m. to

4:00 p.m. Pacific Standard Time, Monday through Friday. In addition, technical information

and service bulletins are available from our website. Please contact us at the phone number

or email address below to obtain a Return Authorization (RA) number before sending any

equipment back to the factory.

Phone: (541) 471-7111 Fax: (541) 471-7116

BAM 1020-9800 Manual Rev W.docx Page 5

Address: Technical Services Department

Met One Instruments, Inc.

1600 NW Washington Blvd.

Grants Pass, OR 97526

All BAM 1020 monitors have a serial number on the label on the back panel, embossed on

the two metal NRC tags, and printed on the calibration certificate. This number is needed if

you contact the technical service department to request information about repairs or updates

for your BAM 1020. The serial number begins with a letter which represents the year of

manufacture, followed by a unique four or five digit number. Example: F8029 was built in

2006.

Letter

Year

Letter

Year

Letter

Year

W

1998

H

2008

X

2018

X

1999

J

2009

Y

2019

Y

2000

K

2010

A

2020

A

2001

M

2011

B

2021

B

2002

N

2012

C

2022

C

2003

P

2013

D

2023

D

2004

R

2014

E

2024

E

2005

T

2015

F

2025

F

2006

U

2016

G

2026

G

2007

W

2017

H

2027

1.3 BAM: Beta Attenuation Monitor

The Met One Instruments BAM 1020 beta attenuation mass monitor automatically measures

and records ambient particulate mass concentration levels using the principle of beta ray

attenuation. This method provides a simple determination of the ambient concentration of

particulate matter in mg/m3or μg/m3. A small 14C (carbon 14) element inside of the BAM

1020 provides a constant source of beta rays. The beta rays traverse a path through which

glass fiber filter tape is passed before being detected with a scintillation detector. At the

beginning of the measurement cycle the beta ray count (I0) across clean filter tape is

recorded. Then, an external pump pulls a known volume of PM-laden air through the filter

tape thereby trapping the PM on the filter tape. At the end of the measurement cycle the beta

ray count (I3) is re-measured across PM-laden filter tape. The ratio of I0to I3is used to

determine the mass density of collected PM on the filter tape. A complete description of the

measurement cycle is included in Section 4. In addition, a scientific explanation of the theory

of operation and the related equations is included at the back of the manual.

1.4 Beta Radiation Safety Statement

The Met One Instruments BAM 1020 contains a small 14C (carbon 14) beta radiation-emitting

source. The activity of the source is 60 Ci ±15 Ci (microcurries), which is below the

“Exempt Concentration Limit” of 100 µCi as determined by the United States Nuclear

Regulatory Commission (US-NRC). The owner or operator of the BAM 1020 is not required to

have a license to possess or operate the equipment under US-NRC regulations. The owner

may however elect to return the monitor to Met One Instruments for recycling of the 14C

BAM 1020-9800 Manual Rev W.docx Page 6

source when the monitor has reached the end of its service life, although is under no

obligation to do so. Under no circumstances should anyone but factory technicians attempt to

remove or access the 14C source. 14C has a half-life of about 5730 years, and should never

need to be replaced. Neither the 14C source nor the detector are serviceable in the field.

Should these components require repair or replacement, the BAM 1020 must be returned to

the factory for service and recalibration.

1.5 BAM 1020 US-EPA Configurations

The BAM 1020 is US-EPA designated for PM10, PM2.5 and PM10-2.5 under the following

designation numbers:

•Designation Number: EQPM-0798-122 (PM10)

•Designation Number: EQPM-0308-170 (PM2.5 with BGI/Mesa Labs VSCC™or Tisch

Cyclone)

•Designation Number: EQPM-0715-266 (PM2.5 with URG Cyclone)

•Designation Number: EQPM-0709-185 (PM10-2.5 with BGI/Mesa Labs Cyclones)

US-EPA designated methods using the BAM 1020 are modified from time to time in order to

reflect hardware or software improvements. These modifications do not impact previously

designated configurations of the BAM 1020 but may provide the end user with a product

upgrade path that will allow the monitor to continue to be operated as a US-EPA designated

method. For further details, please contact our service department. Details concerning US-

EPA designated configurations of the BAM 1020 may be found on the US-EPA website:

http://www3.epa.gov/ttn/amtic/files/ambient/criteria/reference-equivalent-methods-list.pdf

1.6 BAM 1020 Other Configurations

The BAM 1020 is used worldwide. Although many international jurisdictions use the US-EPA

configurations, others do not. Please consult with your local monitoring authority for details on

how the BAM 1020 should be configured and operated locally.

BAM 1020-9800 Manual Rev W.docx Page 7

1.7 BAM 1020 Specifications

PARAMETER

SPECIFICATION

Measurement Principle:

Particulate Concentration by Beta Attenuation.

U.S. EPA Designations:

PM10: EQPM-0798-122

PM2.5 EQPM-0308-170

PM2.5 EQPM-0715-266

PM10-2.5 FEM: EQPM-0709-185

Standard Range:

0 - 1.000 mg/m3(0 - 1000 g/m3)

Optional Ranges:

0 - 0.100, 0.200, 0.250, 0.500, 2.000, 5.000, 10.000 mg/m3(special applications)

Accuracy:

Exceeds US-EPA Class III PM2.5 FEM standards for additive and multiplicative bias.

Lower Detection Limit:

(2σ) (1 hour)

< 4.8 g/m3(< 4.0 g/m3 typical) (8-minute count time)

Lower Detection Limit:

(2σ) (24 hour)

< 1.0 g/m3

Measurement Cycle Time:

1 hour

Flow Rate:

16.70 liters/minute

Filter Tape:

Glass fiber filter

Span Check:

Nominally 800 μg/cm2

Beta Source:

C-14 (carbon-14), 60 µCi ±15 µCi (< 2.22 X 106Beq), Half-Life 5730 years.

Beta Detector Type:

Photomultiplier tube with scintillator.

Operating Temp. Range:

0° to +50°C

Ambient Temp. Range:

-40° to +55°C standard. Optional -50 °C temperature sensors available.

Ambient Humidity Range:

0 to 90% RH, non-condensing.

Humidity Control:

Actively controlled inlet heater module, 10% - 99% RH set point.

Approvals:

U.S. EPA, MCERTS, CE, NRC, TUV, CARB, ISO-9001.

Standard User Interface:

Menu-driven interface with 8x40 character LCD display and dynamic keypad.

Optional User Interface:

Graphic color touch screen display module, Model BX-970.

Analog Output:

Isolated 0-1 VDC output standard. 0-10V, 4-20mA, 0-16mA switch-selectable.

Serial Interface:

RS-232 2-way serial ports for PC or modem communications.

Printer Output:

Output-only serial port, data or diagnostic output to a PC or serial printer.

Telemetry Inputs:

Clock Reset (voltage or contact closure), Telemeter Fault (contact closure).

Alarm Contact Closures:

Data Error, Tape Fault, Flow Error, Power Failure, Maintenance.

Compatible Software:

Air Plus™, Comet™, MicroMet Plus®, HyperTerminal®, ProComm Plus®.

Error Reporting:

User-configurable. Available through serial port, display, and relay outputs.

Memory:

4369 records (182 days @ 1 record/hr). Extended memory Report Processor option

Power Supply:

100 - 230 VAC, 50/60 Hz. 0.4 kW, 3.4A max @110V. Not including shelter.

Weight:

24.5 kg (54 lbs) without external accessories.

Unit Dimensions:

H x W x D = 31cm x 43cm x 40cm (12.25”x 17” x 16”).

Specifications may be subject to change without notice.

BAM 1020-9800 Manual Rev W.docx Page 8

2 SITE SELECTION AND INSTALLATION

2.1 Unpacking, Inspection, and Evaluation Testing

If any damage to the shipment is noticed before unpacking, a claim must be filed with the

commercial carrier immediately. Notify Met One Instruments after notification of the

commercial carrier.

Unpack the BAM 1020 and accessories and compare them to the packing list to make sure

you have all of the required items for the type of installation you plan to perform. A separate

quick setup guide with color photos of most of the common accessories will be included with

the this manual. You can use the quick setup guide to fully configure and operate the BAM

1020 on a test bench if desired.

The BAM 1020 is shipped with one or two white foam rings and a white plastic shim inside

the front of the BAM 1020, which prevent the moving parts of the tape control assembly from

being damaged during transit. The rings and shim should be replaced when the BAM 1020 is

being transported in order to avoid damaging the tape control mechanism. Do not ship or

transport the BAM 1020 with filter tape installed. We recommend that you keep the special

shipping box and foam packing material which the BAM 1020 came in as they could be re-

used if you must return the BAM 1020 to the factory for any reason.

2.2 Enclosure Selection and Temperature Control

The BAM 1020 monitor is not weatherproof. It is designed to be mounted in a weatherproof,

level, low vibration, dust free, and temperature-stable environment where the operating

temperature is between 0oC and +50o C, and where the relative humidity is non-condensing

and does not exceed 90%. There are two standard configurations described below for

providing a weatherproof location in which to install the BAM 1020. Please contact Met One

Instruments for advice if you plan to have a non-standard mounting or enclosure

configuration.

1. A walk-in shelter or building: These are usually semi-portable pre-fabricated

shelters or portable trailers with a flat roof, or a room in a permanent building or

structure. The BAM 1020 may be placed on a workbench or mounted in an equipment

rack. The inlet tube of the BAM must extend up through a hole in the roof of the

structure with appropriate sealing hardware. AC power must be available. Instructions

for this type of installation are included in this section of this manual.

2. BX-902/903/906 mini weatherproof enclosures: these small pre-fabricated

enclosure are just big enough for the BAM and related accessories, and are installed

on the ground or on the roof of a larger building. They are available with a heater (BX-

902), or with a heater and air conditioner (BX-903). A dual-unit air conditioned mini

shelter is also available (BX-906). These enclosures are all specified by Met One to

accept the BAM 1020, and are supplied with a supplemental installation manual.

Shelter Temperature Control Notes: The air temperature inside a BAM shelter or enclosure

is not required to be regulated to any specific narrow range or set point (such as 25 °C),

subject to the following caveats:

BAM 1020-9800 Manual Rev W.docx Page 9

1. The shelter temperature must stay between 0 and 50 °C inside at all times or alarms

and failures may result. Remember that the vacuum pump and inlet heater can

contribute significantly to shelter heating.

2. The exact shelter temperature within the 0-50 °C range is not critical. However

temperature changes during the measurement cycle can lead to measurement

artifacts. These artifacts, when present tend to present only during hourly

measurements and are generally insignificant when daily averages are calculated.

3. Met One Instruments recommends logging the temperature inside non-air conditioned

mini enclosures such as the model BX-902. Met One Instruments offers a BX-592-1

room temperature sensor which can be logged directly by the BAM 1020 for this

purpose

4. BAM 1020 users in hot climates where the ambient temperature exceeds 40 °C should

consider using the model BX-903 air conditioned mini shelter or an air conditioned

walk-in shelter to avoid over-heating the BAM 1020.

5. The portion of the inlet tube inside of the shelter or building should always be

adequately insulated. This is especially important when the equipment is operated

under conditions of high ambient dew point. Otherwise condensation could occur

inside the sampling tube and/or measurement artifacts could result. If this proves to be

an issue, the user may consider increasing the temperature inside the shelter to a

point closer to ambient temperature. The BAM 1020 should not be placed directly in

the path on an air conditioning vent.

2.3 Site Selection and Inlet Positioning Criteria

We recommend that you check for local regulations and guidance documentation that may

exist before selecting the site in which to install the BAM 1020. For example, US-EPA

provides a variety guidance documents where site selection issues are addressed. Such

guidance and regulation may provide information concerning:

1. Inlet height

2. Spacing and clearance

3. Proximity to particulate sources, both mobile and stationary

4. Additional siting criteria or considerations

These details should be understood before selecting a site.

2.4 Mounting Options in a Walk-In Shelter

When the BAM 1020 is to be located in a walk-in shelter, it may be installed in either an

equipment rack or on a bench top. Take the following into account when planning the

mounting:

•Rear Access: It is important that you leave plenty of access to the rear of the BAM

1020 for wiring connections and maintenance. At least five inches is required. Full

access to the back is recommended whenever possible. There must be adequate

access to the power switch located on the back of the instrument.

•Top Access: It is necessary to have a minimum of eight inches clearance between

the top of the BAM 1020 inlet receiver and the bottom of the shelter ceiling to

accommodate the smart inlet heater.

BAM 1020-9800 Manual Rev W.docx Page 10

•Mobile Shelters: If the BAM 1020 is being installed into an equipment rack in a mobile

trailer or van, then additional care should be taken to ensure that the mounting can

handle the additional strain. The foam shipping rings must also be inserted any time a

mobile shelter is moved with the BAM 1020 inside.

•Rack Modifications: It is usually necessary to modify the top plate of the equipment

rack by cutting a 2 inch diameter (75mm) hole to allow the inlet tube to extend through

to the ceiling. The BAM 1020 dimensional drawings below show the location of the

inlet. Note: The inlet heater installs onto the inlet tube two inches above the top of the

inlet receiver of the BAM 1020. If the BAM 1020 is to be mounted in a rack, it will be

necessary to leave extra room above the BAM 1020 in the rack for the heater, or to

make the hole in the top of the rack larger in order to clear the heater diameter. The

heater is supplied with a foam insulation sleeve which may be modified as needed.

Make sure these parts are going to fit before installing the BAM 1020.

2.5 BAM 1020 Installation Instructions

When installing the BAM 1020 into a shelter or structure the following issues should be taken

into consideration.

1. Roof Modifications: Determine the exact location where the BAM inlet tube will pass

through the roof of the shelter, and drill a 2 ¼” or 2 ½” (60mm) diameter hole through

the roof at that location. Make sure the hole is directly above where the inlet receiver is

to be located, so the inlet tube will be perfectly vertical. A plumb weight is useful for

determining where to locate the hole. Note that the inlet receiver on the BAM 1020 is

slightly off-center! BX-902/903 mini shelters do not require any roof drilling.

2. Waterproof Roof Flange: Apply all-weather silicone caulking around the top of the

hole, and install the BX-801 roof flange onto the hole. The threaded barrel of the

flange is usually installed downward. Secure the flange in place with four lag bolts or

self-tapping screws (not supplied). Caulk around the screws to prevent leaks. Apply

Teflon tape to the threads of the gray plastic watertight fitting, and screw it into the roof

flange tightly. BX-902/903 mini shelters come with a roof flange installed, and only

need the watertight fitting. Note: Some users prefer to fabricate their own roof flange

instead of using the one supplied by Met One Instruments, due to factors such as high

snow loading or a sloped roof. Equipment damage from a leaking roof is not covered

under warranty.

3. Inlet Tube Installation and Alignment: Remove the white threaded cap and rubber

seal from the watertight inlet tube seal assembly. This makes it easier to install the

inlet tube since the rubber seal is a tight fit. Lower the inlet tube through the flange

assembly and into the inlet receiver on the BAM 1020, making sure that the inlet tube

is fully seated. It is very important for the inlet tube to be perpendicular to the top of the

BAM 1020. The nozzle may bind if the inlet is misaligned. A simple check is to rotate

the inlet tube back and forth by hand before tightening the roof flange seal or the BAM

1020 inlet set screws. If the inlet tube is straight, then the tube should rotate fairly

easily while inserted into the BAM 1020. If it does not rotate, check the inlet tube for

vertical alignment or move the BAM 1020 slightly.

BAM 1020-9800 Manual Rev W.docx Page 11

It is always recommended that the exposed portion of the inlet tube inside the

shelter be insulated.

4. Smart Inlet Heater Installation: Before tightening the inlet tube in place, the BX-827

or BX-830 smart inlet heater (used on most BAM 1020 monitors) must be installed

onto the tube. Lift the inlet tube out of the top of the BAM 1020, and pass the tube

through the hole in the heater body (the cable end is the bottom). Then re-insert the

inlet tube into the BAM. Position the bottom of the smart heater unit two inches above

the top of the inlet receiver on the BAM, and securely tighten the two set screws in the

heater to fasten it to the tube.

Included with the smart heater is a 12” tube of white insulation. The tube is split down

its length for easy application. Wrap the insulation around the heater body and peel

back the adhesive cover strip to secure in place. The insulation may be cut to fit if

needed. The insulation sleeve provides more consistent heating, and also prevents

items from coming into contact with the hot heater body.

5. Smart Heater Electrical Connections: All generations of the BX-827/830 Smart

Heater have the same green metal power connector. However, there are two different

configurations for the way the heater plugs into the BAM 1020 depending on the

heater control relay location. Make sure that you recognize which of the two following

configurations you have.

Most units built between 2008 and 2012 were supplied with an external gray relay

module which plugs into a mating black plastic connector on the back of the BAM

1020. The Smart Heater connector plugs into the green connector on the top of this

relay module, as shown in the left photo below. These external relay modules have

their own AC power cord to supply power to the heater, and have a 3A fuse inside.

In the other possible configuration of the kit, the green metal Smart Heater connector

simply plugs directly into the mating green metal connector on the back of the BAM

1020. The heater relay is located inside the BAM 1020, and the heater power comes

from the BAM AC power supply at line voltage and frequency, and is fused by the

main 3.1A fuses in the power input module.

Warning! It is possible to incorrectly force the green metal heater connector into the

black plastic connector on a BAM 1020 which is configured to use the external relay,

even though both connectors have male pins. If this is done the BAM 1020 will not be

damaged, but the heater will not function and no sample RH control will occur!

Warning! The heater relay controls live AC line voltage to the green socket in either

version. Treat the green socket like a live power outlet whenever power is applied. Do

not open or service the relay module or heater module when power is applied.

BAM 1020-9800 Manual Rev W.docx Page 12

Warning! The Smart Heater has triple redundant safety features to prevent

overheating, but the heater surface temperature can exceed 70 degrees C during high

humidity conditions. Use the white insulation sleeve to prevent contact with the heater

during operation.

Two Different Smart Heater Power Configurations

6. Tightening the Inlet: After the inlet tube is aligned and the heater installed, slide the

black rubber seal and white cap down over the top of the inlet tube and into the roof

flange. It is easier if you wet the rubber seal with water first. Tighten the white plastic

cap. Tighten the two set screws in the top of the BAM 1020 inlet receiver.

7. Inlet Support Struts: The BX-801 inlet kit comes with two angled aluminum struts to

support the inlet tube above the roof and prevent the inlet from moving in the wind.

These struts are typically fastened (about 90 degrees apart) to the inlet tube with a

supplied hose clamp. The bottom ends of the struts should be fastened to the roof with

lag bolts (not supplied). Some installations may require different methods or hardware

for supporting the inlet tube. Support the tube in the best manner available. The BX-

902/903 mini shelters do not require inlet tube supports.

8. Temperature Sensor Installation: BAM 1020 units are supplied with a BX-592

(temperature only), BX-596 (AT/BP), or BX-597 (AT/BP/RH) sensor, which attaches to

the inlet tube above the roof. The sensor cable must route into the shelter to be

attached to the BAM. Use a waterproof cable entry point or weatherhead if your shelter

has one. The BX-902/903 mini shelters have a cable entry on the side. Route the

cable into the shelter in the best manner available. In some cases you may need to

simply drill a 3/8” hole through the roof a few inches away from the inlet tube, route the

cable through the hole and caulk it to prevent leaks. The BX-596 and BX-597 sensors

attach directly to the inlet tube with a supplied U-bolt. If using a BX-592, fasten the

aluminum cross-arm to the inlet tube, and clip the temperature probe to the cross-arm.

Connect the cable to the terminals on the back of the BAM 1020 as follows. Additional

optional Met One auto ID sensors may be connected to channels 1 through 5 to log

other meteorological parameters. Details on these optional sensor connections are

given in Section 10.2 of this manual.

Smart Heater

Heater

Power Cord

Version B: Green metal heater

connector plugs into green

metal connector on the BAM,

with no relay module.

Version A: Green metal heater

connector plugs into green metal

connector on the relay module.

Relay module plugs into black

plastic connector on the BAM.

BAM 1020-9800 Manual Rev W.docx Page 13

BX-597 Temp/Baro/RH

Combo Sensor

BX-596 AT/BP Sensor

BX-592 AT Sensor

Wire Color

Terminal

Name

Wire Color

Terminal

Name

Wire Color

Terminal

Name

Blue (AT)

Channel 6

SIG

Yellow (AT)

Channel 6

SIG

Yellow or

White (AT)

Channel 6

SIG

Black/Shield

Channel 6

COM

Black/Shield

Channel 6

COM

Black/Shield

Channel 6

COM

Red

Channel 6

POWER

Red

Channel 6

POWER

Red

Channel 6

POWER

Green

Channel 6

ID

Green

Channel 6

ID

Green

Channel 6

ID

White (BP)

Channel 7

SIG

White (BP)

Channel 7

SIG

Brown (RH)

Channel 1-3

SIG*

9. Inlet Separator Heads: For PM10 monitoring, the BX-802 Size-Selective Inlet is

installed directly onto the inlet tube with no cyclone. To configure the BAM 1020 for

PM2.5 monitoring, install the PM2.5 size fractionator the PM10 head as shown below.

Use O-ring lubricant as needed. Met One Instruments offers a variety of PM2.5

fractionators for use with the BAM 1020.

10.Inlet Tube Grounding: The two ¼”-20 set screws located in the inlet receiver of the

BAM should create a ground connection for the inlet tube to prevent static electricity

from building up on the inlet tube under certain atmospheric conditions. This is also

important in areas near electromagnetic fields, high voltage power lines, or RF

antennas. Check the connection by scraping away a small spot of the clear anodizing

near the bottom of the inlet tube, and use a multimeter to measure the resistance

between this spot and the “CHASSIS” ground connection on the back of the BAM

1020. It should measure only a couple of Ohms or less if a good connection is made

with the set screws. If not, remove the set screws and run a ¼-20 tap through the

holes. Then reinstall the screws and check the electrical resistance again. Note:

Anodized aluminum surfaces are non-conductive.

11.Pump Location and Installation: The best location for the vacuum pump is often on

the floor under the rack or bench, but it may be located up to 25 feet away if desired. It

may be preferable to locate the pump so that noise is minimized if the BAM 1020 is in

an area where personnel are present. If the pump is to be enclosed, ensure that it will

not overheat. The Gast pumps have a thermal shutdown inside which may trip if

overheating occurs. Route the clear 10 mm air tubing from the pump to the back of the

BAM-1020, and insert it firmly into the compression fittings on both ends. The tubing

should be cut to the proper length and the excess tubing saved.

The pump is supplied with a 2-conductor signal cable which the BAM 1020 uses to

turn the pump on and off. Connect this cable to the terminals on the back of the BAM

1020 marked “PUMP CONTROL” The end of the cable with the black ferrite filter goes

toward the BAM. The cable has no polarity, so either the red or black wire can go to

either terminal. Connect the other end of the cable to the two terminals on the pump.

There are two pump types available for the BAM 1020. The Gast rotary vane pumps

are louder and draw considerably more power than the Medo linear piston pumps, but

have better vacuum capacity, especially at higher altitude or in 50 Hz applications. The

Medo pumps are smaller, quieter, and more efficient, but aren’t recommended for 50

Hz use.

BAM 1020-9800 Manual Rev W.docx Page 14

12.Optional External Data Logger Connections: The BAM 1020 has an analog output

which may be recorded by a separate data logger if required. Connect the terminals on

the back of the BAM marked ”VOLT OUT +, -“ to the data logger with 2-conductor

shielded cable (not supplied). Polarity must be observed. The logger input must be

correctly scaled in order to log the voltage accurately! Information on configuring this

analog output is provided in Section 8 of this manual. A current loop output is also

available.

Newer data loggers often interface to the BAM 1020 using the digital serial ports for

better accuracy. Information about this is also found in Section 8. Met One can also

supply additional technical bulletins on the subject.

The BAM 1020 has a variety of other telemetry I/O relays, error relays, and serial data

connections located on the back of the BAM 1020 as shown below. These items are

described in Section 8 and Section 9 of this manual.

BAM 1020-9800 Manual Rev W.docx Page 15

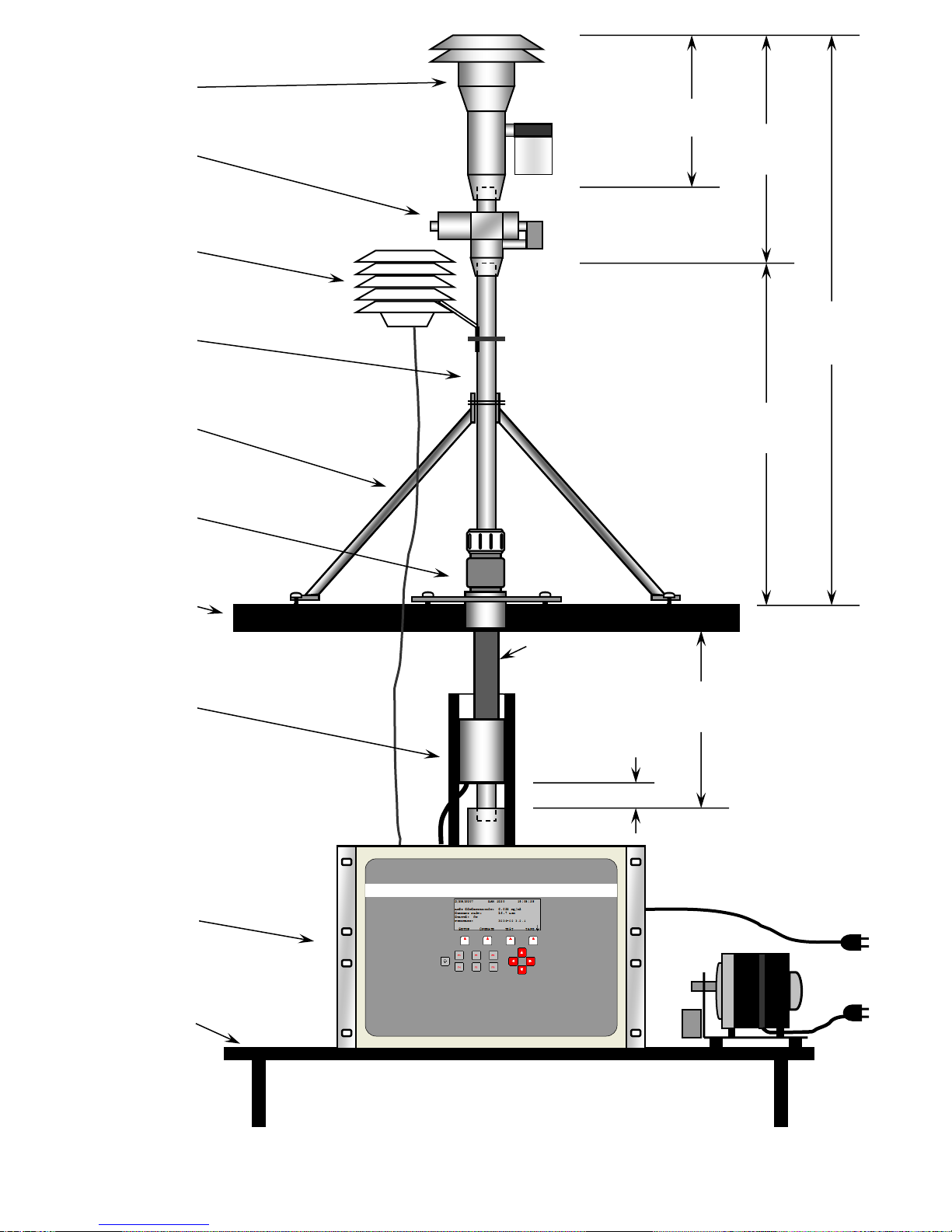

BX-802

PM10 Head

BX-806, BX-

807, BX-808

or BX-809

PM2.5 Cyclone

BX-596

AT/BP Sensor

(or BX-592)

Inlet Support

Struts

8112

Inlet Tube

8’ standard

BX-801

Roof Flange

Enclosure

Roof

BX-827 or 830

Smart Heater

with insulation

Mounting

Bench or Rack

2”

2 Meters

6.5 feet

adds

14.0”

adds

19.0”

BAM-1020

With Medo

vacuum pump or

equivalent

8” min. clearance

3 to 4 feet typical

5’ typical

BAM 1020

MET ONE INSTRUMENTS

Typical BAM-1020 Installation in a walk-in shelter

Pipe Insulation

(recommended)

BAM 1020-9800 Manual Rev W.docx Page 16

BX-802

PM10 Head

BAM 1020

MET ONE INSTRUMENTS

BX-806, BX-

807, BX-808

or BX-809

PM2.5 Cyclone

BX-596

AT/BP Sensor

(or BX-592)

27” Inlet Tube

2”

-Total Height-

6.6 ft (2.0 meters)

without cyclone

7.0 ft (2.1 meters)

with cyclone

adds

14.0”

adds

19.0”

15.5”

27” typical

Inlet tube

Mounting

Rack

BX-902 or 903

Environmental

Enclosure

BX-126

Vacuum Pump

or equivalent

BX-827 or 830

Smart Heater

with insulation

8119 Inlet

Seal

Typical BAM-1020 Installation in a BX-902 mini enclosure

BAM 1020-9800 Manual Rev W.docx Page 17

12.25”

BAM 1020

MET ONE INSTRUMENTS

14.25”

19”

17”

120 VOLTS

16”

5”min. rear clearance

74mm (2 15/16 “)

from front face of BAM

14mm (9/16”)

from center

CL

9.25”

3.5”

FRONT

BACK

TOP

BAM-1020 mounting dimensions

71mm (2 13/16 “)

from front of rack

Lifting Notes:

The main unit weighs slightly over 50 lbs,

with the center of mass near the front of

the BAM-1020. Lift by the rack rails or by

the bottom corner bracket. Observe

proper lifting and carrying techniques.

BAM 1020-9800 Manual Rev W.docx Page 18

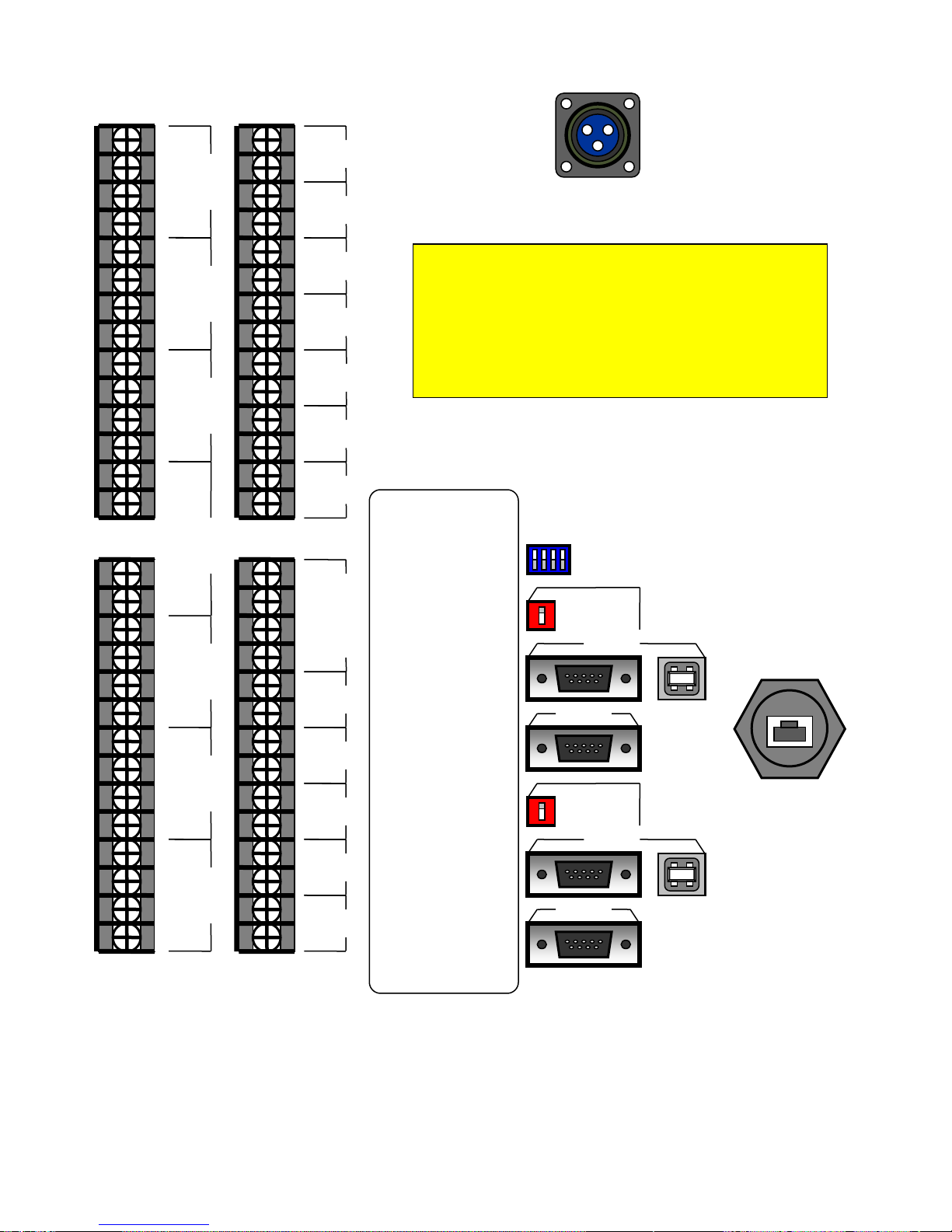

RELAY 1 NC

COMMON

COMMON

RELAY 1 NO

COM 3

REPORT

PRINTER

RS-232

OPTION

SWITCH

1 2 3 4

TELEMETRY

FAULT

NO VOLTAGE

SIGNAL

COMMON

POWER

ID

CHAN 1

SIGNAL

COMMON

POWER

ID

SIGNAL

COMMON

POWER

ID

SIGNAL

COMMON

POWER

ID

SIGNAL

COMMON

POWER

ID

SIGNAL

COMMON

POWER

ID

SIGNAL

COMMON

POWER

ID

EXTERNAL

RESET

NO VOLTAGE

+

EXTERNAL

RESET VOLTAGE

-

TAPE

FAULT

INVALID

DATA

MAINTENANCE

FLOW

FAULT

PUMP

CONTROL

POWER

FAIL

+

VOLTAGE

OUTPUT

-

CHASSIS

GROUNDS

+

CURRENT

OUTPUT

-

CHAN 2

CHAN 3

CHAN 5

CHAN 6

CHAN 7

CHAN 4

RS232

POLARITY

C1 NORMAL

C2 REVERSE

REPORT

POLARITY

C1 NORMAL

C2 REVERSE

SW1 OFF= 0-1V

SW1 ON= 0-10V

SW2 OFF= 0-16mA

SW2 ON= 4-20mA

SIGNAL

COMMON

POWER

SIGNAL

POWER

COMMON

NC

COMMON

NO

POWER

ID

SIGNAL 1

COMMON

SIGNAL 2

CHAN 8

CHAN 9

CHAN 10

RELAY 2

SMART

HEATER

Notes About Expanded Digital Ports:

There are several generations of the BAM-1020 digital port

configurations. Older units do not have the

REPORT, COM 3,

USB, or Ethernet

ports. The optional BX-965 Report Processor

back panel adds and enabled these data ports. Starting in 2012,

all units have these physical back panel connections, but they

are

not enabled unless the optional BX-965 daughter board

is installed inside the BAM

. Contact technical service for

further details.

BAM-1020 Rear Panel Connections

ETHERNET

BAM 1020-9800 Manual Rev W.docx Page 19

2.6 BAM 1020 Power and Electrical Service

The BAM 1020 uses internal 120V AC motors for the tape control system. The power supply

is factory-wired to run on either 110-120V or 220-240V, and either 50Hz or 60Hz. The

external vacuum pump and inlet heater are also AC powered and voltage-specific, and

should match the voltage setting of the BAM 1020. Note: The pump power cord is hardwired,

and may need to be replaced or adapted to match local outlet types outside of North

America.

Warning: Your shelter and/or electrical service must be wired for the correct voltage and

frequency in accordance with local electrical codes. Running the BAM 1020, vacuum pump,

or inlet heater on incorrect line voltage or frequency will cause improper operation.

The current draw of the system varies considerably depending on optional accessories and

environmental conditions. A dedicated 15 Amp electrical circuit is generally adequate to run a

single complete BAM 1020 system, unless a large air conditioner is on the same circuit.

Consult a qualified electrician if unsure. A summary of some worst-case loads is given below:

Model

Description

Amps

Wattage

BAM 1020

BAM 1020 only, 120V, worst case with tape transport motors running.

0.17A

20W

BX-126

Medo Linear Piston Pump, 120V, 60Hz, at 16.70 L/min through clean tape.

1.25A

150W

BX-121

Gast Rotary Vane Pump, 120V, 60Hz, at 16.70 L/min through clean tape.

4.44A

530W

BX-122

Gast Rotary Vane Pump, 230V, 50Hz, at 16.70 L/min through clean tape.

2.30A

530W

BX-827

Smart Inlet Heater, 120V, 60Hz, running at 100% high RH duty cycle.

0.85A

100W

BX-830

Smart Inlet Heater, 230V, 50Hz, running at 100% high RH duty cycle.

0.76A

175W

BX-902B

Shelter One Mini Shelter, 120V, worst case with shelter heater ON

4.2A

500W

BX-903

Ekto Mini Shelter, 120V, 2000 BTU air conditioner.

7.4A

586W

BX-904/906

Ekto Mini Shelter, 120V, 4000 BTU air conditioner.

13.5A

1172W

Notes:

•The BAM transport motors only run for a few seconds each per hour. Quiescent BAM current is 0.1A.

•The vacuum pump runs for either 42 or 50 minutes per hour. Startup inrush current is higher.

•Smart Heater wattage drops to idle at 20% (120V) or 6% (230V) when filter RH is below 35%.

•The BX-902B shelter heater is usually off whenever shelter temp is over 40 degrees F, and can be disabled.

•Values are based on measurements or best available information. Additional information is available from Service.

Fuses: There are two 5x20mm, 3.15A, 250V fuses located inside

the BAM 1020 power switch module on the back of the BAM

1020. They can be accessed by prying open the top of the small

cover surrounding the switch. The power cord must be removed

in order to open this cover.

Power Outages and Battery Backup: Any momentary AC

power outages will reset the BAM 1020 CPU and prevent data

collection for the sample hour. The BAM 1020 may be plugged

into a PC-style uninterruptible power supply (UPS) battery back-

up unit to prevent this. A UPS of at least 300 Watts is usually

sufficient. The vacuum pump does not need to be connected to the UPS, because the BAM

1020 can compensate for short pump flow outages of less than 1 minute duration. If the

pump is to be backed up, then a much larger UPS wattage is required.

Chassis Ground: Connect one of the terminals marked “CHASSIS” on the back of the BAM

1020 to an earth ground point using the green/yellow ground wire supplied with the BAM

1020. A copper earth-ground rod is recommended. The chassis ground is primarily for added

RFI/EMI noise immunity. The power cord also uses the standard electrical safety ground.

BAM 1020-9800 Manual Rev W.docx Page 20

3 INITIAL SETUP OF YOUR BAM 1020

This section describes the process for setting up and configuring your BAM 1020, as well as

the basic steps required to put the BAM 1020 into operation. Some of the topics in this

section will direct you to other sections of this manual for more detailed information. It is

assumed that the BAM 1020 is already installed and sited as described in Section 2. In some

cases it is useful to first set up the BAM 1020 on a test bench before deployment or

installation in order to explore the functions and perform setups. The following steps for

starting up your BAM 1020 are described in this section:

1. Power on and warm up.

2. Familiarize yourself with the user interface.

3. Load a roll of filter tape.

4. Perform a Self-Test.

5. Set the real-time clock, and review your SETUP parameters.

6. Perform a leak check and a flow check.

7. Return to the top-level menu and wait for automatic start at the top of the hour.

8. View the OPERATE menus during the cycle.

3.1 Power Up

The power switch is located on the back of the BAM 1020 above the power cord. Verify that

the BAM 1020 is plugged in to the correct AC voltage, and that any electrical accessories are

correctly wired before powering it up. (Section 2.6) When power is switched on, the main

menu screen should appear after a few seconds as shown below. The screen may flash an

error indicating that there is no filter tape installed. Note: Units running revision 3.1 or earlier

firmware will display a slightly different main menu screen.

3.2 Warm-up Period

The BAM 1020 must warm up for at least one hour before valid concentration data can be

obtained. This is because the beta detector contains a vacuum tube which must stabilize.

This also allows the electronics to stabilize for optimal operation. This applies any time the

BAM 1020 is powered up after being off for more than a moment. Instrument setups and filter

tape installation can be performed during this warm up time. You may consider discarding the

first few hours of data after the equipment is powered up.

3.3 The Main Menu and Using the Keypad and Display

When the BAM 1020 is powered up it will display the main menu (top level menu) on the LCD

display. This menu is the starting point for all functions of the BAM 1020 user interface. Note:

The main menu will have a slightly different layout on BAM 1020 units configured in the dual-

unit PM-coarse configuration.

Table of contents

Other Met One Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Optika Italy

Optika Italy IM Series instruction manual

Thermo Scientific

Thermo Scientific CTS Xenon user guide

ERL

ERL tesla lite user manual

IKA

IKA Mini MR standard operating instructions

Four E's Scientific

Four E's Scientific Ironman III operating instructions

LW Scientific

LW Scientific BioVID instruction manual