Metal-Fach Z562 User manual

BALER

Z562

INSTRUCTIONS MANUAL –PART I

TRANSLATION OF THE ORIGINAL INSTRUCTIONS MANUAL,

REV. IV

JULY 2018

Instructions manual No. Z562-04-167/2013

EC DECLARATION OF CONFORMITY

The

undersigned

Jacek Kucharewicz, Chairman of the Board,

hereby declares, with full responsibility, that the complete machine

NAME

1.1.

Brand (trading name of manufacturer)

Metal-Fach

1.2.

Type

Z562

1.2.1.

Variant

1.2.2.

Version

1.2.3.

Name(s) (if any)

1.3.

Category, Subcategory and Vehicle-

Speed Indicator

S1a

1.4.

Company name and

manufacturer’s address

Metal-Fach sp. z o.o.

ul. Kresowa 62

16-100 Sokółka, Poland

1.4.2.

Name and address of the authorised

representative of the manufacturer (if

applicable)

1.5.1.

Location of the rating plate of the

manufacturer

On the front part of the main

frame of the machine

1.5.2.

Method used to fix the rating plate of

the manufacturer

Bonded

1.6.1.

Location of the vehicle

identification number on the

chassis

On the front part of the main

frame of the machine

2.

Machine-identification number

complies with all the appropriate regulations of Directive 2006/42/EC and the Regulation of the

Minister of the Economy dated 21 October 2008 on the principal requirements for machines (Journal

of Laws of 2008, No. 199, item 1228, as amended)

The following harmonised standards were applied to assess the compliance

PN-EN ISO 4254-11 2012, PN-EN ISO 4254-1: 2013, PN-EN ISO 12100: 2012,

PN-EN ISO 13857: 2010

and standards PN-ISO 36001998, PN-ISO 11684:1998 and the Regulation of the Minister of

Infrastructure dated 31 December 2002 on the technical conditions of vehicles and the range of their

essential equipment (Journal of Laws of 2003, No. 32, item 262, as amended).

Safety Testing Report No. MF/4/2010

This declaration of conformity EC becomes null and void if the machine is changed

or reconstructed without the manufacturer's consent.

Sokółka

(Place)

01/12/2010

(Date)

Jacek Kucharewicz

(Signature)

Chairman of

the Board

(Position)

4INSTRUCTION MANUAL –BALER Z562

Machine Data

Type of machine

Baler

Type designation

Z562

Serial number(1):

Machine manufacturer

METAL-FACH Sp. z o.o.

ul. Kresowa 62

16-100 Sokółka

Phone (0-85) 711 98 40

Fax (0-85) 711 90 65

Seller

Address

Phone/Fax

Delivery date

Owner or

user

Name

Address

Phone/Fax

(1) The data is located on the machine-rating plate located on the front part of the

machine main frame

INSTRUCTION MANUAL –BALER Z562 5

INTRODUCTION TO THE MANUAL

The information included in the instructions manual is valid as of the date of issue. The

manufacturer reserves its right to make design changes to machines, and, due to this fact,

some values or illustrations might not correspond to the actual state of the machine supplied

to the user. The manufacturer reserves its right to make design changes without changing

these instructions. The instructions manual is included in the basic equipment of the machine.

The user is obliged to read the contents of this manual before commencing operations and to

meet the recommendations included in it. It will ensure safe operation and trouble-free machine

operation.

The machine was constructed in compliance with the standards in force and the current

legal provisions. The manual describes the basic safety and operation principles of the baler

manufactured by Metal-Fach, type Z562.

The substantive obligations of the manufacturer are presented on the guarantee card,

which includes the complete, and currently in-force, regulations on guarantee coverage.

If the information included in the instructions manual proves to be incomprehensible,

you should address the seller from whom the machine was purchased, or the manufacturer

directly, for assistance.

The spare-parts catalogue functions as a separate list, and is enclosed in the form of a

CD in machine purchase, and also is available on the Manufacturer’s website

www.metalfach.com.pl .

This instructions manual, according to the Act of 4 February 1994 on copyrights and

related Laws (Journal of Laws of 1994, No. 2017, item 880), is protected by copyright. It is

prohibited to copy and distribute the contents and figures without the consent of the proprietor

of the copyright.

The warranty card, together with the warranty terms, is attached to this Instructions

Manual as a separate document.

Manufacturer’s address

Metal-Fach sp. z o.o.

ul. Kresowa 62

16-100 Sokółka

Telephone

Phone (0-85) 711 98 40

Fax (0-85) 711 90 65

6INSTRUCTION MANUAL –BALER Z562

The symbols used in these instructions.

Hazard-warning symbol. This indicates the presence of a serious-hazard

condition, which, if not avoided, can result in death or serious injury. The

symbol warns against the most-dangerous situations.

The symbol pointing to especially important information and

recommendations. Non-compliance with the described

recommendations poses a serious threat of damage to the machine due

to its incorrect operation.

The symbol indicating the possibility of the presence of a hazard which,

if not avoided, can result in death or serious injury. This symbol indicates

a lower level of risk of injury than the symbol including the word

“DANGER”.

The symbol indicating useful information.

The symbol indicating service operations which should be performed

periodically.

DANGER

WARNING

WARNING

INSTRUCTION MANUAL –BALER Z562 7

Table of contents

PART I

1 General Information....................................................................................................11

1.1 Introduction .....................................................................................................11

1.2 Baler Identification...........................................................................................11

1.3 Baler Intended Use..........................................................................................13

1.4 Baler Design....................................................................................................14

1.5 The Technical Specifications Of The Baler......................................................15

1.6 General Safety Principles................................................................................16

1.6.1 Safety Signs ....................................................................................................24

1.6.2 Warning Signs .................................................................................................24

1.7 Baler Transport................................................................................................31

1.7.1 Load Transport ................................................................................................31

1.7.2 Road Traffic Participant...................................................................................33

1.8 Baler Cleaning.................................................................................................34

1.9 Baler Storage...................................................................................................35

1.10 Risk..................................................................................................................35

1.10.1 Residual-Risk Description................................................................................35

1.11 Residual-Risk Assessment..............................................................................36

1.12 Dismantling And Disposal................................................................................36

1.13 Accessories .....................................................................................................36

2 The First Start-Up .......................................................................................................37

2.1 The First Start-Up Of The Baler.......................................................................37

3 Using The Machine....................................................................................................40

3.1 Foreword .........................................................................................................40

3.2 Attaching The Baler To A Tractor....................................................................40

3.2.1 Connecting With The Lower Tractor Transport Hitch.........................................40

3.2.2 Coupling The Baler With The Rear PTOFF Shaft............................................42

3.2.3 Hydraulic System Installation...........................................................................43

3.2.4 Lighting Connection.........................................................................................43

3.2.5 Connecting The Control System......................................................................44

3.2.6 The Braking System ........................................................................................44

3.2.7 Drive Disconnection.........................................................................................46

8INSTRUCTION MANUAL –BALER Z562

3.3 Operational Check...........................................................................................47

3.4 Preparing The Machine For Operation............................................................47

3.4.1 Mounting And Operating The Twine-Binding Unit ...........................................47

3.4.2 Mounting And Operating The Net-Binding Unit ...............................................48

3.4.3 The Ensilage Applicator...................................................................................50

NAME AND ABBREVIATION INDICES......................................................................53

ALPHABETICAL INDEX .............................................................................................54

INSTRUCTION MANUAL –BALER Z562 9

PART II

3.5 Control-Panel Operation...................................................................................8

3.5.1 Switching on the panel ...................................................................................9

3.5.2 Switching Off The Panel...............................................................................10

3.5.3 Selecting The Bale-Binding Option...............................................................10

3.5.4 Delay-Time Change......................................................................................10

3.5.5 Resetting ......................................................................................................10

3.5.6 Zeroing The Workday Counter.....................................................................11

3.6 Hydraulic Installation.......................................................................................11

3.6.1 The Standard Hydraulic System...................................................................12

3.6.2 The Optional Hydraulic System....................................................................14

3.7 The Electrical System.....................................................................................15

3.8 Windrow Collection.........................................................................................16

3.8.1 The Principles Of Operation.........................................................................16

3.8.2 Operations Description.................................................................................16

3.8.3 Straw Collection............................................................................................18

3.9 Removing The Accumulated Material.............................................................18

3.9.1 Removing the Accumulated Material............................................................19

3.9.2 Removing the Accumulated Material on The Rotor......................................19

3.10 Ending Operations........................................................................................19

4Maintenance and Adjustment.................................................................................20

4.5 Pick-Up-Wheels Adjustment...........................................................................22

4.6 Adjusting The Drive-Chain Tensioning (Every 10 Hrs Of Work).....................22

4.6.1. Adjusting The Pick-Up Chain Tension Of The Baler To The Feeding Roller23

4.7 Pick-Up Cam Adjustment................................................................................24

4.8 Replacing The Locking Bolt In The Pick-Up...................................................26

4.9 Replacing The Locking Bolt In The Supplying Unit ........................................27

4.10 Adjusting The Degree Of Compaction............................................................28

4.11 Adjusting The Twine-Binding Device..............................................................30

4.11.1 Sharpening The Twine Blades....................................................................30

4.12 Adjusting The Net-Binding Device...............................................................30

4.13 Adjusting The Cover Stop Valve..................................................................31

4.14 Adjusting The Lock......................................................................................32

4.15 Sharpening The Blades...............................................................................33

4.16 Transmission-Fluid Exchange (Once A Year) .............................................35

4.17 Lubrication...................................................................................................36

4.17.1Lubricating The Pick-Up ..............................................................................38

4.17.2The Automatic Lubrication System For Chains ...........................................40

4.17.3Lubricating the Bearings..............................................................................42

4.18 Tyres Inspection (Every 30 Days Of Work)....................................................42

10 INSTRUCTION MANUAL –BALER Z562

5Possible Faults.......................................................................................................43

NAME AND ABBREVIATION INDICES .................................................................46

ALPHABETICAL INDEX.........................................................................................47

NOTES...................................................................................................................50

INSTRUCTION MANUAL –BALER Z562 11

1 General Information

1.1 Introduction

THIS USER MANUAL IS PART OF THE BASIC ACCESSORIES

OF THE BALER

The machine may be operated only by persons who have read this Instructions Manual,

andknow thedesignand functioningofthebaler, andthefunctioning ofthetractorto be worked

with. To operate the machine safely, adhere to and follow all the instructions set out in this

Instructions Manual. Adhering to the guidelines of the Instructions Manual ensures the User

works safely and the machine service life is longer.

1.2 Baler Identification

The identification data is on the rating plate located on the front part of the frame. The

rating plate shows the data used to identify the machine, i.e. code, serial number, year of

manufacture, and pressure on the hitch.

Figure 1. Example of a rating plate

WARNING!

Check the condition and legibility of the rating plate. In the case it is

destroyed report at the service.

WARNING!

It is prohibited to enter public roads with a bale-wrapping press without the

rating plate or with an illegible rating plate.

WARNING

WARNING

12 INSTRUCTION MANUAL –BALER Z562

Figure 2. Location of the nameplate on the machine

Keep the instructions in a safe place, where it should be available to the user and the

service technician through the entire life cycle of the machine.

If selling the machine to another user it is obligatory to hand over the instructions

manual. It is recommended that the seller of the baler file the instructions-manual receipt

confirmation by the purchaser when the manual is submitted with the machine to the new user.

On purchase, check the compliance of the serial number on the

nameplate of the machine against the number shown in the user manual

and warranty card.

The manual should be retained for future users.

On purchase, check the compliance of the serial number on the

nameplate of the machine against the number shown in the user manual

and warranty card.

Rating plate

INSTRUCTION MANUAL –BALER Z562 13

If the instructions manual is damaged or lost, notify the service centre and provide the

manual number or the data from the rating plate to receive a new copy of the baler-operation

manual. You can also download the instructions manual from the website

www.metalfach.com.pl .

Before you start the machine after a longer period of stoppage, carefully read the

information on use and safety contained in this manual.

You must read all parts of the instructions manual, and, if necessary, contact a local

Metal-Fach distributor. The contact details of the distributors and service centres are published

on www.metalfach.com.pl. The machine should be operated, serviced and repaired by people

familiar with its specific characteristics and acquainted with the rules of conduct in terms of

occupational safety.

The manufacturer of the machine shall not be held liable for any damage arising from

non-compliance with the principles contained in this instructions manual!

USE ORIGINAL SPARE PARTS ONLY!

If you need any spare parts, call a local Metal-Fach distributor or directly Metal-Fach in

Sokółka.

1.3 Baler Intended Use

The Z562 baler is designed for picking up the material raked into windrows by rolling

them into bales of hay with a humidity of up to 20%, and green fodder with a humidity of up to

60%, and straw.

All the working actions must be by one person - the operator seated in the tractor cab.

Using the baler for any purpose other than that designated shall be considered contrary

to the intended use. Metal-Fach shall have no responsibility for damage caused to persons or

animals, or for any other damage resulting from the improper use of the machine.

14 INSTRUCTION MANUAL –BALER Z562

1.4 Baler Design

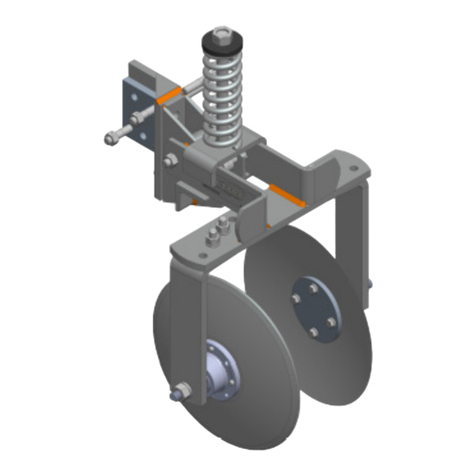

Figure 3. Z562 baler design

1 –Drawbar

2 –PTOFF shaft

3 –Hydraulic hoses

4 –Support foot

5 –Pick-up

6 –Collector

7 –Rolling roller

8 –Twine-binding unit

9 –Chain-and-rod conveyor set

10 –Control panel

11 –Ground wheel

12 –Housing

13 –Indicator

14 –Clamp

INSTRUCTION MANUAL –BALER Z562 15

The front section of the baler features the pick-up (5) which collects the windrows. It

works in conjunction with the collector (6) which directs the picked-up windrow onto the rolling

rollers (7), where compaction and rolling takes place. The activity of picking up the windrow,

rolling and unloading bales is shown in Figure 25. Achieving a pre-set degree of compaction

is signalled by the digital control (13) when it indicates the red area, and an acoustic signal on

the control panel (10) in the operator's cab. After the pre-set compaction degree is achieved,

the twine-binding unit (8) ties the bale with twine. For net bale binding applications, you must

activate this process manually in the control panel (10).

The baler coupling with the tractor is achieved by means of the drawbar (1), PTOFF

shaft (2) and hydraulic hoses (3). The support foot (4) is used for supporting the machine in

the stationary position, and for coupling and detaching the machine from the tractor. The baler

is fitted with ground wheels (11) for riding behind the tractor.

1.5 The Technical Specifications Of The Baler

Table 1 The technical specification of the baler

No.

Contents

General information

1.

Machine Type

Baler

2.

Manufacturer

METAL-FACH Sp. Z o.o.

ul. Kresowa 62, 16-100 Sokółka,

3.

Nameplate Location

Front bar

4.

Number Stamp Location

Front body, right side

5.

Type

Z562-0…

Z562-1…

Z562-2…

Dimensions

6.

Length [mm]

3900

4000

4000

7.

Width [mm]

2470

2470

2470

8.

Height [mm]

2050

2050

2050

Weights

9.

Max. weight [kg]

2350

2450

2750

Technical data

10.

Pressure on the hitch [kN]

4.7 kn

11.

Rolled-bale dimensions

(diameter/width) [mm]

1200/1200

12.

Bale weight [kg]

100-600

13.

Efficiency [bales/h]

Max. 20

Max. 40

Max. 40

14.

Rolling assembly –chamber type

Cylindrical, fixed chamber

15.

Bale density

Variable

16.

Drawbar-eye diameter [mm]

44

17.

Number of operators

1 (tractor operator)

Requirements for tractor

18.

Power demand [kW/HP]

35/48

50/68

70/95

19.

Power demand on the power

take on [kW/HP]

Ca. 25/34

Ca. 40/55

Ca.

60/81

20.

PTOFF rotational speed [rpm]

540

21.

Connected with the tractor by

Lower transport hitch

22.

Hydraulic system

1 unidirectional manifold,

1 dual-directional manifold (for baler with blades –

optional equipment)

16 INSTRUCTION MANUAL –BALER Z562

23.

Required pressure in the tractor’s

hydraulic system [Atm./MPa]

140/14

24.

Electrical system [V]

12

25.

Plug

“Lighter” type

26.

Transport speed [km/h]

40

Pick-up

27.

Pick-up type

Drum and tine, 4-bars

28.

Pick-up width [mm]

1800

29.

Max. distance between the extreme

pick-up tines [mm]

1520

30.

Number of pick-up tines

44

31.

Working-height adjustment

Mechanical, 5 settings

Binding

32.

Binding unit

Automatic binding with a single twine, net-

binding (optional)

33.

Twine-binding-density adjustment

3-step

32.

Number of net rolls

1

Tyres

33.

Size

400/60 –15.5

34.

Load-capacity and speed index

(14 PR) 145 A8

35.

Pressure in tyres [kPa]

250

Power take-off shaft (PTOFF)*

36.

Type

Standard

Wide-angle

37.

Transferred torque [Nm]

2000

1860

38.

Minimum length [mm]

1410

1210

39.

Type of coupling

Shear

Shear

40.

Catalogue No.

60025/602.K6-1/5NW

60064/S602.K61-1/5NW

Wheel-Braking System (optional equipment)

Service brake

41.

Type

Mechanical, drum brake

42.

Control

Hydraulic

(two-hose hydraulic system)

Parking brake

43.

Type

Mechanical, drum brake

44.

Control

Manual, via crossed helical gear

* The wide-angle shaft is an optional accessory for the baler

1.6 General Safety Principles

Before starting the baler operation, read this instructions manual to avoid risks. Apart

from the information included in the instructions manual all the principles and local legal

regulations related to the safety of work and utilisation of the machines should be met.

The baler was designed and made to provide maximum safety of use.

Before first start-up, read all the chapters of the instructions manual carefully.

Metal-Fach shall not be held liable for any damage arising from non-compliance with

the principles contained in this baler-instructions manual.

INSTRUCTION MANUAL –BALER Z562 17

WARNING!

Before starting the operation, check the machine for correct

functioning, completeness, and the proper securing of its moving parts.

The company shall also waive all responsibility for any damage arising from the

improper use of the machine or any unauthorised changes made to the machine.

Check the condition of the machine regularly. Pay special attention to the correct

functioning of all safety components. All protective guards must be installed according to the

manufacturer's instructions.

You should take note of all the warning signs indicated in the manual and present on

the machine. All signs which warn about risks present on the machine must be visible at all

times. Please ensure that the safety signs are kept clean at all times and, if damaged or barely

legible, they are replaced. You can find a list of safety signs with their locations in Section

WARNING!

The baler may be operated only by qualified persons who have read

this instruction manual.

DANGER!

Take particular care while getting in and out of the tractor.

WARNING!

Never leave the tractor unattended when its engine is running.

WARNING!

Never leave the machine unattended during operation.

WARNING

WARNING

WARNING

WARNING

DANGER

18 INSTRUCTION MANUAL –BALER Z562

WARNING!

Noise –the equivalent A-weighted emission sound-pressure level

(LpA) must not above 76 dB

DANGER!

During work, it is strictly forbidden to go near the rotating components,

to touch the moving parts, or to reach into them.

Keep your face, hands and legs away from all rotating parts. Keep at a

safe distance at all times.

Do not use tubes, hoses or other parts of the machine as handrails.

Carrying persons or animals on the machine or tractor is strictly

forbidden.

WARNING!

Always keep oils and lubricants out of the reach of children. Always

carefully read the warnings and precautions placed on packaging. Do

not allow the contact of skin with any hazardous substances. Wash

yourself thoroughly after you have used the above-mentioned

hazardous substances.

WARNING!

Working on pressurised hoses is prohibited, as it can cause pollution

or serious injuries.

WARNING

WARNING

WARNING!

During maintenance and repair works, wearing protective clothing,

safety gloves, protective footwear and goggles is mandatory.

WARNING

DANGER

WARNING

INSTRUCTION MANUAL –BALER Z562 19

WARNING!

Wear well-fitting clothes which cannot be caught by movable elements,

and boots with non-slippery soles. In the event of the risk of item ejection

wear a protective helmet with eye protection.

DANGER!

The machine’s working area is considered a danger zone. Prior to

starting up the machine make sure that there are neither people nor

animals around in the close proximity of the machine. If anyone appears

near the machine the baler must be stopped immediately and you must

make all unauthorised persons leave the zone. Never stop close to or

just under terraces, or balconies, or in front of open rooms or any kind of

platform where there might be people or animals. The baler operator is

responsible for all kinds of damages caused by the machine during

operation.

WARNING!

The operation of the baler without mounted and closed guards which

protect the moving parts is strictly prohibited.

WARNING!

It is not allowed to leave farming equipment on slopes or other inclines

without securing the vehicle against accidental rolling away.

WARNING!

Prior to each starting-up of the baler, check the machine condition,

completeness, and mounting of the guards.

WARNING!

Hydraulic connections must be always kept clean. After use the plastic

cover supplied on the machine purchase.

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

20 INSTRUCTION MANUAL –BALER Z562

Check, and if necessary replace, any damaged tube guards and fixing. All

moving tube guards must be replaced every 5 years. Hydraulic lines must be

replaced every 6 years. You must record the date of the latest replacement. Before

putting pressure in the hoses, check if all the hoses and their fixing are air-tight. In

order to check that there are no leaks from the hoses use blotting paper or paper.

DANGER!

All the adjustment, repair and service works should be carried out with

the tractor engine off, making sure beforehand that it is protected in the

correct way against accidental starting up.

DANGER!

Prior to starting and during the collecting of swathes, make sure that

there are no bystanders present, especially children.

WARNING!

Take special care during operation on inclined areas. Pay special attention

to the possibility of bales’ rolling down.

WARNING!

It is strictly forbidden to operate the baler under raised and unprotected

machine units.

WARNING

DANGER

DANGER

WARNING

WARNING

WARNING!

Prior to each baler start-up and ride on public roads, check the

correctness of the machine connection with the tractor, the tightness of

the wheels, and the correct drawbar and tractor connection.

Other manuals for Z562

2

Table of contents

Other Metal-Fach Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Yetter

Yetter 2920-012A Operator's manual

Ferrari Costruzioni Meccaniche

Ferrari Costruzioni Meccaniche REMOWEED Operator's manual

Tume

Tume Draco 3000 user manual

Spearhead

Spearhead Q1200-OS Handbook & Parts Manual

Range Road

Range Road EcoPro300 Assembly manual

Little Cottage

Little Cottage Round Roof Chicken Coop Construction manual