Metal-Fach Z562 User manual

1

Thank you for choosing our Z562 baling press designed

for efficient operation.

The following manual will let you fully use the

advantages of our baling press and to optimise the bale

wrapping process.

The Manual contains a detailed table of contents

followed by descriptions which will allow to easily

identify the device and to make the best use of it.

The information regarding safety and comfort of

operation, description of coupling with a tractor,

technical service activities and storage conditions are

listed on the following pages of the manual.

A spare parts catalogue containing the list of the baling

press major components allowing for easy ordering

is attached to the Manual in a digital form on a CD.

A printed version of the catalogue can be purchased

at authorised service outlets or directly from the

manufacturer.

Both the manual and the spare parts catalogue contain

basic information on the product. The elements fitted to

the equipment may be slightly different than presented

in the manual.

The manufacturer reserves the right to introduce

changes without notice.

Legend

Warning:

This is a warning symbol and it indicates

that it is required to pay special attention

to the operator and bystanders'

safety requirements or safe operation

requirements.

Information:

This symbol indicates additional

information which allows to optimise

the device operation.

Environmental protection:

This symbol indicates the need to pay

special attention to environmental

considerations.

Cross-reference:

this symbol directs you to a page on

which detailed information on a given

subject is presented.

2

Table of contents

1 Baling press identification, general safety rules 3

1.1 Baling press identification 3

1.2 Z652 baling press construction 5

1.3 Z562 baling press characteristics 6

1.4 Z562 baling press dimensions 8

1.5 Location of symbols 9

1.6 Warning Symbols 12

1.7 General safety rules 13

2 Drive operation 15

2.1 Drive coupling 15

2.2 Disconnecting from the drive 17

3 Commissioning 17

4 Controls and ongoing adjustments 19

4.1 Location of the controls 19

4.2 Location of ongoing adjustment points 21

5 Baling press operation 29

5.1 Wrapping assembly 29

5.2 Hydraulic system 31

5.2.1 Standard hydraulic system 31

5.2.2 Optional hydraulic system 33

5.3 Electrical system 34

5.4 LP02 counter 35

5.4.1 LP02 counter system 35

5.4.2 Counter symbols 35

5.4.3 Connecting and commissioning of the counter 36

5.4.4 Counter operation 36

5.5 Wrapping 38

5.6 Finishing work 41

6 Periodical inspection 41

6.1 User inspection 41

6.2 Service checks 41

7 Authorised service 42

7.1 Warranty service 42

7.2 Ongoing maintenance 42

7.3 Ordering of spare parts 42

8 Press Transport 42

8.1 Transporting a load 42

8.2 Driving on public roads 43

9 Baling press storage 44

10 Hazards 45

10.1 Description of residual risks 45

10.2 Assessment of residual risks 45

11 Baling press disposal 46

12 Typical problems and troubleshooting 46

13 Accessories 47

14 Names and abbreviations 47

Warranty card 48

3

1 Baling press identication, general safety rules

1.1 Baling press identication

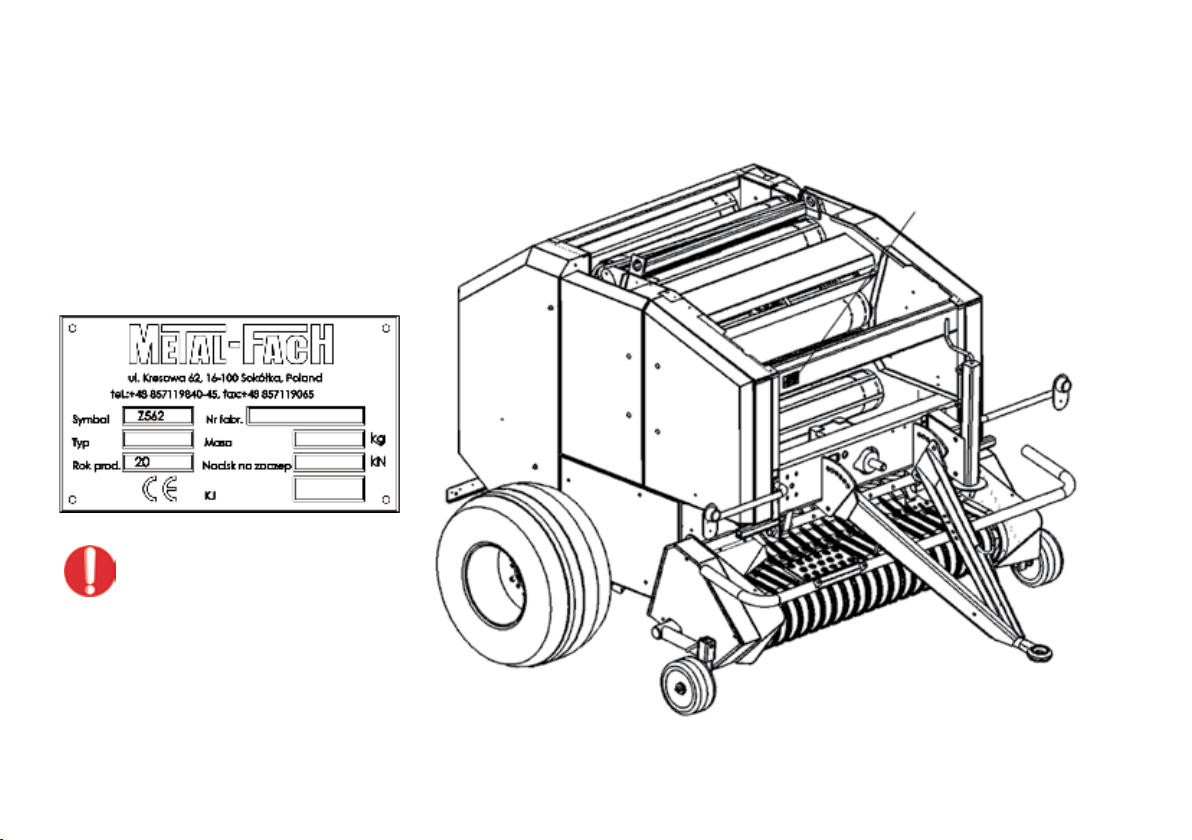

The baling press is identified by its nameplate securely

fastened to the front guard of the machine.

The information presented on the nameplate is shown

on the diagram below.

Dziękujemy za wybór naszej owijarki bel Z237

zaprojektowanej do efektywnej pracy.

Niniejsza instrukcja obsługi pomoże Państwu

w pełni wykorzystać zalety owijarki i jednocześ-

nie zoptymalizować proces owijania bel.

Instrukcja zawiera szczegółowy spis treści a po

nim opisy ułatwiające identyfikację i poznanie

owijarki.

Informacje na temat bezpieczeństwa i komfortu

pracy, opis agregowania z ciągnikiem, pracy,

czynności serwisowych i warunków magazynowa-

nia znajdują się na kolejnych stronach instrukcji.

Katalog części zamiennych zawierający wykaz

podstawowych części owijarki ułatwiający ich

zamawianie dołączony jest do niniejszej instruk-

cji w formie elektronicznej na płycie CD.

Katalog w formie papierowej możecie Państwo

nabyć w autoryzowanych punktach sprzedaży,

lub bezpośrednio u producenta.

Zarówno instrukcja obsługi jak i katalog części

zamiennych zawierają podstawowe informacje

o wyrobie. Poziom wykończenia i kompletacji

wyrobu może nieznacznie odbiegać od przedsta-

wionego w opracowaniu.

Producent zastrzega sobie prawo wprowadzania

zmian konstrukcyjnych bez uprzedzenia.

Legenda

Ostrzeżenie:

symbol ten ostrzega i wskazuje

na konieczność bezwzględnego

przestrzegania wymogów

bezpieczeństwa operatora, osób

postronnych, lub bezpiecznej

pracy wyrobu.

Informacja:

symbol ten wskazuje dodatkowe

informacje pozwalające optyma-

lizować pracę wyrobu.

Ochrona środowiska:

symbol ten zwraca uwagę na

konieczność zachowania wymo-

gów ochrony środowiska.

Odsyłacz:

symbol ten odsyła Państwa do

strony, na której umieszczono

szczegółowe informacje na dany

temat.

1

It is forbidden to drive the baling press

on public roads without its nameplate or

with an illegible nameplate.

When purchasing the machine check the serial number indicated in the Manual and the warranty sheet against the

serial number stamped on the nameplate.

Data plate

4

The manual consist a part of the Z562

baling press's equipment.

If the machine is sold to another user, it must be

supplied with the operating manual. It is advised that

the supplier has a confirmation stating that the manual

was transferred together with the machine, signed by

the buyer and filed.

Carefully read the operating

manual.

If the rules stated in this manual are complied with,

it will help prevent hazards and operate the machine

efficiently; it will also allow to retain the warranty

throughout the period granted by the manufacturer.

Detailed information on the structure, operating

principles,technologyandotherdetailsmaybeobtained

from authorised outlets and the press manufacturer.

It is forbidden for persons who have not

read the manual to operate the baling

press.

The baling press shall be operated according to its

intended use by coupling it with a tractor with the

nominal power exceeding 30-70 kW and towing power

class of at least 0.9 - 1.4 (depending on the variant),

equipped with a PTO (with six keys) and allowing for the

external use of the hydraulic power system.

The Z562 baling press is designed for gathering of

material raked into embankments into bales: hay

(humidity up to 20%) and silage (humidity up to 60%)

and post harvest straw and unloading the rolled bales

on the ground.

During operation, the operator is not subject to noise

which may cause the loss of hearing, as the noise level of

the machine does not exceed 70 dB (A) and the operator

works inside the tractor cabin.

During the operation of the baling press, the operator

is not subject to harmful vibration as the vibration level

transferred to the upper limbs does not exceed 2.5 m/

s2, and the vibration level transferred to the body is

lower than 0.5 m/s2and the operator is positioned in the

tractor's cabin.

Continuous and systematic care for control

and adjustment elements and compliance

with the machine‘s maintenance schedule

will ensure optimum and long operating

life.

The manufacturer recommends to clean

the following daily: net/cord wrapping

assembly, rolling shafts and the drive

(chains, sprocket wheels, bearing

housings).

Any unauthorised changes to the baling

press structureabsolvethe manufacturer

from all responsibility for the threats and

damage it may cause.

Grass and other papilionaceous plants prepared for

souring and wrapping should be mowed in the early

phase of heading (best done in the afternoon). On

the next day, after a few hours of drying, the mowed

materialshouldbegathered usingthewrapping presses.

Maximum bale compression must be maintained.

5

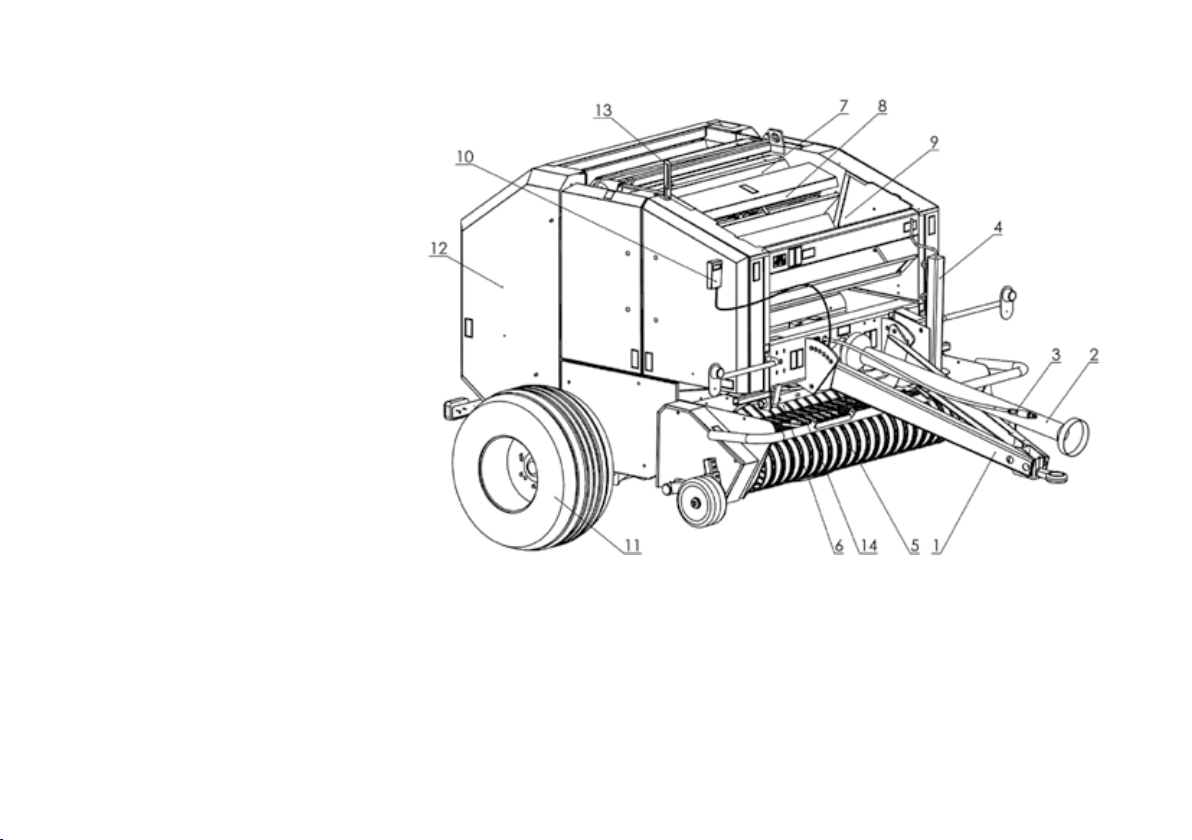

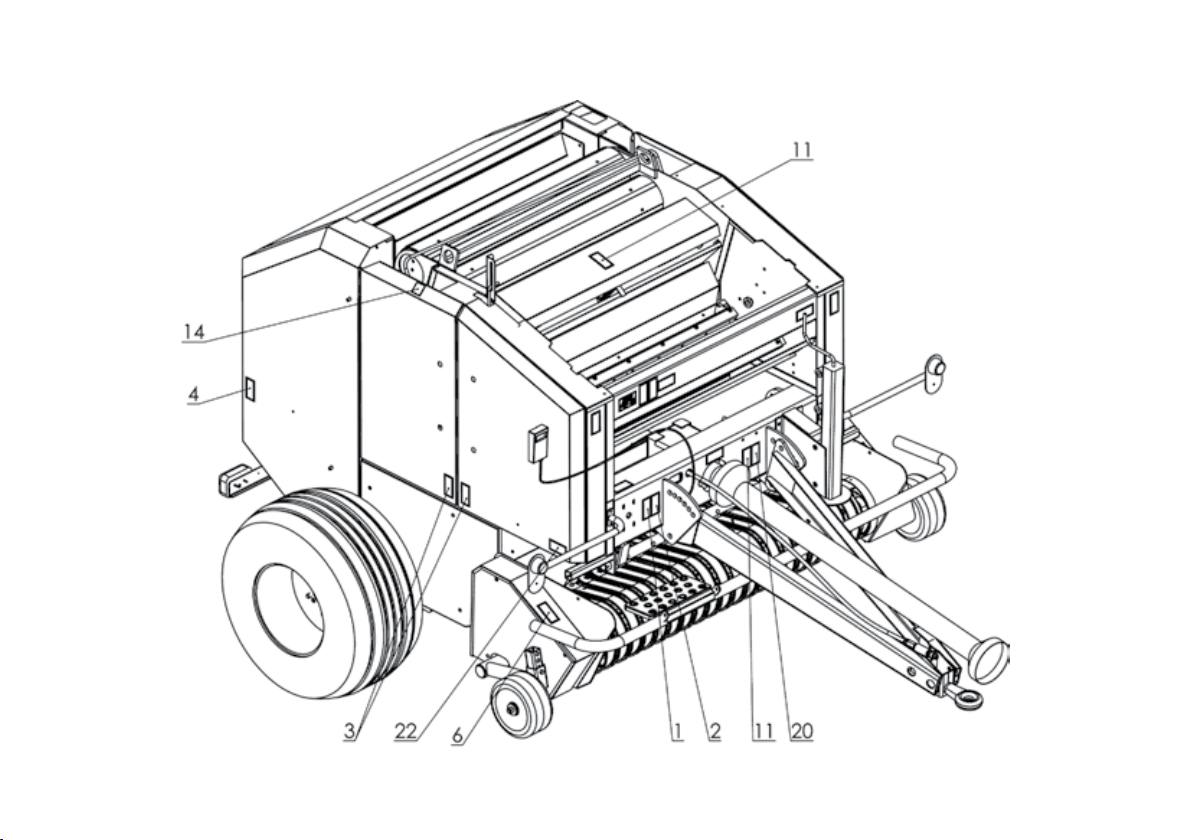

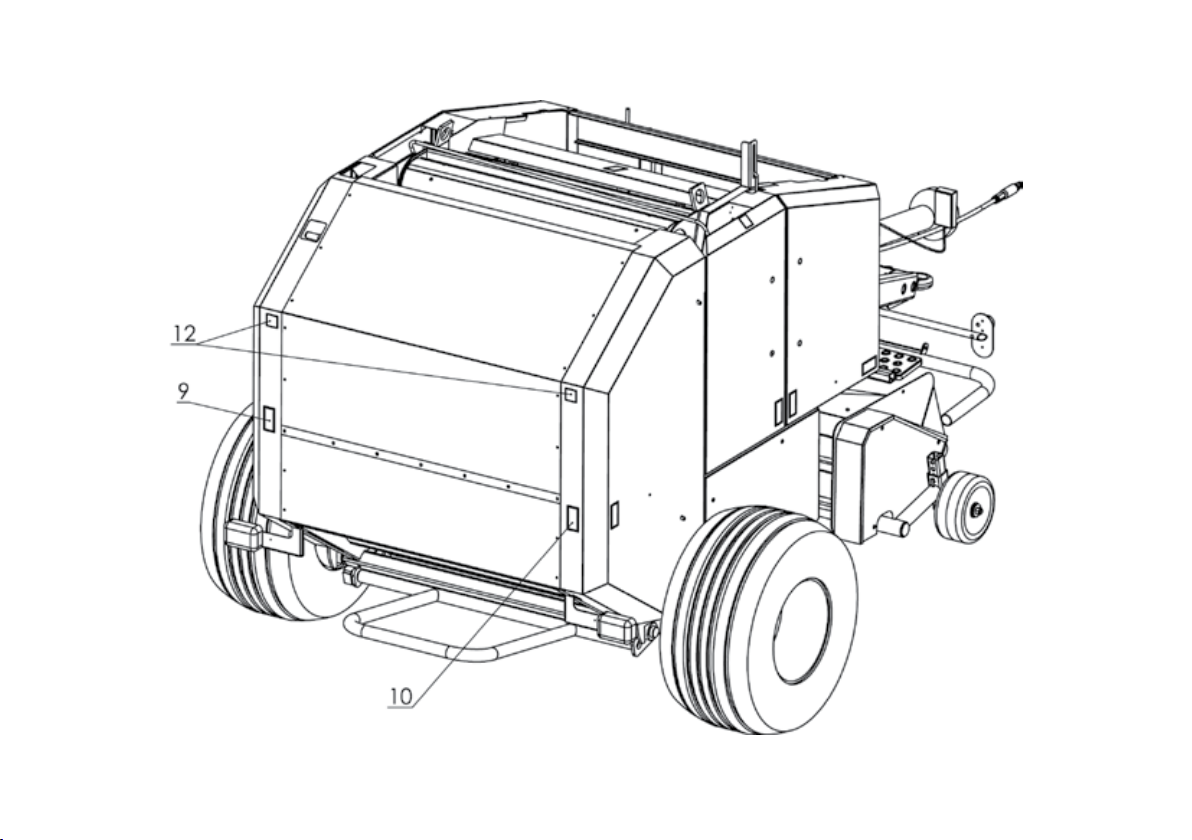

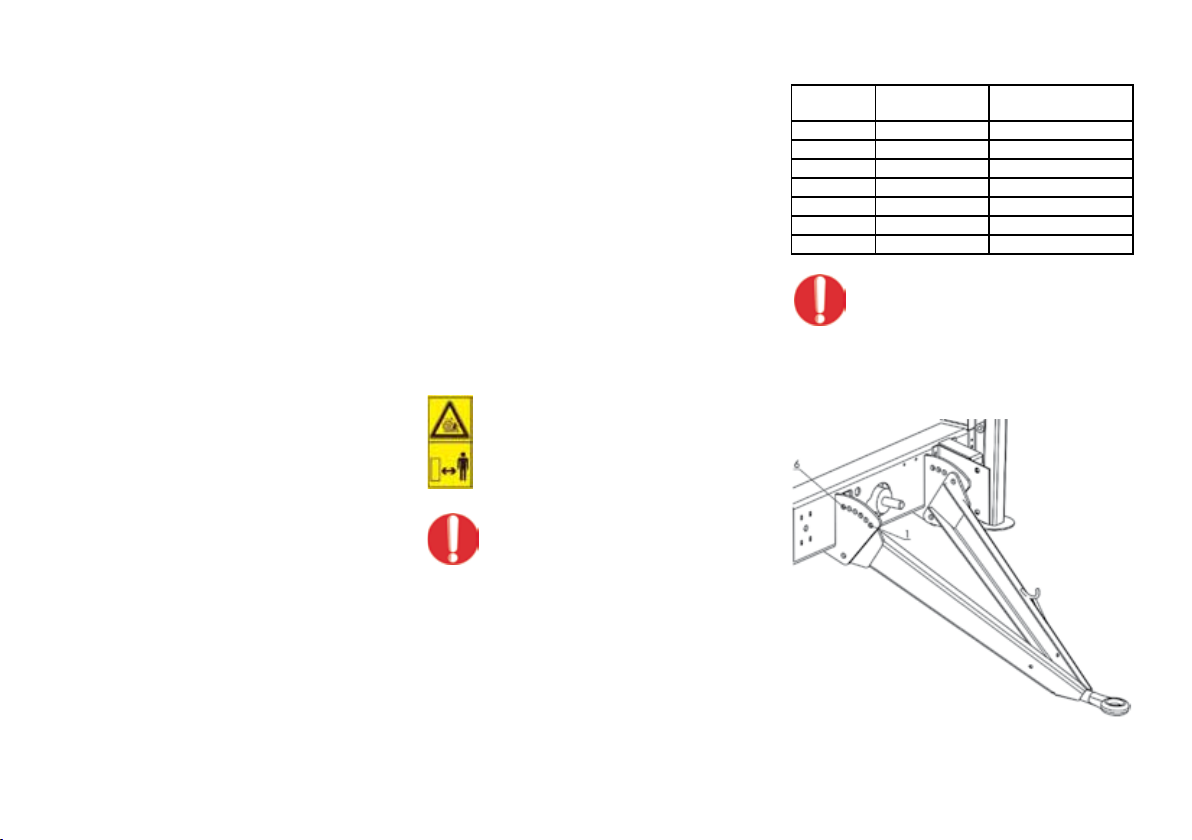

1.2 Z652 baling press construction

The Z562 baling press consists of the following units:

• Drawbar item 1

• PTO shaft item 2

• Hydraulic lines item 3

• Support foot item 4

• Pickup item 5

• Collector item 6

• Rolling shaft item 7

• Cord wrapper item 8

• Net wrapper item 9

• Control panel item 10

• Driving wheel item 11

• Cover item 12

• Indicator item 13

• Clamp item 14

In the front part of the press a pickup (5) is located, used to collect the swath formed into embankments. It works with a collector (6) directing the collected swath to the rolling

shafts (7) where it is pressed and rolled. The swath collection process and the bale unloading are presented on a diagram on the next page. When the desired compression

level is obtained it is indicated by the position of the indicator (13) in the red field and a sound signal located in the operator's cabin. When the programmed compression level

is obtained, the wrapper (8) wraps the bale with cord. When using a net, the wrapping is started manually from the control panel after the mentioned sound signal is heard.

The press is coupled to the tractor using the tow bar (1), the PTO shaft (2) and the hydraulic line (3). The support foot (4) is used to support the machine at rest and to couple and

uncouple the machine. The press is equipped with driving wheels (11) used for towing the machine behind the tractor.

6

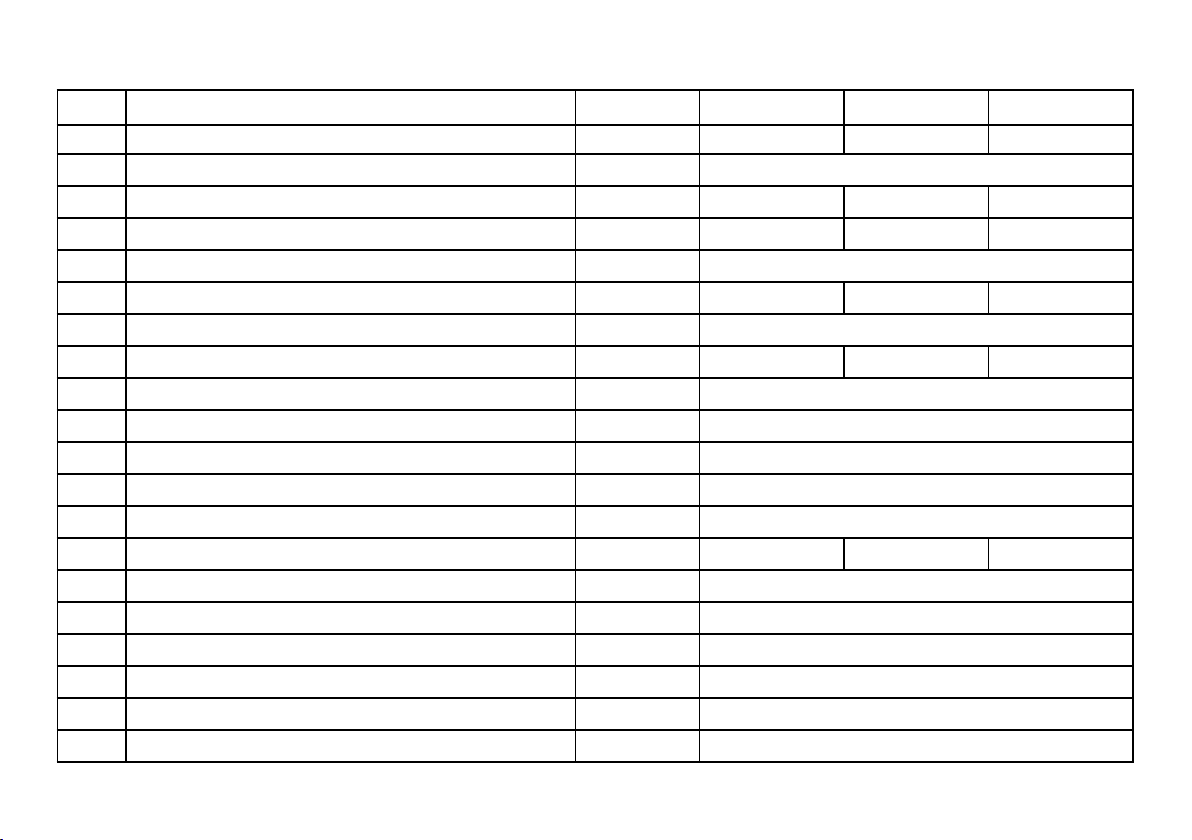

1.3 Z562 baling press characteristics

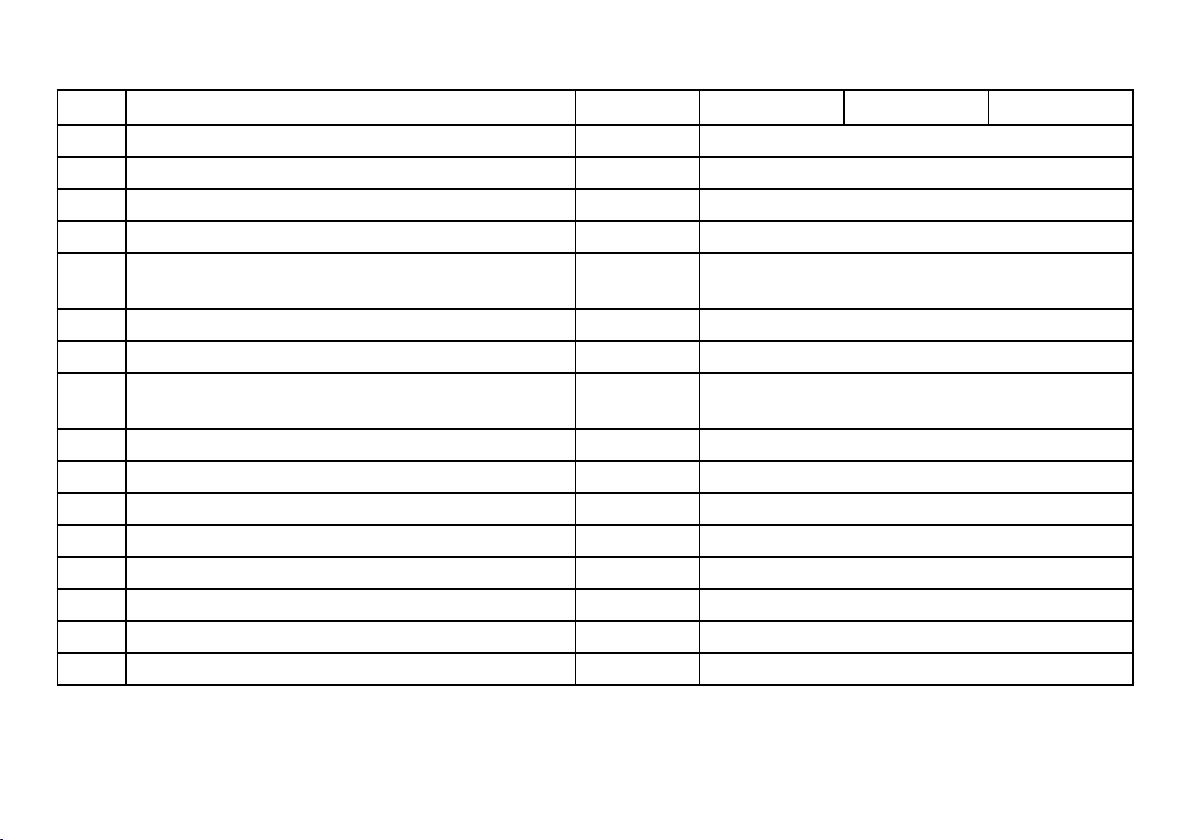

No. Details Units Z562-0... Z562-1... Z562-2...

1. 2. 3. 4. 5. 6.

1. Press type –hitched

2. Overall dimensions: length/width/height mm 3730/2470/2050 3800/2470/2050 3800/2470/2050

3. Weight kg 2200 2300 2400

4. Operating/transport speed km/h up to 10 / up to 20

5. Minimum tractor power output kW 35 50 70

6. Required tractor hydraulic system pressure Atm./MPa 140/14

7. PIC power demand kW approx. 25 approx. 40 approx. 60

8. PTO rotational speed RPM 540

9. Hitch load kN 4.0

10. Operating personnel – 1 (tractor driver)

11. Rolled bale dimensions (diameter x width) mm 1200x1200

12. Bale weight kg 100-600

13. Production efficiency bales/h max. 20 max. 40 max. 40

14. Harvested bank width mm up to 1600

15. Undercarriage type –mono-axial

16. Tyres –400/60 - 15.5 14 PR

17. Tyre pressure kPa 350

18. Drawbar hitch-ring diameter mm 44

19. Coupling with a tractor - through – the lower hitch

7

No. Details Units Z562-0... Z562-1... Z562-2...

20. Pickup type – drum-pin, 4 beams

21. Pickup width mm 1800

22. No. of pickup pins pcs 44

23. Rolling assembly – chamber type –cylindrical, constant displacement

24. Rolling assembly – rolling mechanism – automatic wrapping with a single cord

optional – net wrapping

25. Rolling assembly – cord wrapping spacing adjustment –4 increments

26. Telescopic jointed shaft type/brand LFMR S.A. Lublin

27. Telescopic jointed shaft symbol C-60970, designated with

the KRUS Safety Mark

28. Telescopic jointed shaft product no. 6R-602-7-BA-K601

29. PTO drive-shaft – rated torque: 540 kN 540

30. PTO drive-shaft – nominal transmitted power kW 30

31. PTO – minimum shaft length mm 1010

32. PTO – operating speed RPM 540

33. PTO – coupling/clutch type –K601/1600 Nm w/shear pin

34. Electrical system voltage V12

35. Light system – acc. to the Traffic Code

8

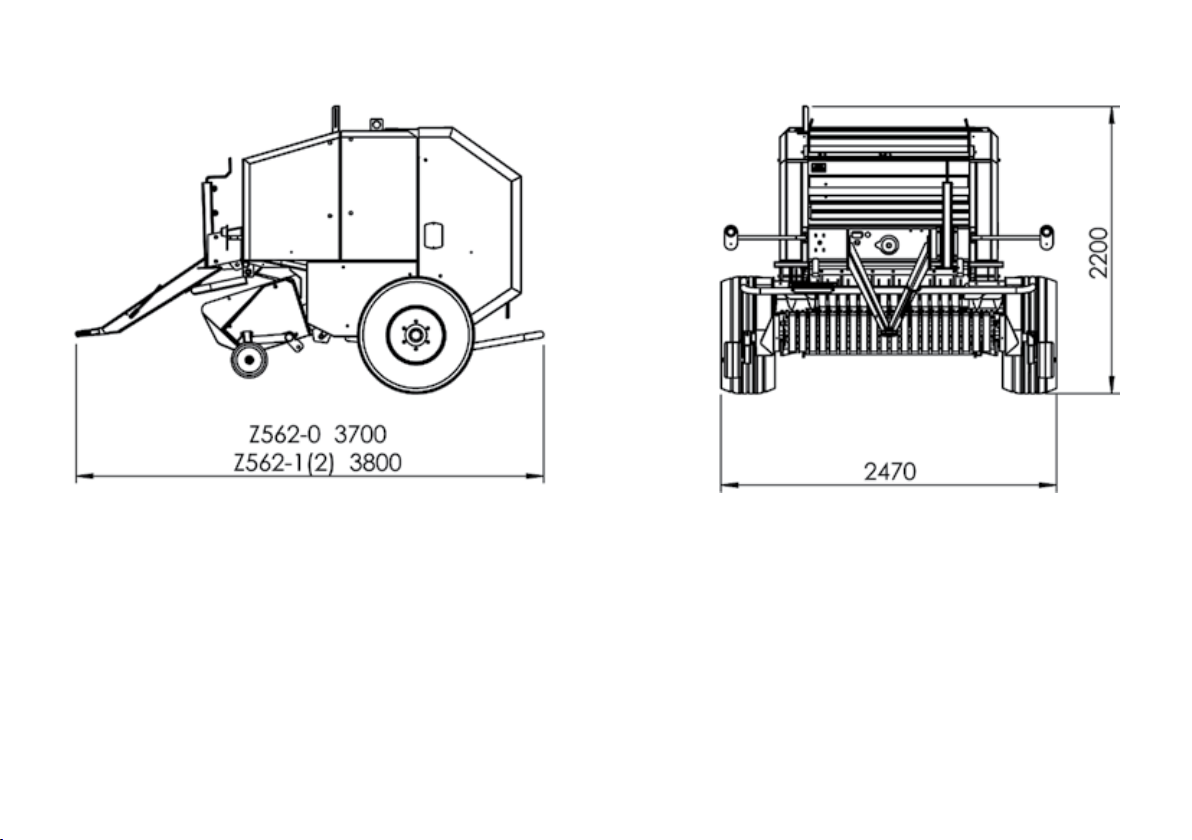

1.4 Z562 baling press dimensions

The drawings show the dimensions of the baling press in the working position (in mm).

9

1.5 Location of symbols

Location of symbols - right

The meaning of symbols is explained in Section 1.6 of the Manual.

10

Location of symbols - le

The meaning of symbols is explained in Section 1.6 of the Manual.

11

Location of symbols - rear

The meaning of symbols is explained in Section 1.6 of the Manual.

12

1.6 Warning Symbols

Warningsymbolson themachine ( Section 1.5) inform

the operator about the hazards and dangers which may

occur during the machine operation. Keep the symbols

clean and legible.

Replace illegible symbols with new ones.

New symbols can be purchased from the

manufacturer.

Symbol 1

Refer to the operating manual before

performing this action.

Symbol 2

Turn off the engine and remove the

ignition key before servicing or repairs.

Symbol 3

Do not open or remove the safety

guards during machine operation.

Symbol 4

Keep a safe distance from the raising

guards during machine operation.

Symbol 5

Secure the lifting cylinder before

entering into the hazard zone.

Symbol 6

Do not reach into the pickup zone

while the tractor engine and PTO are

operating.

Symbol 7

Do not approach the working strands

during the baling press' operation.

Symbol 8

Do not approach movable, articulated

connections while the engine is

running.

Symbol 9

Do not stand below the raised cover

which is not protected against dropping

down.

Symbol 10

Crushing hazard - caused by the rolling

bale. Keep a safe distance from the

working machine.

Symbol 11

Do not open or remove the safety

guards during machine operation.

Symbol 12

Keep a safe distance from the

working machine.

Symbol 13

Main lubrication points of the

baling press.

Symbol 14

Lifting sling fixing point.

13

Symbol 15

Information symbol.

Symbol 16

Information symbol.

Symbol 17

Attention!

While turning around and while

negotiating sharp corners

disconnect the tractor's PTO drive.

Information symbol.

Symbol 18

Information symbol.

Symbol 19

Information symbol.

Symbol 20

Do not approach the rotating PIC shaft.

Symbol 21

Do not stand on ladders and platforms

while the tractor is moving.

Symbol 22

Information symbol.

1.7 General safety rules

1.7.1 During operation and repair of the Z562 baling

press the farming health and safety regulations

contained in the Regulation of the Minister of

Agriculture and Food Economy of 12 January 1998 must

be complied with.

1.7.2 Only an adult with a valid agricultural tractor

driver's licence and familiarised with the occupational

health and safety regulations regarding agricultural

equipment and this Manual may operate this machine.

1.7.3 The following manual must be read and adhered

to, paying special attention to directions regarding the

safe operation of the baling press.

1.7.4 The manual indicates the machine parts which

pose a potential threat. Hazardous areas are marked

with yellow stickers with warning symbols. Pay special

attention to the hazardous areas and strictly adhere to

the rules.

1.7.5 The operator must familiarise themselves with the

meaning of the symbols.

1.7.6 It is forbidden to operate the baling press without

the safety guards installed on moving components.

1.7.7 Every time before the the baling press is started,

check the condition and completeness of the machine

and positioning of its safety guards.

MAX 540 RPM

3.5 bar

NOTE!

THE MACHINE MAY ONLY BE STARTED

AFTER ALL COVERS ARE CLOSED

14

1.7.8 Before starting the baling press and entering

public roads, inspect the attachment of the machine

to the tractor, attachment of the wheels and proper

connection of the drawbar to the tractor.

1.7.9 All adjustment, repair and maintenance works

shall be conducted with the tractor engine turned off

and making sure that the machine is secured against

accidental start.

1.7.10 Before commencing swath collection and during

this process, make sure that there are no bystanders,

especially children, nearby.

1.7.11 During the operation of the baling press, allow

for free space near the rotating elements. During bale

rolling, no people or animals are allowed near the

rotating elements.

1.7.12 Exercise extreme caution when working on an

inclined land. Note that the bales may roll down slopes.

1.7.13 It is forbidden to operate the baling press with

any of the assemblies lifted.

1.7.14 Do not remain between the baling press and the

tractor when the tractor engine is running.

1.7.15 Exercise extreme caution when coupling/

decoupling the press with/from the tractor. The

machine should be coupled with the tractor equipped

with a lower hitch able to withstand the vertical load

larger than the vertical load exerted on the baling press

drawbar. Section 1.3.

1.7.16 During operation, use appropriate protective

clothing and shoes with anti-slip soles.

1.7.17 While loading the wrapping cord or net, the

tractor engine must be turned off and protected against

accidental activation (ignition key removed, parking

brake on).

1.7.18 It is forbidden to operate damaged hydraulic

lines. The damaged lines must be immediately replaced

with new ones. During the replacement of hydraulic

lines, use impermeable protective clothing.

1.7.19 The machine hydraulic system shall only be

operated from the tractor cabin.

1.7.20 Before driving the machine check the position of

the support foot. The support foot should be placed in a

transport position.

1.7.21 Follow the traffic code regulations and the

manufacturer's recommendations when travelling on

public roads. Section 8.2.

1.7.22 Before entering public roads, perform a visual

inspection of the transported machine.

1.7.23 It is forbidden to stand on the press during

machine operation or transport.

1.7.24 While travelling on public roads, it is forbidden

to transport swath or silage bales in the press chamber.

1.7.25 It is forbidden to operate the baling press while

under influence of alcohol.

1.7.26 It is forbidden to operate the baling press while

under influence of drugs or medicines with similar

effects.

1.7.27 It is forbidden to operate the machine while

under influence of medicines which affect the ability to

drive vehicles or reduce psychophysical fitness or cause

concentration disorders and increase reaction time.

1.7.28 It is forbidden to drive the baling press near

sources of open flame.

1.7.29 It is required to strictly adhere to the fire

protection regulations and immediately extinguish any

fire which may occur during the baling press use or at

its standstill.

1.7.30 Do not approach the working baling press with

open flame and do not smoke near the machine.

15

1.7.31 Every time before commencing work, check if the

tractor is equipped with a dry powder extinguisher. If

not, place a dry powder fire extinguisher on the tractor.

2 Drive operation

2.1 Drive coupling

The baling press should be coupled with agricultural tractors

of the rated power not lower than 35 - 70kW and towing

power class 0.9 - 1.4, equipped with two hydraulic system

connections, a rear PTO shaft with six keys and the nominal

of RPM 540.

The baling press shall be coupled to the lower hitch allowing

for the maximum vertical load of 4.0 kN.

Coupling the machine to the tractor's

lower hitch.

Make sure that there are no bystanders,

especially children, in the coupling area.

Before coupling the equipment, place

the tractor axis in the machine axis on

a hard, flat, level surface. Turn off the

tractor engine, remove the ignition key

and engage the tractor parking brake.

Set the appropriate hitch height by

selecting the proper adjustment lug as

shown on the diagram.

The height of the drawbar above the ground is given in the

table below.

Slot no. Units Height of the tow bar above

the ground

123

Slot no. 1 cm 15.50

Slot no. 2 cm 31.00

Slot no. 3 cm 46.50

Slot no. 4 cm 63.00

Slot no. 5 cm 78.50

Slot no. 6 cm 94.00

Couple the hitch-ring with the lower

hitch and check whether the machine is

properly connected and secured against

accidental disconnection.

16

Only couple the machine to tractors with

weight appropriate for the machine.

Make sure that the tractor hydraulic

system is tight.

Connect the electric power source. Check if the electric and

signalling systems work properly.

Connect the hydraulic power source. Check if the hydraulic

systems work properly, especially the baling press door

opening and closing mechanism.

Coupling the press with the rear PTO

Before connecting the telescopic jointed

shaft check the direction and speed of

shaft revolutions.

Turn off the tractor engine, remove the

ignition key and engage the tractor

parking brake. Slide the outer socket of

the telescopic jointed shaft on the six

notch rear PTO. Place the second outer

socket on the press' PIC until the locks

snap in place. Install the shaft cover

chains on both sides of the shaft.

It is forbidden to use telescopic jointed

shafts with parameters other than

specified by the manufacturer.

It is strictly forbidden to use a telescopic

jointed shaft with its guards missing or

damaged and without the additional

cone guards at the tractor PTO and the

machine PIC sides.

Shortening or extending the telescopic

jointed shafts may only be performed at

specialist service stations.

Every time the telescopic jointed shaft

is coupled and every time the machine

is put into operation it is required to

make sure that the shaft condition is

undamaged and the protection pipe and

cone are properly attached.

If the safety bolts of the telescopic

jointed shaft overload clutch are

sheared, replace them with new bolts

with the same technical parameters.

The manufacturer suggest to use the

machine in straight line runs. It is

advised to turn off the drive while the

machine is negotiating sharp corners

and during transport.

17

2.2 Disconnecting from

the drive

Make sure that there are no bystanders,

especially children, in the baling press

storage area and its vicinity.

Place the baling press for storage on a hard, flat and

level ground. Turn off the tractor engine, remove the

ignition key and engage the tractor parking brake.

Disconnect the electric power supply.

Disconnect the hydraulic system.

Lower the main frame support. Disconnect the hitch-

ring from the tractor hitch. Make sure that the machine

will not move accidentally.

Disconnect and dismantle the telescopic

jointed shaft. Place the shaft on the

support designed for its storage. Protect

the PTO and telescopic jointed shaft

couplings with covers.

3 Commissioning

The commissioning of a newly purchased

baling press should be performed by

a dealer's service representative or a

manufacturer's representative in the

presence of the operator - owner of the

machine.

Before commissioning the baling

press, familiarise yourself with the this

manual, paying special attention to the

fragments regarding the safety of the

operator and bystanders.

If there are any doubts regarding

safety issues, please contact your sales

representative or the manufacturer.

Before each start up of the baling press, the LP02

counter shall be installed in the tractor operator's cabin.

Section 5.4.3.

Commissioning the baling press

Take extra caution during

commissioning.

The presence ofpersons undertraining in

the machine's operation zone increases

the safety hazard.

During the commissioning of a newly purchased

baling press a dealer's service representative or a

manufacturer's representative in the presence of the

operator - owner of the machine performs the following

actions:

3.1 Control of press operation and equipment:

3.1.1. Completeness and technical condition check,

3.1.2. Sound signal device and lighting equipment

functional test,

3.1.3. Functional test of the hydraulic system:

- lifting and lowering of the pickups,

- lifting and lowering of the rear chamber,

- lifting and lowering of the shredder blades

(optional equipment)

3.1.4. Rear chamber lock engagement and locking test,

3.1.5. Functional test of the pickup,

3.1.6. Functional test of the wrapping mechanism:

- test with cord,

- test with net (optional supply).

3.1.7. Functional test of the central lubrication system

(optional supply),

3.1.8. Functional test of the ensilage applicator (optional

supply).

18

3.2. User training in proper operation of the press:

3.2.1 Review of the pickup design and principles of

operation:

- adjustment of spring attack angle,

- overload clutch functions,

- clutch installation after the bolts are sheared,

- replacement of the complete overload clutch,

- lubrication of the roller raceways.

3.2.2 Review of the cord wrapping mechanism design

and principles of operation:

- review of the principle of operation,

- installation of the cord,

- adjustment of the wrap spacing and cord tension,

- adjustment of the bale compression ratio,

- cleaning the cord feeder.

3.2.3 Review of the net wrapping mechanism design

and principles of operation (optional supply):

- review of the principle of operation,

- installing the net,

- adjusting the wrap number,

- adjusting the spring tension for the blade

support bracket.

3.2.4 Review of the central lubrication system design

and principles of operation (optional supply):

- review of the principle of operation,

- adjustment of the (dosing) pump delivery.

3.2.5 Review of the ensilage applicator design and

principles of operation (optional supply):

- review of the principle of operation,

- start up and dosing adjustment.

3.2.6 Review of the rotor and the shredder design and

principles of operation (optional supply):

- review of the principle of operation of the rotor,

- review of the principle of operation of the

shredder,

- disassembly, blade sharpening and assembly.

3.2.7 Review of the LP02 counter design and principles

of operation

3.2.8 Review of the principles of operation of the

tractor-baling press unit during baling:

- tractor operation during swath collection along

a straight line,

- tractor operation during swath collection along

curves and sharp bends,

- explanation of hazards.

3.2.9 Performing the full bale wrapping with cord +

net by the user under supervision of the service

technician

3.2.10 Review and adjustment of the chain tension

3.2.11 Review of the lubrication procedures and ongoing

maintenance of the press

3.2.12 Review of user questions and remarks.

The commissioning is performed by the

service without any additional charges.

The service technicain's signature on the warranty

card confirms that the commissioning process was

performed as described in this section. The customer's

signature confirms that the commissioning of the baling

press was performed in the presence of the buyer/user.

19

4 Controls and ongoing adjustments

4.1 Location of the controls

Hydraulic system controls

The baling press hydraulic system is controlled using the tractor's control levers.

The control levers are used to adjust the pickup position and opening and closing of

the baling chamber. Section 5.2 Hydraulic system

Press control using the counter

For operation and control of press operation the manufacturer supplied the electronic

LP02 counter with baling press control functions and information functions.

Before starting the baling press, the LP02 counter shall be installed in

the tractor operator's cabin. Section 5.4.3.

Description of baling press control using the counter Section 5.4

Ensilage application

The ensilage applicator is offered by the manufacturer as separately purchased

optional supply.

The applicator is used for precise dosing of liquid ensilage preparation facilitating the

silage forming process.

The applicator is located in a location indicated in the diagram below. If the applicator

is purchased separately at a later date the user may install it on his own (checking

if the purchased equipment is not missing any parts) or at an authorised reseller or

manufacturer.

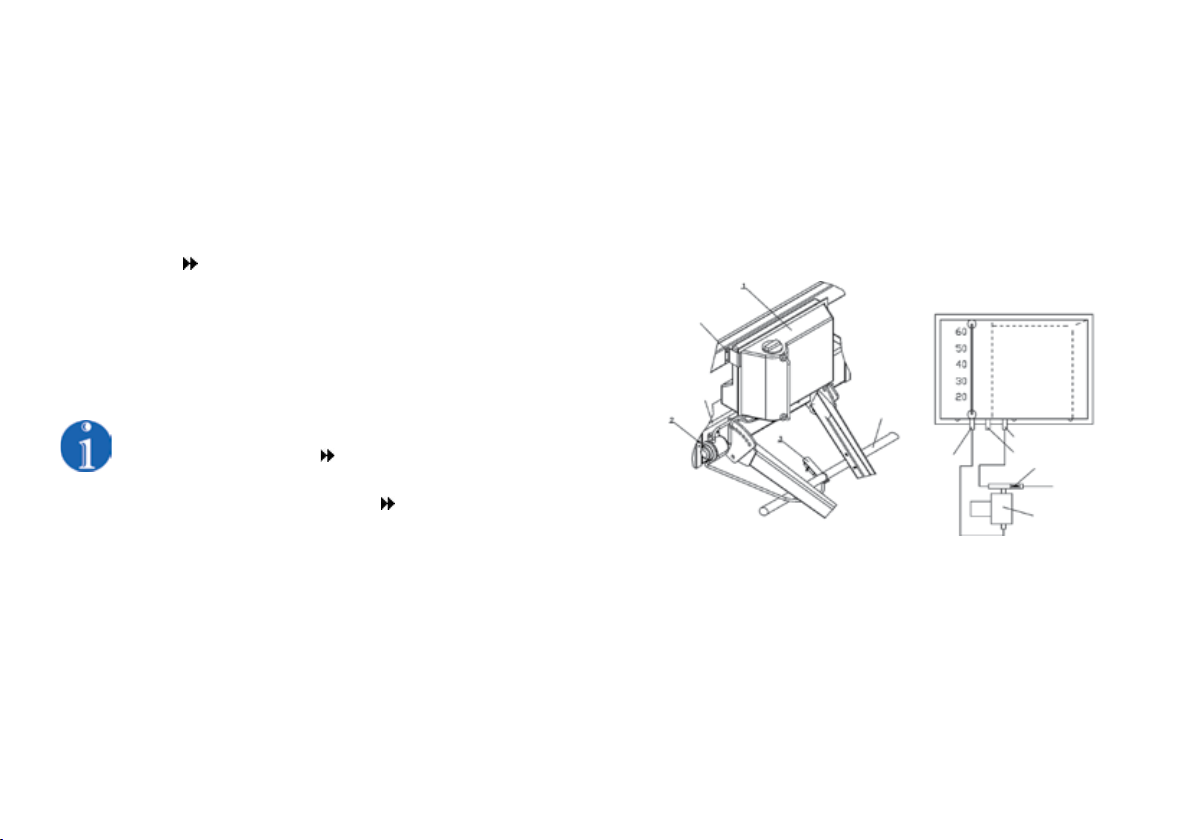

The applicator consists of the following parts:

- 60 litre tank,

- filler with filtering insert,

- 2 connector pipes,

- drain valve;

- cut-off valve;

- spreading nozzles rated at:

350 ml/min,

600 ml/min,

1000 ml/min,

Metal brackets

Diagram for the installation of the

pump and spraying nozzles

Crossbeam

Pickup pipe

Return stub pipe

Drain valve

Cut-off valve

Pump

Spraying nozzle hose

Inlet stub pipe

20

- inlet hose Ø10 mm, length L=70 cm - 1 pc.

- return hose Ø10 mm, length L=70 cm - 1 pc.

- pressure conduit Ø12 mm, length L=110 cm - 1 pc.

- 12 V electric pump.

Begin the installation of the applicator by installing the pump (item 2) on the crossbar,

in a place indicated in the diagram. Then, using M8x30 blots and M8 nuts install the

60 litre tank (item 1). Install the spraying nozzles (item 3) on the pickup pipe. This

will allow the dosing of the preparation at the entire width of the harvested material

between the machine pickup and the rolling chamber. Connect the inlet hose, return

hose and pressure conduit as indicated on the diagram.

Using the plug connect the applicator's power supply to the press electric system.

The press is equipped with a socket dedicated for the applicator power supply. It is

located under the front cover on the right side of the press.

Turning the press on/off is performed by pressing the on/off button on the counter.

For preparing silage the manufacturer suggests using biological

preparations or preparations containing effective microorganisms.

Before starting the pump fill the tank with liquid. Prepare the liquid as specified by the

ensilage preparation manufacturer.

Pour the properly mixed preparation through the filtering insert in the tank inlet.

When the tank is full, fully open the stub pipe and switch on the pump using the ON

button on the counter. The pump will start sending liquid to the nozzles. The spraying

of the material with ensilage begins.

Depending on the collected swath use nozzles with appropriate flow rate:

- deflector nozzle in white body – output 1000 ml/min;

- deflector nozzle in red body – output 600 ml/min;

- deflector nozzle, w/o body – 350 ml/min.

Do not start the pump if the tank is empty. The pump may be destroyed

after a period of "dry running".

When the work is nished ush the applicator and ltering insert. Remove all remains

of the preparation and all mechanical remains. Remove all residues from the tank

through the drain valve.

Other manuals for Z562

2

Table of contents

Other Metal-Fach Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions