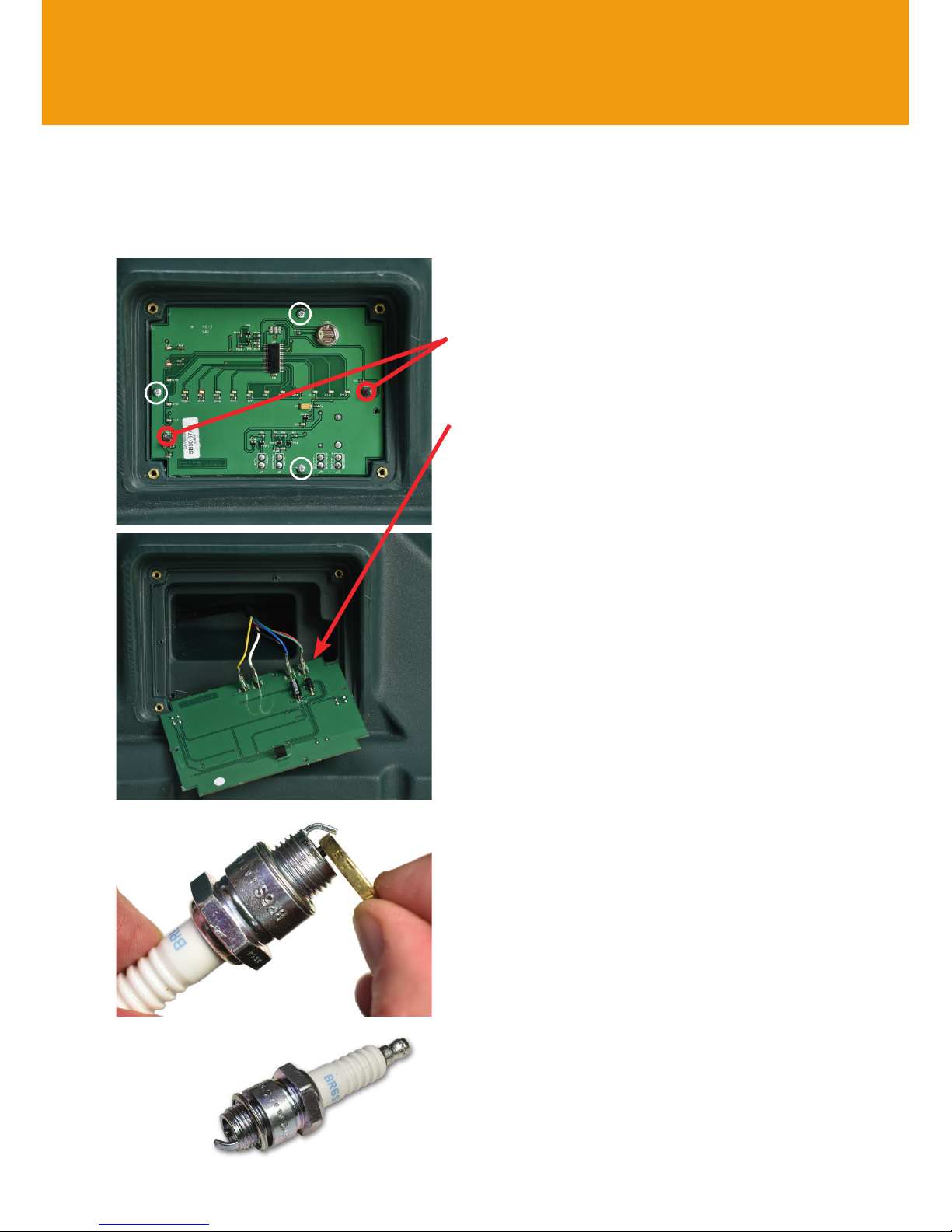

8Spark Generator and Gas Delivery

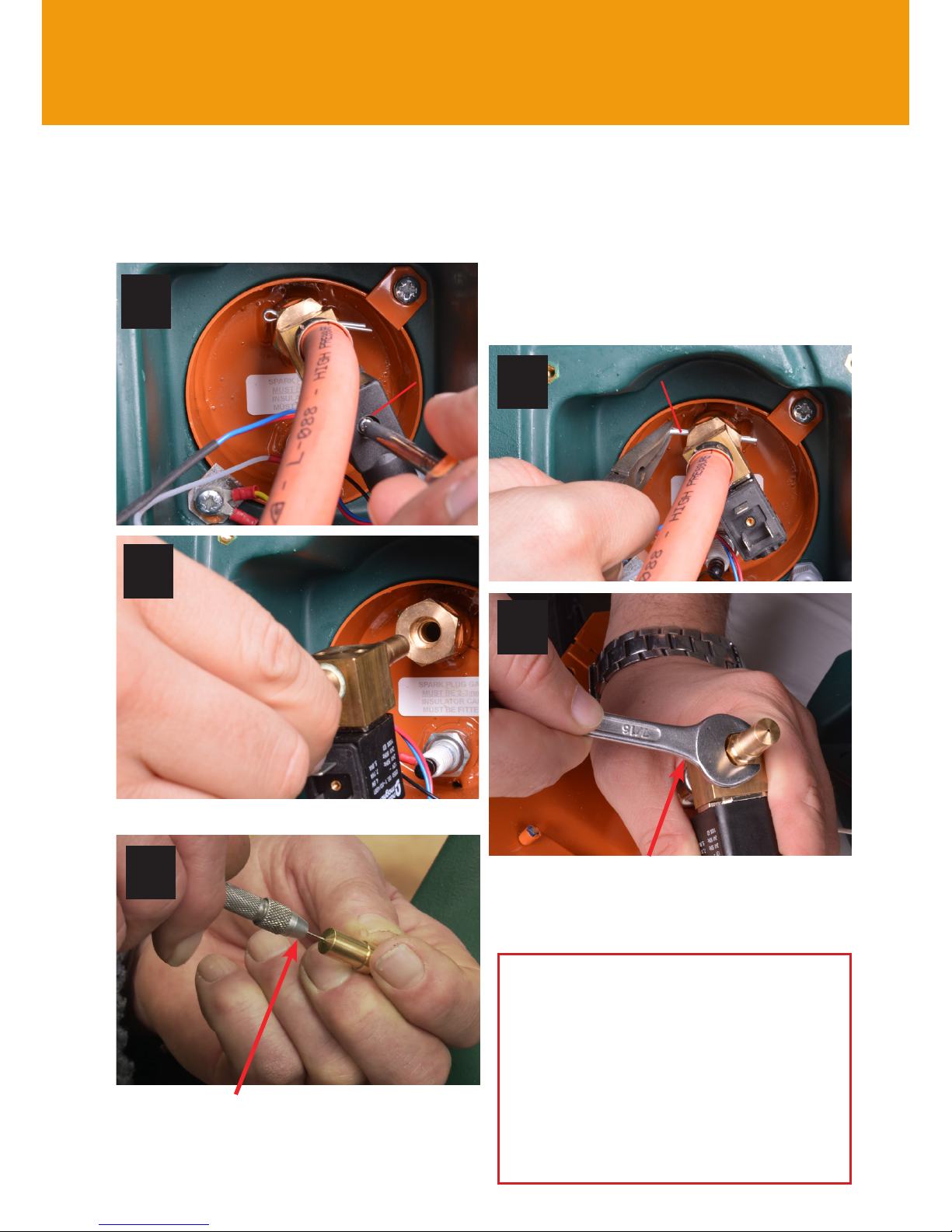

SPARK GENERATOR

If your Scatterbird is still not working, check and clean the wiring to the spark generator and

test again.

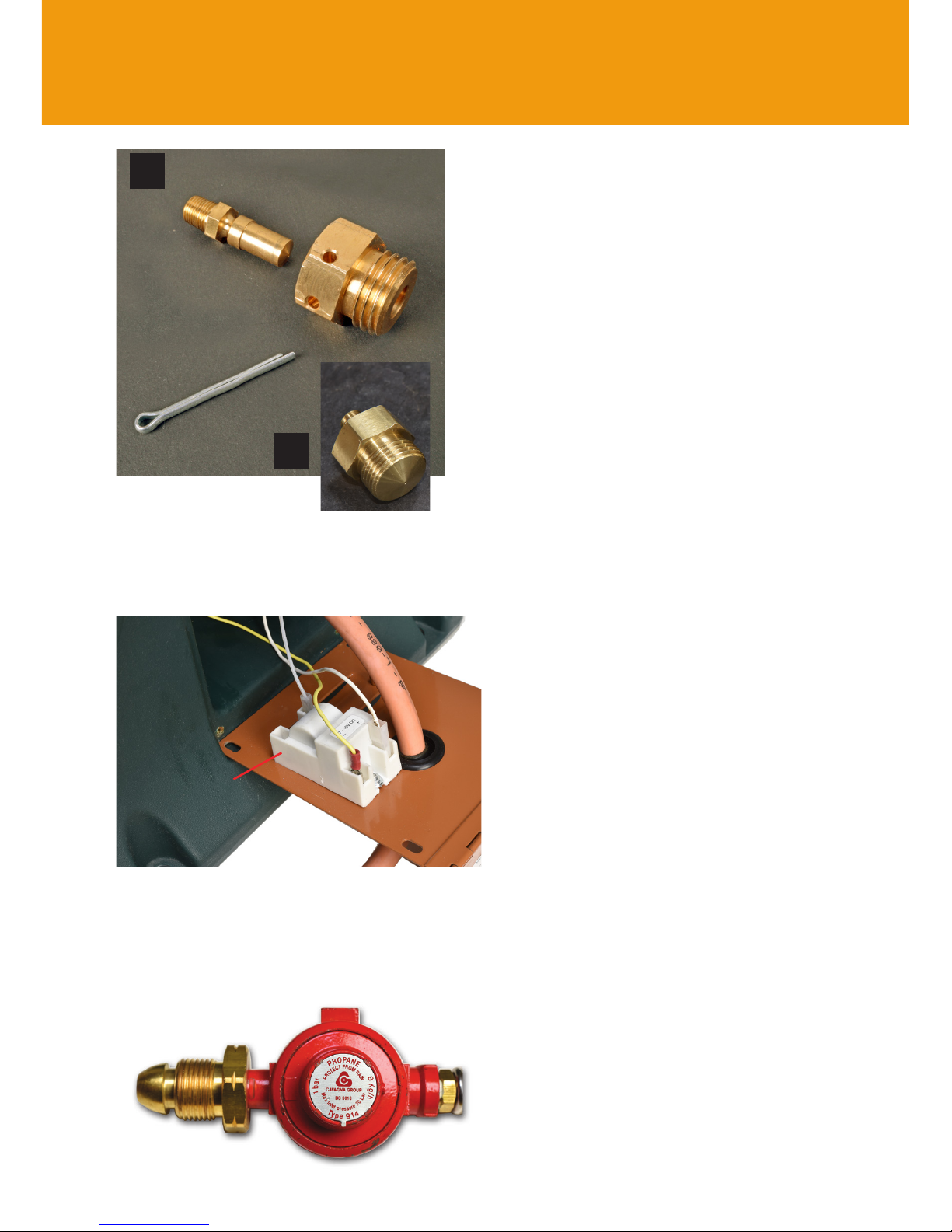

2 TYPES OF GAS JET

Early Scatterbirds were fitted with a single piece

jet (B) which was later superseded by the

two part jet (A).

We recommend replacing the single piece

jet with the two piece jet for faster and more

convenient maintenance. For removing the one

piece jet please contact technical services on

01234 889 454.

Note: If the Scatterbird is fitted with the two

part jet, ensure that the rubber cap is fitted

to the top of the spark plug (see page 4)

to make sure it is not shorting against the

solenoid housing.

GAS DELIVERY

To check for problems with gas delivery, check the bottle is turned on and contains gas. Try

to avoid completely emptying the bottle as it contains sediment which can block jets and

regulators.

You will hear an initial click of the solenoid

opening to allow the gas in, followed 3

seconds later by the rapid clicking of the

spark generator firing the spark plug. If you

cannot hear a rapid clicking and all the spade

contacts have been thoroughly cleaned, then

the spark generator will have to be replaced.

If you do not hear the initial click then the

issue may be with the solenoid.

The spark generator may be green in colour

and not white as shown.

Next, check that the correct regulator is

fitted. Use only a One Bar Regulator. If the

correct one is fitted, check the connections

for damage or loose fitting. Replace or

tighten as necessary. When changing the

regulator make sure it does not come into

contact with the ground as soil particles can

block or damage the unit.

TWO

PIECE JET

EARLY SINGLE

PIECE JET

This might

be green in

colour

A

B