Metal Samples Company MS4500E User manual

MS4500E

High Resolution ER Data Logger

Operator’s Manual

Metal

Samples Company

ADivisionof Alabama SpecialtyProducts,

Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256)

358-4515

Table of

Contents

I.Introduction..............................................................................................................................................1

A.GeneralDescription...................................................................................................................1

B.PrinciplesofOperation..............................................................................................................1

C.TechnicalSpecifications.............................................................................................................3

II.StartUpandOperation............................................................................................................................4

A.ReceivingtheMS4500EDataLogger.........................................................................................4

B.StartUp......................................................................................................................................4

1.PortDetailsandProbeConnection..............................................................................4

2.PowerUp......................................................................................................................5

a.SafeAreaUsage...............................................................................................5

b.HazardousAreaUsage......................................................................................6

c.BatteryReplacement.........................................................................................7

3.SetupandOperation.......................................................................................................8

a.SelectProbe.....................................................................................................8

i.NewProbe....................................................................................................9

ii.ExistingProbe...............................................................................................9

iii.DeleteExistingProbe..................................................................................10

b.MakeMeasurement....................................................................................... 11

c.RecallReadings................................................................................................12

d.DeleteReadings..............................................................................................13

e.SetTime&Date............................................................................................14

f.SetMeasurementTimer.................................................................................. 15

g.Communications.............................................................................................16

h.Language........................................................................................................ 22

i.PowerOff......................................................................................................... 22

j.BacklightOn/Off...............................................................................................22

C.Maintenance............................................................................................................................23

1.TestingtheMS4500EHighResolutionDataLoggerwiththeMeterProver..............23

D.Troubleshooting.......................................................................................................................24

III.ServiceandWarrantyInformation....................................................................................................... 25

A.Warranty..................................................................................................................................25

B.ObtainingServiceandReturningtheInstrumentforRepair...................................................25

C.InstrumentRepairForm...........................................................................................................26

AppendixA‐Drawings...............................................................................................................................27

ControlDrawing(HazardousAreaWiringDiagram)..................................................................... 28

AppendixB–RevisionHistory...................................................................................................................29

1

I. Introduction

A.GeneralDescription

TheMS4500Eisahand‐held,batterypowered,corrosionmetercapableofmeasuringandstoringdata

fromalltypesofelectricalresistance(ER)corrosionprobes.Theinstrumentislightweight,

microprocessor‐based,andfeaturesasimple,menu‐driveninterfaceusingakeypadandabacklit

graphicalLCDdisplay.

Corrosionratemeasurementsaremadeusingtheelectricalresistancemethod.Essentially,theinstrument

measurestheresistanceoftheprobeelementwhichchangesovertime,asmetallossoccurs.Therateof

changeisdirectlyproportionaltocorrosionrate.Thismethodfindsawidevarietyofapplicationssinceit

canbeusedinconductiveandnonconductiveenvironmentssuchaspetroleum,chemical,water,soil,or

evenatmosphere.Thenewhigh‐resolutionmeasurementoftheMS4500Edetectssmallerincrementsof

metalloss,providingfasterresponsethantraditionalERinstruments.

Aftertakingareading,theinstrumentdisplaysmetallossinmilsandcorrosionrateinmilsperyear(mpy).

Thereadingcanthenbestoredtomemoryordiscarded.Allstoredreadingsareautomaticallytimeand

datestamped.Readingsarestoredtonon‐volatileFlashmemorywhichretainsdatawithouttheneedfor

abatterybackup.

TheMS4500EHighResolutionERDataLoggercanstore16,000readingsperprobeonupto250different

probes(4milliontotal).StoreddatacanbedownloadeddirectlytoaUSBFlash(“jump”)driveinnon‐

hazardousareas.DatacanbeopenedandchartedusingtheprovidedCDMSsoftware,orcanbeimported

intoanystandarddataanalysis(spreadsheet)programsuchasMicrosoftExcel.Datacanalsobereviewed

andchartedontheinstrument’sLCDdisplayforquickreference.

B.PrinciplesofOperation

TheMS4500EHighResolutionERDataLoggeroperatesontheElectricalResistance(ER)techniqueand

isusedinconjunctionwithanERprobe.TheERprobeutilizesaresistivesensingelement

manufacturedfromthematerialofinterest(oracloseapproximation)whichisexposedtoacorroding

environment.ThisiscalledtheExposedorCorrodingElement.TheresistanceoftheExposedElement

isdirectlyrelatedtoitsthickness,soastheelementcorrodestheresultinglossofmetalcausesa

proportional

increasein

theelement’sresistance.TheprobealsocontainsaninternalReference

ElementwhichisusedtocompensatefortheinfluencesoftemperatureontheExposedElement.

TheMS4500EHighResolutionERDataLogger isdesignedtoworkwithanystandardERprobe,butit

isrecommendedthatCylindricalandLargeFlushtypeprobesbeusedtoensureoptimum

performance.TheirphysicaldesignplacestheReferenceElementincloserproximitytotheExposed

Elementcomparedtootherprobetypes,providingmoreeffectivetemperaturecompensationand

thusreducingtheeffectsofthermalnoise.

2

Becausetheyaredesignedtocorrode,ERprobesaresacrificialinnature.EachERprobewillhavea

finitelifethatisbasedontheelementthickness.ERprobesareavailableinanumberofgeometries

andthicknessesdesignedtosuitawidevarietyofapplications.Table1liststhecommonERelement

optionsavailablefromMetalSamplesandtheeffectivelifeofeach.

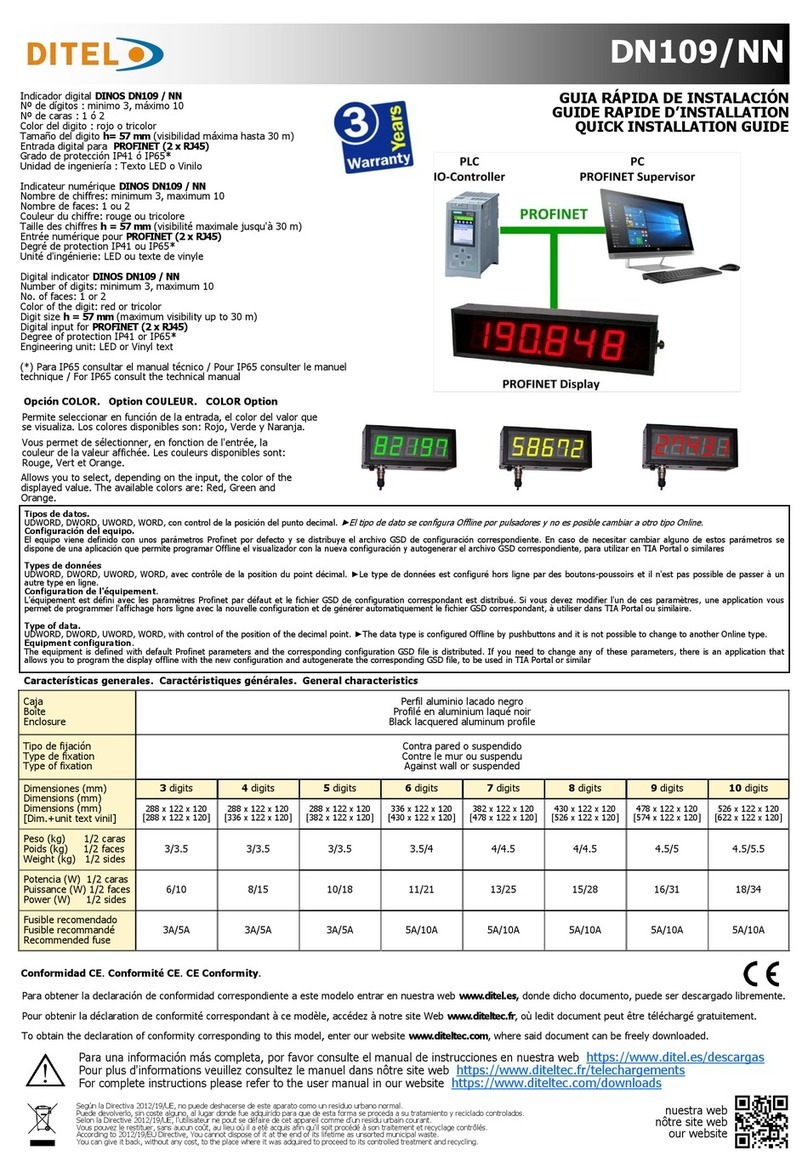

ElementTypeCompatibilityThicknessProbeLife

(Span)

TubularLoopCompatible

42

84

WireLoopCompatible

4010

8020

Flush(Small)

Compatible

42

84

2010

Cylindrical

Preferred

105

2010

5025

Flush(Large)

Preferred

52.5

105

2010

4020

Table1.StandardERProbeElements

TheMS4500EHighResolutionERDataLoggermeasuresanERprobeutilizingahigh‐resolution,16‐bit

measurement.Thisallowstheunittodetectmuchsmalleramountsofmetalloss,thusresponding

fastertocorrosioneventsandupsets. At16‐bitresolutiontheMS4500EERDataLoggercan

measuremetallossamountsassmallas0.004%oftheprobelife. Forhighlysensitiveprobes

suchasthe5‐millargeflushshownabove,thatresultsinadetectionlimitoflessthanoneangstrom.

3

C.Technic alSpecifications

ModelMS4500EHighResolutionERDataLogger

Physical Data

InstrumentWeight(w/boot):1.71lb.(0.78kg)

TotalWeightw/Case&Accessories:6.96lb.(3.16kg)

InstrumentDimensions(w/boot):8.75"Lx4.54"Wx2.20"D(21.77cmx11.53cmx5.59cm)

InstrumentDimensions(w/oboot):7.50"Lx4.00"Wx2.00"D(19.05cmx10.16cmx5.08cm)

CarryingCaseDimensions:14.50"Lx11.38"Wx5.88"D(36.83cmx28.89cmx14.92cm)

OperatingTemperature:‐4°to130°F(‐20°to54°C)

StorageTemperature:‐4°to158°F(‐20°to70°C)

OperatingHumidityRange:30%‐95%

Performance Data

MeasurementType:ERmeasurementusinganystandardERProbeTypes

PreferredProbeTypes:Cylindrical,Flush(Large)

Compatibleprobetypes:TubeLoop,WireLoop,Flush(Small)

Range:0‐25,000probelifeunits(displayedas0.00to1000.00PLU’sin

0.04increments)

Resolution:0.004%ofProbeLife

Repeatability:±0.1%ofFullScale

CycleTime:25Seconds

Electrical Data

PowerRequirements:Four(4)AABatteries

MaximumProbeCableDistance:200ft.(61m)

DownloadMethod:DirectlytoUSBFlashdrive(innon‐hazardousareasonly)

Hazardous Location Certifications –Intrinsic Safety

USA/CanadaConformstoANSI/ULStd.60079‐0,60079‐11,61010‐1

CAN/CSAStd.E66079‐0,E60079‐11&CAN/CSAC22.2No.61010‐1

ClassI,Zone0,AExiaIICT4Ga

ExiaIICT4Ga

‐25°C≤Ta≤+40°C

ClassI,Zone0,AExiaIICT3Ga

ExiaIICT3Ga

25°C≤Ta≤+60°C

EuropeandWorldwideII1GExiaIICT4Ga

(

ATEXandIECEx)‐25°C≤Ta≤+40°C

II1GExiaIICT3Ga

‐25°C≤Ta≤+60°C

ATEXCertificateNo:ITS15ATEX28214X

IECExCertificateNo:IECExITS15.0009X

X–seeSpecialConditions(page8)

Included Accessories

Carryingcase,ProbeCable(1’coiled‐6’extended),MeterProver,OperationManual,CorrosionData

ManagementSoftware,ProtectiveBoot

4

II.Start‐upandOperation

A.ReceivingtheMS4500EHighResolutionERDataLogger

ChecktheMS4500EHighResolutionDataLoggerforanyshippingdamagewhenitisfirstreceived.

Whentheunitisunpacked,verifythatthefollowingitemsareincluded:

CarryingCase

DataLogger

MeterProver

User’sManual

ProbeCable

Intheeventofshippingdamage,quantityshortage,ormissingitems,itisrecommendedthatthe

eventisdocumentedimmediatelyandthatdigitalphotographsaretaken.Anyshortagesormissing

itemsshouldbereportedtoMetalSamplesimmediately.Intheeventofshippingdamage,aclaim

shouldbeopenedwiththeresponsiblecarrier.

B.Start‐Up

CAUTION:

Usingthisproductinanywayotherthanthatspecifiedwithinthismanualmayimpairthe

intrinsicsafetyprotection.

ATTENTION:

l'utilisationdeceproduitdetouteautremanièrequecellespécifiéedansleprésentmanuel

peutaltérerlaprotectiondesécuritéintrinsèque.

Start‐upoftheMS4500EHighResolutionDataLoggerinvolvesthefollowingsteps:

1. PortDetailsandProbeConnection

2. Power‐Up

3. SetupandOperation

1.PortDetailsandProbeConnection

Attention: Utilisez Seulement

dans des endroits Sécurisés

5

TheMS4500EHighResolutionDataLoggerissuppliedwithaprobecableanditcanbeconnectedto

theprobewhosemetallossvalueneedstobemeasured,noadditionalhardwareisnecessary.

Connecttheprobecable‘Lemo’connectorendtothedataloggerprobeconnector‘J9’availableon

topofthedatalogger.Connecttheotherendoftheprobecablei.e.probeconnector(MS

Connector)totheprobe.

2.Power‐Up

Theunitissuppliedwith4AAbatteriesinstalled.Theinstrumentcanbepoweredupbypressingthe

‘ON’buttonontheKeypad.TheStart‐upscreenwiththeMetalSampleslogowillappearonthescreen;

thestart‐upscreenconfirmsthesoftwareversioncurrentlyrunningandtheSDcardstatus.

PowerOnButtonDisplayWindow

1. SELECT PROBE

2. MAKE MEASUREMENT

3. RECALL READINGS

4. DELETE READINGS

5. SET TIME & DATE

6. SET MEASUREMENT TIMER

7. COMMUNICATIONS

8. LANGUAGE / IDIOMA / LINGUAGEM

9. POWER OFF

10. BACKLIGHT ON/OFF

Version 1.7

6

a.SafeAreaUsage

TheMS4500EHighResolutionDataLoggerisapprovedforuseinhazardousareas,butcanbe

usedinnon‐hazardousareasaswell.

ThedatatransferfromtheunittoPCshouldbedoneinasafearea.AcertifiedUSBisolator

shouldbeusedbetweentheunitandPCfordatatransfer.

b.HazardousAreaUsage

CAUTION:Thissectionprovidesgeneralguidelinesforhazardousareausage.However,

regardlessofanythingstatedhere,theMS4500EHighResolutionDataLoggermustbeusedin

fullcompliancewiththecontroldrawinglocatedinAppendixAandallofthelocalarea

requirements.Theentityparametersoftheunitaregivenbelow.

ATTENTION:Cettesectionfountdesdirectivesgénéralespourl’utilisationenzonedangereuse

Toutefois,etindépendammentdetoutedéclarationfaiteici,L’enregistreurdedonnéesde

hauterésolutionMS4500Edoitêtreutiliseenpleineconformitéavecleschémadecontrôle

donneenpage20etavectouteslesexigencesdulocalezonedangereuse.

J9-USB Port & J11- ER Probe cable Connector

Uo= 4.94V

Io= 1.39A

Po= 1.28 W

Co= 21.6 uF (Shared between all Connectors)

Lo= 7.8 uH (Shared between all Connectors)

J8 – Mini USB Port Entity Parameters):

Ui= 5.88V

Uo= 4.94V

Io= 0.47A

Po= 0.64 W

Co= 21.6 uF (Shared between all Connectors)

Lo= 7.8 uH (Shared between all Connectors)

SPECIALCONDITIONS

1.MiniUSBporttotransferthedatafromtheDataLoggertoPCallowedonlyinsafearea.

2.CertifiedUSBisolatorshouldbeusedbetweenthePCandDataLogger.

3.OnlyCertifiedUSBflashdrivesareallowedtouseinHazardouslocations.

CONDITIONSPARTICULIERES

1. Miniportpourtransférerlesdonnéesdel’EnregistreurdedonnéesauPCautorisée

seulementenzonesécurisé.

2. L‘IsolateurCertifiéUSBdoitêtreutiliséentrelePCetl'enregistreurdedonnées.

3. SeulsleslecteursflashUSBcertifiéssontautorisésàutiliserdansdesendroitsdangereux.

7

c.BatteryReplacement

Thebatterycompartmentislocatedonthebackoftheinstrument.Youmustfirstremoveittoaccess

thebatterycompartment.

Toreplacethebatteries,firstloosenandremovethecoverscrew,thenremovethebatterycoverto

exposethebatteries.Removetheoldbatteriesandreplacethemwithfournew1.5V‘AA’size

batteries,beingsuretofollowthepolarity(+/‐)symbolsinthebatterycompartment.Replacethe

batterycoverandcoverscrew.

WARNING:

Donotmixoldandnewbatteries.

Donotmixbatteriesofdifferenttypes(suchasalkalineandlithium.)

DuracellPC1500batteryisrequiredforintrinsicsafety.

Thecoverscrewisusedtopreventunauthorizedtamperingofthebatteriesandisrequiredtoensure

intrinsicsafety.

Donotover‐tightenthecoverscrew,asthismaydamagetheinstrumentcase.

ATTENTION:

Avertissement ! Ne mélangez pas des piles neuves et usées.

Avertissement ! Ne mélangez pas des piles de types différents (telles que des piles alcalines etdes

piles lithium.)

Avertissement ! La pile Duracell PC1500 est requise pour la sécurité intrinsèque.

Avertissement ! La vis du couvercle est utilisé pour éviter toute manipulation non autorisée des

batteries, et est nécessaire pour assurer la sécurité intrinsèque.

Avertissement ! Ne pas trop serrer les vis du couvercle, pour ne pas endommager le boîtier de

l'instrument

BatteryCompartmentLockScrew

8

3.SetupandOperation

MAINMENU

TheMS4500Eallowsyoutomeasuremetallossandcorrosionrate.Reviewthissectionwhich

describesthefunctionsthatdisplayontheMainMenu:

SelectthefunctionsbyusingtheupordownarrowandpressingENTERordirectlyselectingthenumber

usingthekeypadandpressENTER.Pressing‘EXIT’willreturntheselectiontothefirstitemoftheMain

Menu.

a. SelectProbe

Thedisplaywillshowasbelowifyouselect‘SELECTPROBE’menufromthemainmenu.Youcanentera

newprobe,deleteaprobe,orselectanexistingprobefromthissection.

1. SELECT PROBE

2. MAKE MEASUREMENT

3. RECALL READINGS

4. DELETE READINGS

5. SET TIME & DATE

6. SET MEASUREMENT TIMER

7. COMMUNICATIONS

8. LANGUAGE / IDIOMA / LINGUAGEM

9. POWER OFF

10. BACKLIGHT ON/OFF

V

e

r

s

i

o

n 1.7

ENTER NEW PROBE

DELETE EXISTING PROBE

1000: WIRE LOOP PL:10.0

2500: CYLINDRICAL PL:10.0

2500: CYLINDRICAL PL:10.0

0434: TUBE LOOP PL:10.0

PRESS ENTER TO SELECT

9

ENTERNEWPROBE‐ToentertheIDofanewprobe,select‘ENTERNEWPROBE’;thenextscreen

allowsyoutoentertheIDnumberandthetype.

1.EntertheProbeIDusingthenumberkeys.(UsetheUp/Downarrowstoscrollbetween

alphanumericcharacters.UsetheRight/Leftarrowstoadvancetothenextcharacterorgobackto

thepreviouscharacter.)Whena4‐digitProbeIDisenteredthecursorautomaticallyadvancesto

theProbeTypefield.

2.UsetheUp/DownarrowstoselecttheProbeType.UsetheRightarrowtoadvancetotheProbe

Lifefield.

3.EntertheProbeLifeusingthenumberkeys.

4.PressENTER.

SELECTEXISTINGPROBE

ToassistyouwithselectingaprobeID,thescreendisplaysalistofallprobeIDscurrentlyinmemory.

Selectfromthelistofprobesinmemorytheoneforwhichyouwishtorunafunction(Make

Measurement,RecallReadingsandDeleteReadings).

oPressthearrowkeytoselectaprobeID.

oPressENTER.

ENTER NEW PROBE

DELETE EXISTING PROBE

1000: WIRE LOOP PL:10.0

2500: CYLINDRICAL PL:10.0

2500: CYLINDRICAL PL:10.0

0434: TUBE LOOP PL:10.0

PRESS ENTER TO SELECT

PROBE ID: 5385

PROBE TYPE: WIRE 40

PROBE LIFE: 10.0

PRESS UP / DOWN ARROW TO CHANGE

PRESS ENTER TO SET

10

DELETEEXISTINGPROBE

ItisoccasionallynecessarytoremovetheIDofaprobefrommemory,forexample:

oWhenthememorybankisfull

oWhenaprobeisnolongerused

TodeletetheIDofaprobeinmemory,selectDELETEEXISTINGPROBE.

1. EntertheprobeID‐usethenumberkeys(presstheDOWNarrowifyoumakeanerror).

2. PresstheUParrowwhenyou’veenteredthecorrectIDnumber.

TheinstrumentwillconfirmyourchoiceofprobeIDbeforedeletingitfrommemory.

DELETE PROBE

PROBE ID: 1000

USE UP / DOWN ARROW TO CHANGE

PRESS ENTER TO DELETE

11

b.MakeMeasurement

Selectaprobebeforeyourunthefunction

Inorderforyoutorun‘MAKEMEASUREMENT’‘RECALLREADINGS’&‘DELETEREADINGS’,

youmusthavealreadyselectedaprobefrommemory.See‘SELECTPROBE’fromtheMain

menus(page8).

Totakemeasurementfromprobesinmemory,select‘MAKE MEASUREMENT’menufrom

theMainMenu:

ThenextscreendisplaystheprobeIDthatyouselectedearlierfromtheMainMenuitem

‘SELECT PROBE’.

Press‘ENT’buttontostartmeasuringtheprobevalue.Duringmeasurement‘MEASURING..‘

messagedisplaysonthescreen.Oncompletionofmeasurementthedisplayshowsthe

probereading.

Press‘ENT’buttontosavethereading.Press‘Up’Arrowtore‐measuretheprobeagain.

1. SELECT PROBE

2. MAKE MEASUREMENT

3. RECALL READINGS

4. DELETE READINGS

5. SET TIME & DATE

6. SET MEASUREMENT TIMER

7. COMMUNICATIONS

8. LANGUAGE / IDIOMA / LINGUAGEM

9. POWER OFF

10. BACKLIGHT ON/OFF

PROBE ID:1234

TUBE

PRESS ENTER TO START

PROBE ID:1234

PREVIOUS READING : 860.61

PROBE CHECK : 808.69

READING: 860.60

MEASURING…..

PRESS UP ARROW TO REMEASURE

PRESS ENTER TO SAVE

12

c. RecallReadings

Select‘RECALL READINGS’tolookatdatafromdifferentdates.

Selecttheprobeifitisnotalreadyselectedtolookintothereadingsbyusingup/down

arrowsandpress‘ENT’button.Thereadingsoftheselectedprobewillbedisplayedinthe

nextscreen.

Press‘ENT’buttononthekeypadtoplotthegraphoftheselectedprobe.Thegraphwillbe

displayedonthenextscreenwithmetallossvalueandcorrosionrate.

ENTER NEW PROBE

DELETE EXISTING PROBE

1000: WIRE LOOP PL:10.0

2500: CYLINDRICAL PL:10.0

2500: CYLINDRICAL PL:10.0

0434: TUBE LOOP PL:10.0

PRESS ENTER TO SELECT

PROBE ID:1000

RDG# READING DATE(M/D/Y) TIME CHECK

8 859.60 04/24/15 18:45 809

7 759.59 04/24/15 18:45 704

6 841.60 04/24/15 18:45 705

5 459.00 04/24/15 18:45 809

4 118.00 04/24/15 18:45 704

3 434.00 04/24/15 18:45 705

2 118.00 04/24/15 18:45 809

1 456.54 04/24/15 18:45 809

PRESS ENTER TO GRAPH

PROBE ID:1000

P 1000 L

R 04/01/15

O RDG : 860.04

B ML : 8.60

E R

04/27/15

RDG : 860.32

500 ML : 8.60

COR RATE:

U 0.05 MPY

N

I

T

S 0 124 248 372 496

<ENT = UPDATE> # OF READINGS

13

d. DeleteReadings

Select‘DELETE READINGS’fromMainMenutoeraseareadingfrommemory.

Periodicallydeletereadingstocreatemorefreestorageareainmemory.

Selecttheprobefromwhichthereadingsneedtobedeletedbyusingup/downarrowsand

press‘ENT’button.Thereadingsoftheselectedprobewillbedisplayedinthenextscreen.

Selecttheprobereading(RDG#)numberwhichneedstobedeletedbyusingup/downarrows

andpress‘ENT’button.Theselectedprobereadingwillbedeletedpermanentlyfromthe

instrumentmemory.

ENTER NEW PROBE

DELETE EXISTING PROBE

1000: WIRE LOOP PL:10.0

2500: CYLINDRICAL PL:10.0

2500: CYLINDRICAL PL:10.0

0434: TUBE LOOP PL:10.0

PRESS ENTER TO SELECT

PROBE ID:1000

RDG# READING DATE(M/D/Y) TIME CHECK

8 859.60 04/24/15 18:45 809

7 759.59 04/24/15 18:45 704

6 841.60 04/24/15 18:45 705

5 459.00 04/24/15 18:45 809

4 118.00 04/24/15 18:45 704

3 434.00 04/24/15 18:45 705

2 118.00 04/24/15 18:45 809

1 456.54 04/24/15 18:45 809

PRESS ENTER TO DELETE

14

e. SetTime&Date

Select‘SET TIME & DATE’fromMainMenutosettheinternalclockoftheMS4500E

DataLogger.Inorderforinformationinmemorytobeusefulandaccurate,besurethe

timeanddateareaccurate.

CAUTION:TheTimeandDatearesetatthefactory,butmayneedtobeadjustedtoyour

timezone.Also,ifyoutrytochangetheDateorTimeanditconflictswithstored

information,theMS4500EwilldisplayN/A.

ATTENTION:l'heureetladatesontdéfiniesàl'usine,maisilspeuventêtreajustéesàvotre

fuseauhoraire.Aussi,sivousessayezdechangerladateoul'heureetquececiconflitavec

l'informationmémorisée,leMS4500EafficheraN/A.

Usethenumbersonthekeypadandthearrowkeystomakechangestothetimeanddate.

Press‘ENT’buttononthekeypadtoconfirmyourchangesandreturntotheMainMenu,or

Press‘EXIT’buttontodiscardthechanges.

DATE (MM / DD / YY):

04 / 27 / 15

TIME (HH:MM):

03: 42 PM

USE LEFT / RIGHT ARROW TO SELECT

USE UP / DOWN ARROW TO CHANGE

PRESS ENTER TO SAVE

15

f. SetMeasurementTimer

Select‘SET MEASUREMENT TIMER’fromMainMenutosetautomaticprobe

readingatsetintervals.TheMS4500EDataLoggerperiodicallywakesupandtakesthe

measurementandstoresthereading.

Selectaprobebeforeyourunthefunction

InorderforyoutorunMAKEMEASUREMENT,youmusthavealreadyselectedaprobe

frommemory.SeeSelectProbeIDfromtheMainmenus(seepage8).

Ifprobeisnotselectedearlier,selecttheprobefromthedisplay.UseUp/Downarrow

keystoselecttheprobeandpress‘ENT’button.

UseRight/Leftarrowkeystoturnon/offthedatalogging.UseUp/Downarrowto

changedatalogginginterval.Minimumcanbesetas1Hoursandmaximumcanbeset

as99Days.Theunittakesthereadingonceperthesetinterval.

ENTER NEW PROBE

DELETE EXISTING PROBE

1000: WIRE LOOP PL:10.0

2500: CYLINDRICAL PL:10.0

2500: CYLINDRICAL PL:10.0

0434: TUBE LOOP PL:10.0

PRESS ENTER TO SELECT

DATA LOGGING INTERVAL SETUP

PROBE ID : 2500

SELECT DATA LOGGING INTERVAL:

ONCE EVERY 1 HOURS

LOGGING OFF

RIGHT / LEFT ARROW TO TURN ON/OFF

UP/DOWN ARROW TO CHANGE INTERVAL

PRESS ENTER TO SAVE

16

g. Communications

TheMS4500EDataLoggerhastheabilitytostorereadingsastheyaretaken.These

readingscanlaterbetransferredtoyourPCviaUSBport.TotransferdatatoaPCitis

necessarytoinstalltheCorrosionDataManagementSoftware(included).

Todownloaddatafromaninstrument:

•

ConnecttheinstrumenttoanavailablePCUSBport.

•

TurntheMS4500Eon.

•

RuntheCorrosionDataManagementSoftware

•

OpentheInstrumentDownloadCenter

•

Selecttheserialportandinstrument

•

ClicktheDownloadbutton(ensurethatPartStatustogglesto“On”).

•

Select‘COMMUNICATIONS’menufromtheMainMenuoftheinstrument.

•

Select’TRANSFER ALL’orSelecttheProbedatayouwishtodownload.

DatawillbegintotransferfromtheinstrumenttothePC,andwillappearinthedatawindowofthe

InstrumentDownloadCenterasshownbelow.Ifthedataappearsgarbled,thewronginstrument

typehasbeenselected.Selectanotherinstrumenttypeandtryagain.

TRANSFER ALL

1001: WIRE LOOP

PRESS ENTER TO TRANSFER

17

Ifdatadoesnotappearinthedatawindowatall,verifythat:

TheinstrumentisconnectedtoavalidserialorUSBport

Allcablesaresecurelyconnected

Themessage“PortStatus:On”appearsinthestatusbar

Therearenoerrorsontheinstrument

IfusingaUSBadapter,ensurethatthedevicedrivershavebeeninstalled.

SelectingaSerialPort

WhentheMS4500EisconnectedtotheUSBportitwillappearasavirtualCOMport.Usethe

SerialPortselectionboxtoselectthevirtualCOMportnumber.IftheCOMportnumberis

unknown,itcanbefoundinWindowsDeviceManagerunder

“Ports(COM&LPT)”.

SelectinganInstrument

UsetheInstrumentoptionboxtoselectthemodelofMetalSamplesinstrumentbeingdownloaded.

Thissetstheappropriatecommunicationparameters,whichwillbedisplayedinthestatusbaratthe

bottomofthewindow(“9600,N,8,1”foranMS1500,“2400,N,8,1”foranMS3500).

DownloadingData

Totoggletheselectedportonandoff,clicktheDownloadbutton.Togglingtheportonandoff

willalsoclearthedatawindow.

Onceavalidserialportandinstrumenthavebeenselected,clicktheDownloadbuttontoturnthe

portonandenablethecomputertoreceivedata.Ifavalidserialporthasbeenselected,the

statusbaratthebottomofthewindowwilldisplaythemessage“PortStatus:On”.

Ifaninvalidserialporthasbeenselected,anerrormessagewillappear,andthestatusbarwilldisplay

themessage“PortStatus:Off”.Ifthishappens,anotherserialportshouldbeselected.

SavingData

Tosavethedatainthedatawindow,clicktheSavebutton.Thedataiscomma‐delimitedASCIItext.

Itcanbesavedtoastandardtext(.txt)file,oritcanbesavedtoacomma‐separatedvalues(.csv)file,

whichgreatlysimplifiestheprocessofimportingthedataintosomespread‐sheetprogramssuchas

Excel®orQuattroPro®.

PrintingData

Toprintthecontentsofthedatawindow,clickthePrintbutton.Aprintdialogboxwillbedisplayedto

allowprinterselectionandsetup.

ChartingData

Tochartthecontentsofthedatawindow,clicktheChartDatabutton.Ifthedatahasnotyetbeen

saved,theuserwillbepromptedtodosobeforethechartingprocessbegins.Formoreinformation

onchartingdata,seetheDataAnalysissection.

18

DataAnalysis

TheDataAnalysisutilityisaconvenienttoolforchartingdatafromMetalSamplesERandLPRdata

loggerinstruments.TheDataAnalysisutilitycanbeopenedfromtheMainMenu,oritcanbe

openeddirectlyfromtheInstrumentDownloadCenter.

IftheDataAnalysisutilityisopenedfromtheInstrumentDownloadCenter,thecontentsofthedata

windowwillbeloadedintothechart.However,iftheDataAnalysisutilityisopeneddirectlyfromthe

MainMenu,avaliddatafilemustbeloaded.TheSelectFileboxwillopentoallowselectionofa

datafile.

LoadingaDataFile

Afterselectingadatafile(orclickingtheChartDatabuttonfromtheInstrumentDownloadCenter)a

statuswindowwilldisplaytheprogressofthefilebeingopened,alongwiththeInstrumentType,

ProbeType,andProbeIDforthedatafile.

DataTable

Afterafilehasbeensuccessfullyloaded,thedatawillbedisplayedintheDataTableforreview.By

default,alldatapointswillbeincludedinthechart.However,datapointscanbeturnedoff,or

excluded,fromthechart.Ifthe“Excluded”flagappearsinthe

statuscolumnforadata

pointthatdatapointwillnotappearinthechart.Totoggletheexclude/includestatusofadata

point,double‐clickthedatapoint,orselectthedatapointandclickExclude/IncludeintheOptions

menu.

Table of contents

Popular Measuring Instrument manuals by other brands

Industrial Temperature Sensors

Industrial Temperature Sensors Series P400 operating instructions

Masimo

Masimo PRONTO-7 Operator's manual

Mictrack

Mictrack MT950 user manual

MONARCH INSTRUMENT

MONARCH INSTRUMENT Pocket Tach 99 instruction manual

OHAUS

OHAUS ST20C-A instruction manual

Agilent Technologies

Agilent Technologies FieldFox MW N9913A Service guide