- iv -

Contents

Page

Prior to Use.......................................................................................................................................... i

Safety Symbols..................................................................................................................................... i

Safety Cautions................................................................................................................................... ii

1. OVERVIEW............................................................................................................................... 1

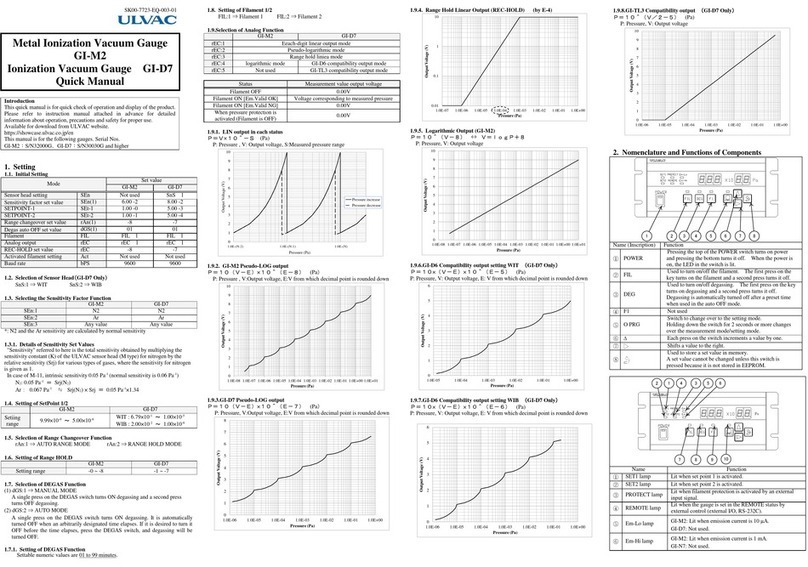

1.1. Specifications....................................................................................................................... 1

1.2. Options................................................

エラー! ブックマークが定義されていません。

1.3. Description of Components.................................................................................................. 4

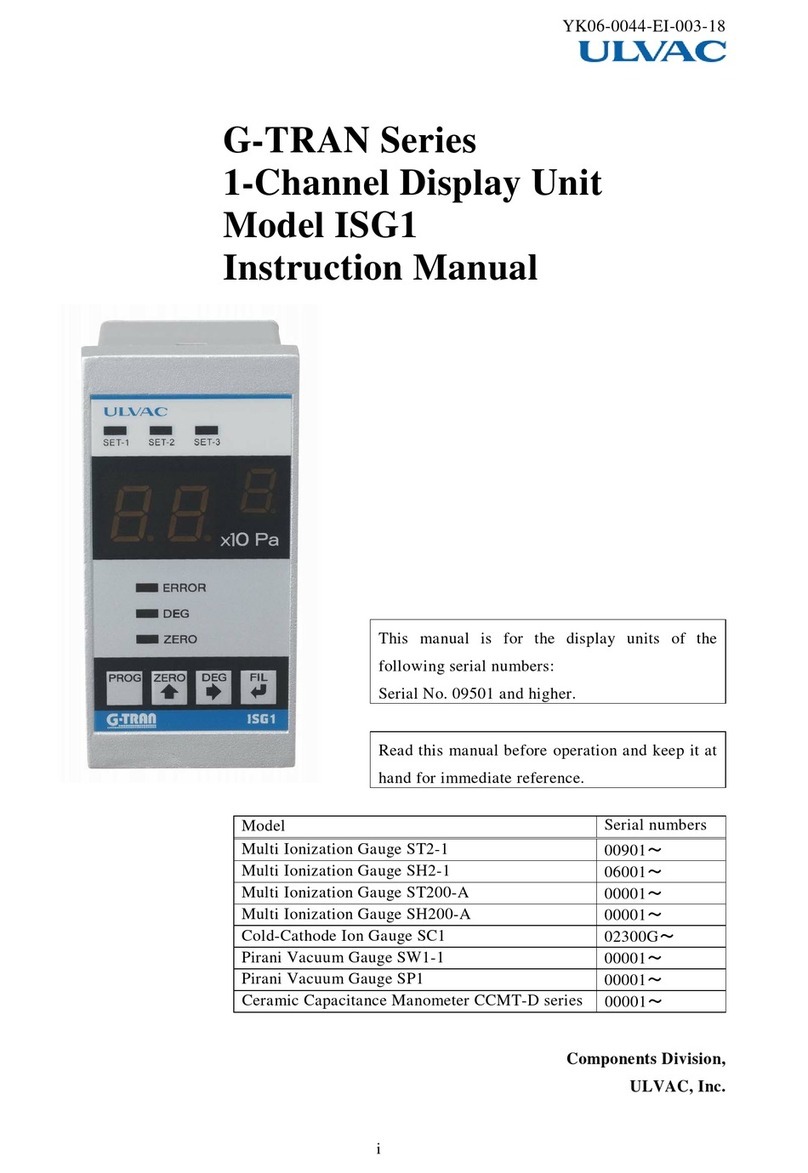

1.3.1. Front panel ................................................................................................................... 4

1.3.2. Rear panel..................................................................................................................... 5

1.3.3. LCD panel.................................................................................................................... 6

2. INSTALLING THE PIRANI VACUUM GAUGE.................................................................. 7

2.1. Preliminary Operation.......................................................................................................... 7

2.2. Installation............................................................................................................................ 7

2.2.1. Installing the controller ................................................................................................ 7

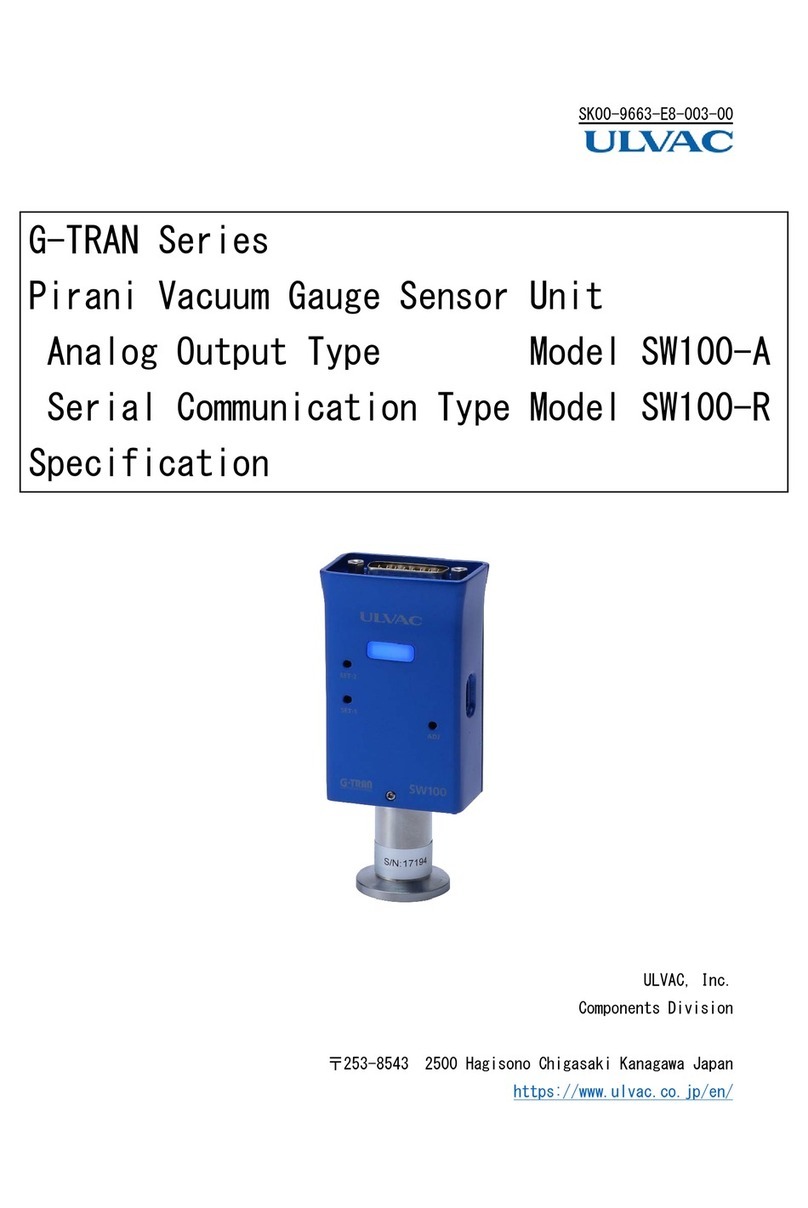

2.2.2. Installing the sensor head............................................................................................. 8

2.2.3. Electrical connection.................................................................................................... 9

2.2.4. A sensor head installation method to GP-H............................................................... 10

3. OPERATING PROCEDURE ................................................................................................. 11

3.1. Cautions in Handling.......................................................................................................... 11

3.2. How to Set the DIP Switch ................................................................................................ 12

3.3. Display of Pressure out of Measurement Pressure Range.................................................. 13

3.4. Relay Setpoint Output........................................................................................................ 14

4. EXTERNAL INPUTS/OUTPUTS.......................................................................................... 15

4.1. External Input/Output Connector Assignment................................................................... 15

4.2. BCD Output ....................................................................................................................... 16

4.3. Strobe Signal...................................................................................................................... 17

5. RECORDER OUTPUTS......................................................................................................... 18

5.1. Linear Output 1.0 ×10+3 Pa(1.0 ×10+1Torr)f.s.................................................................. 18

5.2. Linear Output 1.0 ×10+2 Paf.s. .......................................................................................... 19

5.3. Dummy Log Output Each Range 1V................................................................................. 20

5.4. Non-Linear Output............................................................................................................. 21

6. HOW TO USE COMMUNICATION (RS-232C).................................................................. 24

6.1. Specifications..................................................................................................................... 24

6.2. Connecting the Communication Cable .............................................................................. 24

6.3. Communication Commands............................................................................................... 25

6.4. Action................................................................................................................................. 25

7. APPENDIX............................................................................................................................... 26

7.1. Principles of Operation....................................................................................................... 26

7.2. Types of Gas Measured and Indication.............................................................................. 27

7.3. Change of Indication with Ambient Temperature.............................................................. 29

8. TROUBLESHOOTING........................................................................................................... 30

9. WARRANTY............................................................................................................................ 32

10. CE DECLATION OF CONFORMITY.............................................................................. 33

11. China RoHS Declaration ..................................................................................................... 34

12. Certificate of Decontamination........................................................................................... 35

13. RELATED DRAWINGS ..................................................................................................... 36